Automatic tea packaging device

An automatic packaging and tea technology, which is applied in packaging, solid separation, filtering and sieving, etc., can solve the problem of reducing the taste of tea and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

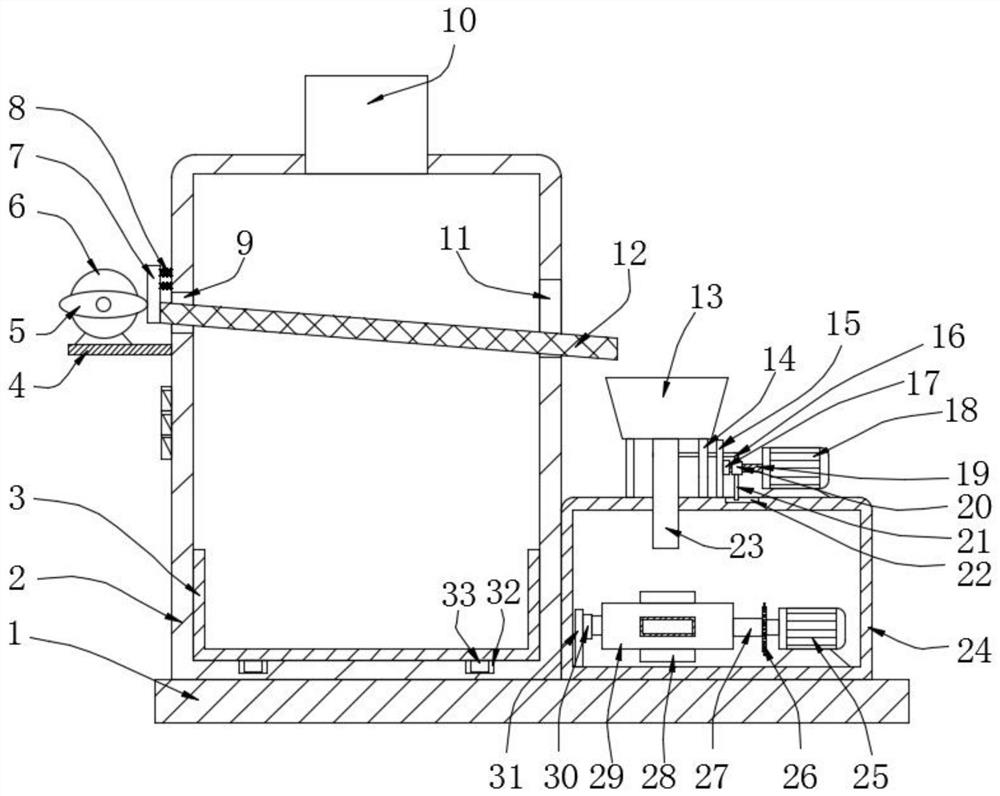

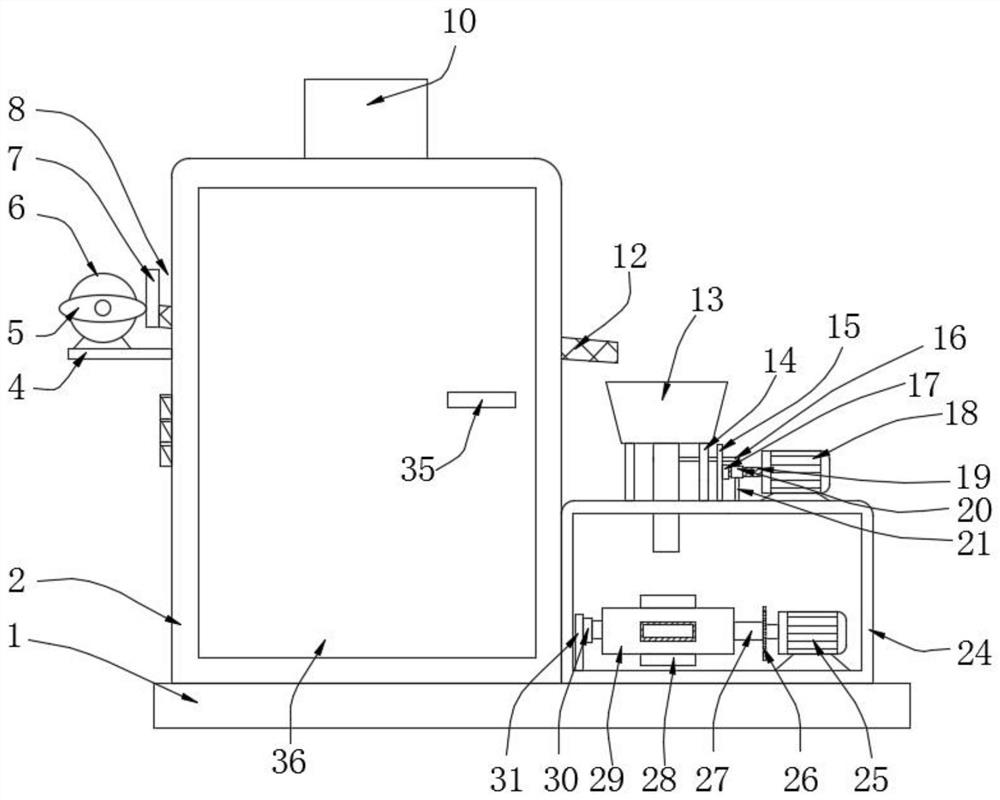

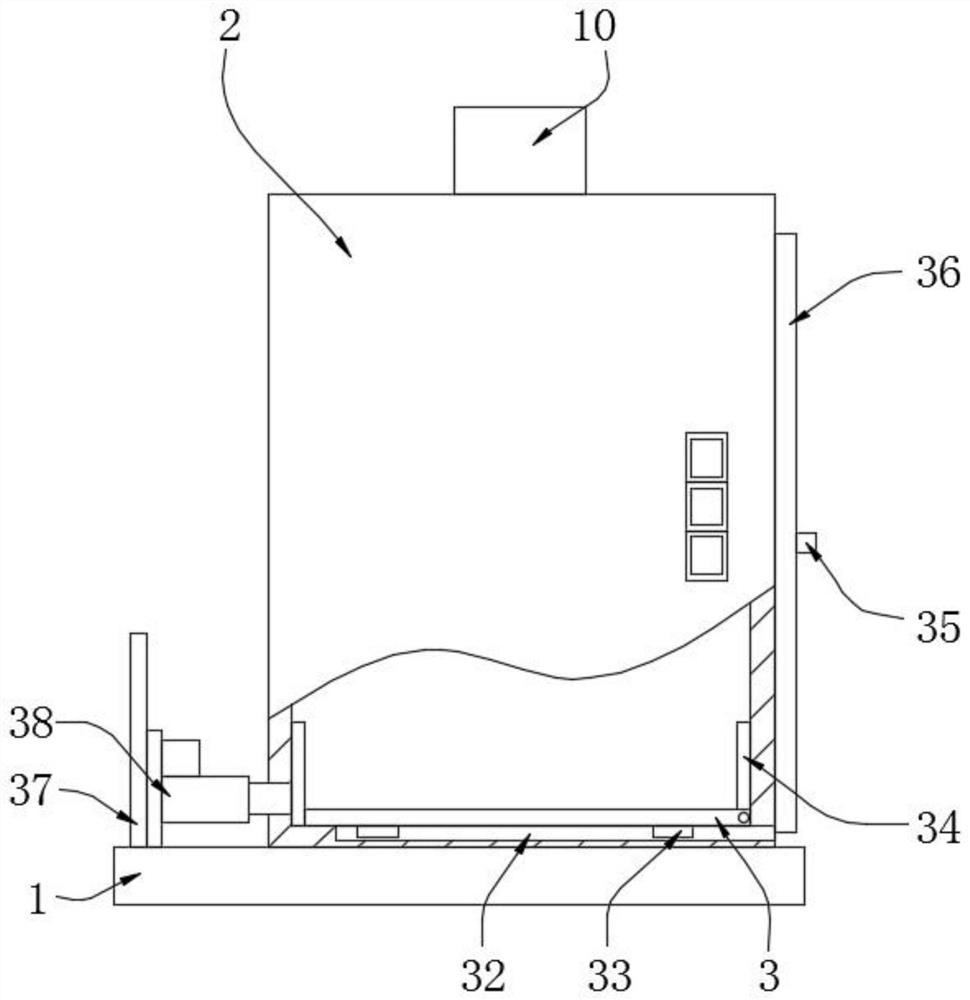

[0026] see Figure 1-5 , the present invention provides a technical solution: an automatic packaging device for tea, comprising a base 1, the upper surface of the base 1 is welded with a first shell 2, and the inner bottom wall of the first shell 2 is slidably connected with a collection box 3, which collects The front surface of the box 3 is hinged with a sixth plate 34, the upper surface of the base 1 is welded with a seventh plate 37, and the front surface of the seventh plate 37 is symmetrically equipped with two electric push rods 38, two electric push rods 38 The piston rod passes through the rear surface of the first housing 2 and is welded to the rear surface of the collection box 3. A first plate 4 is welded on one side of the first housing 2, and a first plate 4 is installed on the upper surface of the first plate 4. Motor 6, the output end of the first motor 6 is welded with a second plate 5, one side of the first housing 2 is provided with a first through-slot 9, a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap