Online high-temperature separation and purification device and method for carbon black fuel oil

A separation device and fuel oil technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of untargeted design of separation and purification, shortened carbon black production process, and single purification method, etc. To achieve separation and purification, purification outflow, the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

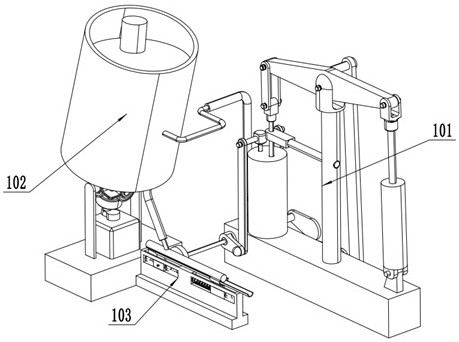

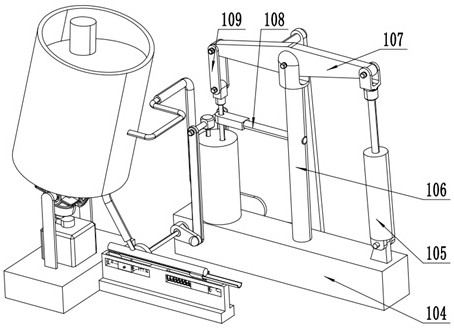

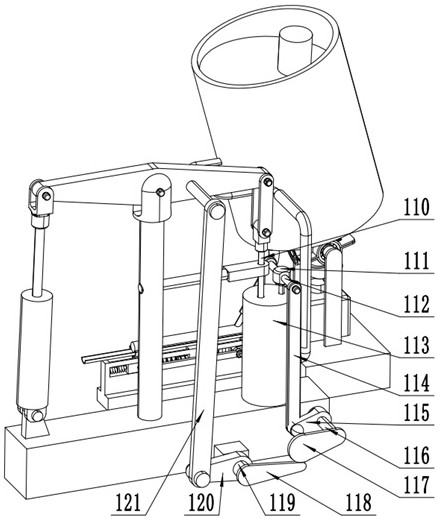

[0021] Example: such as Figure 1-Figure 5 A kind of online high-temperature separation and purification device for carbon black fuel oil includes a pressurization device 101, a separation device 102, and a purification device 103. The pressurization device 101 and the separation device 102 are connected through a first oil outlet pipe 122 and a connecting hose 123. The separation device 102 is connected with the purification device 103 through the second oil outlet pipe 126. The pressurizing device 101 is used to pressurize the carbon black fuel oil, so that the carbon black fuel oil to be separated and purified is compressed. The separation device 102 is used to treat the carbon black fuel oil. The oil is centrifuged to remove moisture impurities in the carbon black fuel oil, and the purification device 103 is used to purify the centrifuged carbon black fuel oil.

[0022] Such as Figure 1-Figure 5As shown, the first base 104 in the pressurizing device 101 is the installation pl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap