Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29 results about "Centrifugal separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stephanoporate zinc oxide nano-powder and preparation method thereof

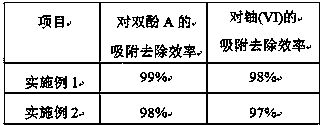

InactiveCN101318690AReduce the probability of collisionAvoid formingZinc oxides/hydroxidesNanoparticleZinc nitrate

Owner:WUHAN UNIV

Preparation method of oryzenin antioxidant peptide

InactiveCN101748182AOptimize composition ratioHigh in proteinFermentationAlkaline proteaseProteinase activity

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Preparation for water-soluble high-substitution cellulose sodium sulfate

Owner:ZHEJIANG UNIV

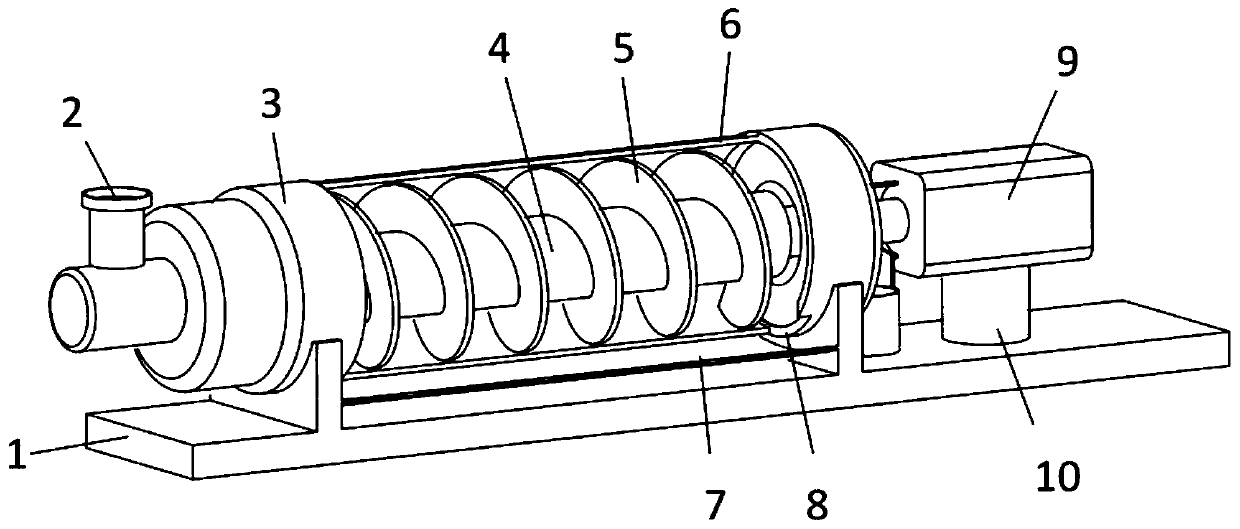

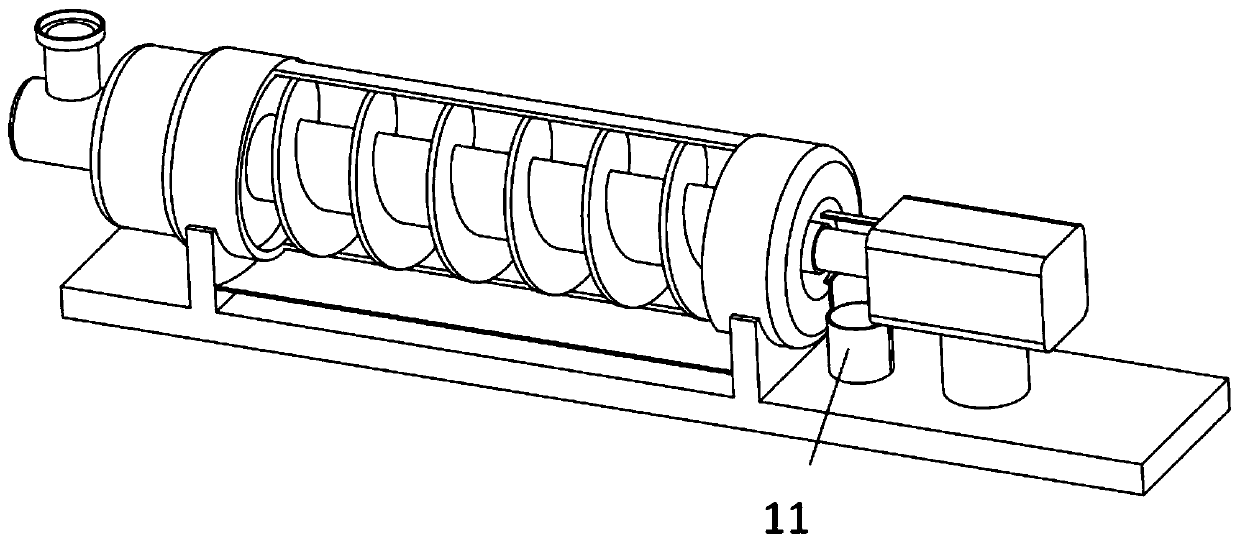

Straw carbonization and separation technique and separating device used thereby

InactiveCN101735836AAchieve refinementBiofuelsDispersed particle separationCombustible gasCarbonization

The invention discloses a straw carbonization and separation technique and a separating device used thereby to realize the carbonization of the straw and extract various useful substances, such as wood tar oil, wood vinegar, mixed combustible gas and the like in a carbonization process. The technique comprises the following steps of: processing the straw into segmented straw, sending the segmented straw into a furnace kiln and igniting to heat the segmented straw at a high temperature to produce smoke gas and placing the treated straw into a sharp quenching multi-pipe separating device to extract wood tar oil; extracting mixture of wood tar oil and wood vinegar liquid in a multi-layer staggered separating device; extracting wood vinegar liquid in an internal rotation centrifugal separating device; and sending remaining gas into a purification tower to purify and controlling the temperature to be between 60 and 80 DEG C. The invention has the advantages that: a new straw carbonization and separation technique is developed and the extraction of various useful substances, such as wood tar oil, wood vinegar and mixed combustible gas, is realized when bio-carbon is produced.

Owner:崔宝玲

Method for preparing organic carbon fertilizer from agricultural wastes as raw materials

The invention discloses a method for preparing organic carbon fertilizer from agricultural wastes as raw materials. The method comprises, 1, raw material pretreatment: crushing agricultural wastes, adding water into the agricultural wastes and carrying out blending, 2, acid addition and digestion reaction, and 3, centrifugal separation or settling separation and supernatant collection. The agricultural wastes comprise straws. The straws comprise corn stalks, wheat straws, paddy rice straws, sugar cane stalks, cotton stalks or the rest part of crops treated by seed collection. The acid comprises more or more of sulfuric acid, nitric acid, perchloric acid, hypochlorous acid and hydrogen peroxide. The digestion reaction temperature is in a range of 80-180 DEG C and digestion reaction time is in a range of 1-30min. A mass ratio of the agricultural wastes to the acid is 100: (1-9). The method has simple and fast processes and small energy consumption. The obtained organic carbon fertilizer comprises micromolecule organic carbon and can be absorbed easily by crops.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Natural fruit vinegar and processing process thereof

InactiveCN103045454ANatural ponkan aromaNatural colorMicroorganism based processesVinegar preparationAcetic acidCarrot juice

Owner:谭媛文

Blood disease related drug concentration detection method and application

The invention relates to a blood disease related drug concentration detection method and application, and the method comprises the following steps: mixing a blood sample to be detected with a cell lysis solution or a buffer salt solution, adding a methanol solution of an isotope internal standard of the drug to be detected, oscillating, carrying out centrifugal separation, and collecting the supernatant; injecting the supernatant into a rapid liquid chromatography system for separation and analysis, then entering a triple quadrupole mass spectrometry detector, collecting and processing data through chromatographic software, and calculating the drug concentration in a blood sample to be detected. According to the blood disease related drug concentration detection method, according to the characteristics and clinical needs of the blood diseases, a scheme for detecting the blood concentration of the medicines related to the blood diseases is established, and the scheme has the advantagesthat a chromatographic column and a mobile phase do not need to be replaced, so that the detection efficiency and the operation convenience are greatly improved, and the method is suitable for large-scale clinical popularization.

Owner:BEIJING LU DAOPEI BIOTECHNOLOGY CO LTD

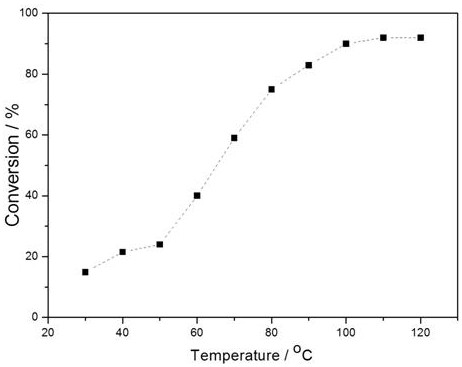

Preparation method of transglucosidase

InactiveCN105505896AImprove conversion rateReduce manufacturing costMicroorganism based processesGlycosyltransferasesMicroorganismHigh density

The invention relates to a preparation method of transglucosidase. The technical problem that during isomaltose hypgather production, the glucoside conversion rate is low is mainly solved. In order to solve the problem, according to the technical scheme, the aspergillus niger strain (General Microbiology Center of China Committee for Culture Collection of Microorganisms, CGMCC No.3.6478) serves as the original strain, a liquid fermentation culture medium is adopted, inductors are specially added, the aspergillus niger strain is induced to secrete a large amount of efficient transglucosidase through the four steps of slope cultivation, shake flask expanded cultivation, liquid deep fermentation and centrifugal separation, and then high-density transglucosidase fermentation liquid is prepared. The product can be applied to the key step, namely, the conversion stage, in isomaltose hypgather production.

Owner:SHANGHAI KINRY FOOD INGREDIENTS +1

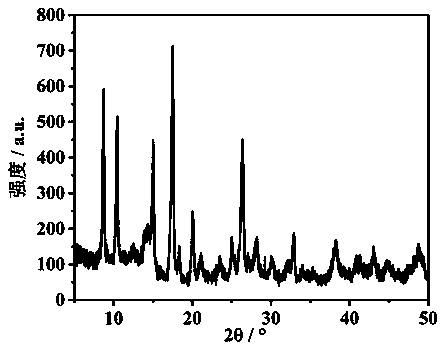

Method of synthesizing nano zinc silicate light emitting material by using waste silicon powder by hydrothermal method

InactiveCN104087289ATo achieve the purpose of resource recyclingSimple methodLuminescent compositionsPolytetrafluoroethyleneMaterials science

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets

The invention relates to a separation method of waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets. The separation method comprises the steps that the waste polyphenylene sulfide and polytetrafluoroethylene blended dust settling pockets are firstly smashed, then the smashed mixed materials are added into a separating medium with the density between the density of polyphenylene sulfide and the density of polytetrafluoroethylene for centrifugal separation, blended fabric is smashed according to the different densities of two fibers, and the aim of recycling polyphenylene sulfide and polytetrafluoroethylene in the waste dust settling pockets is achieved through centrifugal separation. The purity of polyphenylene sulfide materials obtained after separation reaches 97% or above, the purity of polytetrafluoroethylene materials reaches 91% or above, the material separation purity is high, the separation effect is good, and the recycling value is high.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

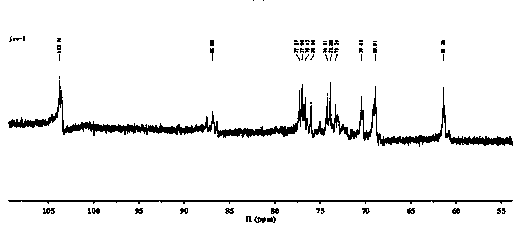

Method for decolorizing tremella root polysaccharide

The invention relates to polysaccharide, in particular to a method for decolorizing tremella root polysaccharide. The method comprises the following steps of S1, extraction of root crude polysaccharide for standby application; S2, purification of the root crude polysaccharide, wherein the obtained root crude polysaccharide is subjected to chromatography by a polyamide resin chromatography column to obtain a polyamide purified polysaccharide solution; S3, secondary purification, wherein the obtained polyamide purified polysaccharide solution is added into HP-20 macroporous resin for adsorption,and centrifugal separation is carried out to obtain a root decolorization polysaccharide solution; S4, concentration and drying, wherein the obtained root decolorization polysaccharide solution is subjected to decompression concentration and vacuum freezing in sequence to obtain the tremella root polysaccharide. The method for decolorizing the tremella root polysaccharide has the advantage of improving the decolourization rate of the tremella root polysaccharide by using a double standing adsorption method of polyamide combined with the macroporous resin.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

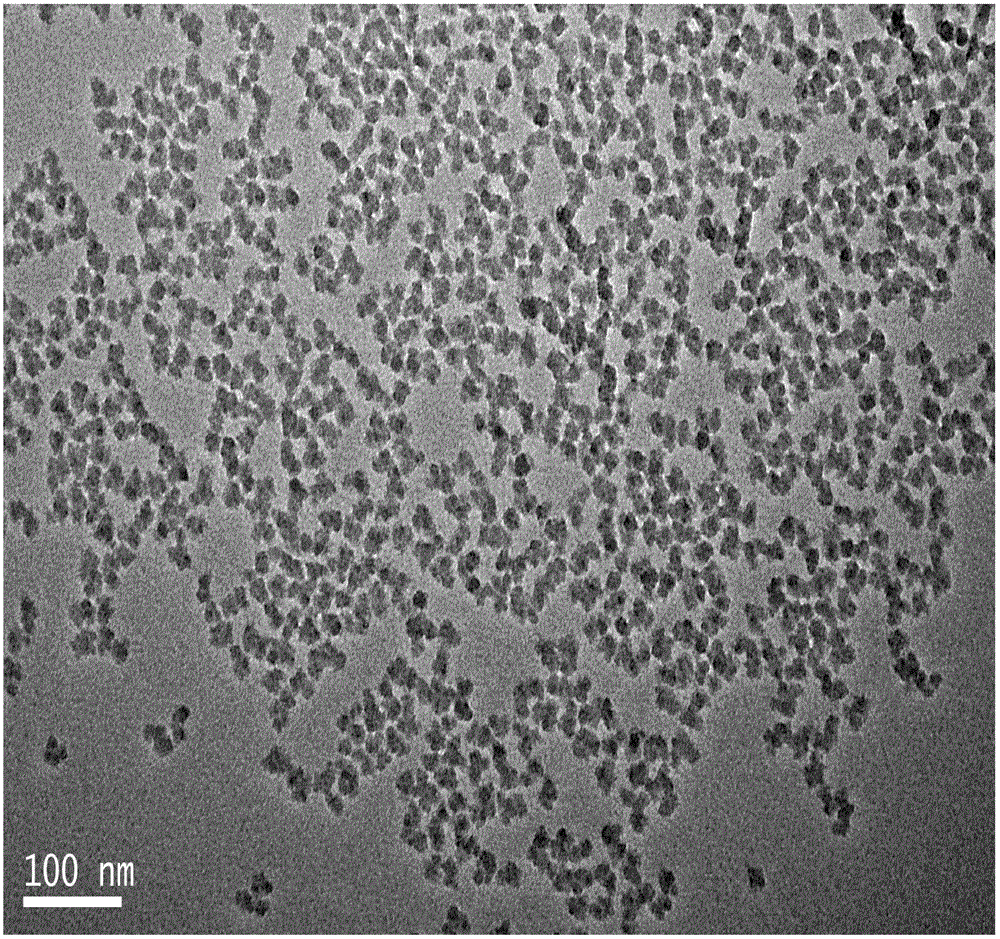

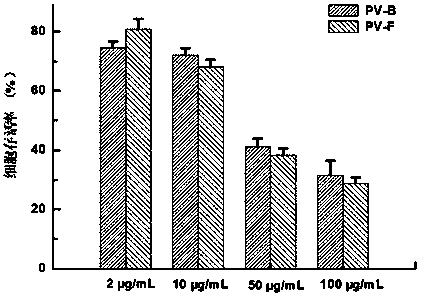

Extraction method for phellinus vaninii polysaccharide

ActiveCN110183542AGood biocompatibilityAntiproliferative activityAntineoplastic agentsFreeze-dryingTumor cells

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Coated iron oxide black pigment and preparation method thereof

InactiveCN112300605AAvoid oxidationGood dispersionPigment treatment with macromolecular organic compoundsPigment physical treatmentIron oxide blackPhysical chemistry

The invention discloses a coated iron oxide black pigment and a preparation method thereof, and belongs to the technical field of iron oxide black pigment preparation. The method comprises the following steps: (1) adding an iron oxide black filter cake and water into a reaction container, and uniformly stirring; (2) preparing an additive into an aqueous solution, adding the aqueous solution into areaction container, and mechanically ball-milling and dispersing to obtain an iron oxide black dispersion liquid; (3) heating the iron oxide black dispersion liquid, adding a soluble aluminum salt under a nitrogen atmosphere condition, heating, and controlling the temperature for coating; and (4) carrying out centrifugal separation, drying the filter material, and calcining to obtain the iron oxide black pigment coated with the aluminum layer. Air is isolated in the coating process, and black iron oxide is prevented from being oxidized in the coating process; the dispersion performance of theiron oxide black is improved by adopting the additive and a mechanical ball milling mode, and more stable dispersion liquid is obtained. The pigment is uniform in particle size, and the outer layer is coated with a layer of compact aluminum film, so that the pigment cannot be oxidized even at high temperature, and the performance of the pigment is more stable.

Owner:YIXING YUXING IND & TRADE

Extraction technology for swida wilsoniana oil

ActiveCN108865417AImprove extraction qualityImprove oil yieldFatty-oils/fats refiningFatty-oils/fats productionFiltrationOil water

Owner:于都中和光皮树开发有限公司

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

InactiveCN112442187ARegulatory loadModulation of crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceWater methanol

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

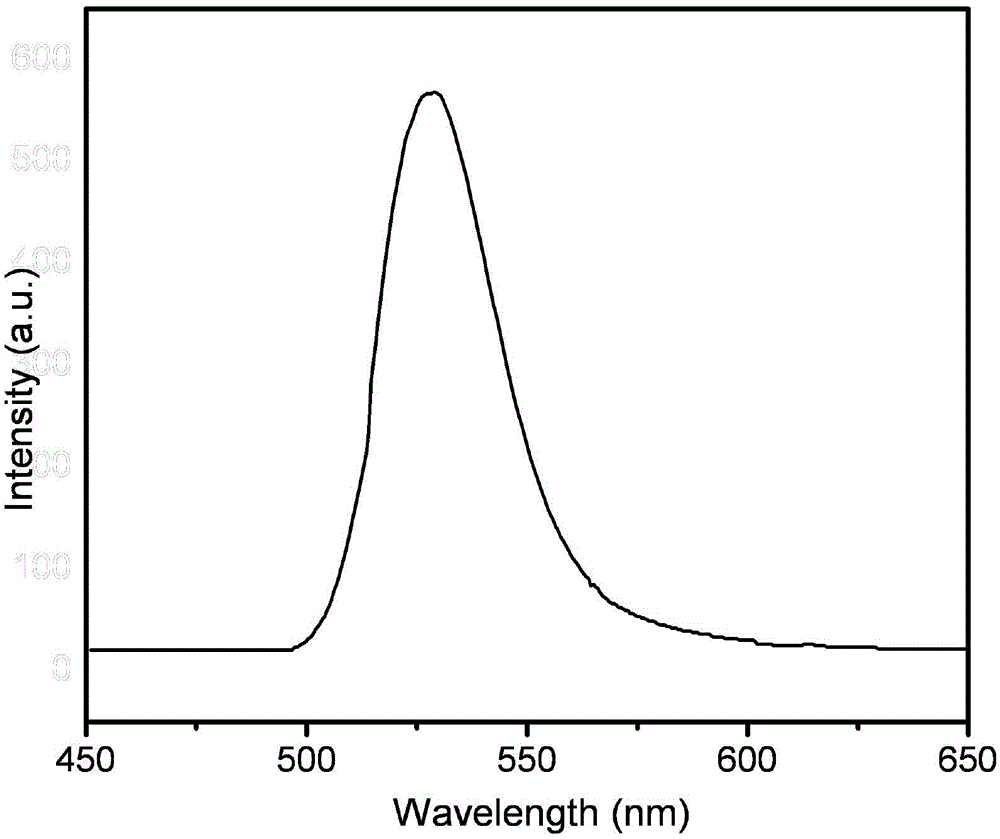

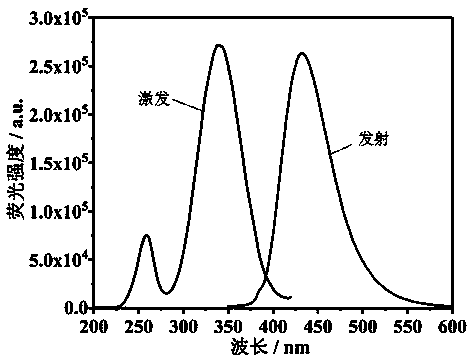

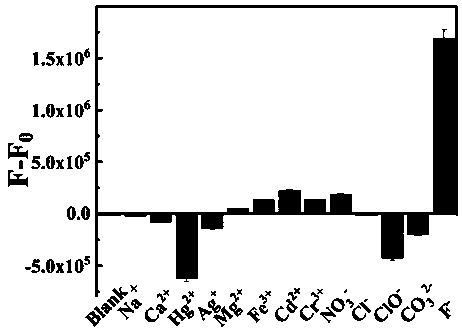

Preparation of water-soluble metal-organic framework composite material and application of water-soluble metal-organic framework composite material in detecting concentration of fluorine ions in water

InactiveCN111454461AFluorescent signal enhancementRealize specific identification detectionFluorescence/phosphorescenceLuminescent compositionsFluoProbesMetal-organic framework

Owner:NORTHWEST NORMAL UNIVERSITY

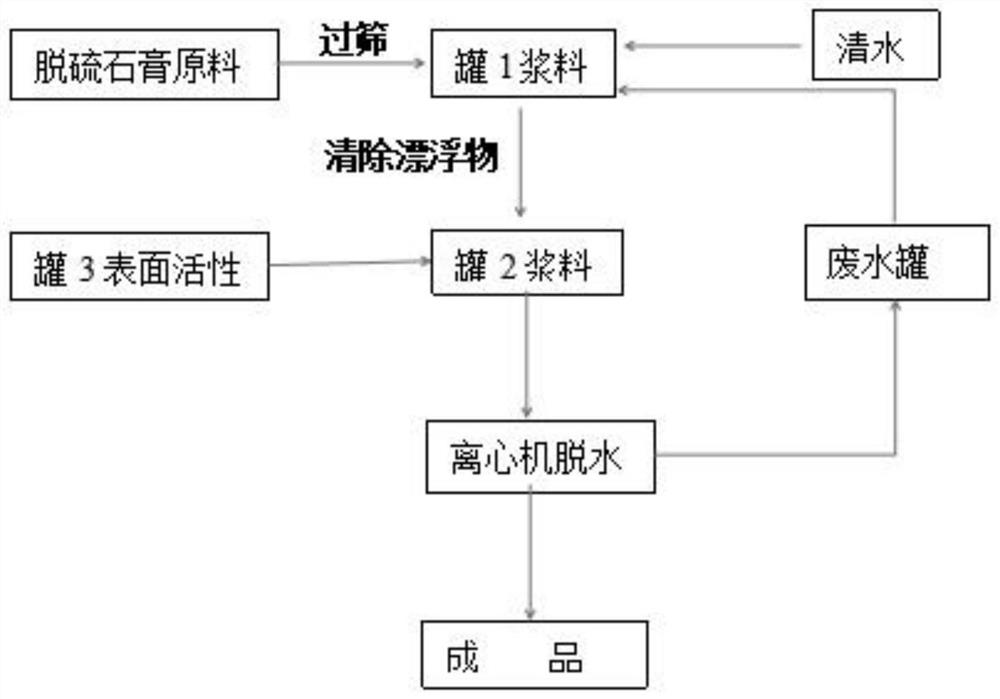

Preparation method for reducing content of organic matter in desulfurized gypsum

PendingCN113135585ASimple processLow costCalcium/strontium/barium sulfatesSeparation technologyActive agent

Owner:SHENZHEN QINGQINGYUAN TECH

Inkjet ink

ActiveCN112745714APrevent subsidenceLong-term stable printing statusInksPigment dispersionEngineering

The purpose of the present invention is to provide: an inkjet ink which has excellent moisture resistance and light resistance after printing, in which pigment particles do not easily settle, and which can maintain a stable printing state over a long period of time without being circulated or stirred; and a method for producing the inkjet ink. An inkjet ink which is formed from components including at least a pigment containing iron oxide, a dispersant, and a dispersion medium, each component satisfying a pharmaceutical additive standard, and in which all of the components are non-aqueous materials, and each component is dispersed and mixed to obtain a pre-dispersion, and the pre-dispersion is dispersed and mixed with the pigment containing iron oxide to obtain supernatant. By using the supernatant obtained by centrifuging the pre-dispersion, iron trioxide or yellow iron trioxide having an average dispersion particle diameter (D50) of 50-200 nm and a maximum dispersion particle diameter (D99) of less than 400 nm is dispersed as a pigment.

Owner:KISHU GIKEN KOGYO CO LTD

Method for preparing magnetic hybridized microsphere adsorption material for sewage treatment

InactiveCN110743488AReduce contentImprove adsorption capacityOther chemical processesRadioactive contaminantsMicrosphereDissolution reaction

Owner:邵帅

High-thermal-conductive composite material and preparation method thereof

InactiveCN110283430AImprove heat transfer efficiencyHeat-exchange elementsVacuum assistedFreeze-drying

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Online high-temperature separation and purification device and method for carbon black fuel oil

ActiveCN113786647AEfficient outflowAchieve separationLiquid separation auxillary apparatusFiltration circuitsPurification methodsProcess engineering

Owner:烁元新材料(东营)股份有限公司

Preparation method of special-morphology micro nano structural lithium-rich manganese-based cathode material

ActiveCN110143619AAchieving controllable equipmentRealize controllable preparation of special morphologyMaterial nanotechnologyPositive electrodesNickel saltHigh energy

Owner:JISHOU UNIVERSITY

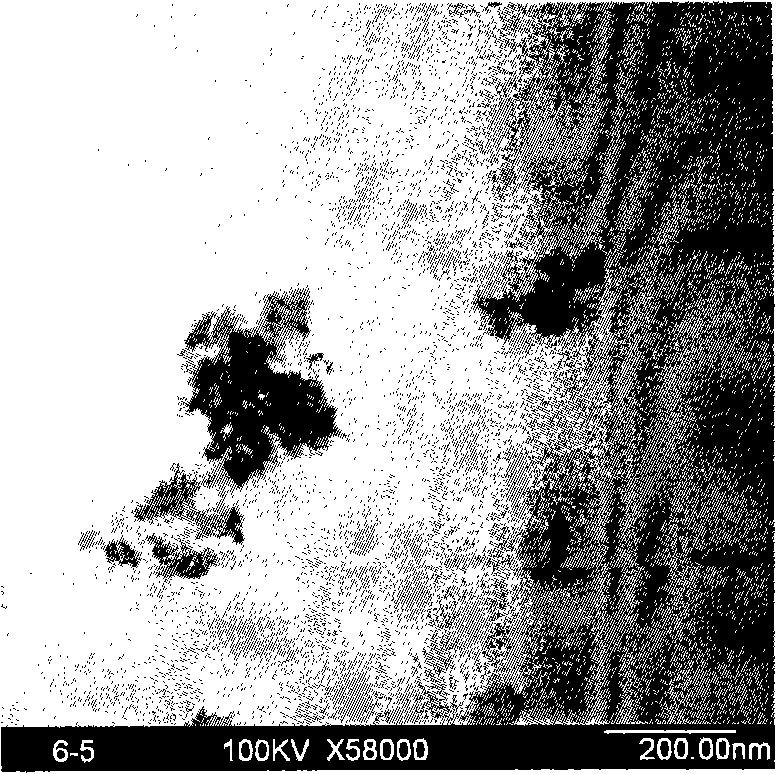

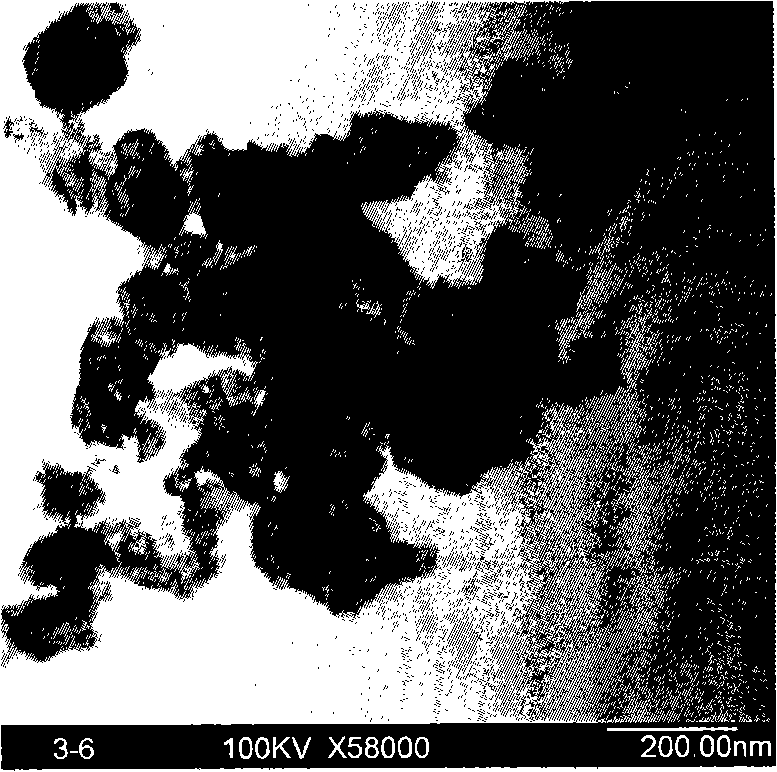

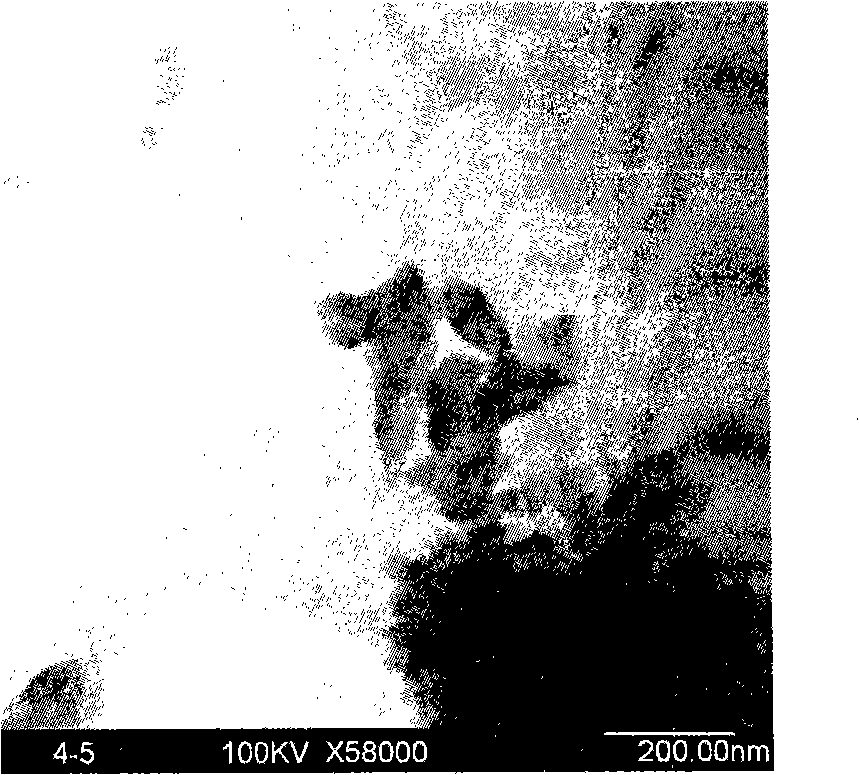

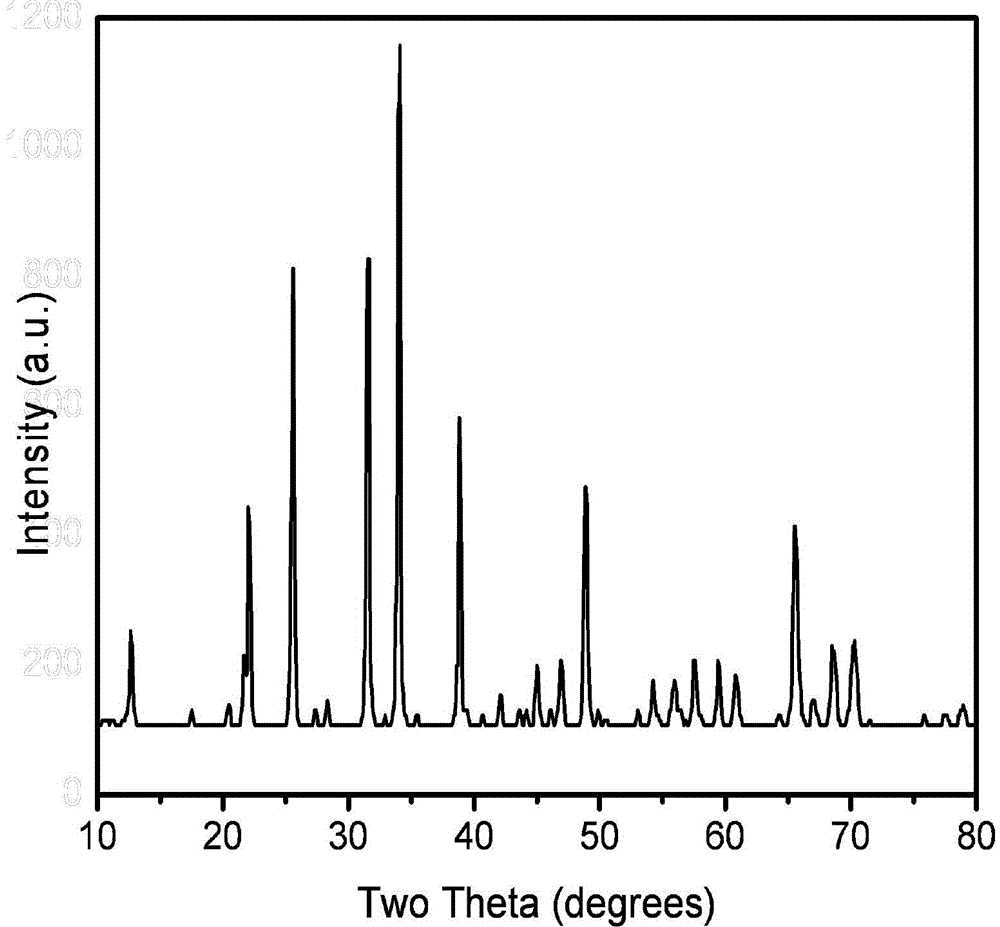

Environment-friendly indium oxide hydro-thermal synthesis method

ActiveCN103011260AReduce churnEmission reductionGallium/indium/thallium compoundsIndium(III) hydroxideIndium

The invention discloses an environment-friendly indium oxide hydro-thermal synthesis method which comprises the following steps of: (1) preparing an indium hydroxide precursor, namely a, adding a surfactant and an indium salt into deionized water under magnetic stirring conditions, continuously stirring for uniformly dispersing, adding excessive solid alkali to ensure that the pH value is 8-10 after reaction, stirring to obtain a uniform solution, and continuously stirring for 25-35 minutes; b, transferring to a polytetrafluoroethylene container, sealing in a stainless steel high-pressure reactor, heating, reacting and cooling to room temperature; and c, centrifuging and separating the products and washing, drying the precipitate, and grinding to prepare indium hydroxide In(OH)3; and (2) preparing the environment-friendly indium oxide, namely calcining the indium hydroxide In(OH)3 prepared by drying and grinding at the temperature of 500-600 DEG C for 1-2 hours, and preparing the cubic form indium oxide.

Owner:HENAN SHENGMAX TECH CO LTD

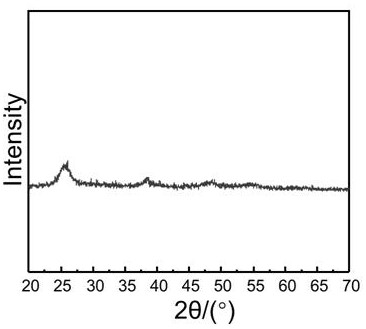

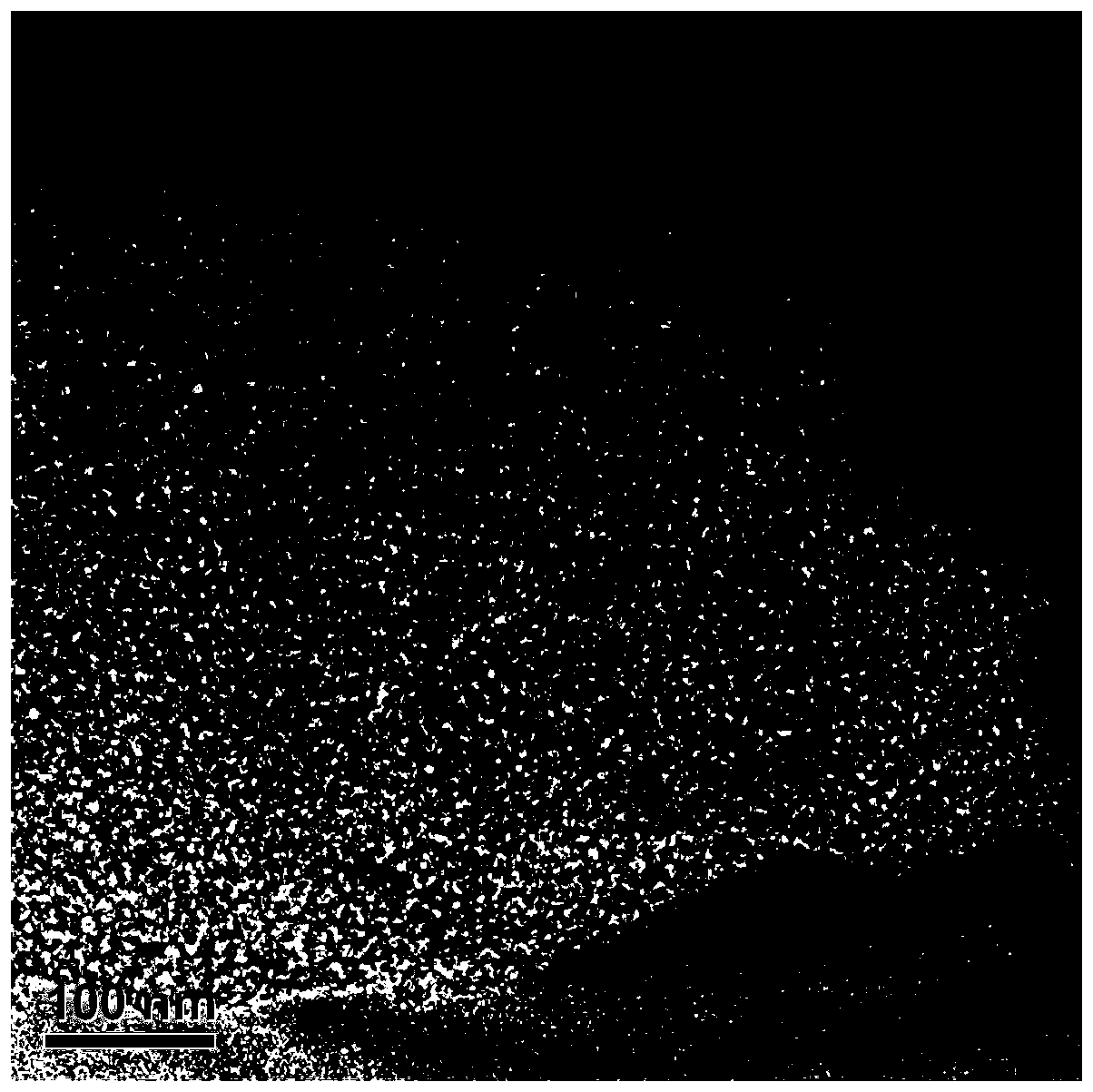

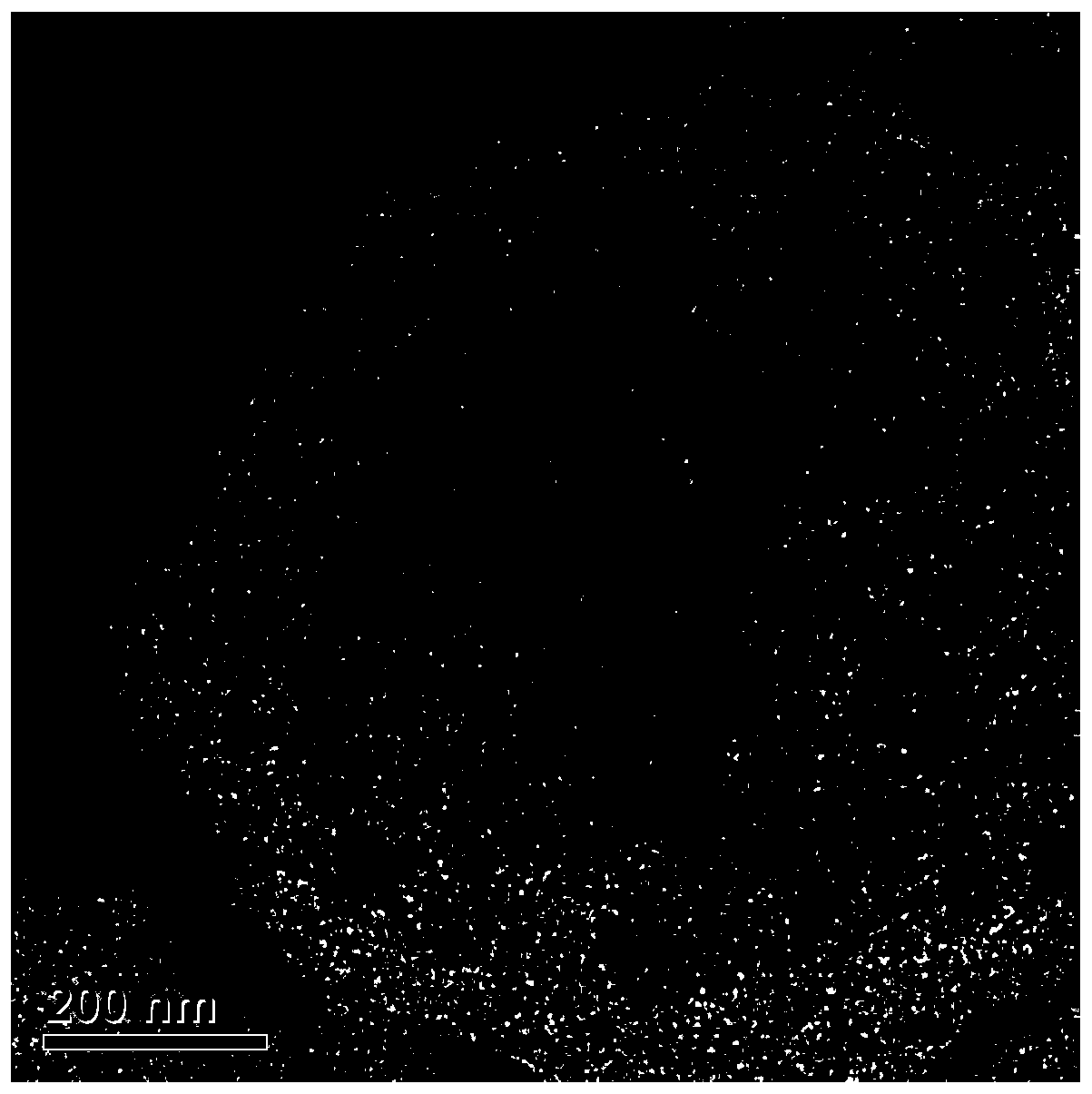

A kind of preparation method of gold palladium nano-catalyst in CO oxidation reaction

ActiveCN108355652BHigh catalytic activityImprove catalytic stabilityGas treatmentDispersed particle separationPtru catalystPhysical chemistry

Owner:HENAN NORMAL UNIV

Manufacturing method of liquid dairy product

PendingCN114246217ASimple production processGreat tasteMilk preparationOther dairy technologyUltrafiltrationProtein concentration

The invention provides a manufacturing method of a liquid dairy product. The manufacturing method sequentially comprises the following steps: heating: heating raw milk to 100-140 DEG C; cooling: cooling the heated milk; performing separation: performing centrifugal separation on the cooled milk to obtain skimmed milk; ultrafiltration: performing ultrafiltration desugaring on the skimmed milk, and performing protein concentration on skimmed milk trapped fluid; and sterilization: sterilizing the skimmed milk after ultrafiltration. By means of the manufacturing method, the degreased liquid dairy product high in protein content and low in lactose content can be produced, compared with products in the prior art, the degreased liquid dairy product is better in taste, and better drinking experience is brought to drinkers. The manufacturing method does not comprise a nanofiltration process, and compared with the prior art, the production process is simpler and more convenient, is easier to implement and has higher practicability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Horizontal spiral discharging centrifuge

Owner:西安水牧环境科技有限公司

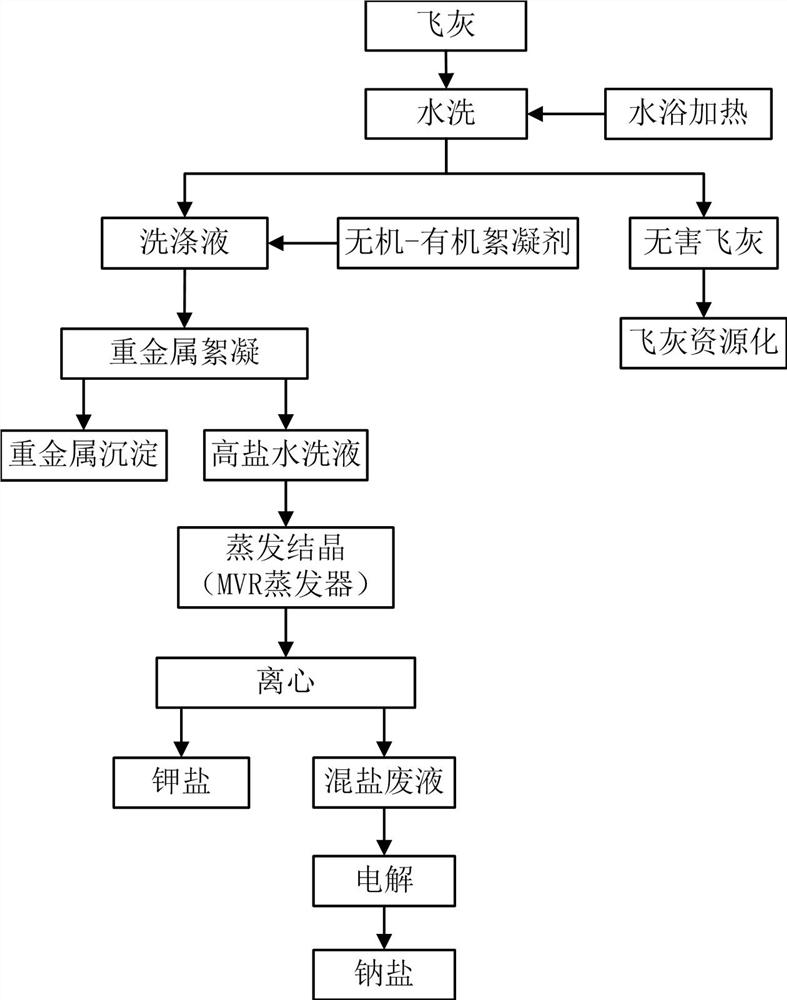

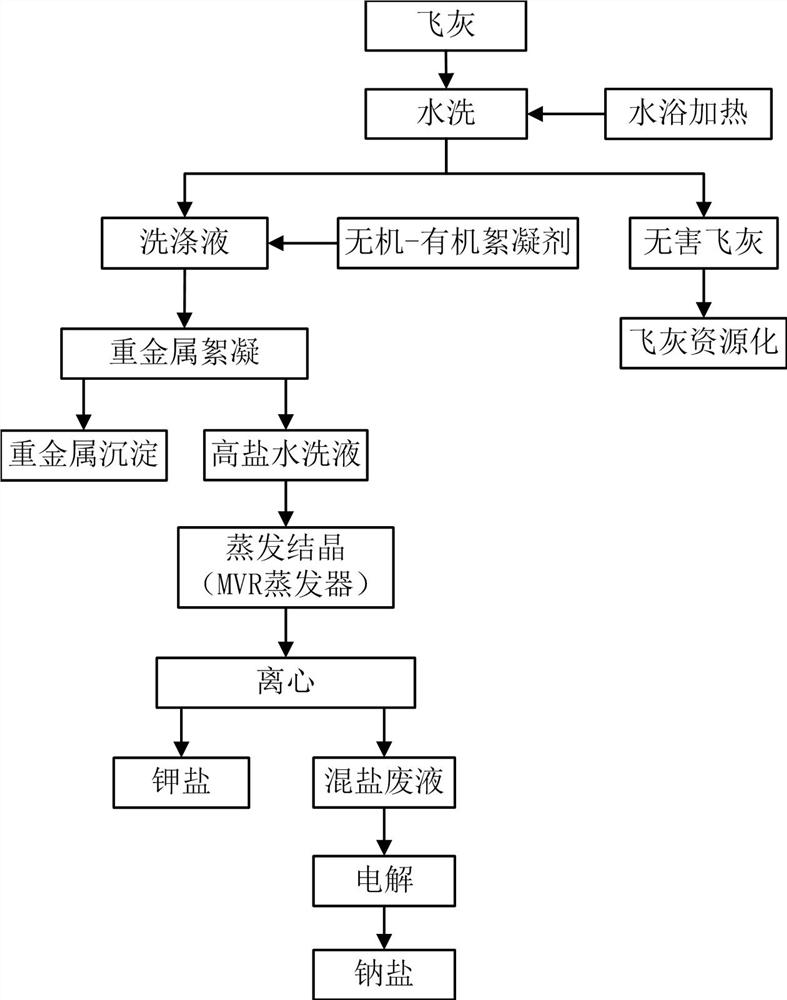

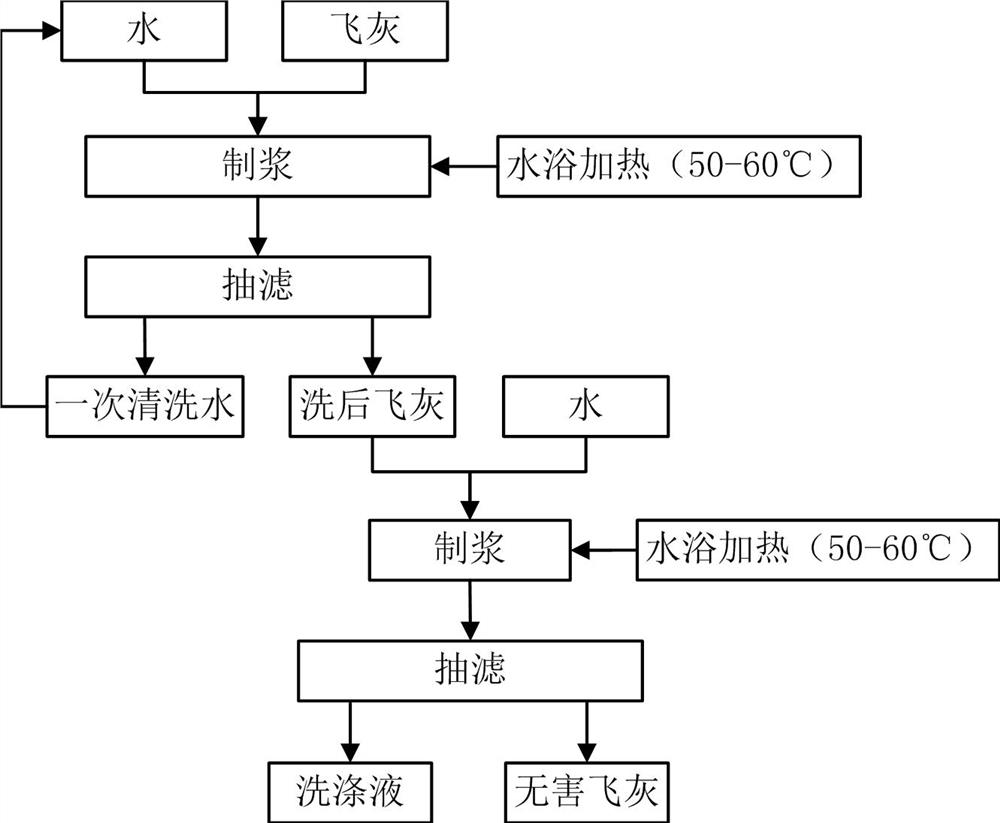

Fly ash enhanced washing and high-salinity wastewater resource utilization method

PendingCN113953303AAchieve harmlessReach resourcesSolid waste disposalWater contaminantsSaline waterSalt water

Owner:JIANGXI GAIA ENVIRONMENTAL SCI & TECH CO LTD +1

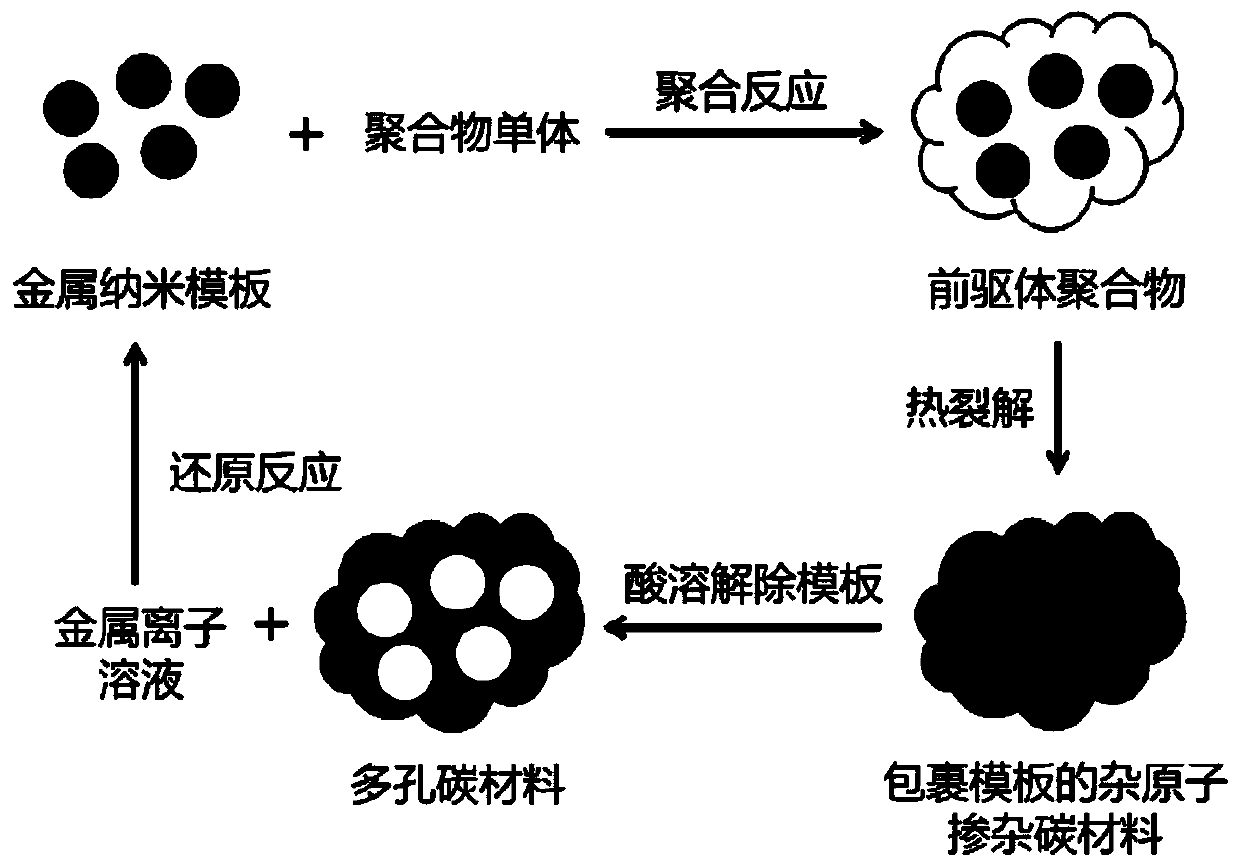

Heteroatom-doped porous carbon material with high specific surface area, and preparation method thereof

InactiveCN110697680AEasy to synthesizeThe particle size is easy to adjustNanotechnologyCarbon preparation/purificationPorous carbonActive agent

Owner:LONGYAN UNIV

Natural antioxidant for biodiesel

InactiveCN106811245AImprove oxidation stabilityOther physical and chemical properties have no obvious effectLiquid carbonaceous fuelsRotary evaporatorBiodiesel

Owner:SHANDONG UNIV OF TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap