Flotation feeding material pretreatment apparatus and method for integrating flotation feeding material pretreatment apparatus and flotation machine

A pretreatment device and flotation technology, applied in mixers with rotary stirring devices, flotation, chemical instruments and methods, etc., can solve the problems of high use and maintenance costs, high processing costs, and large floor space. , to achieve the effect of low processing cost and civil construction cost, low use cost and maintenance cost, and improved pulp throughput.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

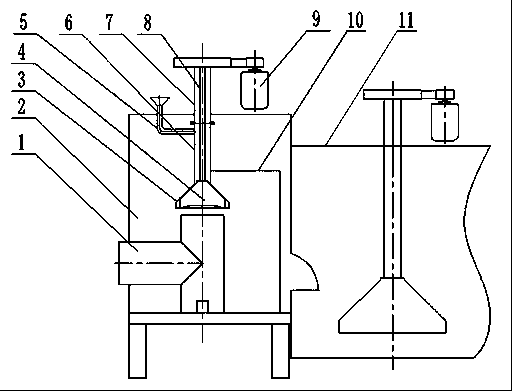

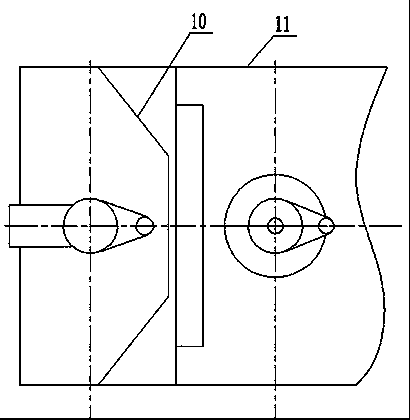

[0026] Attached below figure 1 And attached figure 2 The present invention is further described, but they are not intended to limit the protection scope of the present invention.

[0027] Such as figure 1 and figure 2 As shown, the pretreatment device in this embodiment includes a feed pipe (1), a slurry tank (2), a stator (3), an impeller (4), a drug feed pipe (5), a sleeve (6), Bearing seat (7), transmission shaft (8), driving mechanism (9), overflow plate (10).

[0028] The working principle and working process of the flotation feeding pretreatment device are as follows:

[0029] The ore pulp flows into the mixing tank (2) from the feeding pipe (1) and is sucked into the impeller through the main outlet of the feeding pipe (1). The driving mechanism (9) drives the impeller (4) to rotate through the transmission shaft (8). The slurry is thrown around under the action of centrifugal force, and a negative pressure zone is formed under the impeller (4), and the medicine ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap