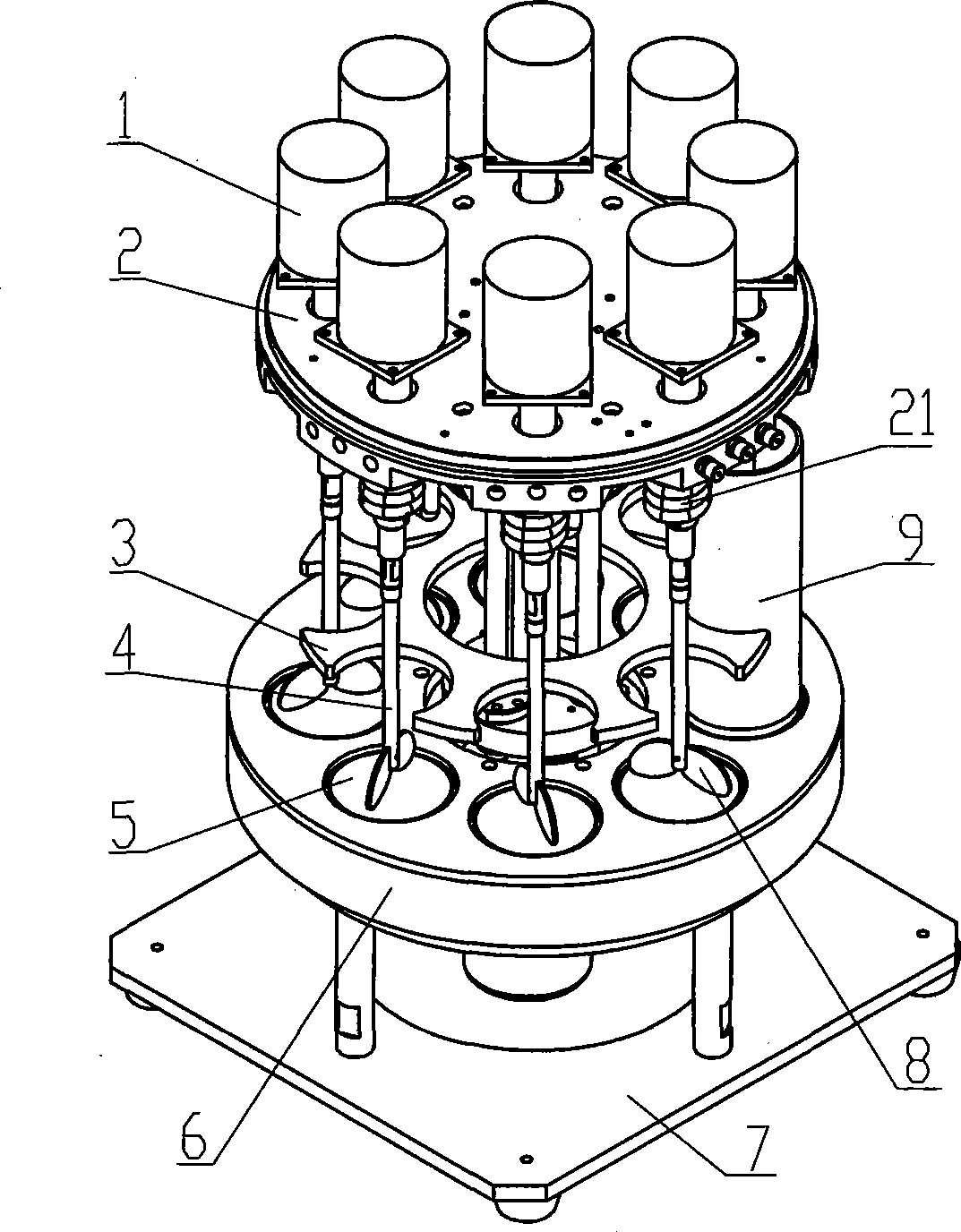

Parallel polymerization synthesis device

A synthesizer and heating kettle technology, which is applied in the field of parallel polymerization synthesis reaction devices, can solve the problems of single type of reaction vessel and cumbersome installation, so as to improve the efficiency of scientific research, speed up the process of scientific research, and reduce the labor intensity of scientific research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

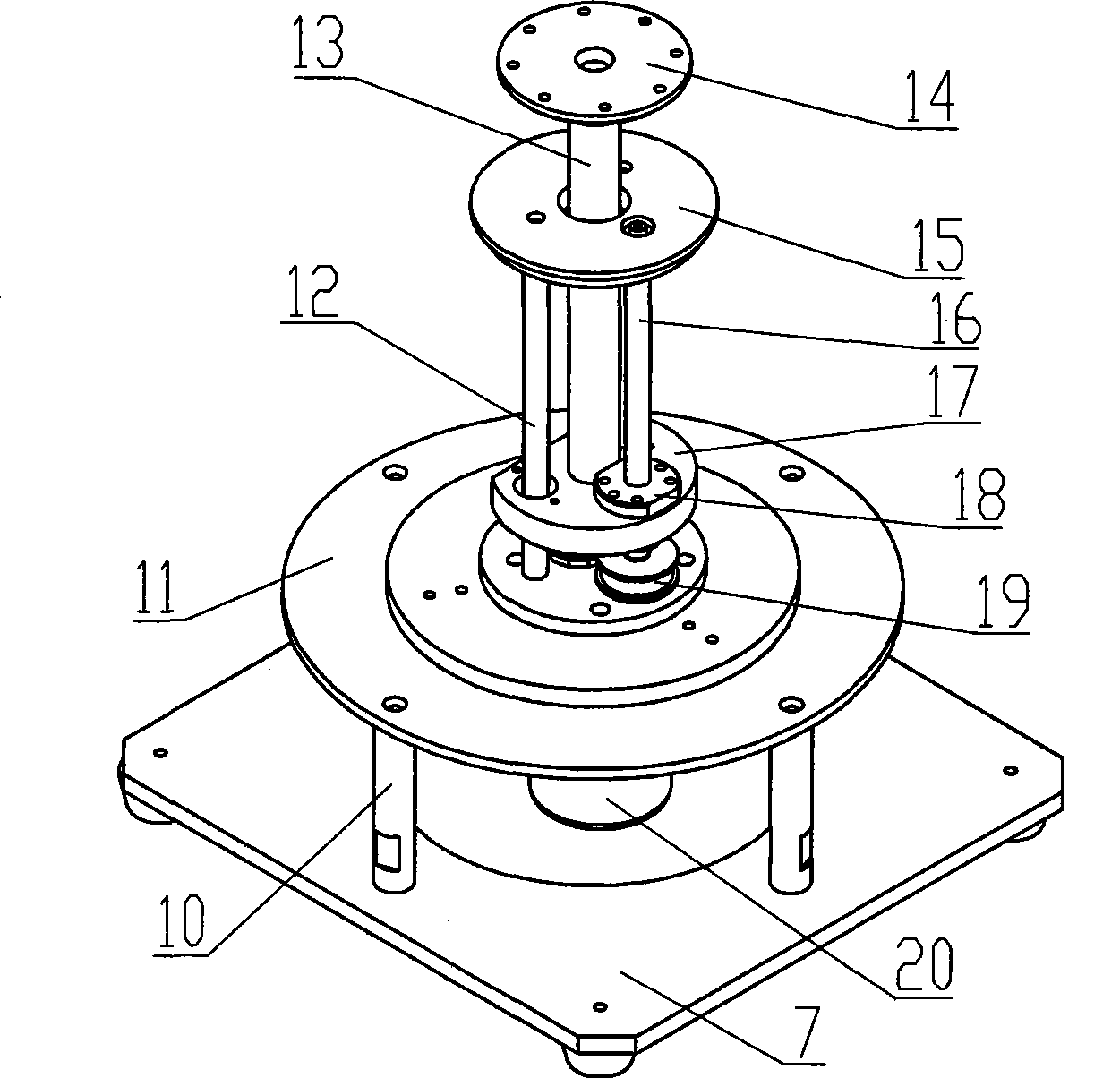

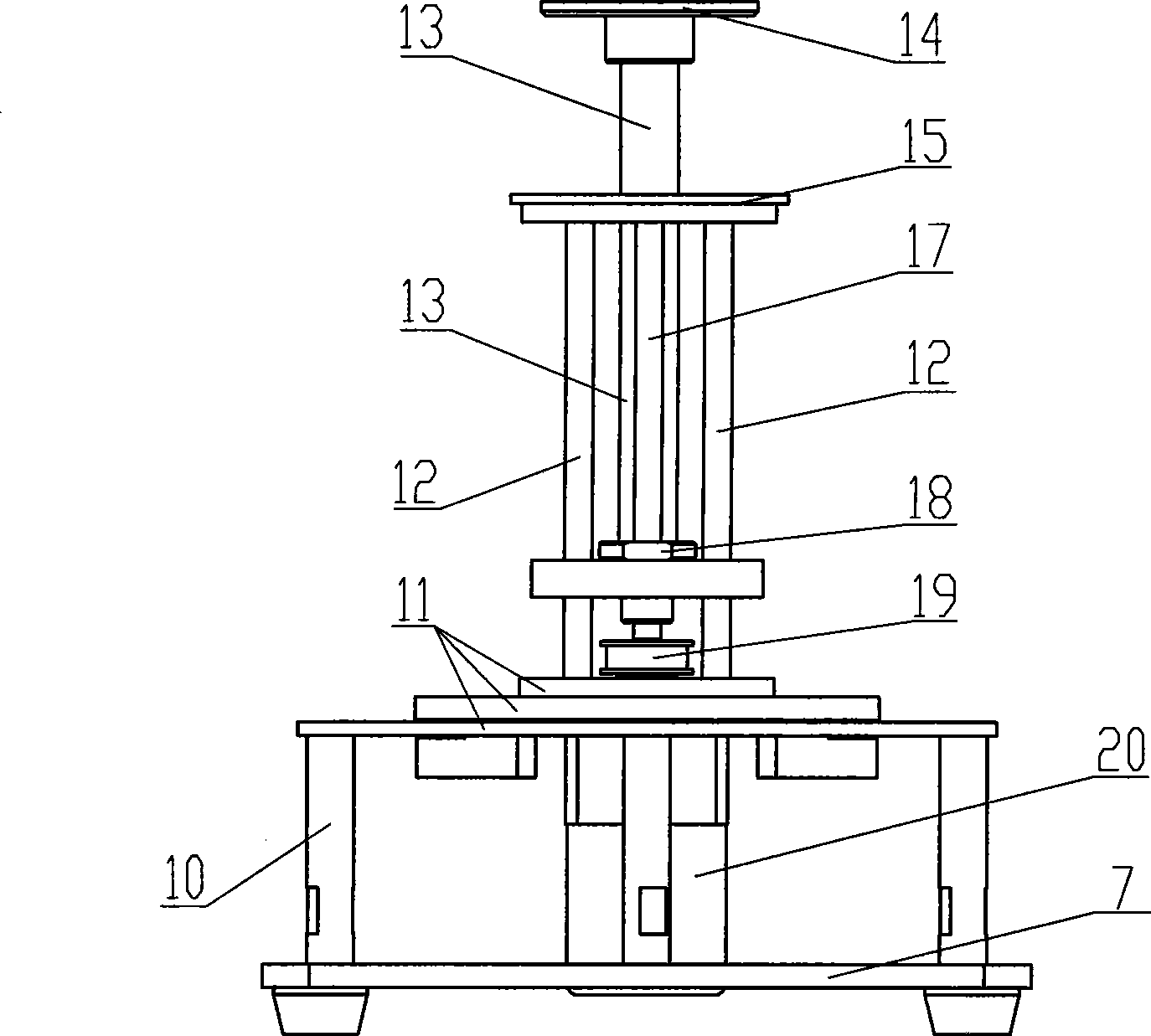

[0027] Such as Figure 1 to Figure 4 The preferred embodiment one of the shown parallel polymerization synthesizer includes a base 7, a plurality of pillars 10 vertically fixed on the base 7, the pillars 10 are connected to the transition seat plate 11, and the transition seat plate 11 The lower part of the center is provided with a lifting platform drive motor 20; the upper ends of two guide rods 12 penetrating a lifting nut mounting block 17 are connected to the upper bearing plate 15, and the lower ends are connected to the transition seat plate 11; the lifting nut mounting block 17 is fixed There is a center guide post 13, which is connected with the lifting tray 14 after passing through the upper bearing plate 15; a ball screw 16 is arranged between the upper bearing plate 15 and the transition seat plate 11, and the ball The screw mandrel 16 cooperates with a ball nut 18 fixed on the lifting nut mounting block 17; the lower end of the ball screw mandrel 16 is provided with

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap