Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Ultrasonic oscillation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An ultrasonic oscillation could occur when part of the output signal is fedback to the input (of the pre or power) such that it enhances bonafide input (of the pre or power).

Method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries

InactiveCN111690813AStrong penetrating powerPromote leachingWaste accumulators reclaimingProcess efficiency improvementEnvironmental engineeringLithium-ion battery

The invention discloses a method for utilizing eutecticevaporate solvent for leaching valuable metal in waste lithium ion batteries and relates to the technical field of comprehensive recovery and utilization of waste lithium ion battery materials. The method comprises the following steps that firstly, the waste lithium ion battery materials are added into eutecticevaporate solvent, ultrasonic oscillation is carried out on the condition of 20 DEG C-40 DEG C, and standing is carried out; and secondly, slurry obtained after ultrasonic treatment is filtered, and separated to obtain a leaching solution containing the valuable metal. The method has the beneficial effects that the eutecticevaporate solvent is adopted for leaching the valuable metal in the waste lithium ion batteries, ultrasonicwaves are adopted for treating a solution obtained after the eutecticevaporate solvent and the waste lithium ion battery materials are mixed, by means of the cavitation effect of the ultrasonic waves,penetrating power of the eutecticevaporate solvent can be increased, the eutecticevaporate solvent can leach out the valuable metal in the waste lithium ion battery materials in a reinforced manner,and thus the leaching efficiency and the leaching rate of the valuable metal in the waste lithium ion battery materials can be improved greatly.

Owner:NANCHANG HANGKONG UNIVERSITY

Preparation method of titanium dioxide/hollow microsphere composite filler

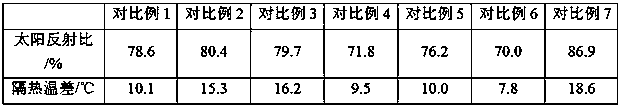

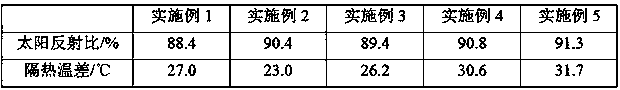

ActiveCN111378310AAvoid reunionAvoid overgrowthReflecting/signal paintsUltrasonic oscillationTitanium

The invention discloses a preparation method of a titanium dioxide / hollow microsphere composite filler. According to the method, a reversed-phase microemulsion system is adopted, an organic titanium source is slowly hydrolyzed on an oil / water interface through ultrasonic oscillation formed by small-frequency-band ultrasound, the surfaces of the hollow microspheres can be better coated with titanium dioxide crystal nucleuses due to the fact that the titanium dioxide crystal nucleuses are generated on a water phase layer; meanwhile, the reaction speed is controlled through two-step temperature rising, and the higher titanium dioxide film forming effect is achieved. According to the composite filler prepared by the method, the coating uniformity of titanium dioxide on the surfaces of the hollow microspheres is improved, so that the filler has obvious reflection performance and heat insulation and heat preservation effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for degrading industrial organic wastewater by ultrasonic wave ozone-microelectrolysis coupling

InactiveCN110776191AReduce surface tensionImprove permeabilitySpecific water treatment objectivesWater/sewage treatment with mechanical oscillationsMolecular sievePtru catalyst

Owner:JIANGHUA WATER TREATMENT EQUIP PLANT JIANGSU

Liquid gas silicon dioxide amine electrolyte for storage battery

InactiveCN102891338AImprove discharge performanceHigh energy ratioLead-acid accumulatorsGas phaseSilicic acid

Owner:YANCHENG XINYUE ENERGY

FG-coated MOF composite material, coating containing composite material, and preparation methods and application of coating

InactiveCN112442187ARegulatory loadModulation of crosslink densityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceWater methanol

The invention belongs to the technical field of anticorrosive materials in a marine environment, and particularly relates to an FG-coated MOF composite material, a coating containing the composite material, and preparation methods and application of the composite material and coating. The preparation method of the coating comprises the following steps: dispersing FG in absolute methanol, carryingout ultrasonic oscillation, adding a metal salt and an imidazole ligand into an FG methanol dispersion liquid, conducting stirring to obtain a turbid liquid, carrying out centrifugal separation to obtain a solid, alternately conducting washing with methanol and deionized water, and carrying out vacuum drying to obtain an FG-coated MOF composite material; and mixing epoxy resin, the FG-coated MOF composite material and a diluent, carrying out ball-milling stirring, adding a curing agent, and conducting uniform mixing to obtain a composite coating. A composite coating layer is obtained by coating the surface of a pretreated metal matrix with the composite coating, and conducting drying and curing. The epoxy resin is modified by the FG-coated MOF composite material, so that an imidazole ringin the composite material is chemically bonded with the epoxy resin, the problem of interfacial compatibility between the FG and the epoxy resin is solved, and the corrosion resistance and the mechanical property of an epoxy resin coating are improved.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap