Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Shake flask" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Culturing method for mycelia of Antrodia camphorata

InactiveCN107586724AOvercome the cycleOvercoming success rateFungiMicroorganism based processesHyphaHyphomycetes

Owner:殷东林 +1

Preparation method of transglucosidase

InactiveCN105505896AImprove conversion rateReduce manufacturing costMicroorganism based processesGlycosyltransferasesMicroorganismHigh density

The invention relates to a preparation method of transglucosidase. The technical problem that during isomaltose hypgather production, the glucoside conversion rate is low is mainly solved. In order to solve the problem, according to the technical scheme, the aspergillus niger strain (General Microbiology Center of China Committee for Culture Collection of Microorganisms, CGMCC No.3.6478) serves as the original strain, a liquid fermentation culture medium is adopted, inductors are specially added, the aspergillus niger strain is induced to secrete a large amount of efficient transglucosidase through the four steps of slope cultivation, shake flask expanded cultivation, liquid deep fermentation and centrifugal separation, and then high-density transglucosidase fermentation liquid is prepared. The product can be applied to the key step, namely, the conversion stage, in isomaltose hypgather production.

Owner:SHANGHAI KINRY FOOD INGREDIENTS +1

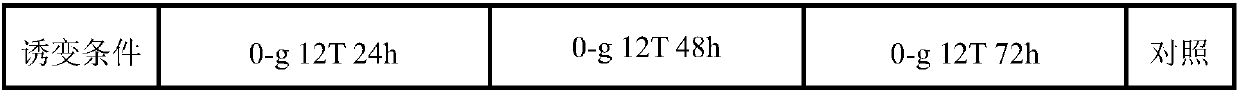

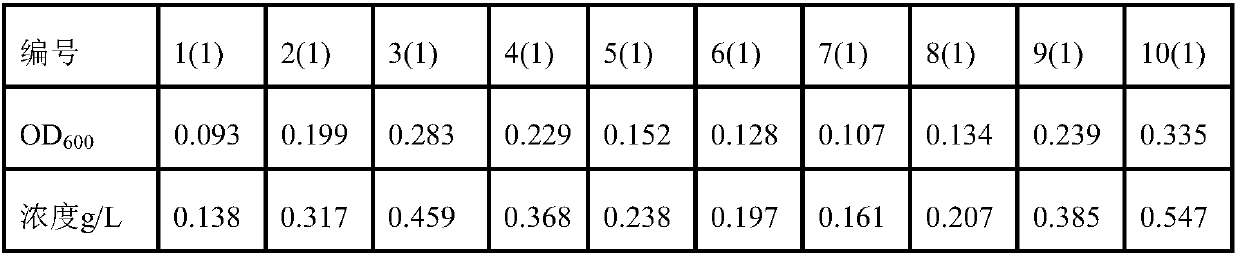

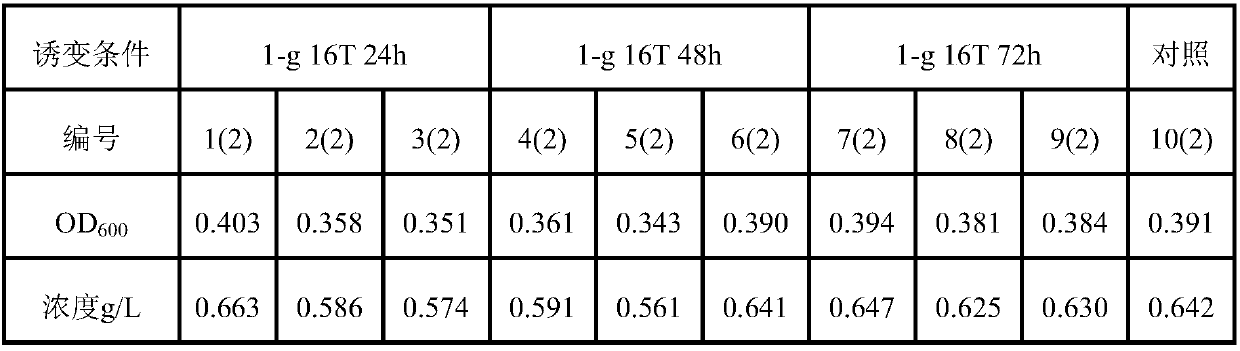

Mutagenesis method for collagenogenesis yeast on the basis of high-magnetic field gravity environment

InactiveCN109536483ARelieve fatigue effectImprove efficiencyFungiMicroorganism based processesScreening effectBacterial strain

Owner:NANJING UNIV OF SCI & TECH

Preparation method of cordyceps sinensis oral liquid and specified culture medium

InactiveCN106119130AKeep active ingredientsRich in trace elementsFungiMicroorganism based processesVegetable oilSaccharum

The invention discloses a preparation method of cordyceps sinensis oral liquid and a specified culture medium. The present situation that a bio-fermentation technology is used for filling up the gap of wild cordyceps sinensis is relieved fundamentally, and the content of the main ingredients of cordyceps sinensis in the oral liquid is increased. The culture medium mainly adopts natural plants and is natural, green, free of chemical residues and comprehensive in nutrition, and more microelements are contained; glucose and one of sucrose, white sugar and brown sugar are added together, and the ingredients are comprehensive and lasting; vegetable oil is used for replacing a traditional chemical defoamer and is nutritious and free of chemical residues; in the production and processing and filling process of the oral liquid, traditional or modern physical or chemical methods such as high temperature, drying, extraction and crushing are not adopted in the whole process, all the active ingredients in the oral liquid are effectively reserved, and the active ingredients are not damaged or destroyed; additives such as a preservative, a thickener, a stabilizer and a colorant are not added from the step of preparing shake flasks to the step of filling the product, and the content of the effective ingredients of the oral liquid is high.

Owner:宫晶晶

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap