Kindergarten bed with capabilities of vertical lifting storage and size adjustment

A vertical lifting and kindergarten technology, applied in the field of furniture, can solve the problems of large storage space, time-consuming and laborious, and unsightly, and achieve the effects of high product flexibility, reduced production costs, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

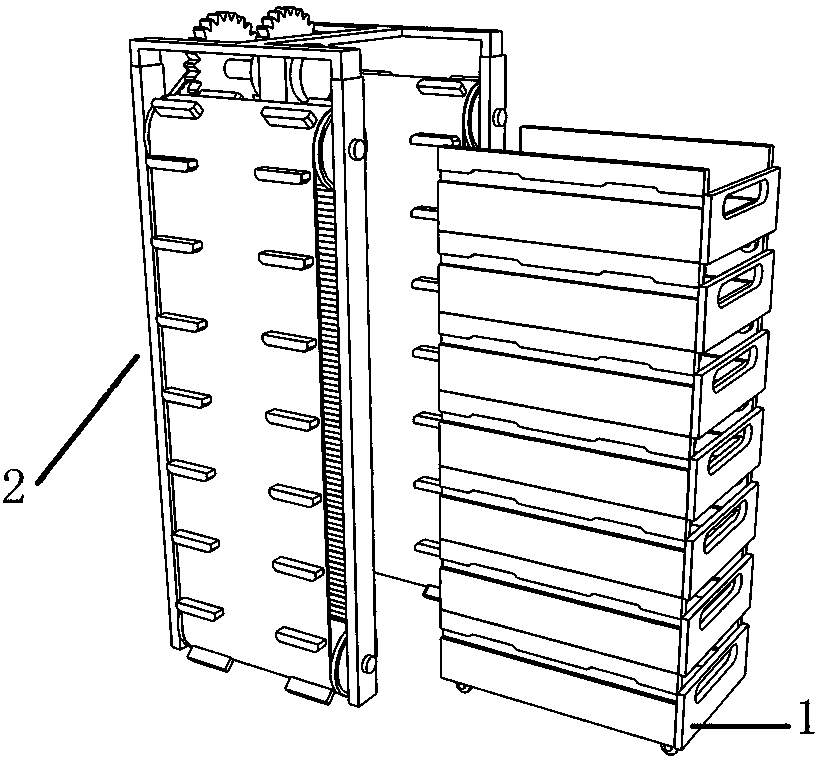

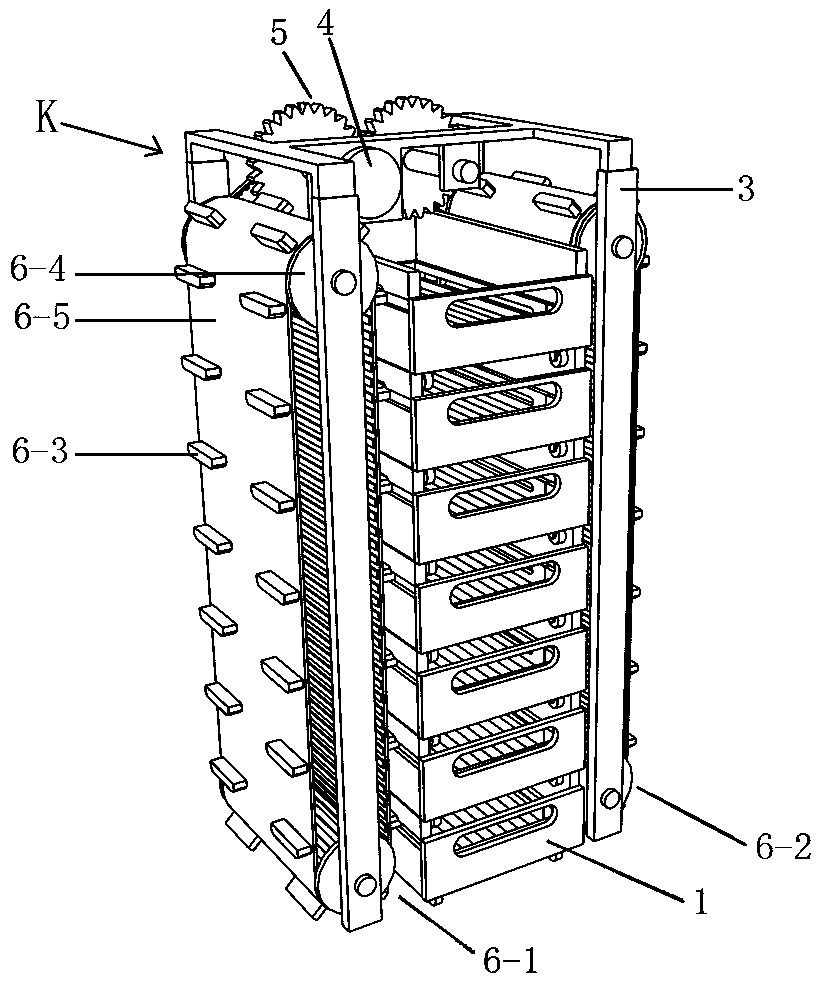

[0027] like Figure 1-4 As shown, a size-adjustable nursery bed that can be vertically lifted and accommodated according to the present invention includes a small bed 1 and a vertical storage mechanism 2, and the vertical storage mechanism 2 includes a storage frame 3, a drive motor 4 fixed on the storage frame 3, and The drive motor 4 drives the lifting mechanism 6 that circulates up and down through the transmission mechanism 5, wherein the storage frame 3 is a four-sided hollow support, and the lifting mechanism 6 includes a left lifting mechanism 6-1 and a right lifting mechanism 6-2, and a left lifting mechanism 6-1 The same structure as the right lifting mechanism 6-2, its outer surface is evenly distributed with a support structure 6-3 cooperating with the small bed 1, and the left lifting mechanism 6-1 and the right lifting mechanism 6-2 a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap