Fly ash enhanced washing and high-salinity wastewater resource utilization method

A high-salt wastewater and fly ash technology, applied in chemical instruments and methods, water/sewage treatment, solid waste removal, etc., can solve the problems of hindering cement hydration, increasing the number of washing times, and consuming water resources, etc., to achieve reduction The number of times of washing, the effect of strengthening the removal effect, and the effect of reducing the cost of water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

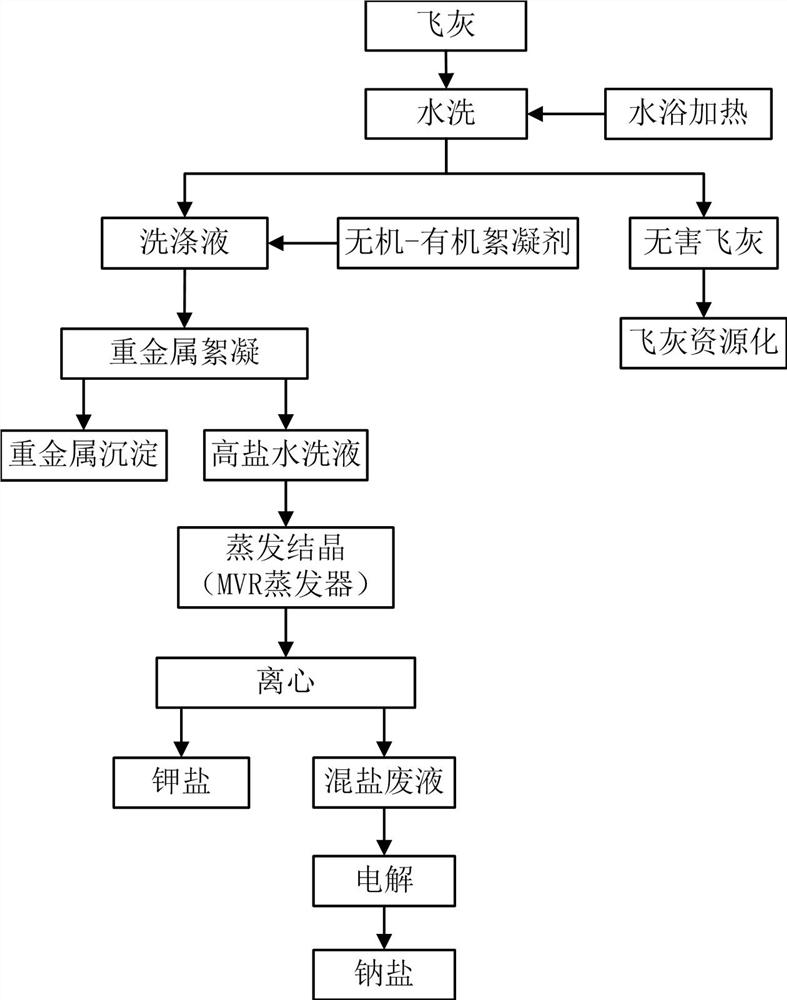

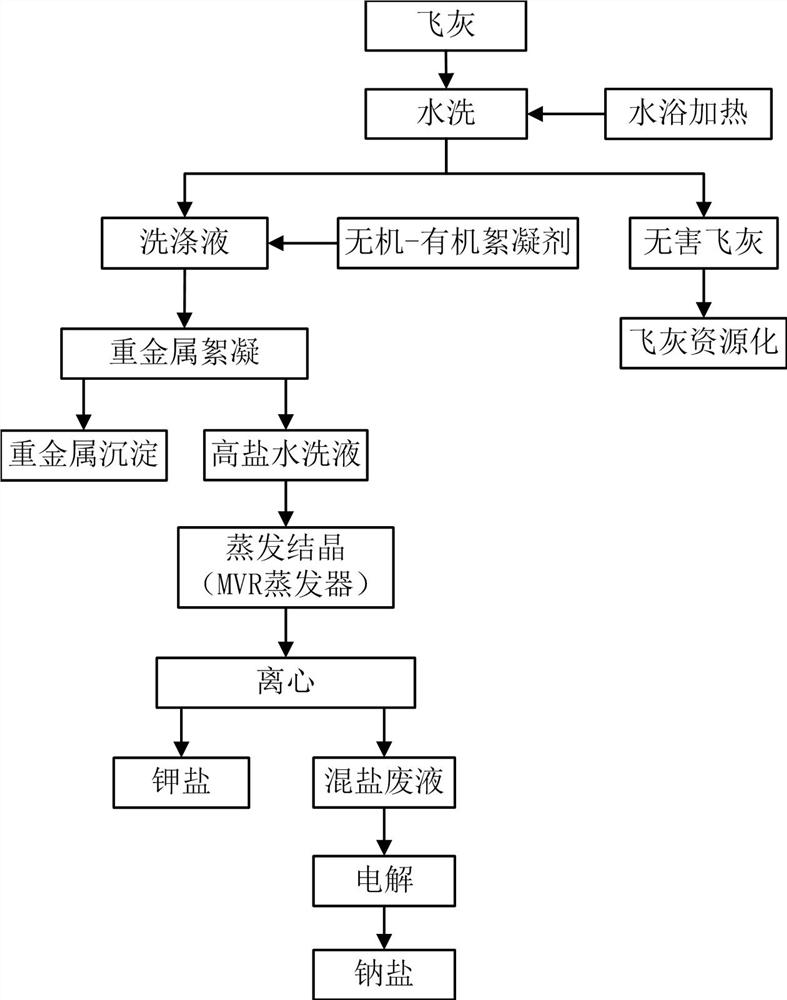

[0024] Example 1, such as figure 1 As shown, it includes the following steps:

[0025] Step 1. Wash the fly ash with water. Mix the fly ash and water according to the solid-to-liquid ratio of 1:4 to prepare a slurry. At the same time, heat the slurry to 50-60°C and put it in a water bath for 30-40 minutes. Slurry is subjected to suction filtration to obtain washing liquid and harmless fly ash;

[0026] Step 2. To precipitate heavy metals, first add an inorganic flocculant to the washing liquid, the mass ratio of the added inorganic flocculant to the heavy metal substances contained in the washing liquid is 1:1.3-1.5, mix and stir evenly , react for 20-30 minutes, then add an organic flocculant, the dosage of the organic flocculant is 30-50 mg / l, mix and stir evenly, react for 20-30 minutes, and use the combination of inorganic-organic flocculant to The heavy metals contained in the washing liquid are flocculated and precipitated, and the solid-liquid separation is performed a

Embodiment 2

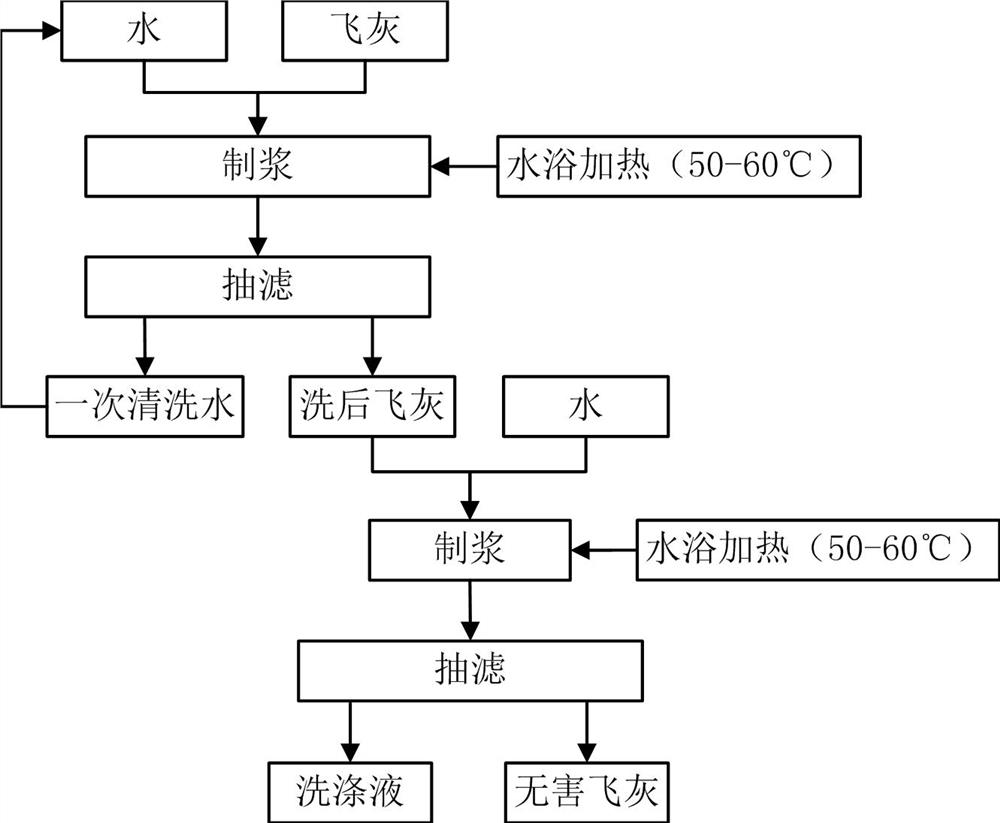

[0028] Example 2, such as figure 1 , 2 As shown, it includes the following steps:

[0029] Step 1. Wash the fly ash with water, use multi-stage water bath to heat and wash with water,

[0030] 1) Prepare slurry by mixing fly ash and water at a solid-to-liquid ratio of 1:4, and heat the slurry to 50-60°C and bathe in water for 30-40 minutes;

[0031] 2) Use a suction filter to filter the slurry heated in a water bath in 1) to obtain primary cleaning water and washed fly ash; wherein, the primary cleaning water is reused in 1) for mixing with fly ash to prepare slurry;

[0032] 3) Mix the washed fly ash obtained in 2) with water at a solid-to-liquid ratio of 1:4 to prepare a slurry, and at the same time heat the slurry to 50-60°C and bathe in water for 30-40 minutes;

[0033] 4) Use a suction filter to filter the slurry heated in a water bath in 3) to obtain washing liquid and harmless fly ash;

[0034] Step 2. To precipitate heavy metals, first add an inorganic flocculant to th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap