Separation method used for preparing isopropanol via hydrogenation of acetone

A separation method, the technology of isopropanol, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve problems such as difficult separation by ordinary distillation, achieve simplified process, reduce equipment investment, and be easy to operate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

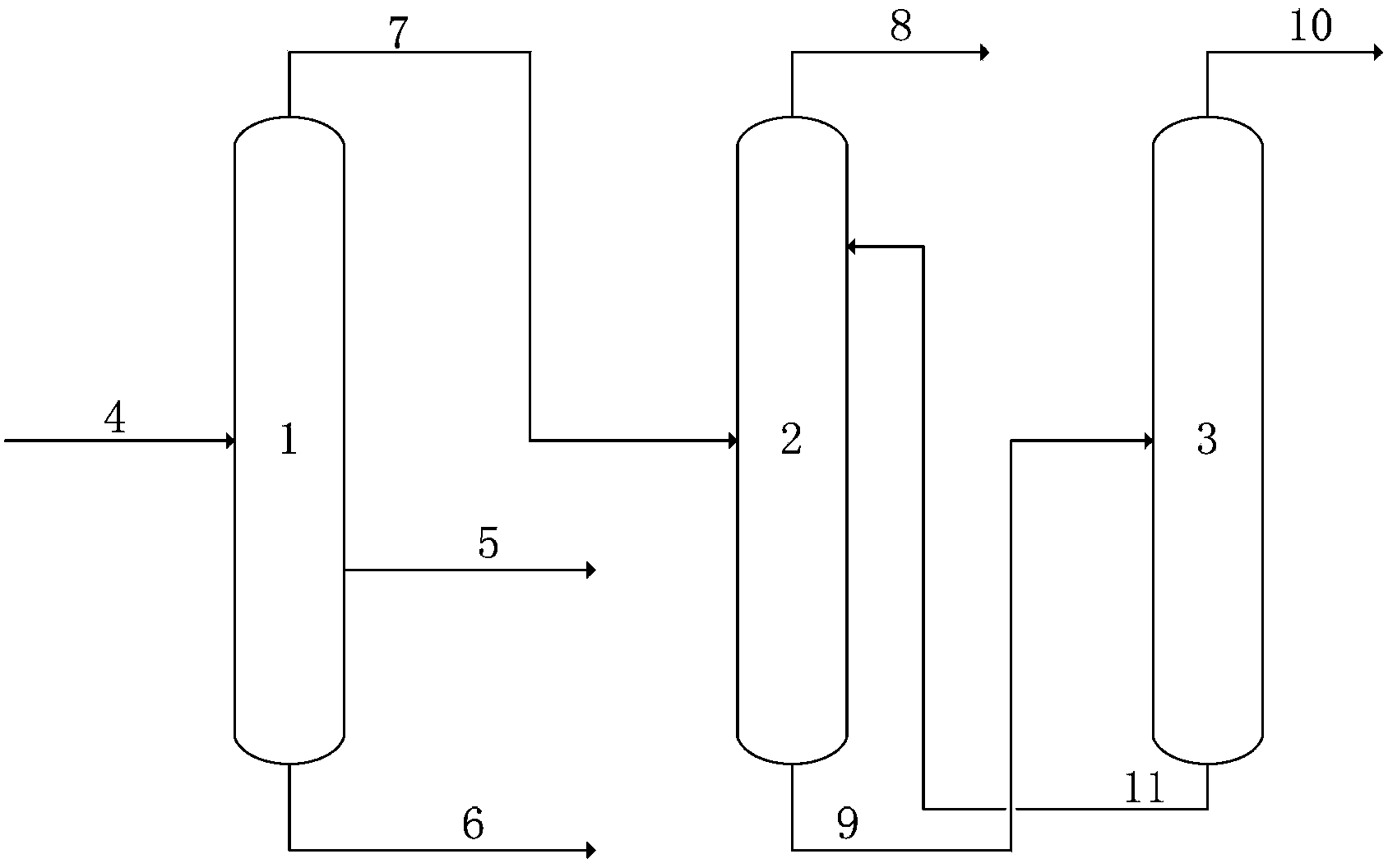

[0036] Such as figure 1 Shown, acetone hydrogenation isopropanol separation method comprises the following steps:

[0037] (1) Refining: outlet stream of acetone hydrogenation reactor (mainly composed of 98% isopropanol, 0.84% acetone, 0.1% isopropyl ether, 0.5% water, 0.4% 4-methyl-2-pentanol, 0.01% propane , methane 0.1%, hydrogen 0.04%) are sent to the rectification tower 1, the number of theoretical plates of the rectification tower is 34, the reflux ratio is 5, the temperature at the top of the tower is 99°C, and the temperature at the bottom of the tower is 120°C. In this stream, isopropanol and water, isopropyl ether and water, acetone and water, isopropanol and isopropyl ether all form an azeotrope, which is extracted from the top of the tower with an azeotropic composition, and methane, hydrogen, propane and other light Components are also withdrawn overhead and vented as noncondensable gases. The output from the tower kettle is mainly heavy components such as 4-meth

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap