Method for controlling terminal by using chlorine trifluoride to etch polysilicon growth furnace

A chlorine trifluoride, endpoint control technology, applied in chemical instruments and methods, crystal growth, post-processing devices, etc., can solve problems such as chlorine trifluoride waste, and achieve the effect of preventing chlorine trifluoride waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

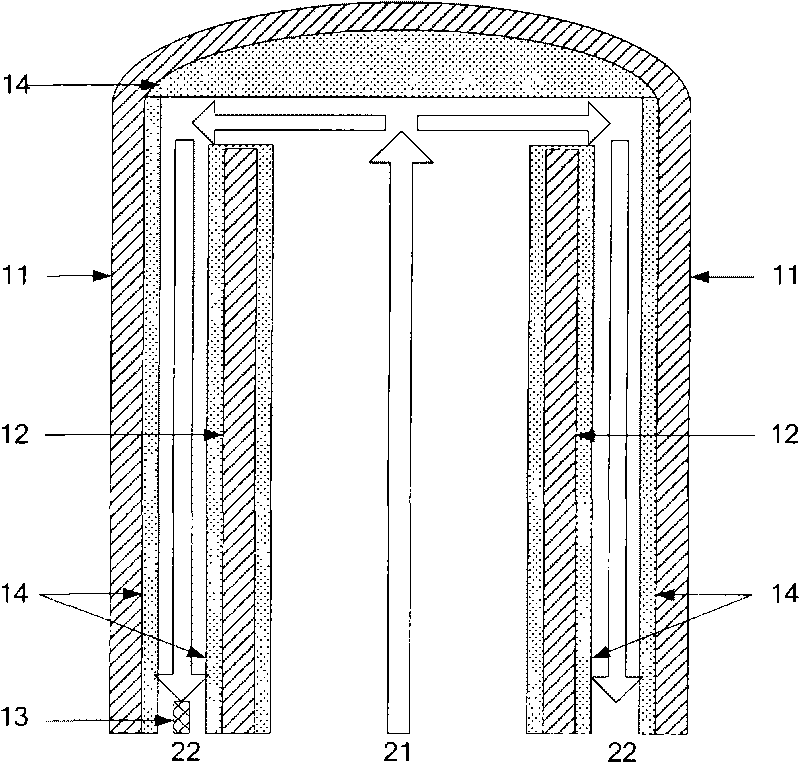

[0013] see Figure 1a , which is a cross-sectional schematic diagram of a polysilicon growth furnace. It includes a quartz outer tube 11 and a quartz inner tube 12 , and at least one temperature detection device 13 is provided between the quartz outer tube 11 and the inner tube 12 near the reaction gas outlet 22 . After the polysilicon growth furnace is used many times, polysilicon 14 grows on the tube walls of the quartz outer tube 11 and the inner tube 12 . After starting to feed chlorine trifluoride gas into the polysilicon growth furnace, chlorine trifluoride enters the polysilicon growth furnace from the bottom 21 between the quartz inner tubes 12, and the gas after the reaction passes between the quartz outer tube 11 and the inner tube 12. The bottom 22 leaves the polysilicon growth furnace.

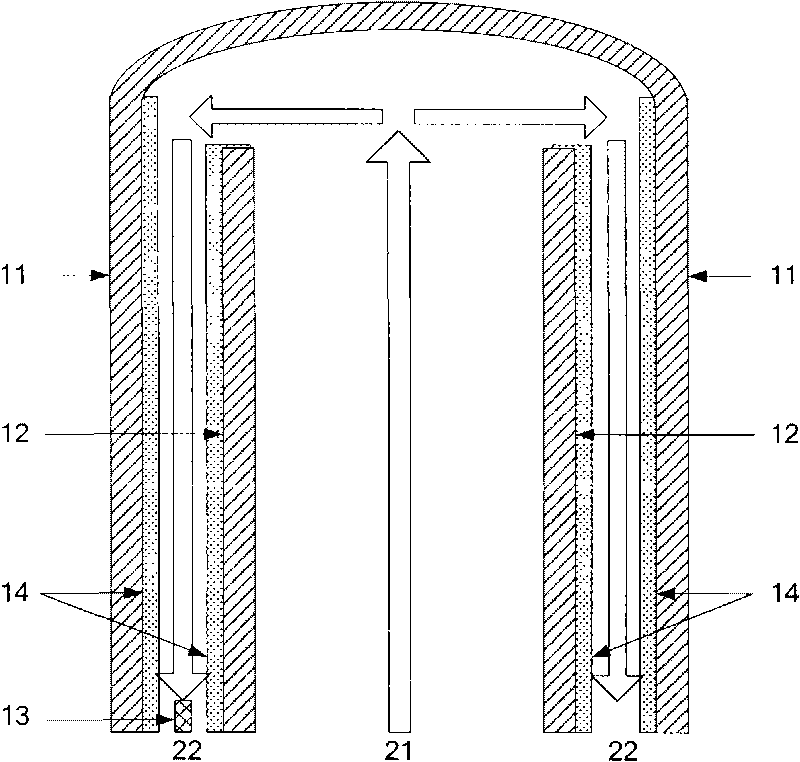

[0014] see Figure 1b After passing chlorine trifluoride gas into the polysilicon growth furnace for a period of time, the polysilicon on the inner wall of the quartz inner tube 12

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap