Two tripper cars of electric variable-amplitude type wheel-bucket stack-taking machine

A bucket wheel stacker and reclaimer, electric technology, applied in the direction of mechanical equipment, clockwork mechanism, belt/chain/gear, etc., can solve the problem of large design space, twisting and deformation of the two-tail car beam, and slow lifting movement of the two-tail car and other problems, to achieve the effect of fast action response, convenient installation and maintenance, and saving design space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiment of accompanying drawing.

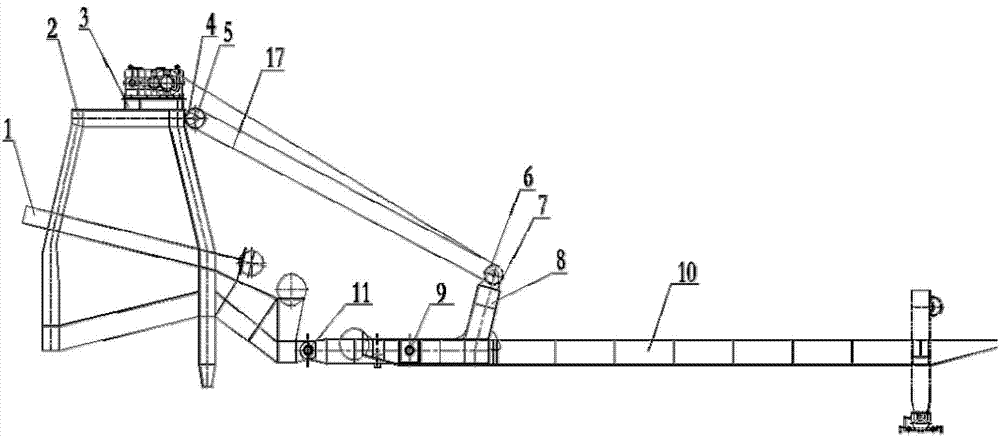

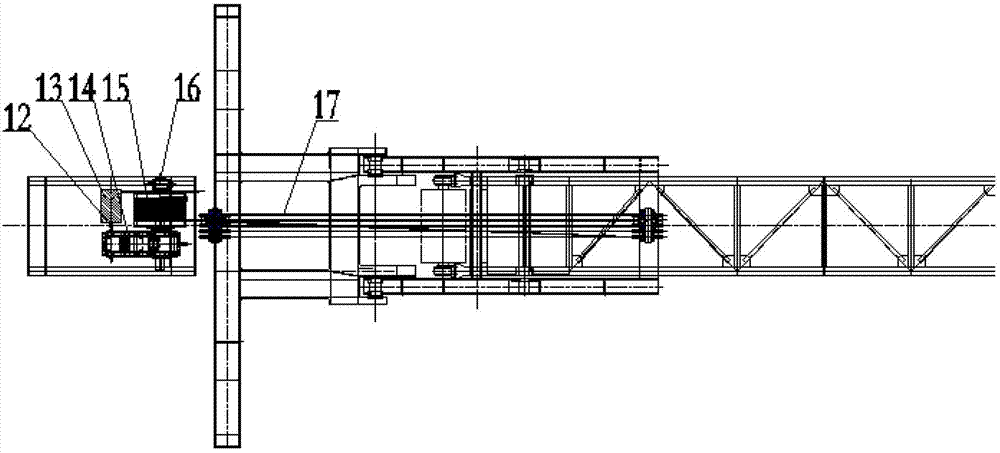

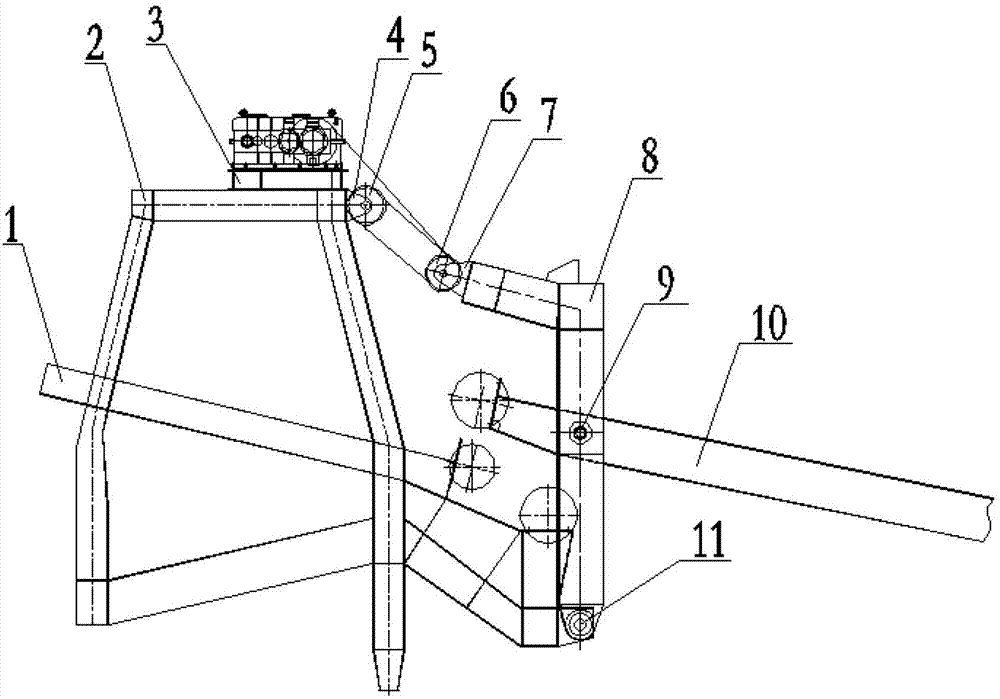

[0021] Electric variable-amplitude bucket wheel stacker and reclaimer two-tail car includes: one-tail car steel structure 1, winch frame 2, drive seat 3, upper pulley block support 4, upper pulley block 5, lower pulley block 6, lower pulley block support 7, pendulum Bar 8, hinge point one 9, two tail car steel structures 10, hinge point two 11, shaft coupling 12, motor 13, speed reducer 14, wire rope reel 15, detection device 16 and wire rope 17.

[0022] Fork 8 is made up of two symmetrical horizontal rods, two vertical rods erected at the ends of the horizontal rods and a crossbeam that connects the two vertical rods at the top of the vertical rods. The middle part of a horizontal bar is provided with a hinge point one 9, and the horizontal bar front end hinge point two 11 is hinged with the steel structure 1 end of the first tail car, and the hinge point o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap