Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Reaction temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Temperature is one of the effects that influence on the rates of reaction. By increasing. the temperature, the rate of a reaction proportionally increases until it reach the limits where. another factors might disturb the reaction from more increases. While the time taken for the. reaction is shorter at a higher temperature.

Preparation method of submicron CuS (copper sulphide) classification ball

The invention discloses a preparation method of submicron CuS (copper sulphide) classification balls. The method comprises the following steps: adding polymer into a good solvent to dissolve and remove big gel particles; adding copper source solution to the good solvent and stirring; adding sulfur source solution and then stirring; reacting the reaction liquid under 100-1,000 KPa at 100-200 DEG C; naturally cooling to the room temperature to obtain black precipitate; and washing and drying the precipitate to obtain the classification balls. The classification balls has the advantages of cheap and readily available templates, environmental friendliness, safety without toxicity, renewability and high water solubility, the contents of raw materials are abundant in nature and the operation of the reaction system is simple; the size and structure of the prepared classification ball are adjustable: the diameter can be controlled by adjusting the molar weight of the added precursor, the template concentration, the reaction temperature and time and the like; the operation is simple; and the prepared classification balls have wide application value in the fields of catalyst, catalyst carrier, optical equipment, sensor, lithium-ion rechargeable battery cathode material, superconductor and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

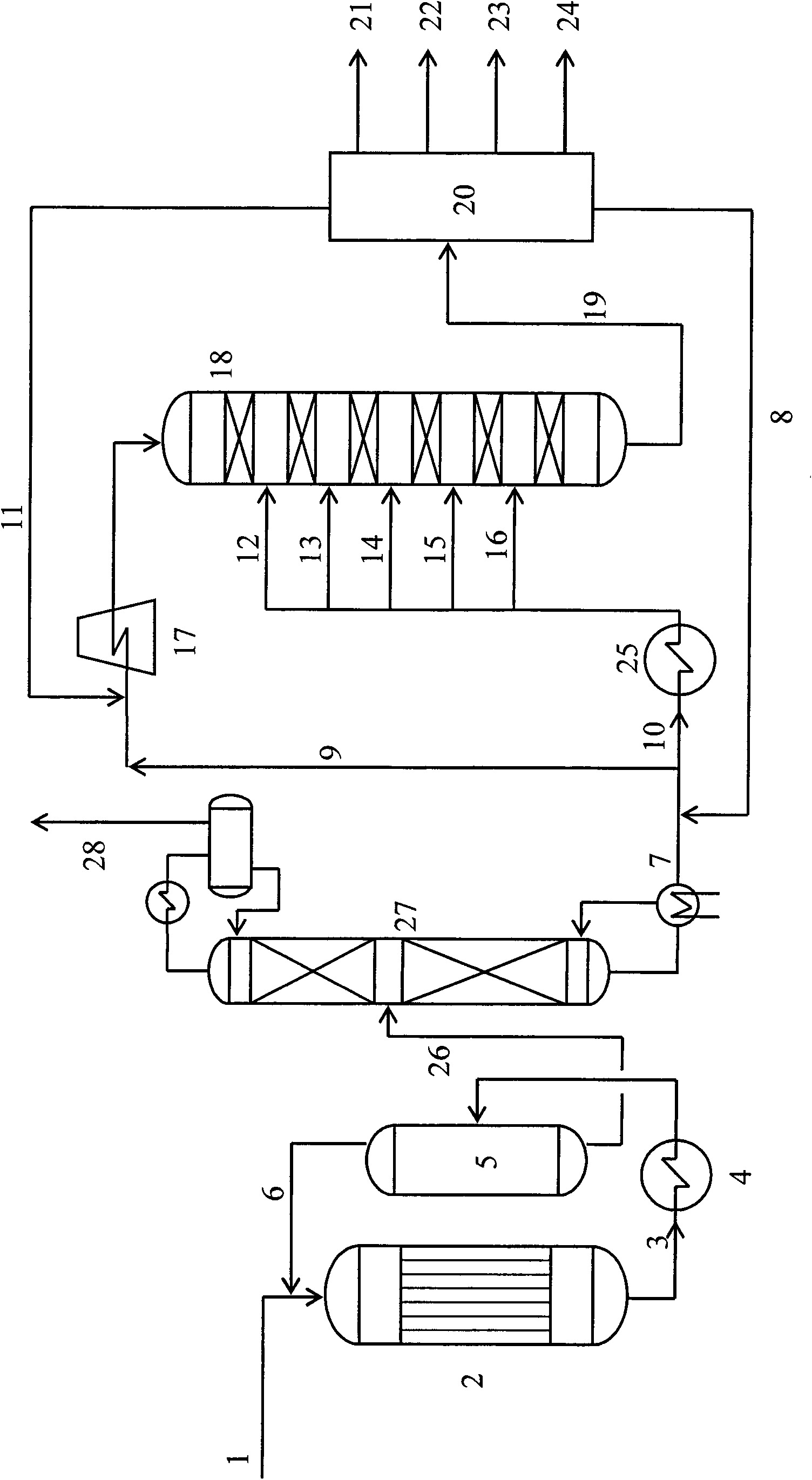

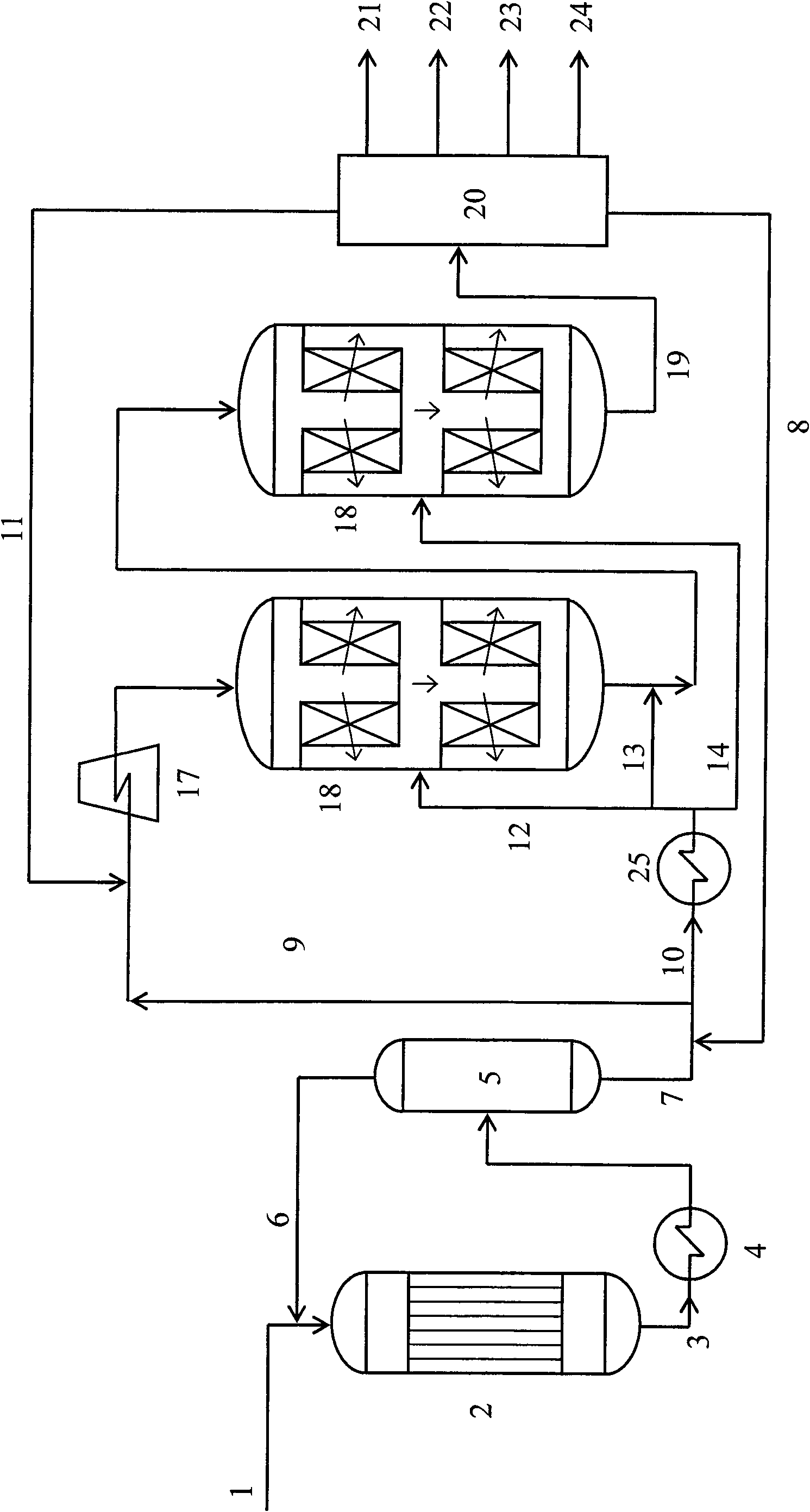

Method for directly preparing propylene from crude methanol

ActiveCN101659592ADistillation purification process omittedReduce energy consumptionHydrocarbon from oxygen organic compoundsEthylene productionMolecular sieveDiluent

Owner:WISON ENG

Catalyst for ternary copolymerization of norbornenes, tetrafluoroethylene and pentenes and ternary copolymerization method

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

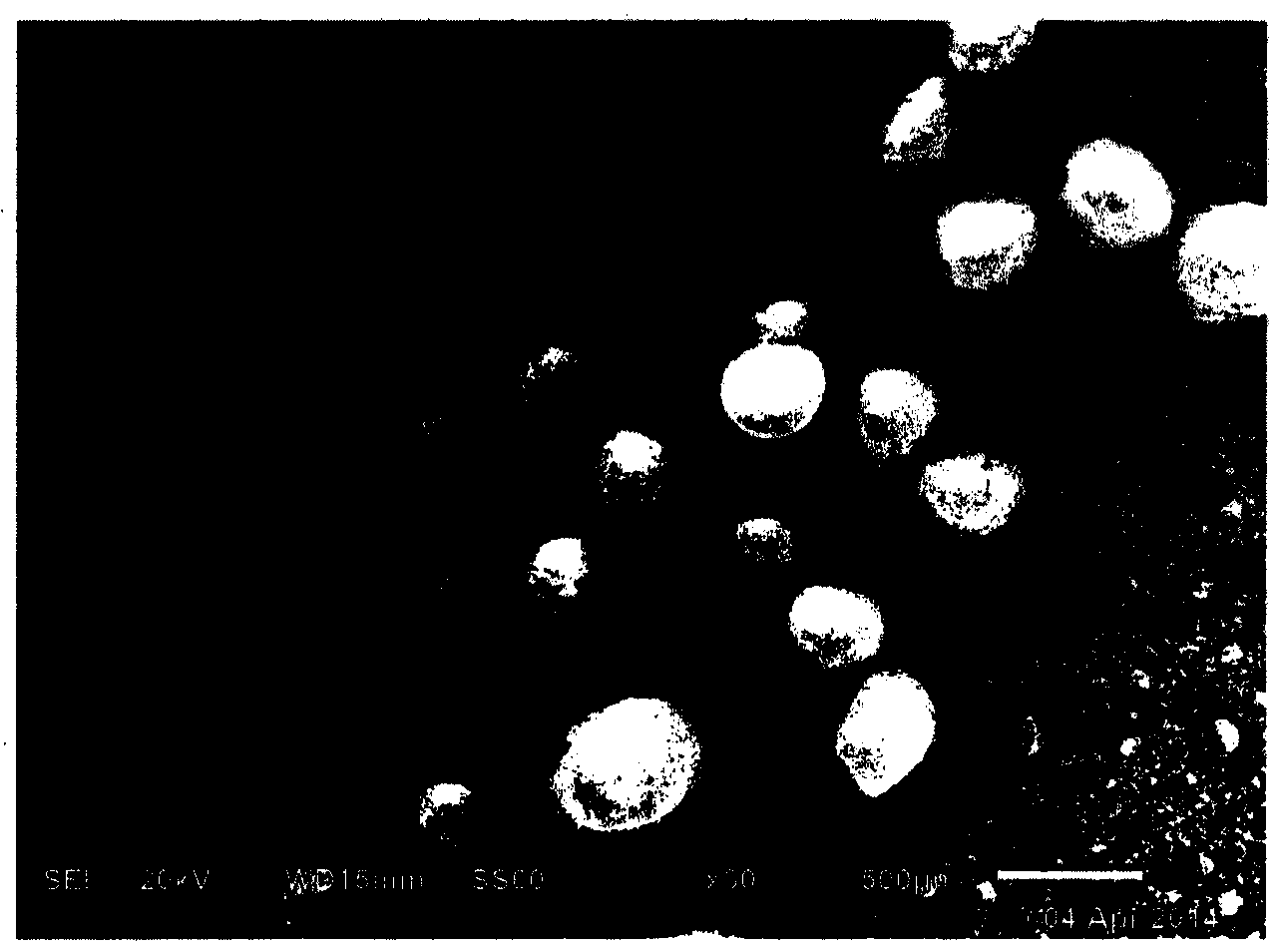

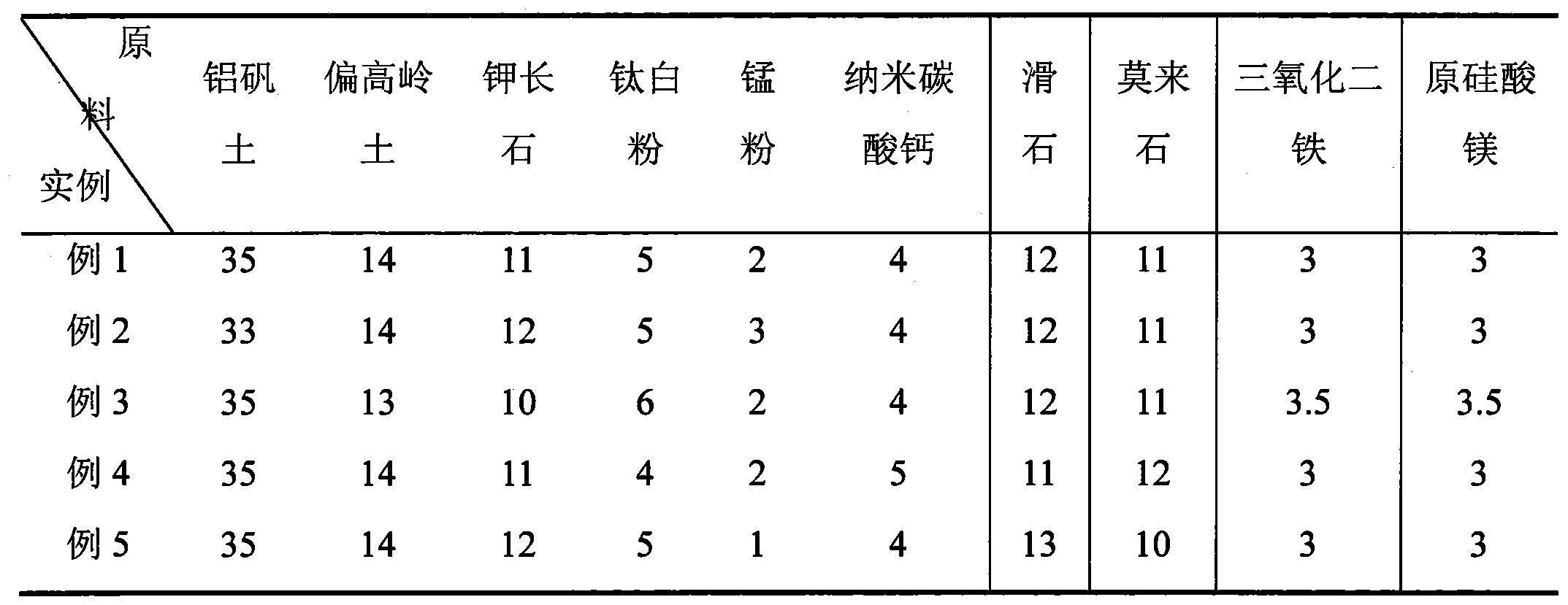

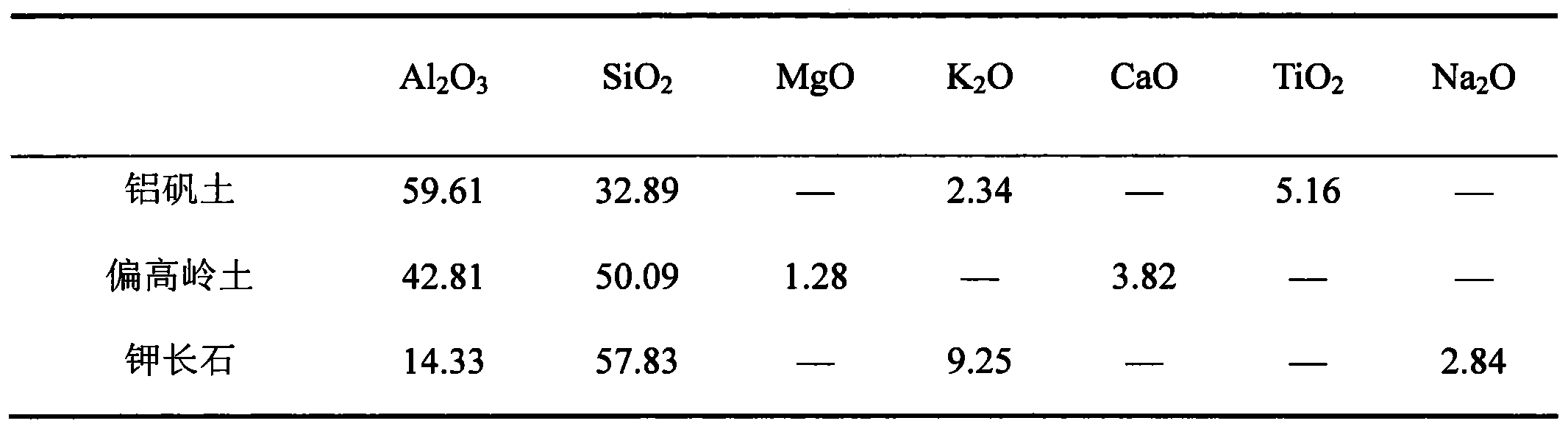

New low-density high-intensity ceramsite fracturing propping agent and preparation method thereof

ActiveCN104099082AAppropriate dispersionEnhancement effect is goodFluid removalDrilling compositionMagnesium orthosilicateExpanded clay aggregate

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

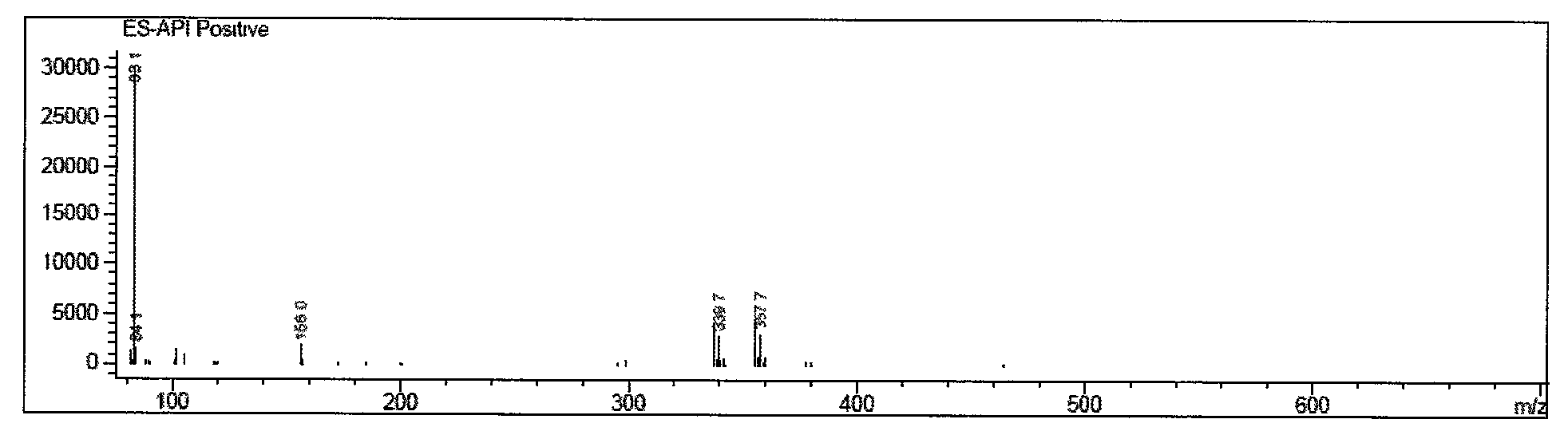

Method for preparing LCZ696

ActiveCN105330609AReduce generationPrecipitation state is goodOrganic compound preparationOrganic chemistry methodsSodium acetateReaction temperature

The invention discloses a method for preparing LCZ696. Please see the synthesis route in the specification. When sodium acetate is used as alkali in the compound III preparation process, the conversion rate is high, hydrolysis impurities are few, system stability is good, and the reaction time is greatly shortened; in the compound I preparation process, acetone and normal heptanes with the mass ratio between 5 to 1and 10 to 1 serve as cocrystallization solvent, the reaction temperature of 35-45 DEG C is adopted, a sodium hydroxide solution is dropwise added into a reaction system at a certain speed at the temperature of 35-45 DEG C, generation of hydrolysis products can be greatly reduced, the solid precipitation state is good, purity is high, aminolysis impurities and hydrolysis impurities can be effectively controlled, and the LCZ696 can directly serve as crude drug to be used for preparations.

Owner:NANJING CHIA TAI TIANQING PHARMA +1

Preparation method of D-threo-2-(dichloromethyl)-4, 5-dihydro-5-(p-(methylsulfonyl) phenyl)-4-oxazole methanol

ActiveCN101550110AFew stepsEasy to operateOrganic chemistryPotassium borohydrideReaction temperature

Owner:JIANGSU HANSYN PHARMA

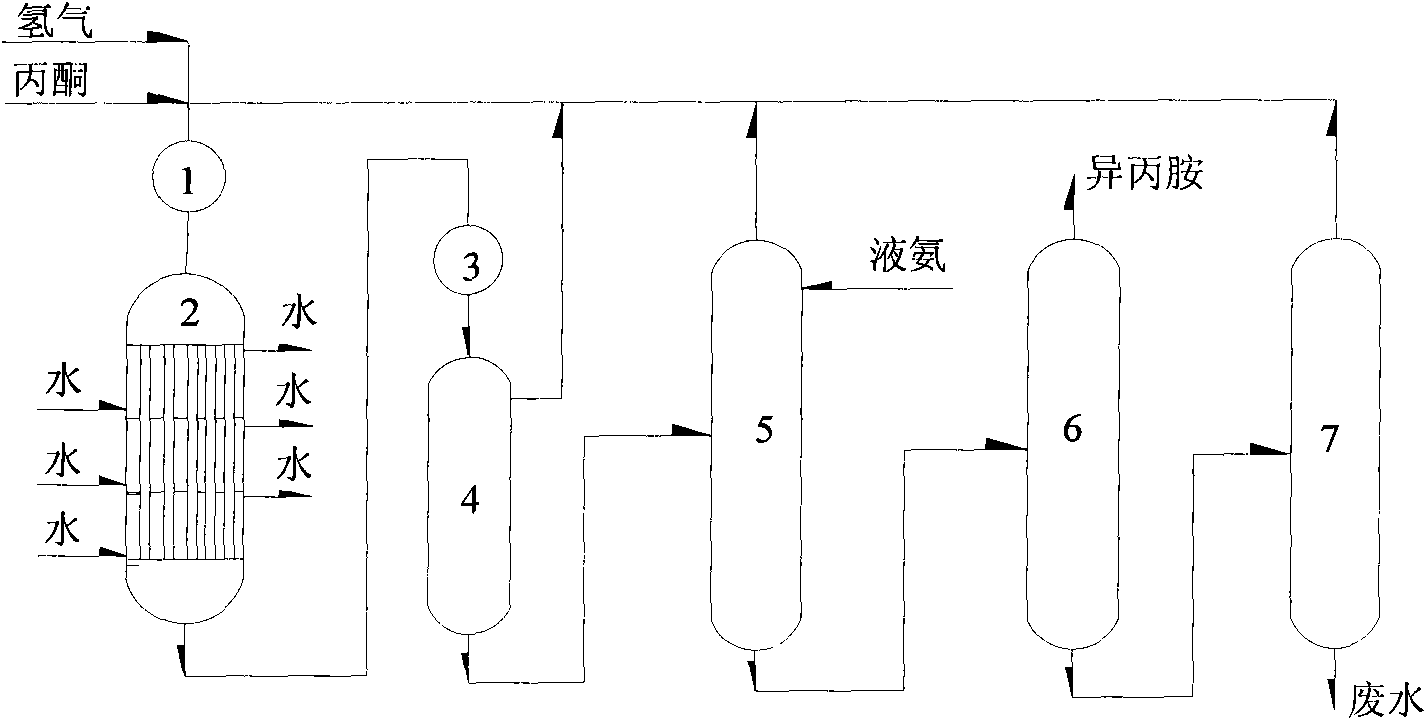

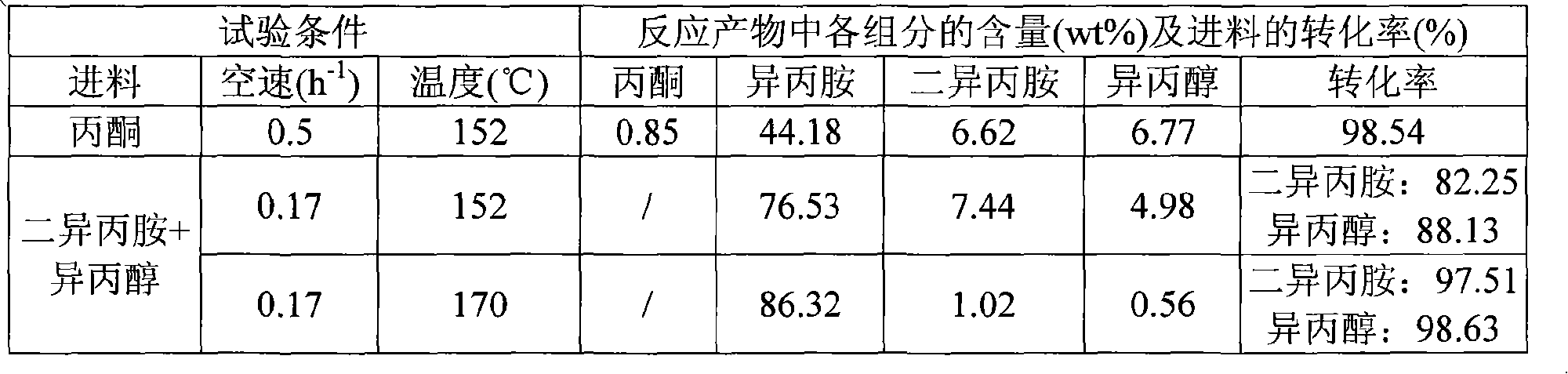

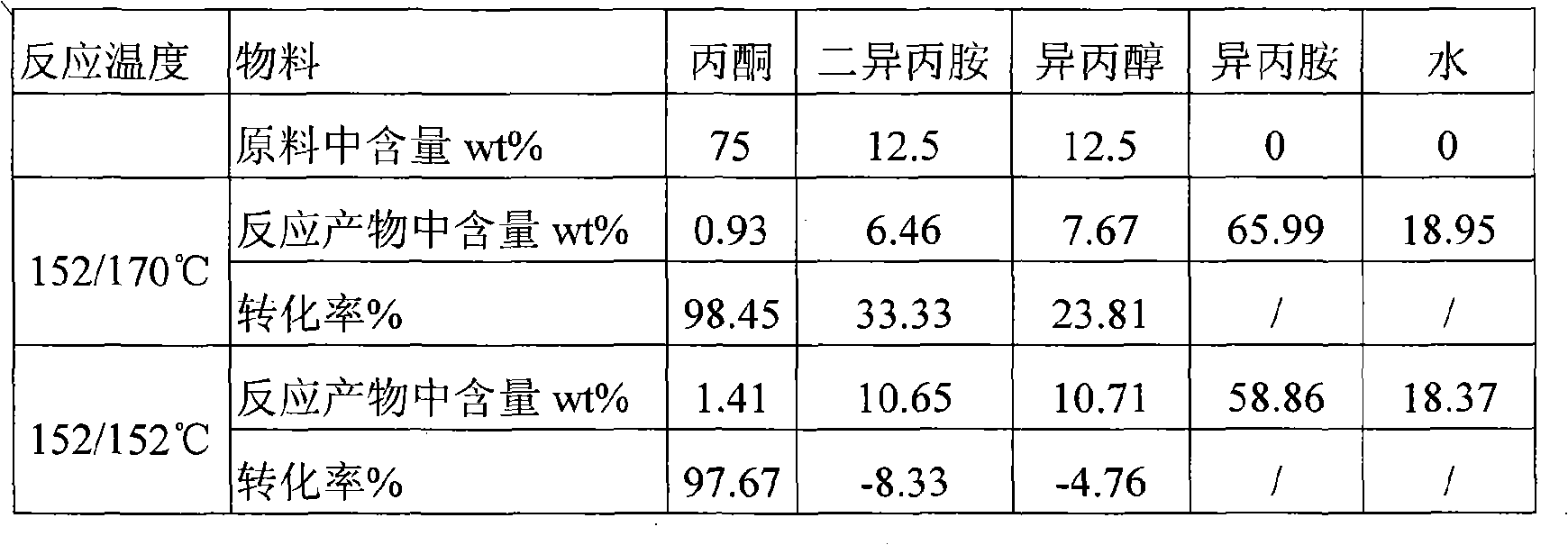

Method for producing isopropylamine

ActiveCN101684073AReduce heatReduce energy costsAmino compound purification/separationPreparation by reductive alkylationReaction temperatureEconomic benefits

Owner:CHINA PETROLEUM & CHEM CORP +1

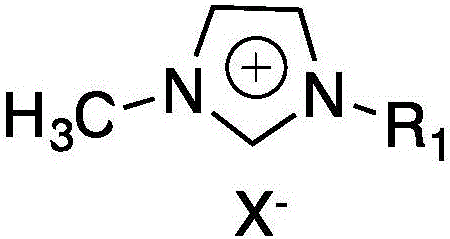

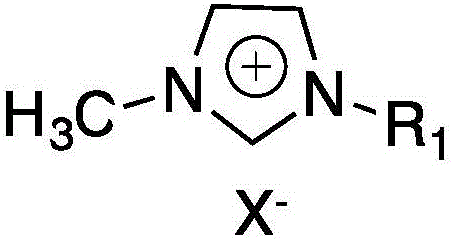

Method for catalysis synthesis of glycerol formal by gemini dication acidic ion liquid

InactiveCN101962377AHigh catalytic activityReduce dosageOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsReaction temperatureControllability

The invention discloses a method for catalysis synthesis of glycerol formal by gemini dication acidic ion liquid. In the method, gemini dication acidic ion liquid is used as catalyst, glycerol and formaldehyde solution are taken as reactant, cyclohexane is taken as water-carrying agent, and the raw material is subject to catalysis synthesis at the temperature of 40-120 DEG C to obtain glycerol formal. The method has moderate reaction condition, low catalyst corrosivity, high catalytic activity, high product selectivity, simple operation process and strong controllability and can be reused.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Zirconium-molybdenum oxide catalyst for methane oxidation to synthesize formaldehyde and its preparation method

InactiveCN1394681AEasy to prepareHigh mechanical strengthMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureOxygen

The molecular formula of zirconium-molybdenum oxide catalyst for synthesizing formaldehyde by means of methane oxidation is (ZrO2)x(Zr(MoO4)2)y (MoO3)z, and its preparalcon method includes the following steps: using zirconium dioxide powder ammonium molbdate powder as raw material, metering and weighing ammonium molybdate powder according to the above-mentioned molecular formula, using deionized water to prepare ammonium modybdate aqueous solution with a certain concentration, adding said aqueous solution into zirconium dioxide powder, drying the mixture, high-temp. roasting, mechanical grinding, press-forming, screening granules so as to obtain the catalyst.

Owner:TSINGHUA UNIV

Vanadium phosphorus oxygen catalyst for preparing acrylic acid and acetic acid by oxidation of propane and preparation method thereof

InactiveCN1557549ASmall particlesEvenly distributedPhysical/chemical process catalystsOrganic compound preparationIsobutanolPolyethylene glycol

The VPO catalyst is prepared with V2O2 and phosphoric acid in mixed isobutanol-benzyl alcohol solvent, and has polyglycol as dispersant. It has P / V atom rati of 1.1, specific surface area as high as 70-78 sq m / g and main material phase of vanadyl pyrophosphate. It is used the catalyst for oxidizing propane with air to preparing acrylic acid and acetic acid, and has single pass converting rate at the reaction temperature range of 380-400 deg.c of 37-72 % typically, acrylic acid selectivity of 5-35 % and total acrylic acid and acetic acid selectivity of 19-83 %. Under proper reaction condition, it has the propane converting rate of 40.3 %, acrylic acid selectivity of 33.8 %, acetic acid selectivity of 49.4 %, acrylic acid yield of 13.6 %, total acrylic acid and acetic acid yield of 33.5 % and space-time yield obviously higher than that with available similar catalyst. The preparation process of the catalyst is also disclosed.

Owner:NANJING UNIV

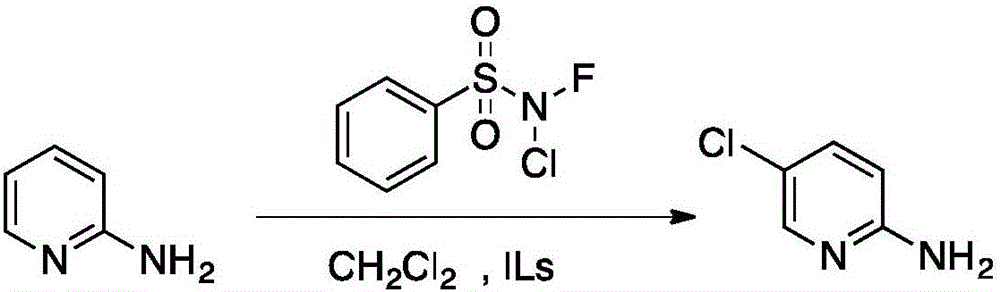

Preparation of 2-amino-5-chloropyridine

ActiveCN106632014AMild reaction conditionsNo pollution in the processOrganic chemistryChemical synthesisChlorobenzene

Owner:JIAXING UNIV

Method for preparing organic carbon fertilizer from agricultural wastes as raw materials

The invention discloses a method for preparing organic carbon fertilizer from agricultural wastes as raw materials. The method comprises, 1, raw material pretreatment: crushing agricultural wastes, adding water into the agricultural wastes and carrying out blending, 2, acid addition and digestion reaction, and 3, centrifugal separation or settling separation and supernatant collection. The agricultural wastes comprise straws. The straws comprise corn stalks, wheat straws, paddy rice straws, sugar cane stalks, cotton stalks or the rest part of crops treated by seed collection. The acid comprises more or more of sulfuric acid, nitric acid, perchloric acid, hypochlorous acid and hydrogen peroxide. The digestion reaction temperature is in a range of 80-180 DEG C and digestion reaction time is in a range of 1-30min. A mass ratio of the agricultural wastes to the acid is 100: (1-9). The method has simple and fast processes and small energy consumption. The obtained organic carbon fertilizer comprises micromolecule organic carbon and can be absorbed easily by crops.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

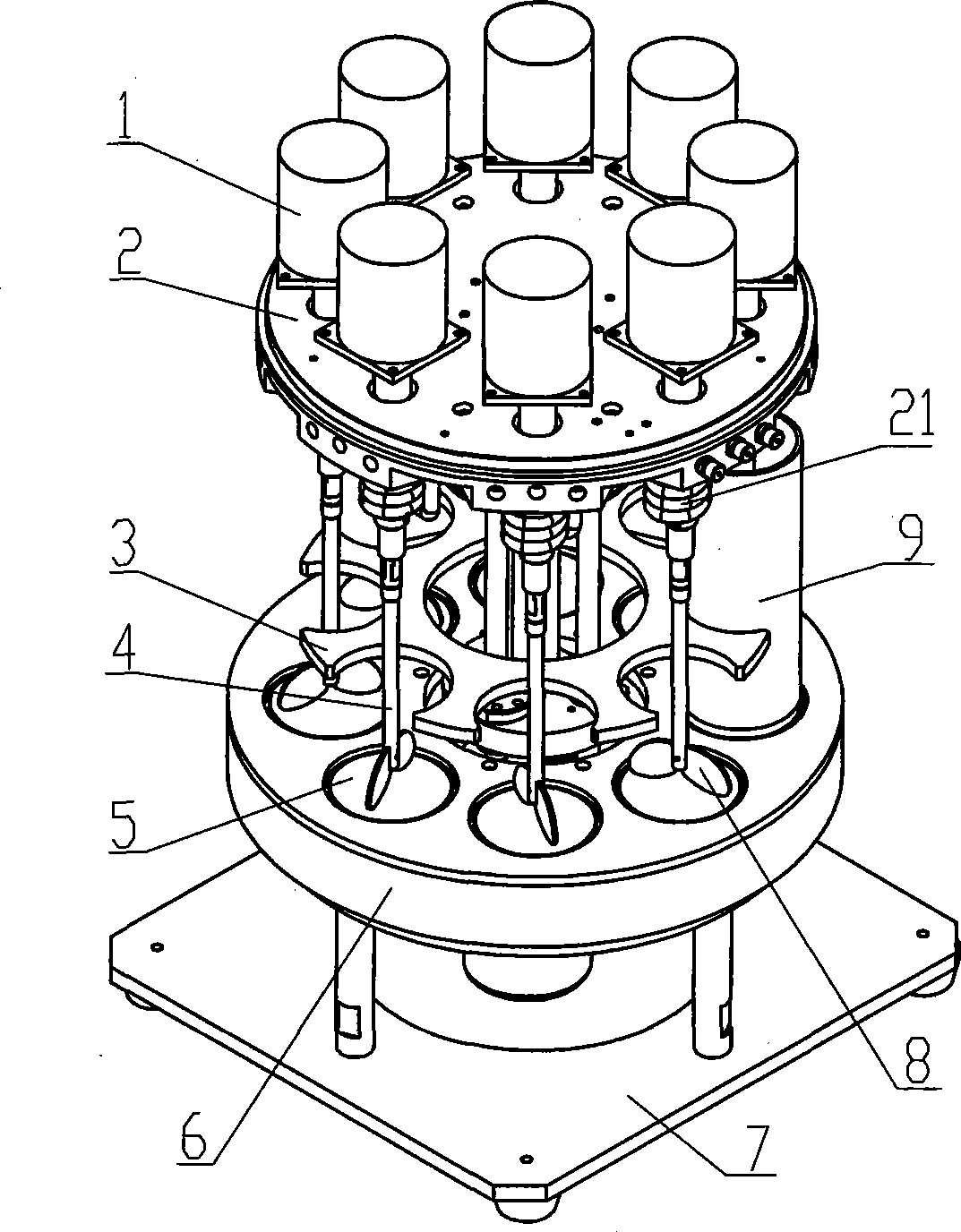

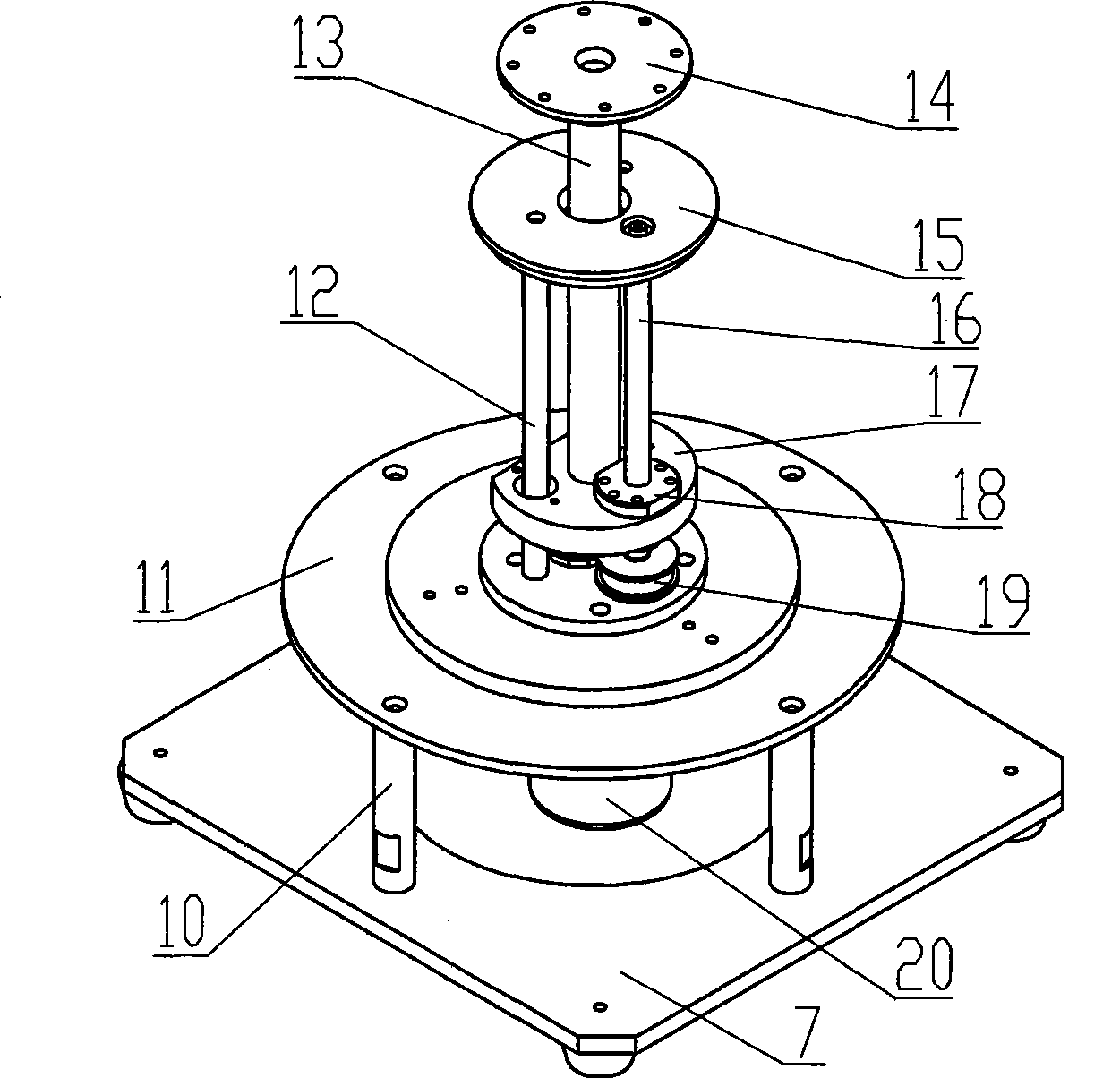

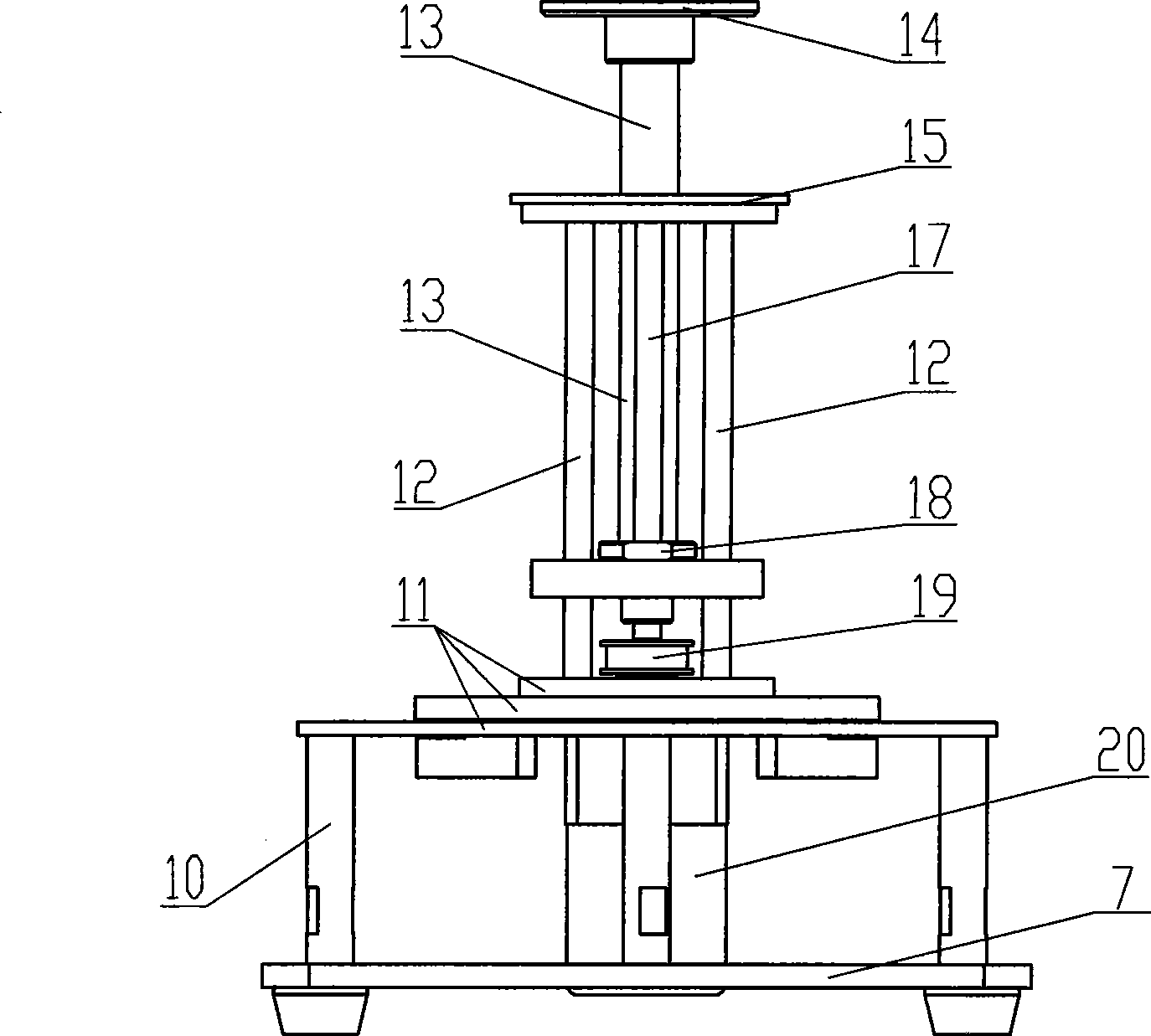

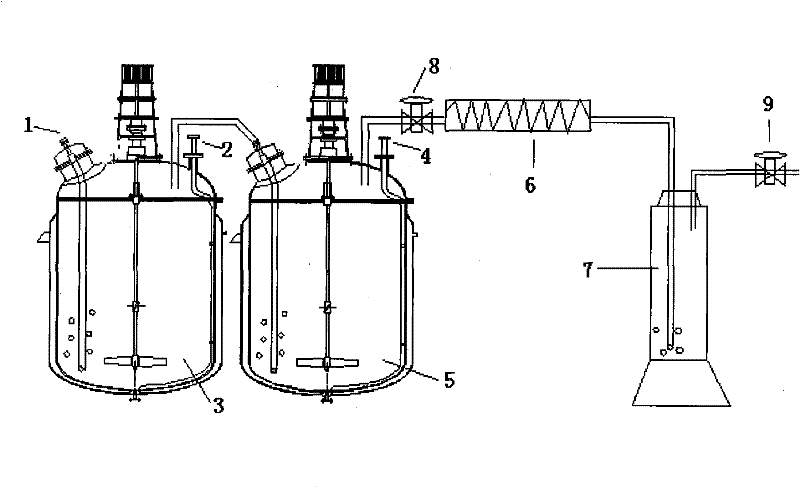

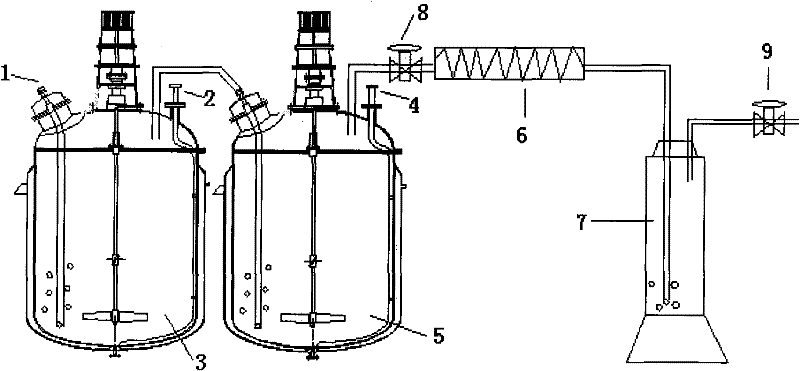

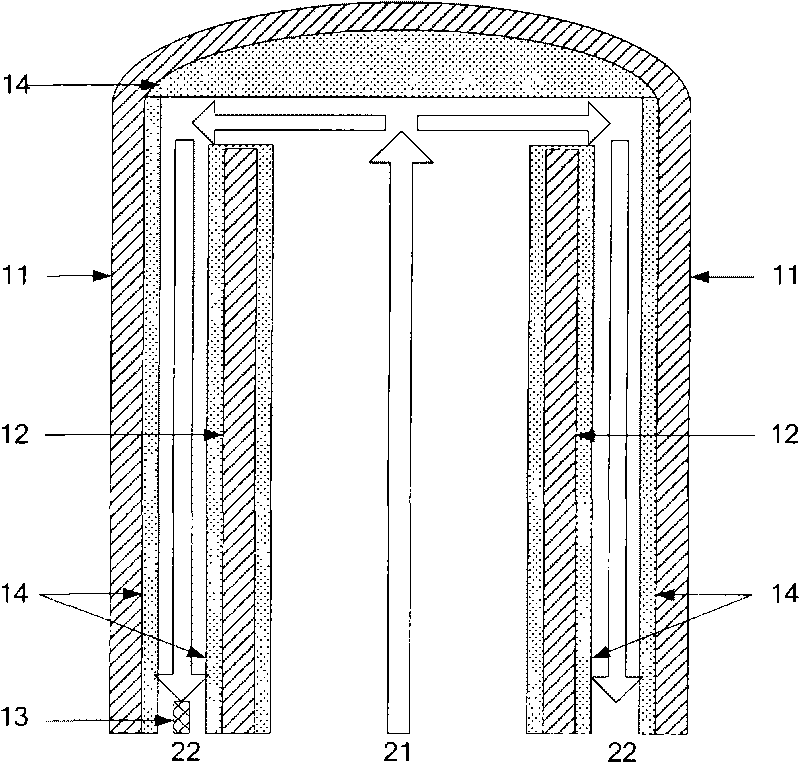

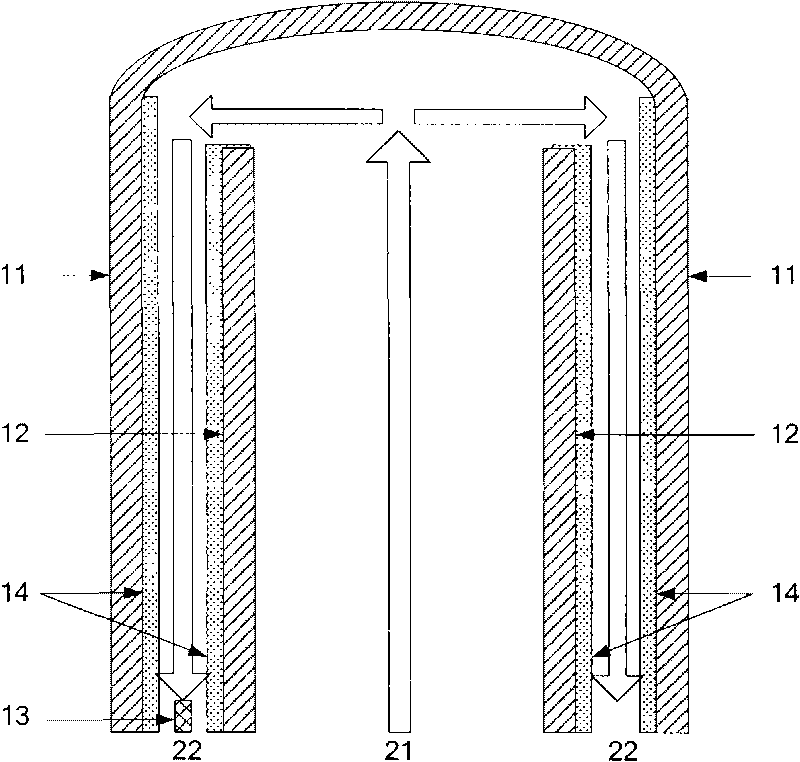

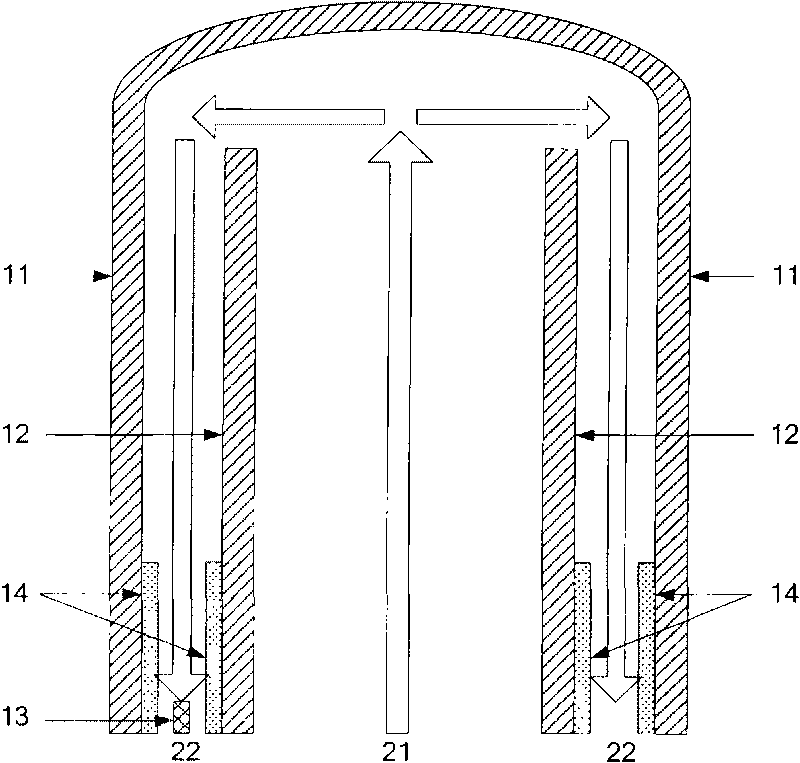

Parallel polymerization synthesis device

InactiveCN101362071AEasy to useSave research timeRotary stirring mixersMixer accessoriesResearch efficiencyReaction temperature

Owner:深圳市新和创智能科技有限公司

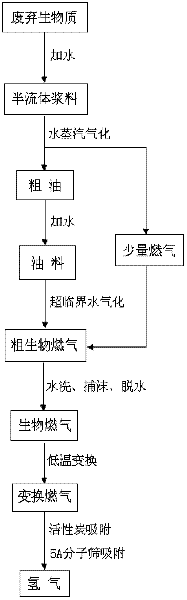

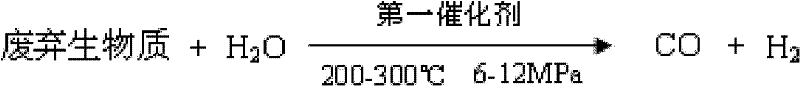

Method for preparing hydrogen by utilizing waste biomass

InactiveCN102653393AReduce pollutionReduce manufacturing costHydrogen separation using solid contactCombustible gas catalytic treatmentRare-earth elementWater vapor

Owner:北京雷恩新材料科技有限公司

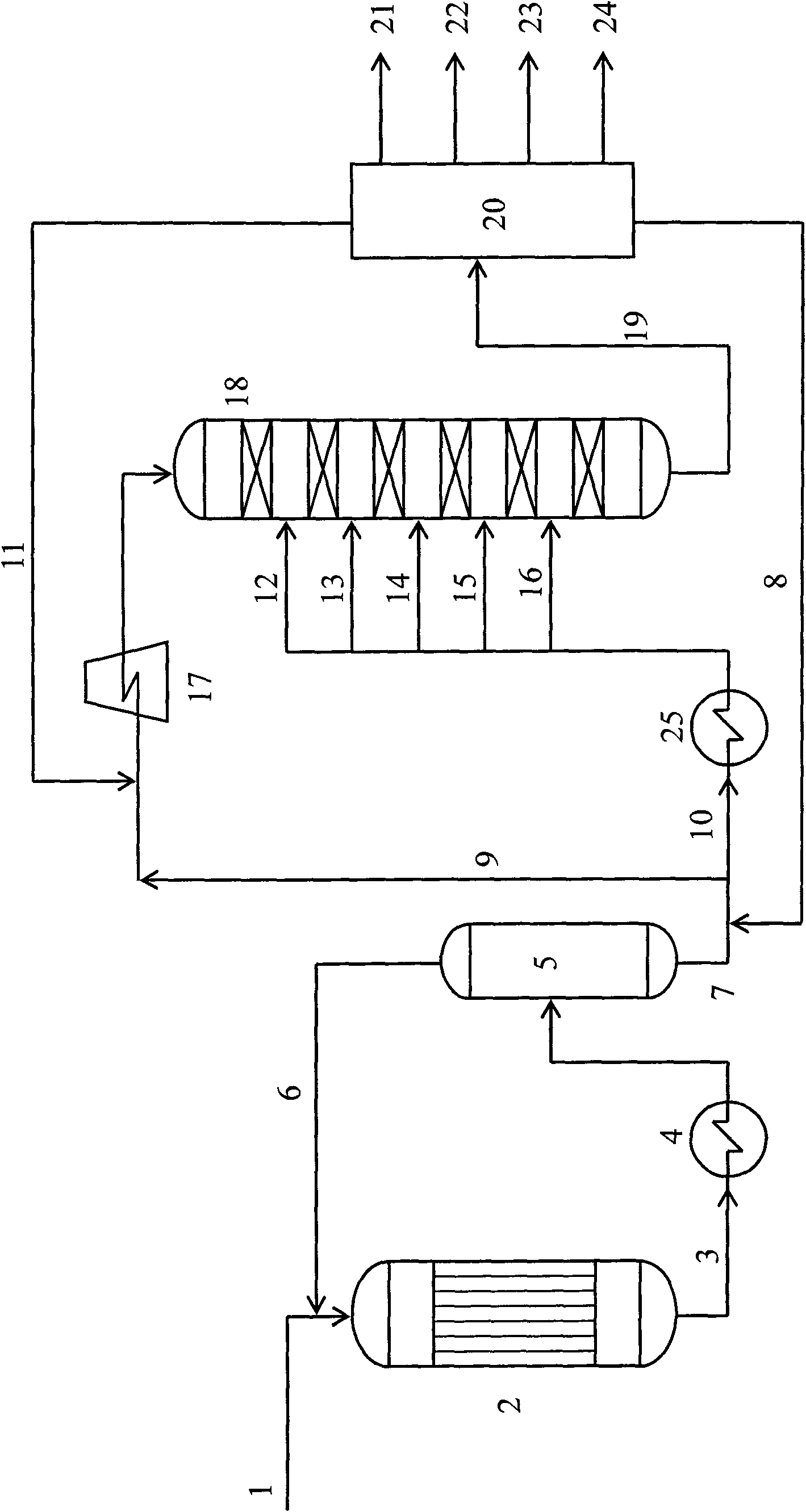

Process for modifying FCC gasoline distillation and co-producing low-carbon olefine and catalyst thereof

InactiveCN1844323AGood transitivityGood reaction selectivityOrganic chemistryNaphtha reformingLiquid productMolecular sieve

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

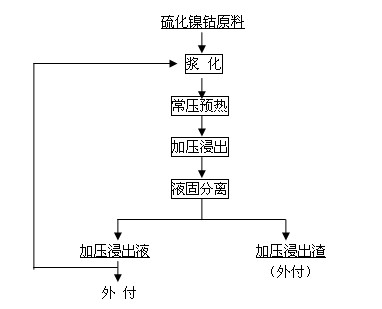

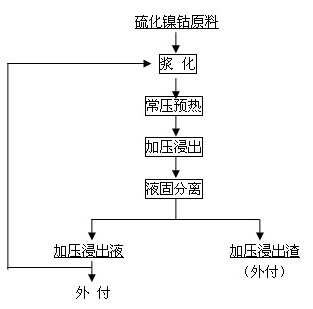

Nickel-containing high-cobalt sulfide leaching technology

ActiveCN102002586ASuitable for handlingSimple processProcess efficiency improvementPregnant leach solutionReaction temperature

Owner:JINCHUAN GROUP LIMITED

Method for catalytic synthesis of dichloropropanol by hydrogen chloride-containing industrial waste gas and glycerol

InactiveCN102234224ATake advantage ofAchieving the goals required by green chemistryPreparation by halogen introductionReaction temperatureGlycerol

Owner:JIANGSU LEE & MAN CHEM

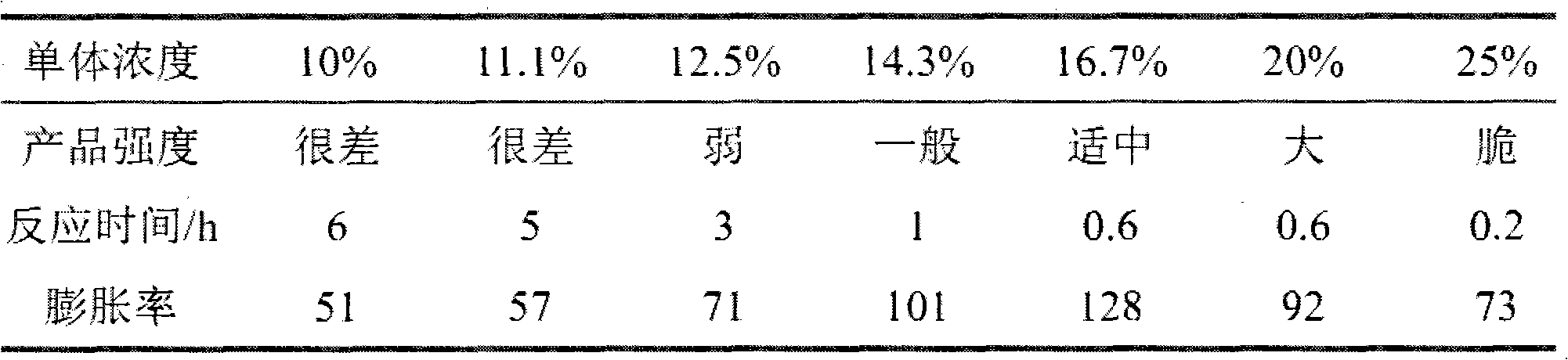

Preparation process of leak protection plugging agent along with drilling based on control of monomer concentration

InactiveCN102993357AImprove performanceIncrease productivityDrilling compositionWater bathsReaction temperature

Owner:倪蕊

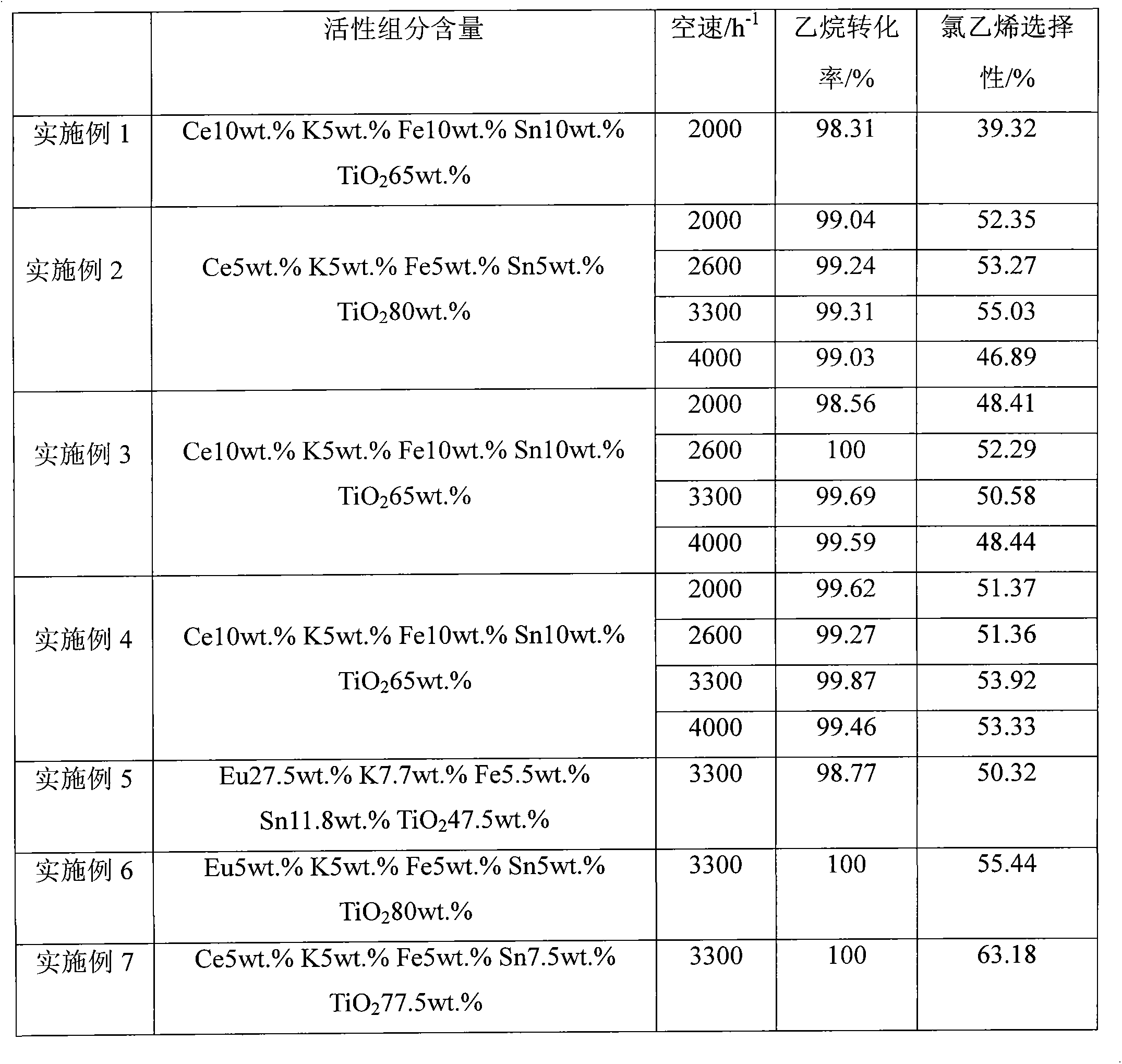

Preparation method for catalyst for preparing chloroethylene via ethane oxychlorination

InactiveCN103055877ASimple processLow reaction temperatureHalogenated hydrocarbon preparationMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementReaction temperature

Owner:INNER MONGOLIA UNIVERSITY

Dialkene-containing gasoline fraction hydrotreating method

InactiveCN102559261AEasy to removeSolve cokingTreatment with hydrotreatment processesFluid phaseReaction temperature

The invention provides a dialkene-containing gasoline fraction hydrotreating method. The method comprises the following steps: (1) directly mixing a dialkene-containing gasoline fraction raw material with a hot hydrogen-donor solvent, and feeding the mixture into a hydropretreating reactor for dialkene-removing reaction when the temperature of the mixture reaches the dialkene-removing reaction temperature; (2) mixing reaction effluent of the hydropretreating reactor with hydrogen gas, feeding the mixture into a heating furnace, heating the mixed material until the temperature of the mixed material reaches the temperature required by the inlet of the hydrotreating reactor, feeding the mixed material into a separator, separating the mixed material into a gas phase and a liquid phase, wherein the liquid phase is mainly the hydrogen-donor solvent and is circulated to the step (1) for use, and the separated gas phase is fed into the hydrotreating reactor so as to be subjected to hydrogenation impurity-removal reaction; and (3) feeding the reaction effluent of the hydrotreating reactor into a separation system, separating out the hydrotreated gasoline fraction and a gas phase, wherein the gas phase is mainly the hydrogen gas and is recycled. Compared with the prior art, the method provided by the invention can be used for effectively solving the coking problem of a dialkene-containing gasoline fraction hydrotreater.

Owner:何裕松

Method for preparing coarse granularity chromium carbide powder

ActiveCN108046259AMeet wear resistanceCorrosiveCarbon compoundsChemical industryAdhesiveWear resistant

Owner:锦州市金属材料研究所

Catalyst-based chlorinated neopentane preparation technology

InactiveCN103265399ASolve the problem of inability to produce high content of chloropentaneSimple processPreparation by halogen halide additionPhosphorous acidReaction temperature

Owner:ZHANGJIAGANG CITY ZHENFANG CHEM

Esterification reaction tower for producing biodiesel

InactiveCN103224838ABlocking dischargeExtended reaction timeFatty acid esterificationBiofuelsBiodieselHeat conducting

The invention discloses an esterification reaction tower for producing biodiesel. The invention is characterized by mainly comprising a tower body, a redistributor, deflector plates, an access hole, a distributor, a gas-phase methanol inlet, a discharge port, a water outlet, a heat-conducting oil inlet, a heat-conducting oil outlet, a heat-conducting oil jacket, a feed port, a water inlet, a safety valve, a thermometer, a pressure meter and a gas-phase methanol outlet, wherein the outer bottom of the tower body is respectively provided with the gas-phase methanol inlet and water outlet; the distributor on the inner bottom is communicated with a pipeline of the gas-phase methanol inlet; the lower part is provided with the heat-conducting oil jacket, heat-conducting oil inlet, heat-conducting oil outlet and access hole; the inner top is provided with the redistributor; the inner cylindrical wall is uniformly distributed with the plurality of deflector plates; and the outer top is provided with the feed port, water inlet and gas-phase methanol outlet. The invention has the characteristics of no need of catalyst, no environmental pollution, low reaction pressure, low reaction temperature, low energy consumption, low investment and operating cost, wide application range of raw materials, high yield and the like.

Owner:YANGGU KAIGE NEW ENERGY BIOTECHNOLOGY CO LTD

Preparation method of top-grade pure nickelous chloride

InactiveCN104108756AMeet the needs of high-end technologyThe process steps are simpleNickel halidesFiltrationReaction temperature

Owner:TIANJIN CHEM REAGENT RES INST

Method for controlling terminal by using chlorine trifluoride to etch polysilicon growth furnace

InactiveCN101724912ATimely detection of reaction endpointsAvoid wastingAfter-treatment apparatusReaction temperaturePolycrystalline silicon

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

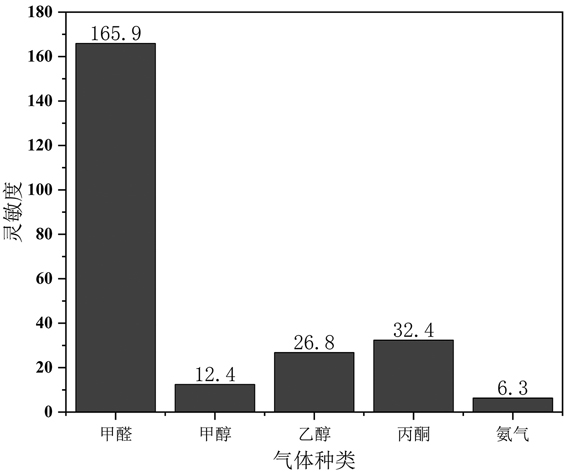

Preparation of Ni-doped stannic oxide formaldehyde sensitive composite material based on ZIF-8 metal organic framework template, product and application

ActiveCN112479246ASimple processLow costMaterial nanotechnologyMaterial resistanceThioureaMetal-organic framework

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

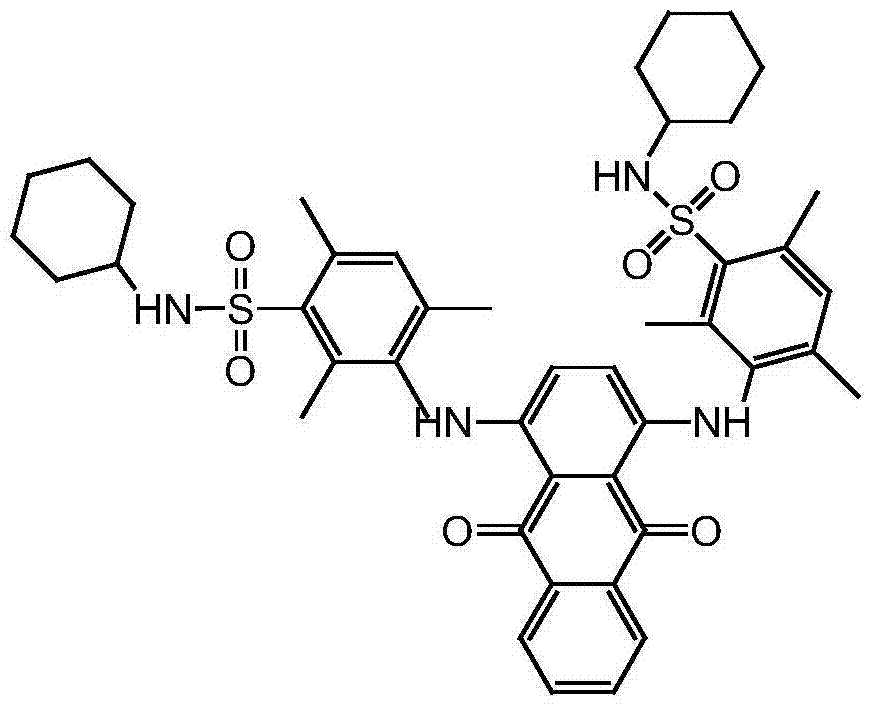

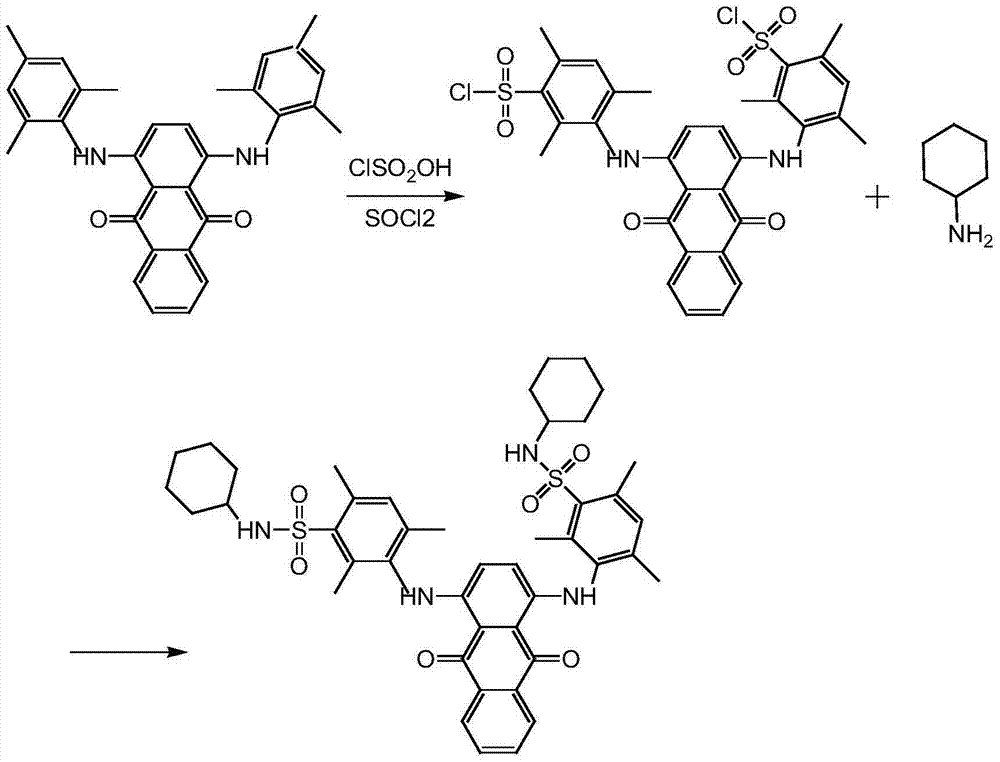

Preparation method of dye

ActiveCN104725891ALittle effect on responseBig impact on qualityAnthracene dyesHydrogenReaction temperature

Owner:JIANGSU DAOBO CHEM

Preparation of 2,4-binitro bromobenzene

InactiveCN101412676BReduce pollutionEasy to separate and purifyNitro compound preparationReaction temperaturePhotochemistry

Owner:SHANXI UNIV

Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof

ActiveCN113264816AHigh selectivityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationChromatographic separationOrganic synthesis

Owner:HUBEI UNIV OF SCI & TECH

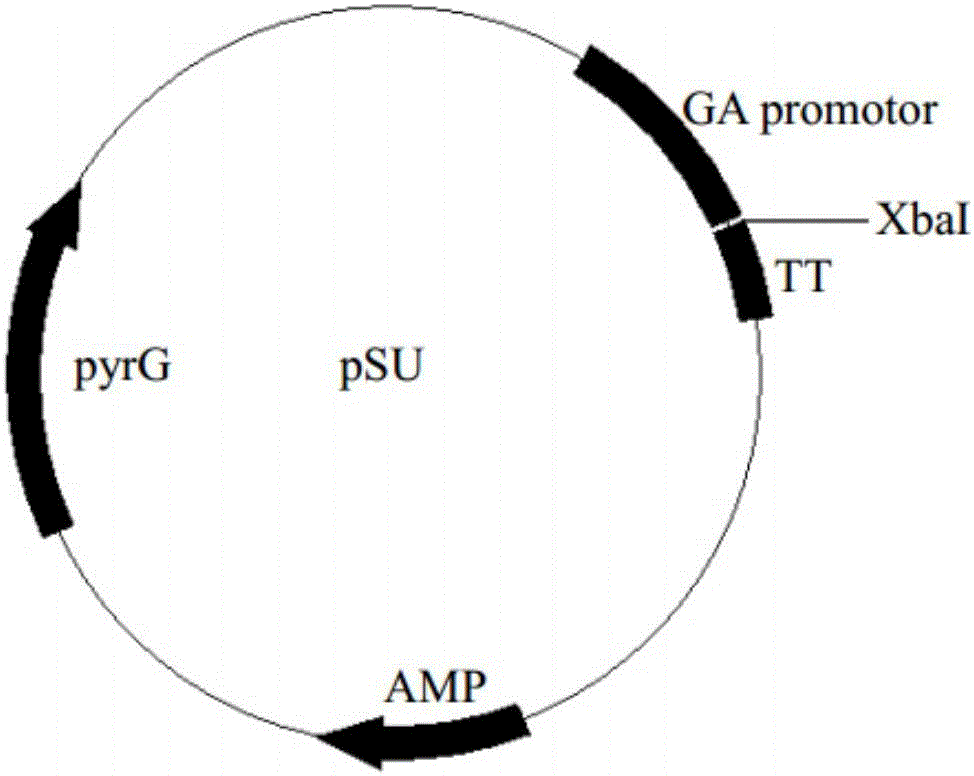

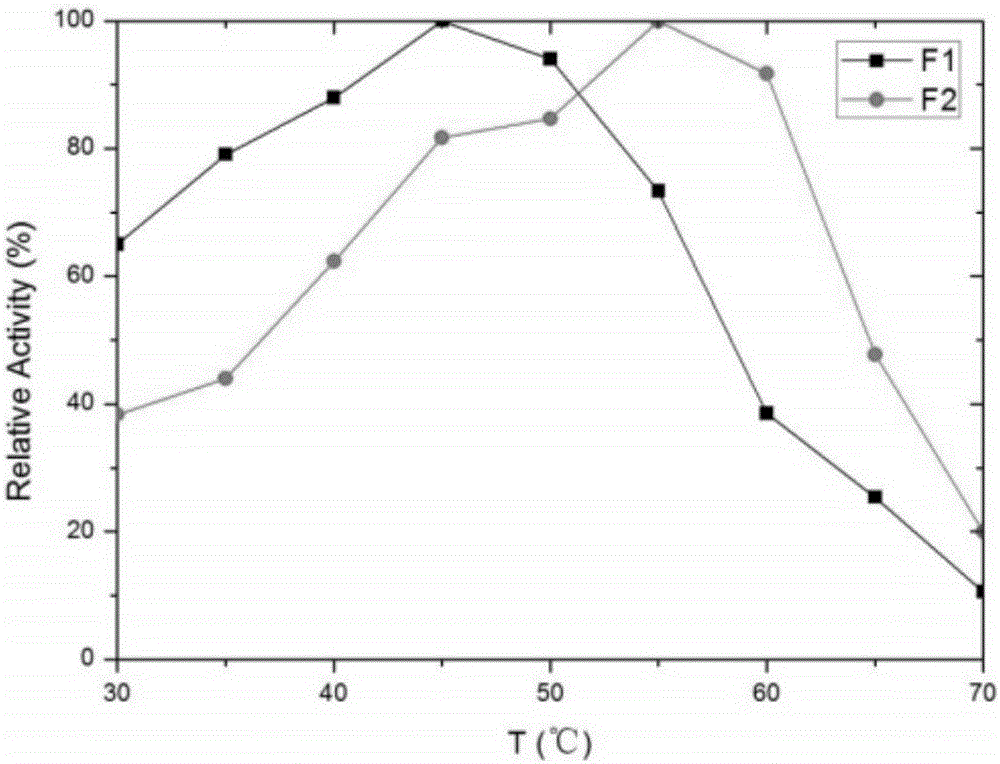

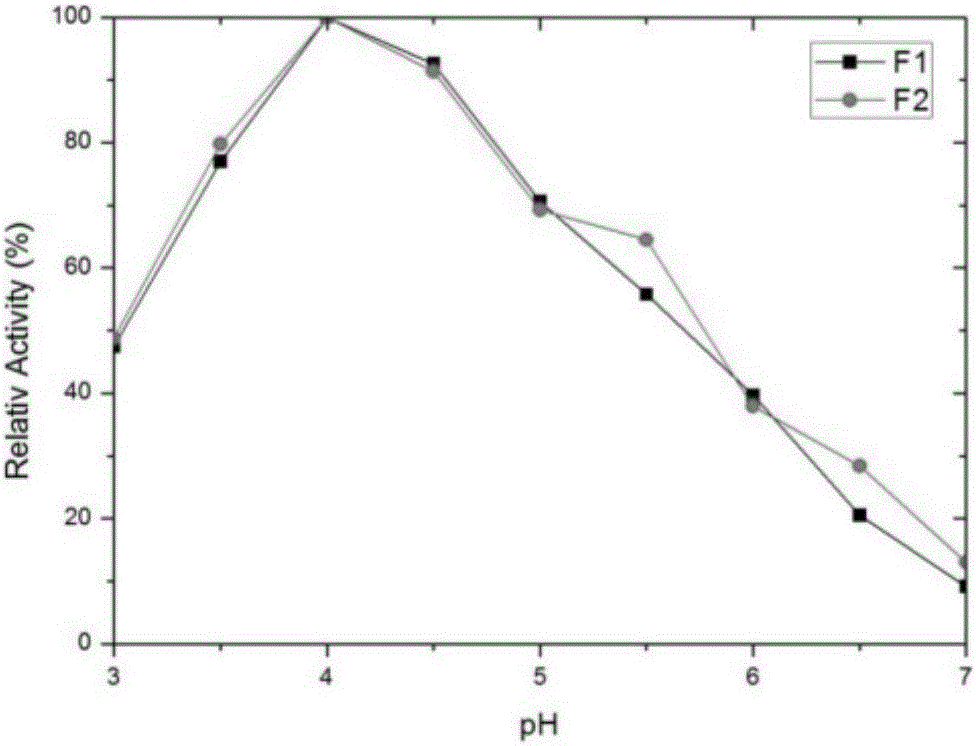

Proline protease mutant and application thereof

ActiveCN106754837AReduce turbidityGood enzymatic effectFermentationGenetic engineeringProteinase activityHeat resistance

Owner:QINGDAO VLAND BIOTECH GRP +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap

![Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof](https://images-eureka.patsnap.com/patent_img_release/5f0377bc-dd3c-49e9-8b4b-0a2a595607ba/HDA0003091577940000011.png)

![Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof](https://images-eureka.patsnap.com/patent_img_release/5f0377bc-dd3c-49e9-8b4b-0a2a595607ba/HDA0003091577940000021.png)

![Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof Spiro [cyclopropane-1, 2'-indene]-1', 3'-diketone derivative and synthesis method thereof](https://images-eureka.patsnap.com/patent_img_release/5f0377bc-dd3c-49e9-8b4b-0a2a595607ba/FDA0003091577920000011.png)