Preparation of Ni-doped stannic oxide formaldehyde sensitive composite material based on ZIF-8 metal organic framework template, product and application

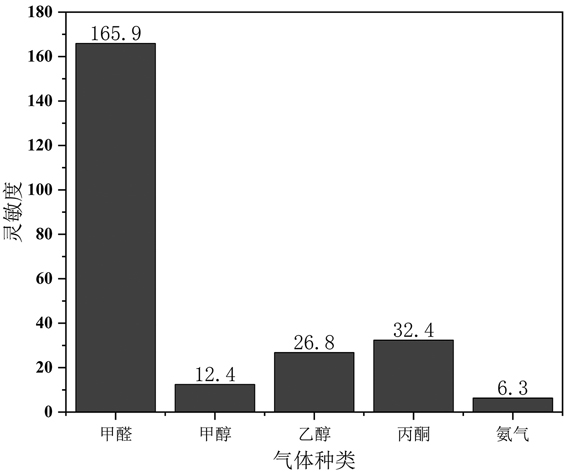

A technology of metal-organic framework and ZIF-8, which is applied in nanotechnology, tin oxide, and analytical materials for materials and surface science, can solve the problems of low sensitivity and poor selectivity of formaldehyde, and achieve high purity, low cost, and The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A Ni-doped tin dioxide formaldehyde-sensitive composite material based on ZIF-8 metal-organic framework template, using ZIF-8 metal-organic framework material as crystallization template, thiourea decomposition under ethylene glycol solvothermal conditions provides S2-, and generates SnS 2 and NiS precursor, by adjusting the calcination temperature and calcination time of the precursor, the Ni-doped SnO based on the ZIF-8 metal organic framework template was prepared 2 The formaldehyde-sensitive ternary composite material is prepared according to the following steps:

[0030] (1) Measure 50mL of N-N dimethylformamide (DMF) and 100mL of methanol with a concentration of 2wt% into the flask, and stir evenly;

[0031] (2) 0.8g zinc nitrate hexahydrate (Zn(NO) 3 ·6H 2 (2) and 0.1g 2-methylimidazole (2-MI) are put into the flask, fully stirred at room temperature;

[0032] (3) Transfer the solution in the flask to a beaker, react completely in an oven at 100°C, take the prec

Embodiment 2

[0038] A Ni-doped tin dioxide formaldehyde-sensitive composite material based on ZIF-8 metal-organic framework template, similar to Example 1, prepared as follows:

[0039] (1) Measure 30mL of N-N dimethylformamide (DMF) and 60mL of methanol with a concentration of 2wt% into the flask, and stir evenly;

[0040] (2) 0.9g zinc nitrate hexahydrate (Zn(NO) 3 ·6H 2 (2) and 0.2g 2-methylimidazole (2-MI) are put into the flask, fully stirred at room temperature;

[0041] (3) Transfer the solution in the flask to a beaker, react completely in an oven at 100°C, take the precipitate, wash and dry it to obtain ZIF-8 powder;

[0042] (4) Put 0.3g dried ZIF-8 powder into 100mL ethylene glycol ((CH 2 Oh) 2 ), while adding 0.15g nickel chloride hexahydrate (NiCl 2 ·6H 2 O), 1.5g stannous chloride dihydrate and 1.3g thiourea (NH 2 CSNH 2 ), stir evenly;

[0043] (5) Transfer the uniformly stirred solution to a polytetrafluoroethylene reactor, react in an oven at 160°C for 24 hours, take

Embodiment 3

[0047] A Ni-doped tin dioxide formaldehyde-sensitive composite material based on ZIF-8 metal-organic framework template, similar to Example 1, prepared as follows:

[0048] (1) Measure 40mL of N-N dimethylformamide (DMF) and 80mL of methanol with a concentration of 2wt% into the flask, and stir evenly;

[0049] (2) 1.0g zinc nitrate hexahydrate (Zn(NO) 3 ·6H 2 (2) and 0.3g 2-methylimidazole (2-MI) are put into the flask, fully stirred at room temperature;

[0050] (3) Transfer the solution in the flask to a beaker, react completely in an oven at 100°C, take the precipitate, wash and dry it to obtain ZIF-8 powder;

[0051] (4) Put 0.3g dried ZIF-8 powder into 100mL ethylene glycol ((CH 2 Oh) 2 ), while adding 0.2g nickel chloride hexahydrate (NiCl 2 ·6H 2 O), 2.0g stannous chloride dihydrate and 1.5g thiourea (NH 2 CSNH 2 ), stir evenly;

[0052] (5) Transfer the uniformly stirred solution to a polytetrafluoroethylene reactor, react in an oven at 180°C for 24 hours, take

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap