Tire bead separation method and device

a technology of tire bead and separation method, which is applied in the field of tire building machinery, can solve the problems of damage to the assembly, extreme difficulty in separating the assembly from one another,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

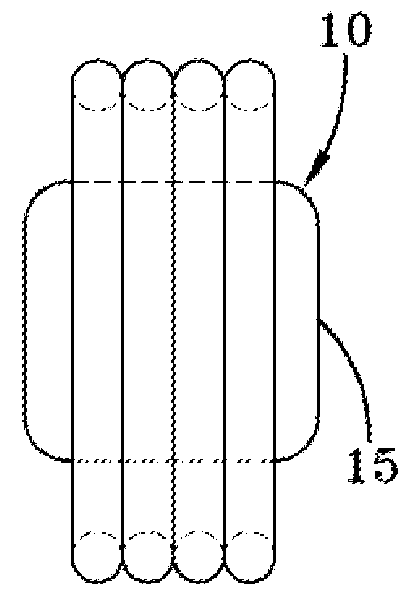

[0026]FIG. 3 illustrates a first embodiment of a separator apparatus 10 of the invention. The bead separator 10 may be used to separate stacked annular components such as annular beads, annular bead and apex assemblies or other stacked components which may or may not be circular in cross-section. The invention is thus not limited to these bead assemblies, and may be utilized to separate other annular components as well, including those annular components unrelated to tire building. The separator apparatus 10 comprises an expansion chamber 15 which may typically be circular in cross-section or any other desired cross-sectional shape which mates with the components to be separated. The expansion chamber 15 may be comprised of rubber or other expandable material. The expansion chamber 15 initially has a smaller diameter than the inner diameter of the beads or other annular component to be separated. The expansion chamber is inserted through the inner diameter of the components to be separ

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap