Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

13 results about "Separation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Separation process. A separation process is a method that converts a mixture or solution of chemical substances into two or more distinct product mixtures. At least one of results of the separation is enriched in one or more of the source mixture's constituents.

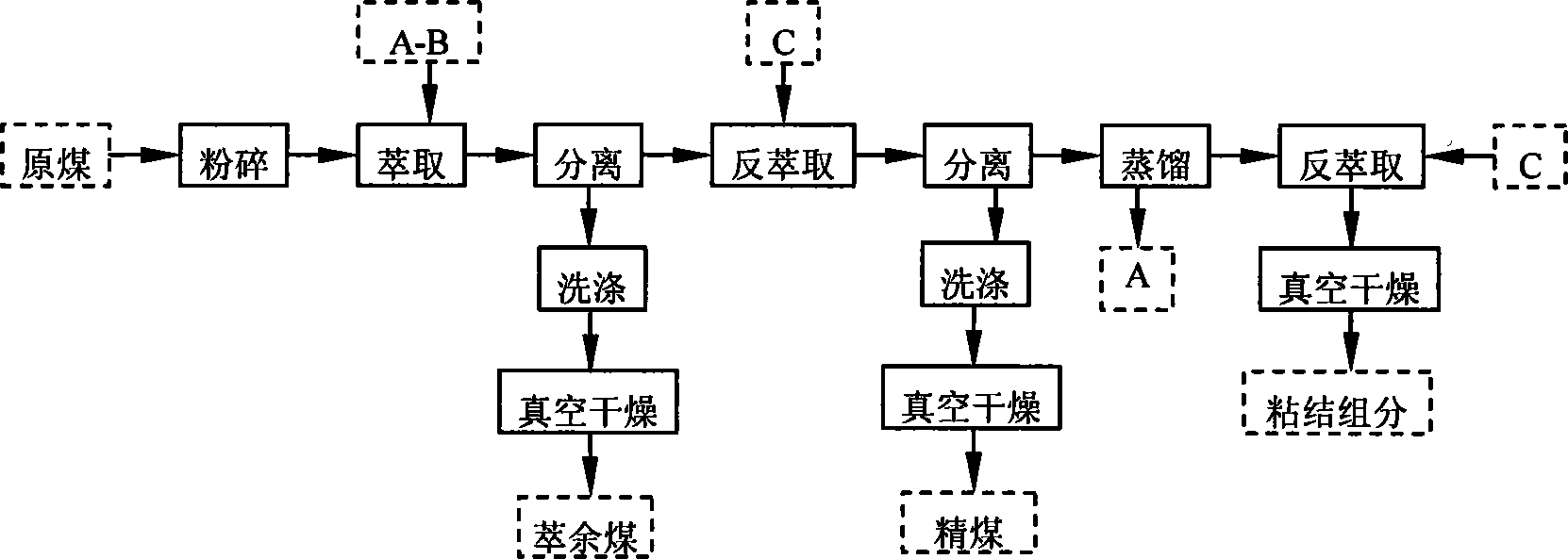

Mild coal-family component separation method based on extraction and back extraction

InactiveCN101070495AEasy to useImprove environmental benefitsSolid fuelsSolid solvent extractionWater useDistillation

Owner:CHINA UNIV OF MINING & TECH

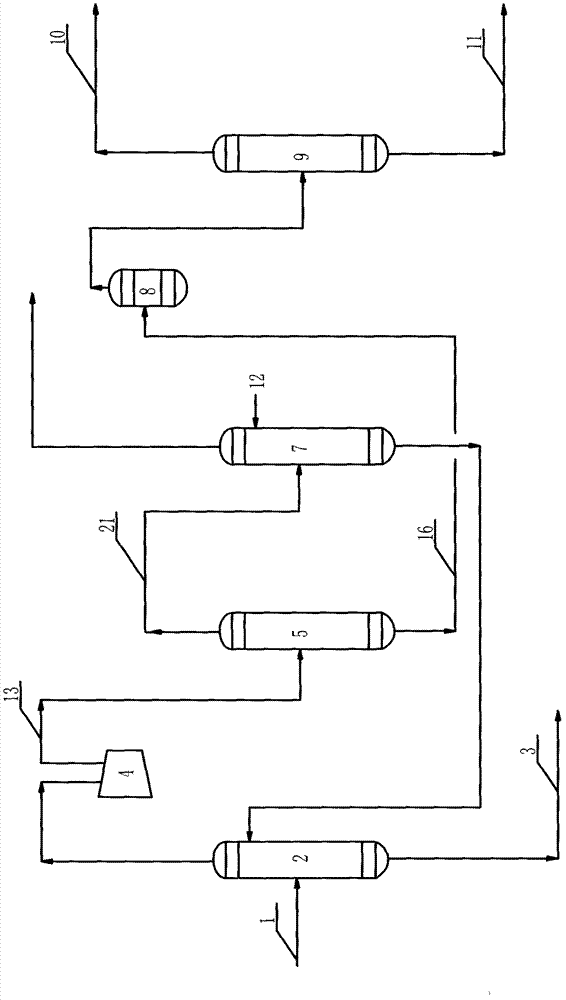

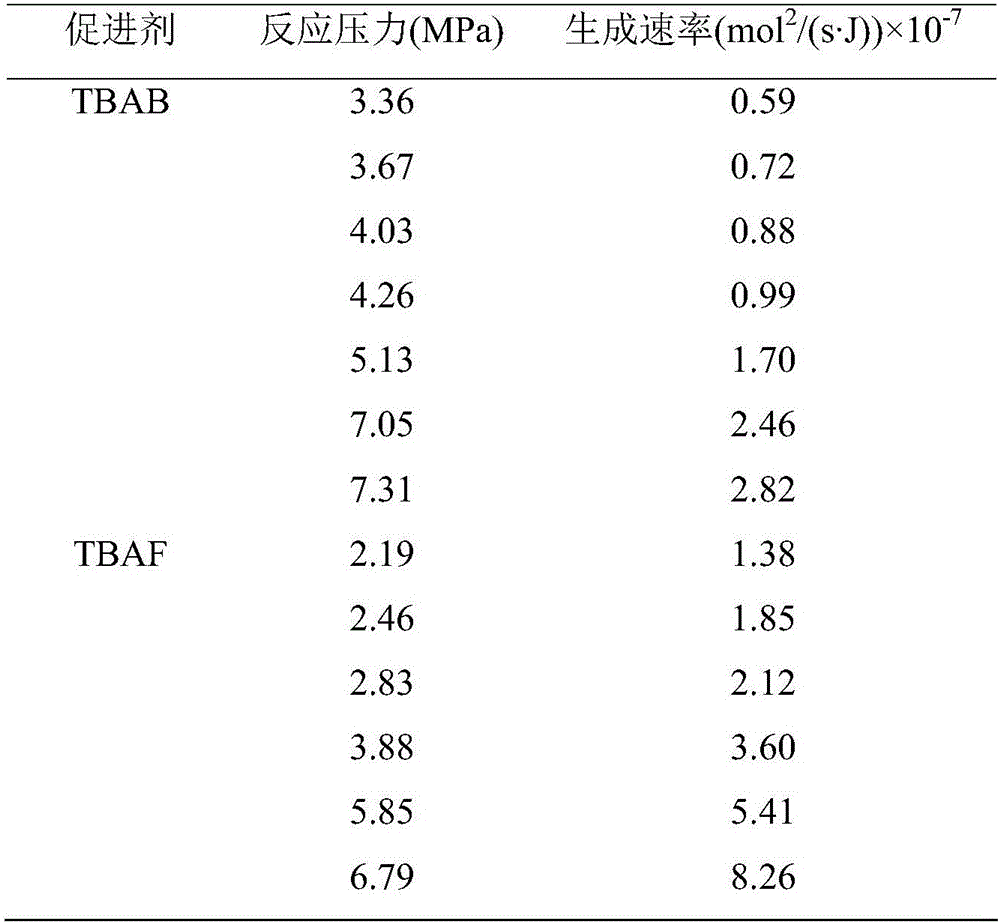

Method for separating low-carbon olefin gas

ActiveCN103242123ALow powerLow operating pressureDistillation purification/separationEthylene productionGas phaseDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

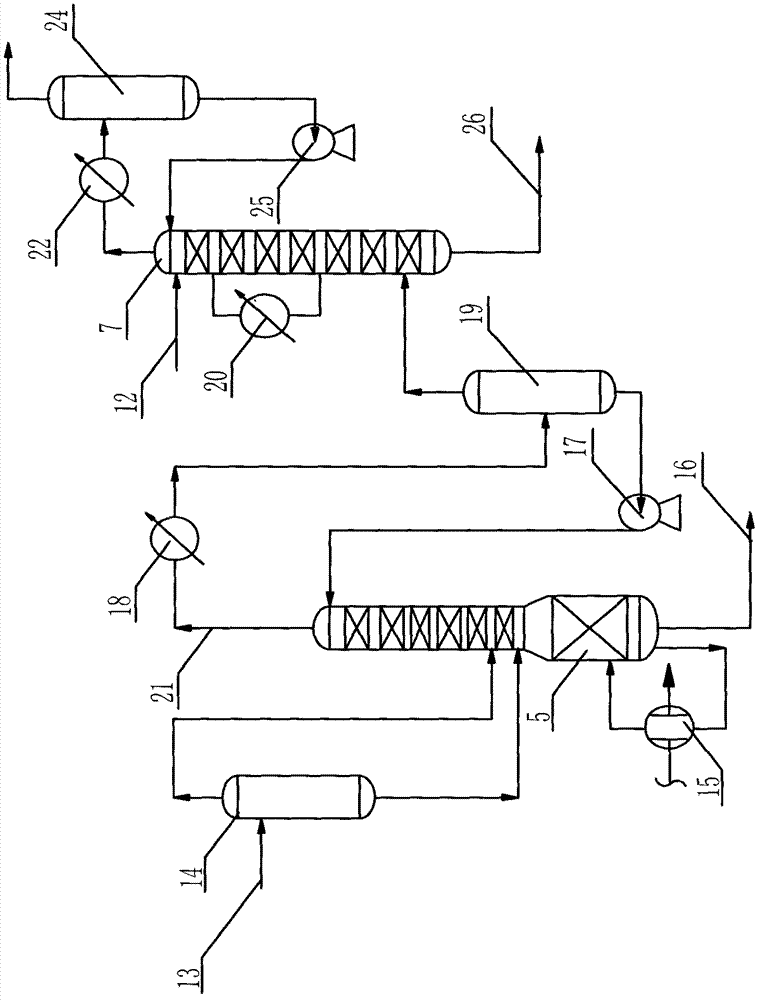

Separation method used for preparing isopropanol via hydrogenation of acetone

ActiveCN103772145ASimple processLess investmentOrganic compound preparationHydroxy compound preparationExtractive distillationAqueous solution

Owner:CHINA PETROLEUM & CHEM CORP +1

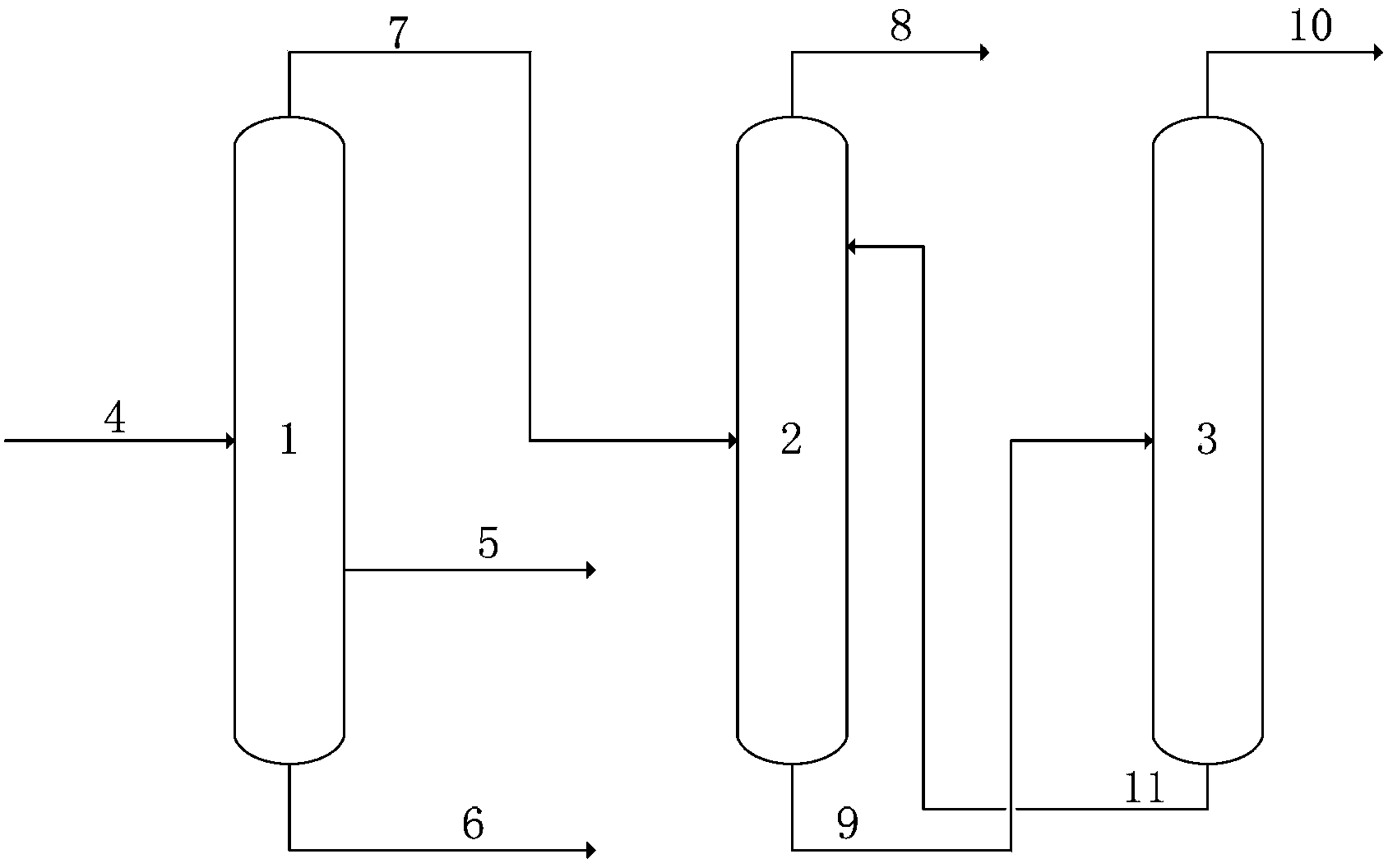

Low-cost separation method and device for fatty acid mixture

InactiveCN105733817AAvoid enteringFatty acids production/refiningChemical industryMixed fatty acidEngineering

The invention discloses a low-cost separation method and device for fatty acid mixture.A decompression rectifying tower is used for continuously separating and refining C12-C22 fatty acid components.A direct contact condensation mode is adopted in the tower top to efficiently cool rising material steam, the cooled rising material steam is processed by a heat recovery boiler into secondary steam to be used, a vapor-phase product on the tower bottom is processed by a demister and then condensed, and acceptable products are extracted.Residues on the tower bottom enter a wiped film evaporator and an erucic acid refining tower to be separated, and high-purity erucic acid is acquired.In the whole process, by means of thermal coupling gradient utilization, the heat consumption in the production process is minimized, and low cost, low emission and high yield are achieved.

Owner:张志炳

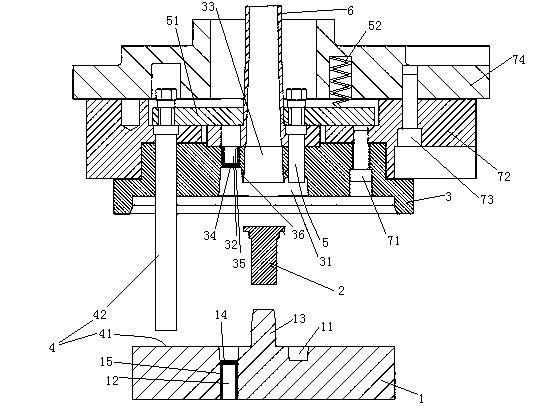

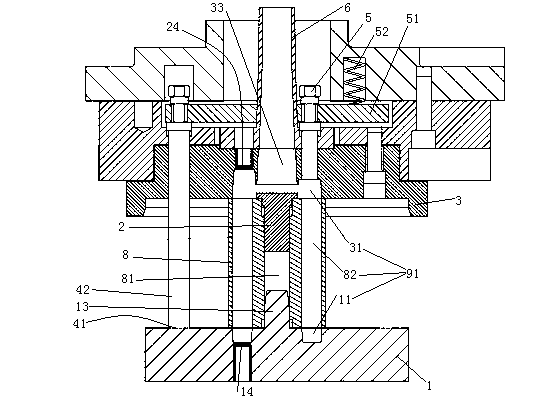

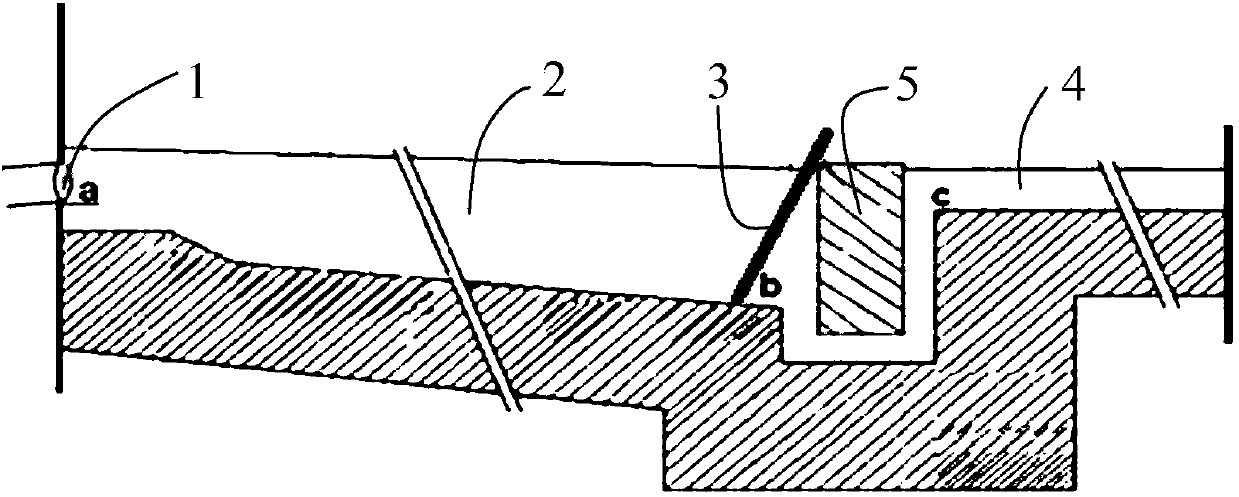

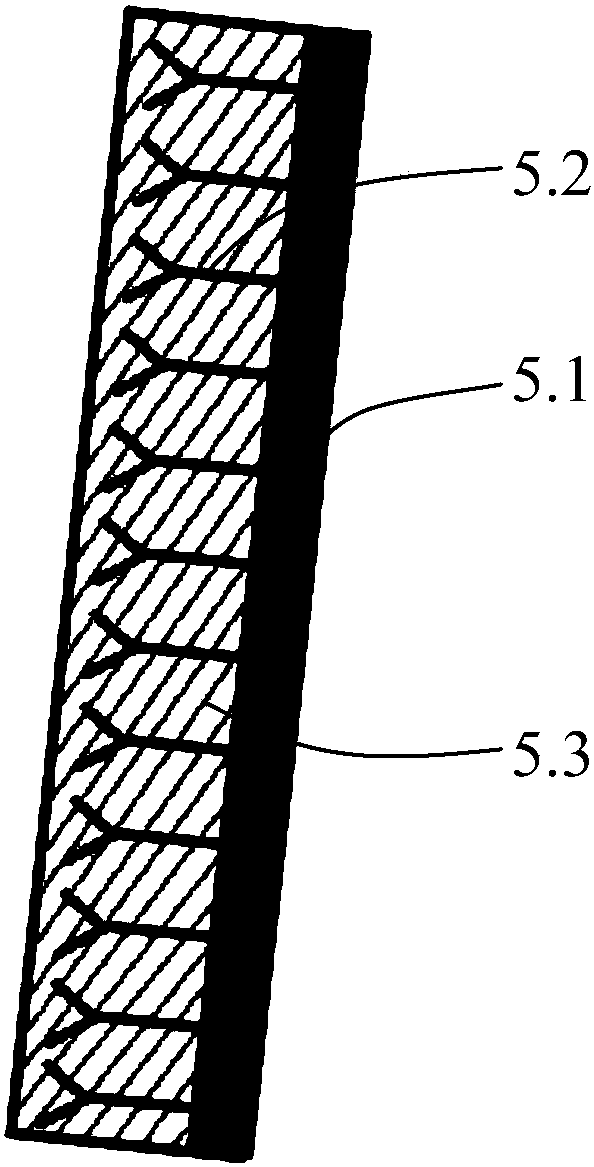

Centrifugal casting material returning method for squirrel cage rotor and centrifugal casting die for implementing method

ActiveCN103084556AOut of order controllableNo deformationAsynchronous induction motorsManufacturing dynamo-electric machinesEngineeringMechanical engineering

Owner:HANGZHOU FUSHENG ELECTRICAL APPLIANCE

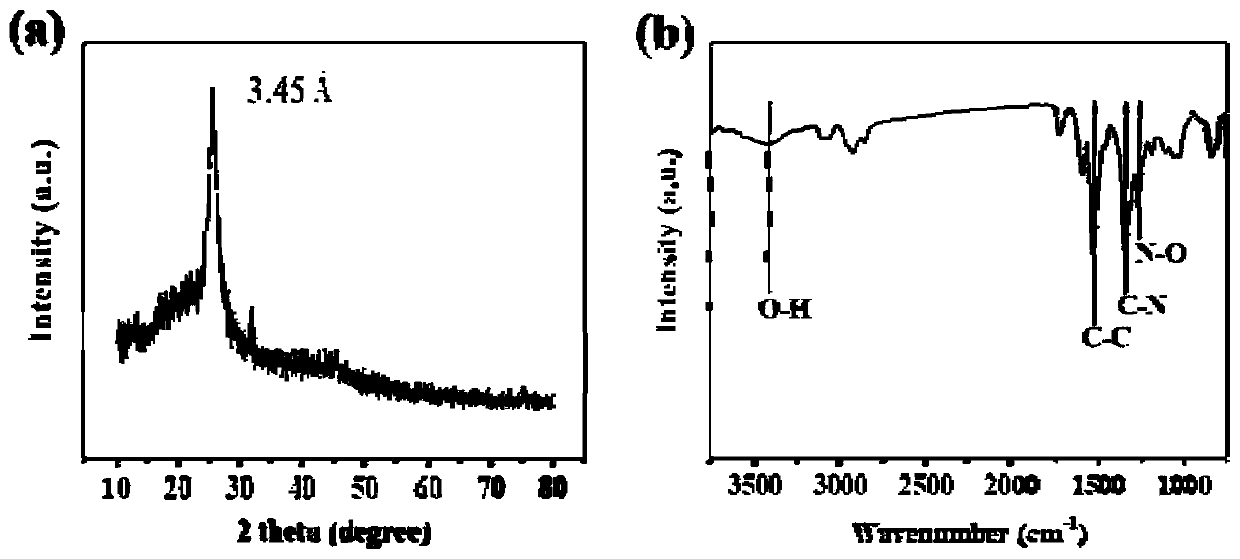

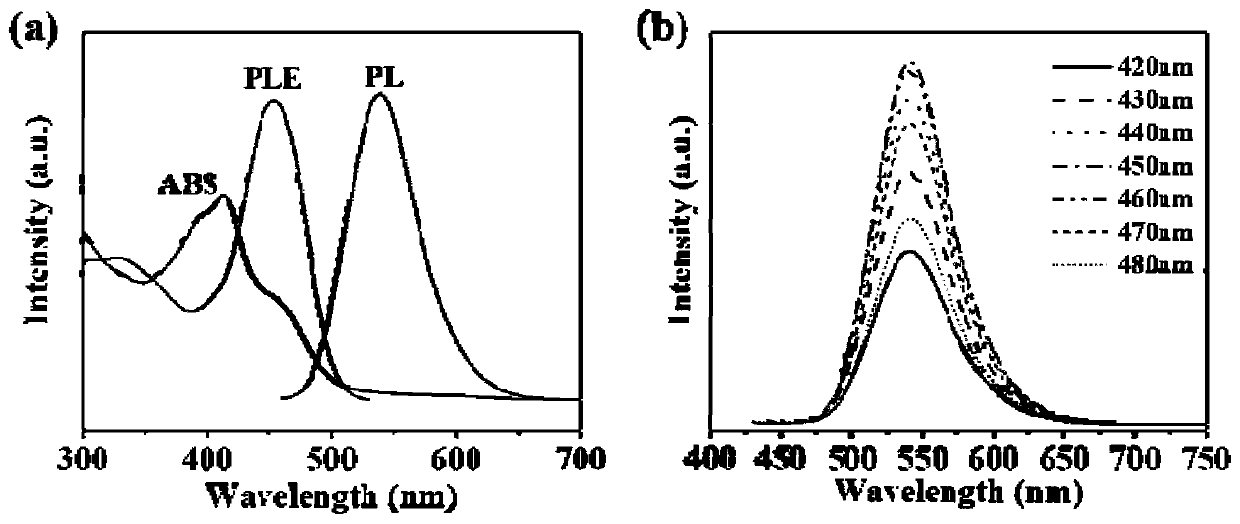

Preparation method of graphene quantum dots

ActiveCN110540192AHigh fluorescence yieldImprove stabilityMaterial nanotechnologyGrapheneFluorescenceFiltration

Owner:SHANGHAI SIXTH PEOPLES HOSPITAL

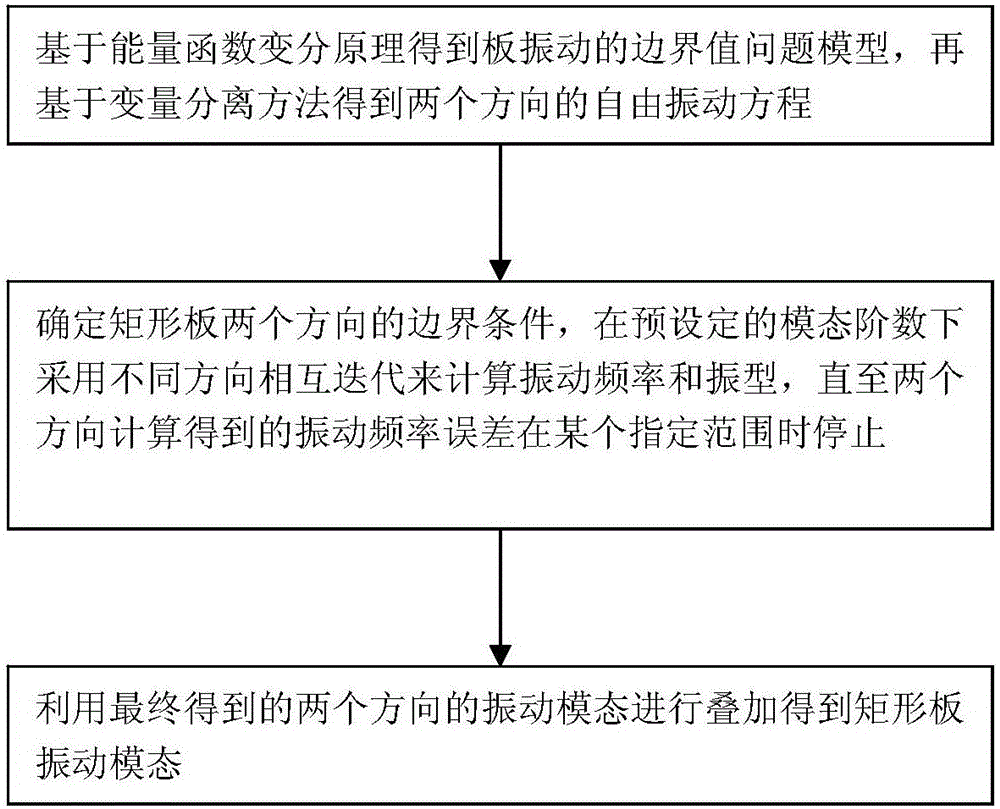

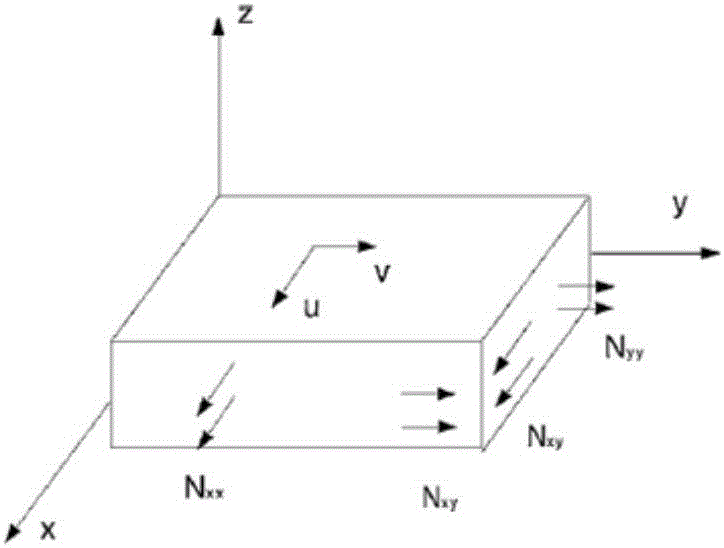

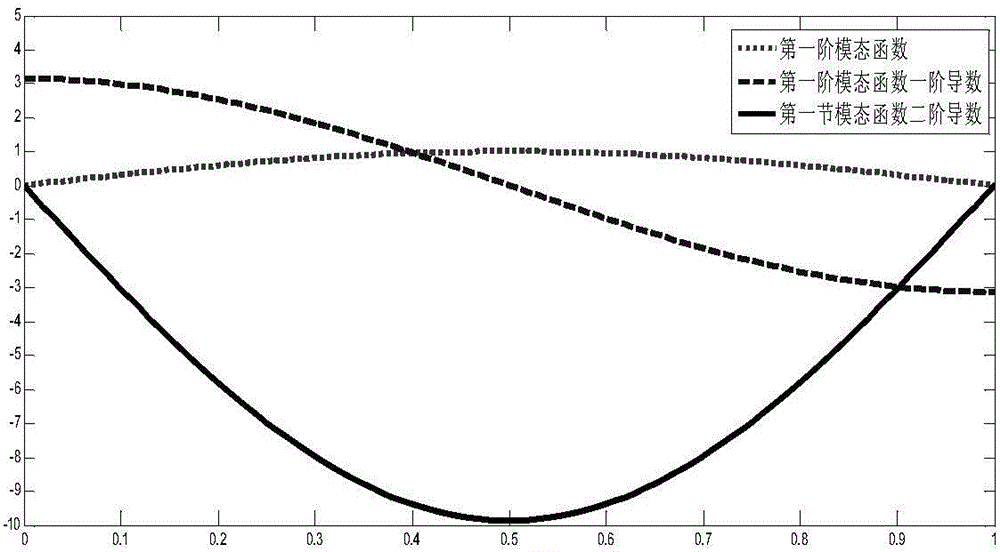

Rectangular plate vibration mode calculation method based on spectrum finite element

ActiveCN106777825ADesign optimisation/simulationSpecial data processing applicationsCalculated resultSeparation method

Owner:HUNAN UNIV OF SCI & TECH

Separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets

The invention relates to a separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets. The separation method comprises the steps that the waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets are firstly smashed, then the smashed mixed materials are added into a separating medium with the density between the density of polyphenylene sulfide and the density of polytetrafluoroethylene for centrifugal separation, blended fabric is smashed according to the different densities of two fibers, and the aim of recycling polyphenylene sulfide and polytetrafluoroethylene in the waste dust settling pockets is achieved through centrifugal separation. The purity of polyphenylene sulfide materials obtained after separation reaches 97% or above, the purity of polytetrafluoroethylene materials reaches 91% or above, the material separation purity is high, the separation effect is good, and the recycling value is high.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

Tire bead separation method and device

Owner:THE GOODYEAR TIRE & RUBBER CO

Extraction and separation method of trace uranium element in liquid sample

ActiveCN107860816ARaise the ratioGood removal effectPreparing sample for investigationMaterial analysis by electric/magnetic meansAmmonium carbonateTrioctylphosphine oxide

Owner:中国人民解放军陆军防化学院

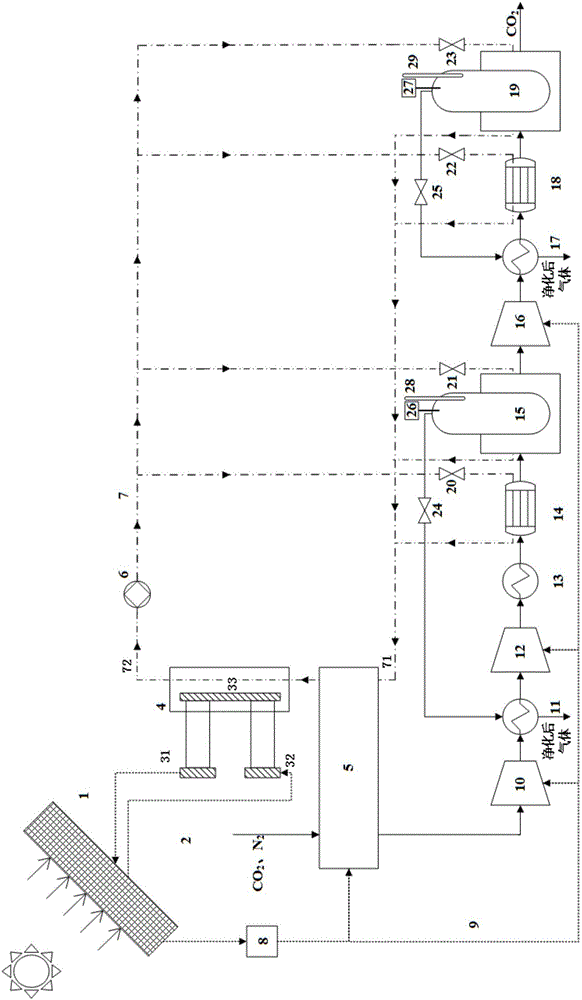

Solar photovoltaic refrigeration assisted hydrate method carbon capture system

InactiveCN105727697ASimple processRaw material economyGas treatmentClimate change adaptationEngineeringSolar power

Owner:TIANJIN UNIV

Slag-iron separation method in initial stage of reblowing after long-time damping down of large blast furnace

InactiveCN107828926ASpeed up the recovery processEmission safetyBlast furnace detailsDischarge devicesSlagRefractory

Owner:MAANSHAN IRON & STEEL CO LTD

Separation method for high-quality cashew proteins

InactiveCN103694310ANot destroyedEasy to separatePeptide preparation methodsUltra high pressureWarm water

Owner:NANCHANG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap