Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Gasket" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. Gaskets allow for "less-than-perfect" mating surfaces on machine parts where they can fill irregularities. Gaskets are commonly produced by cutting from sheet materials.

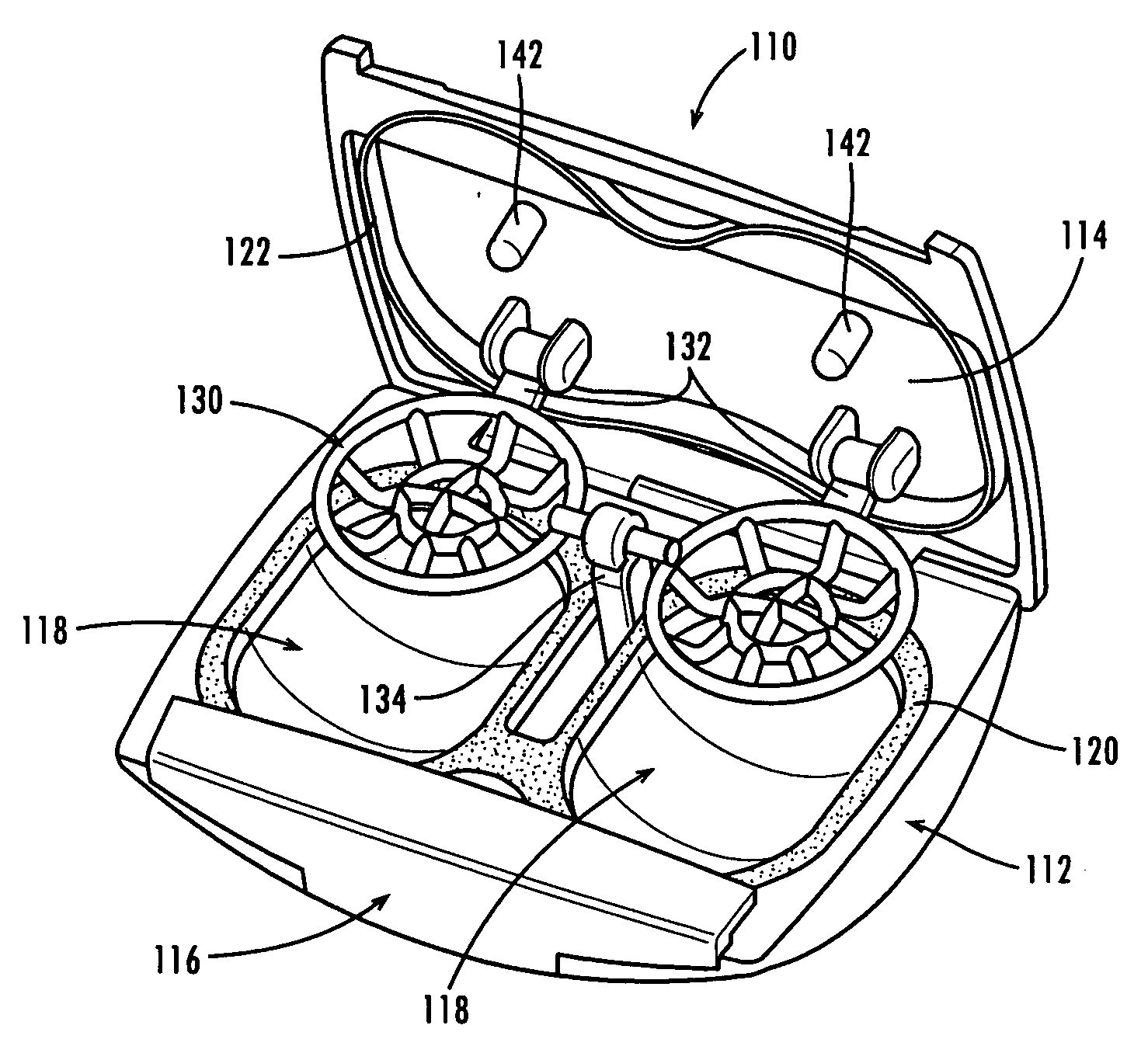

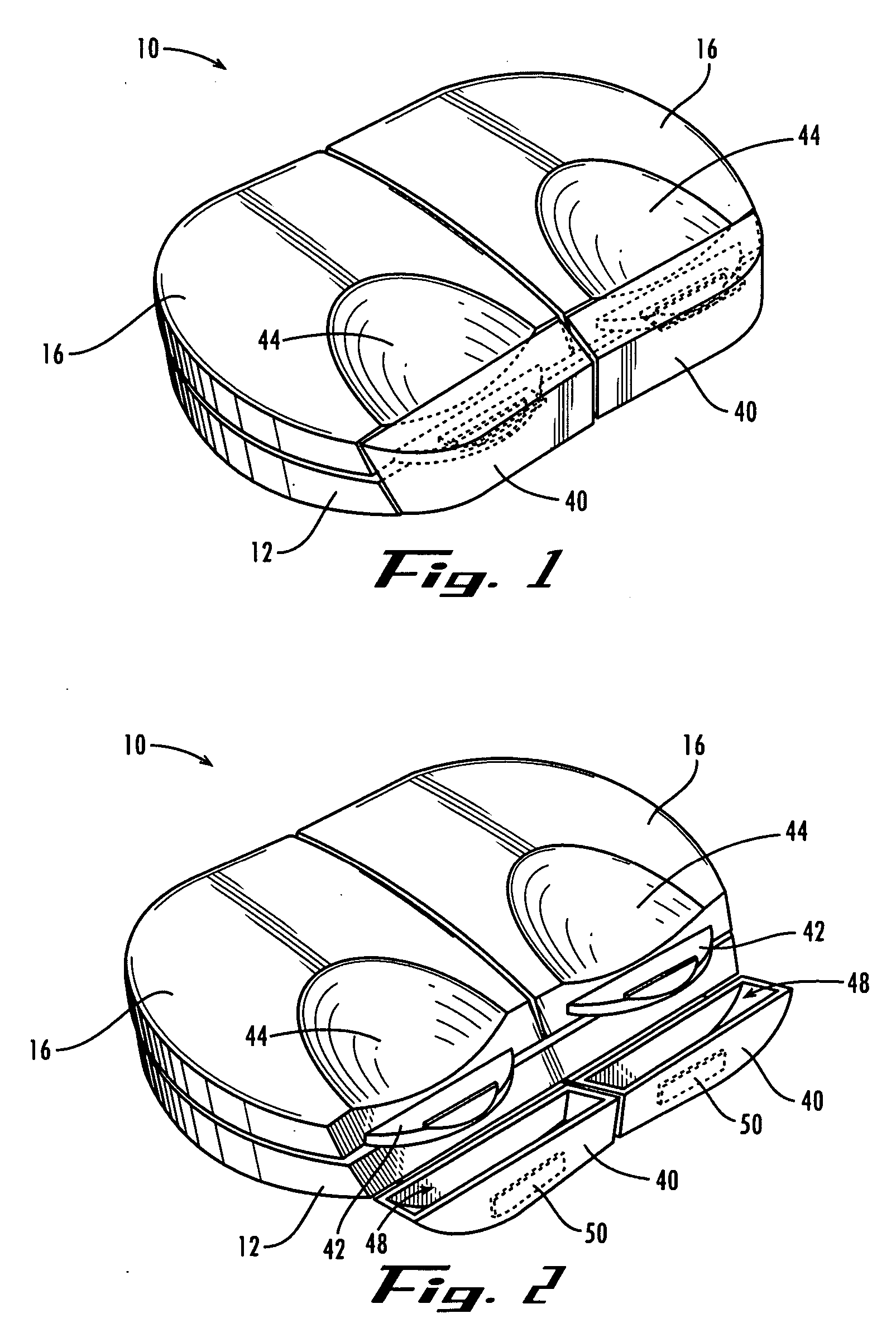

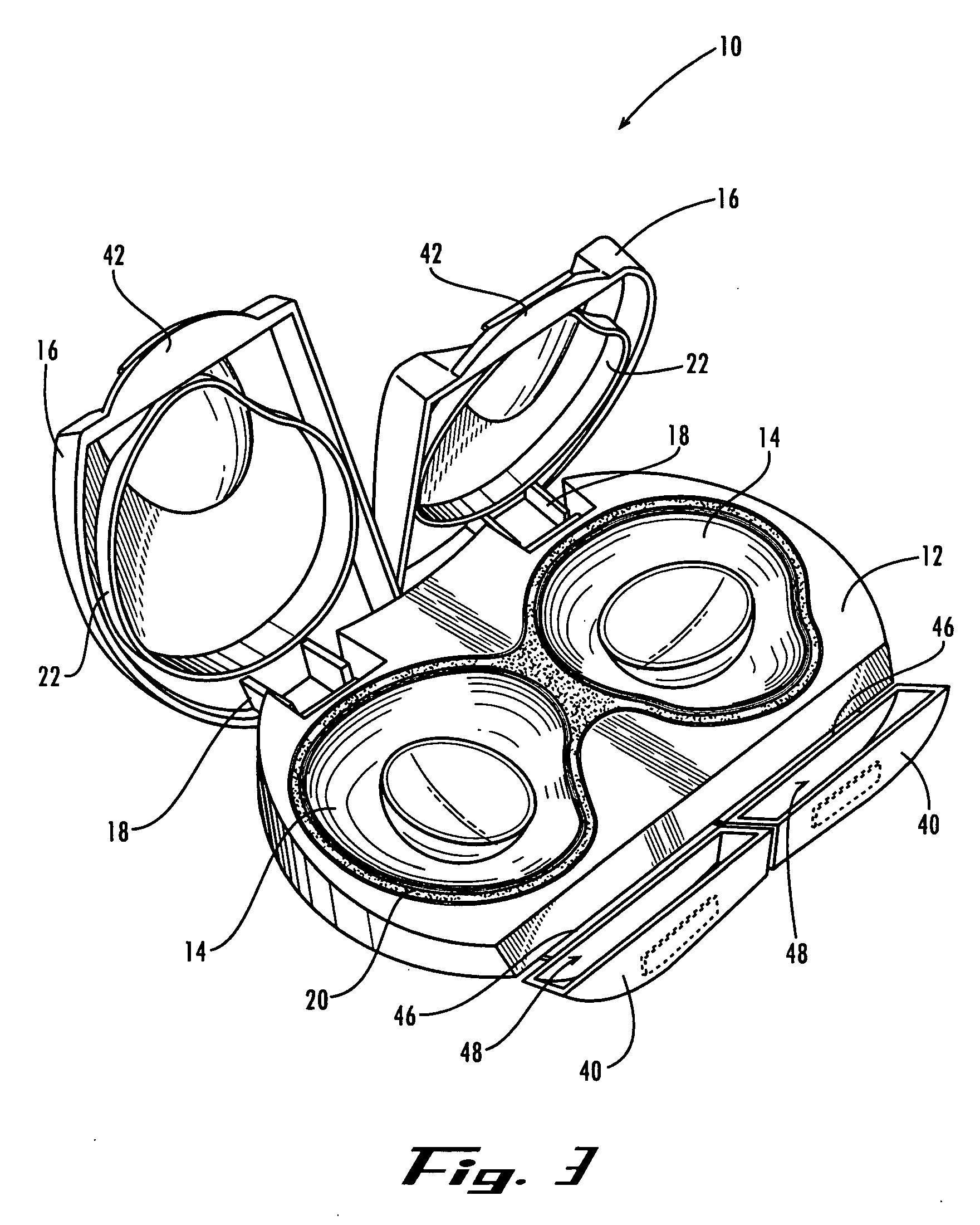

Contact lens case

ActiveUS20050087453A1Easy to handleImprove convenienceBottlesOther accessoriesContact Lens CaseGasket

Owner:ALCON INC

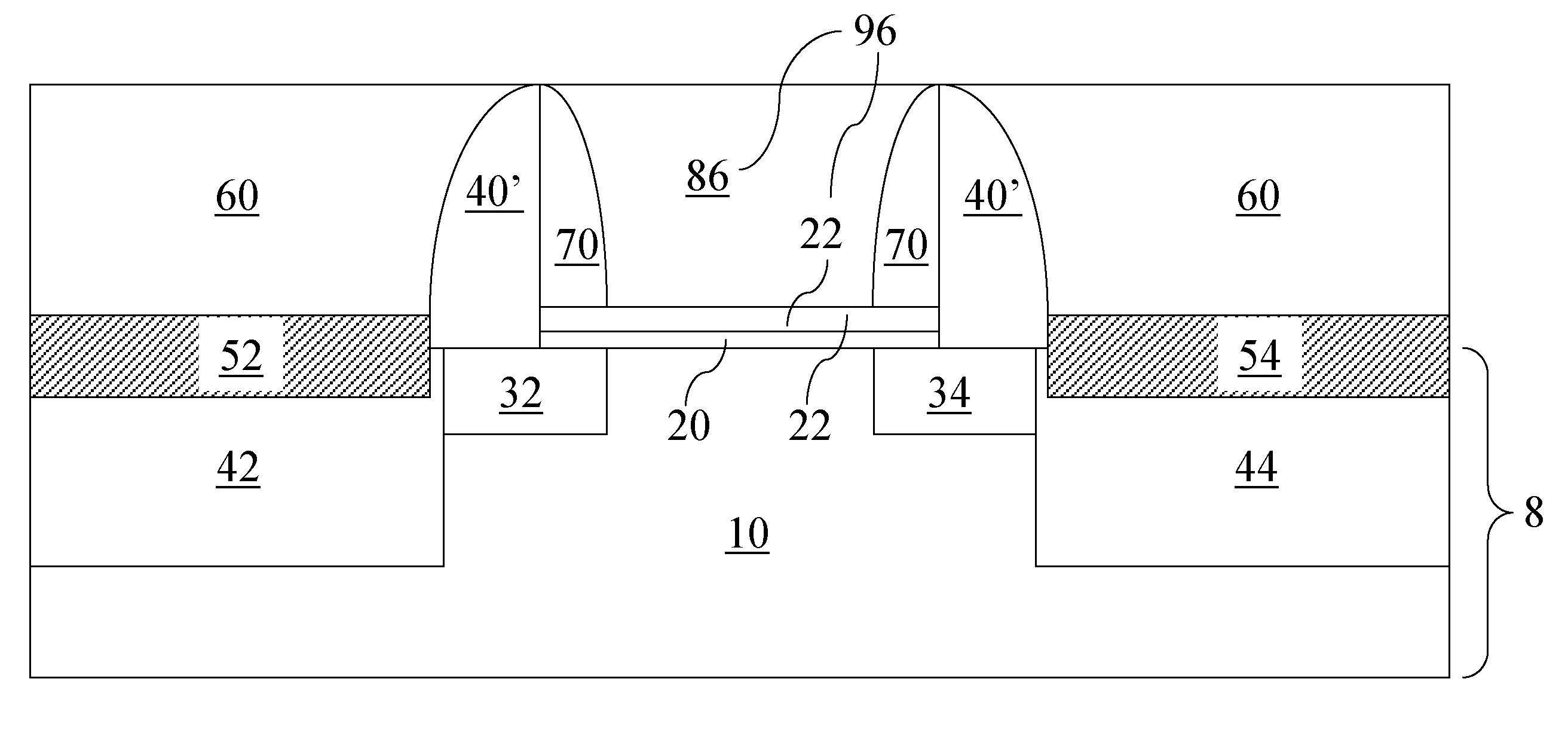

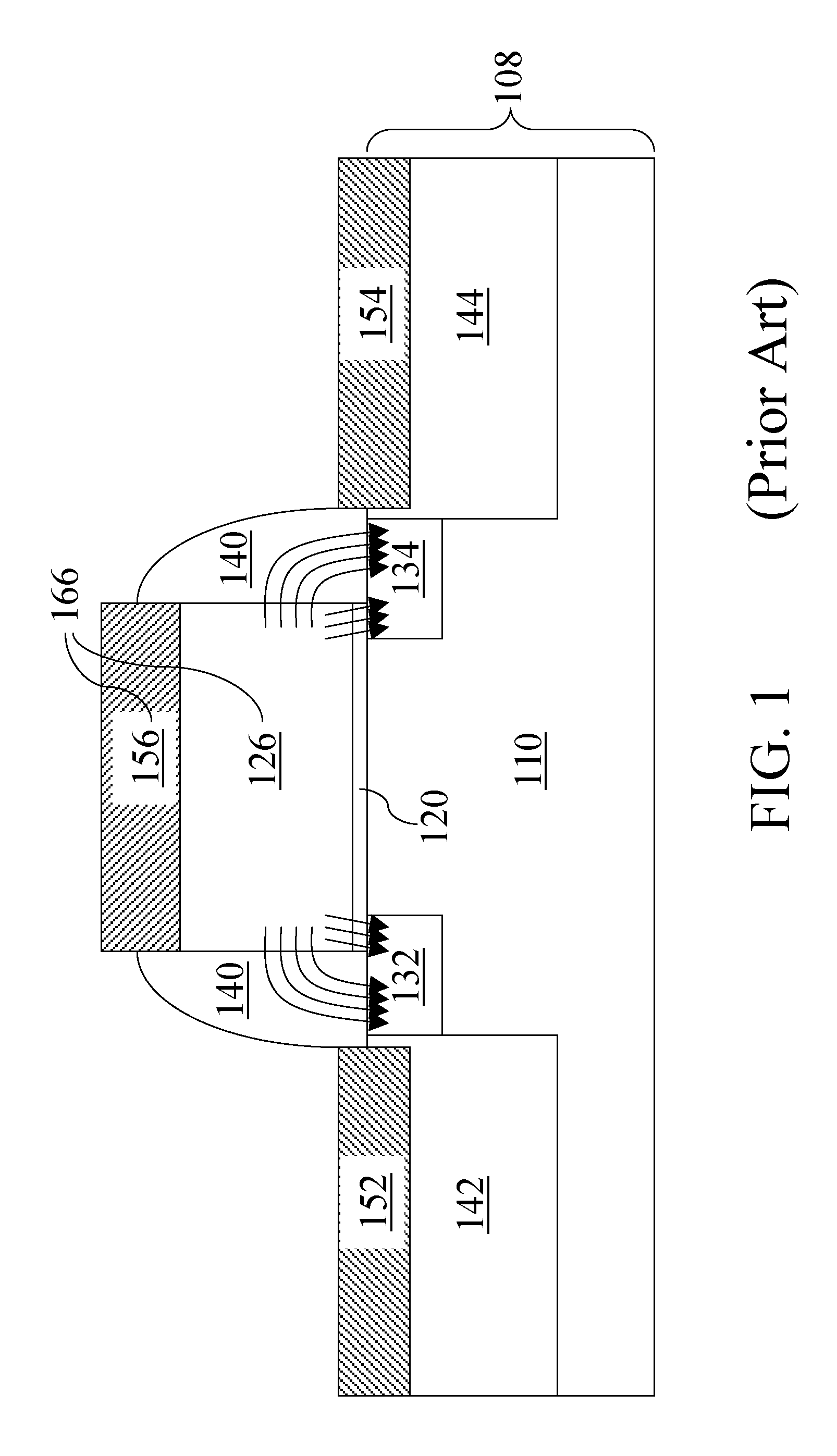

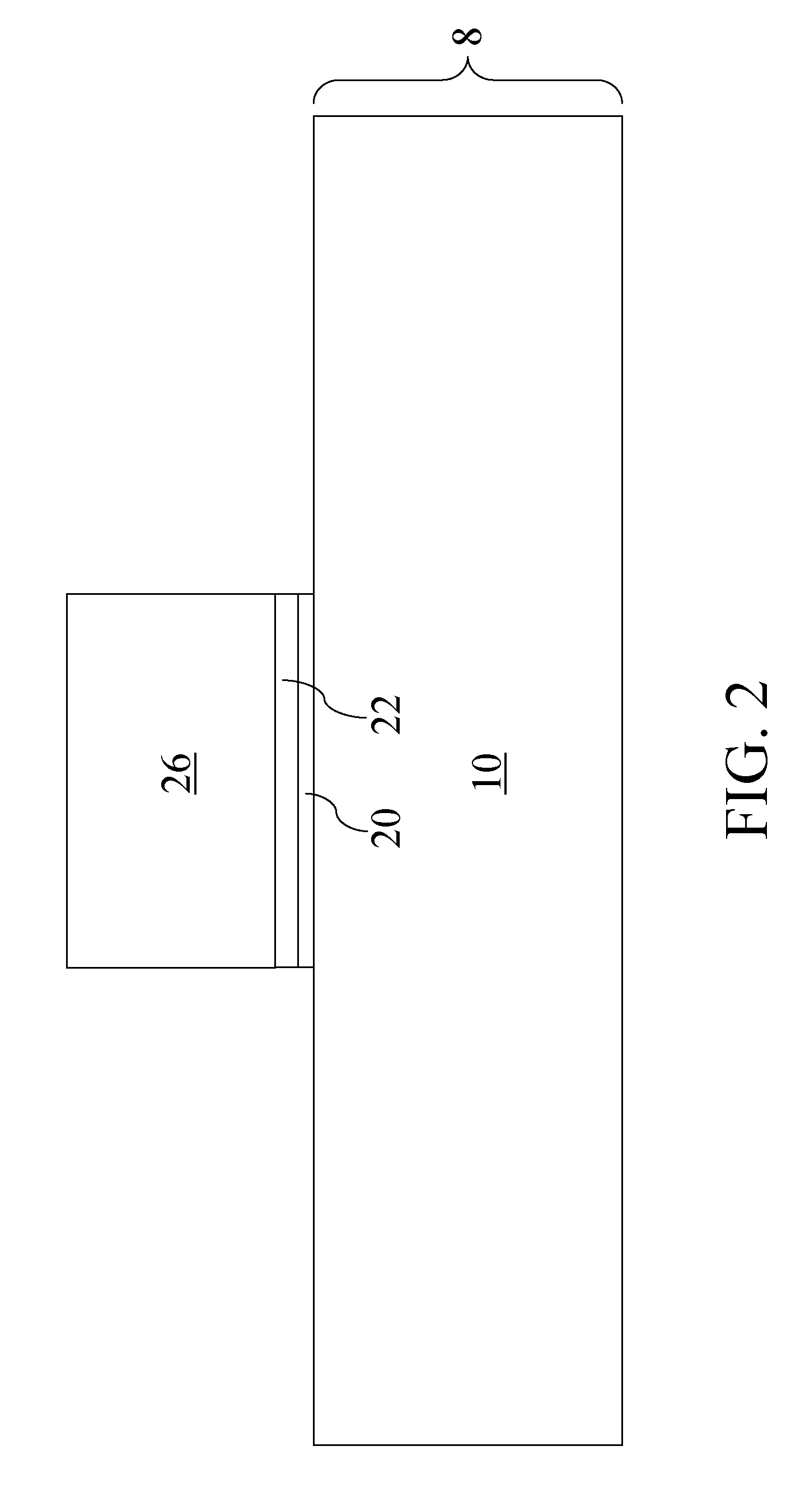

Field effect transistor with reduced overlap capacitance

InactiveUS20090212332A1Reduce Overlap CapacitanceTransistorSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

Owner:GLOBALFOUNDRIES INC

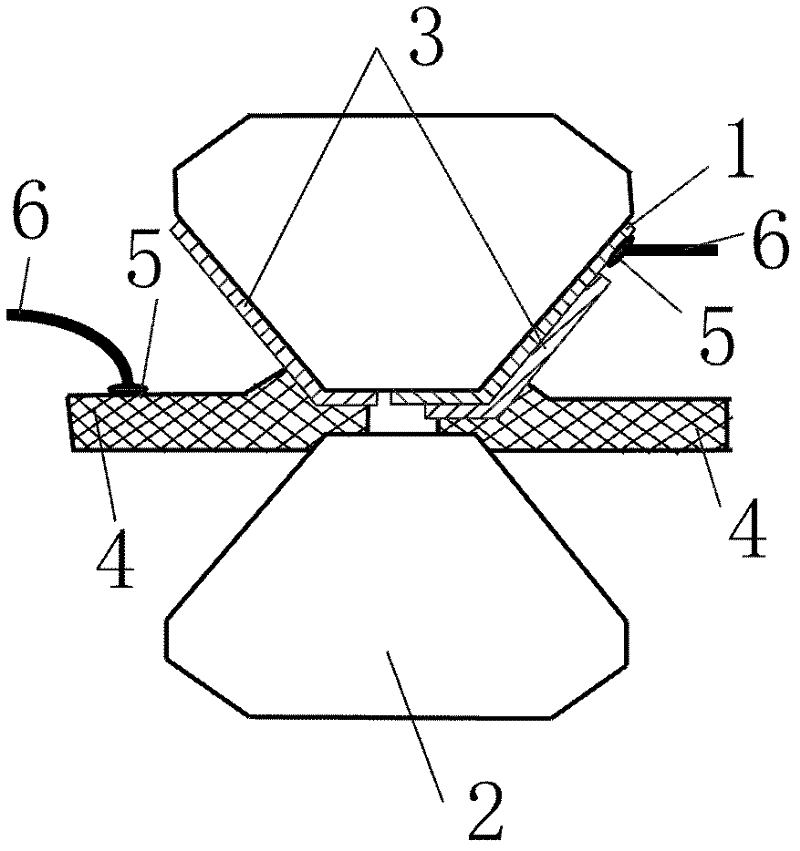

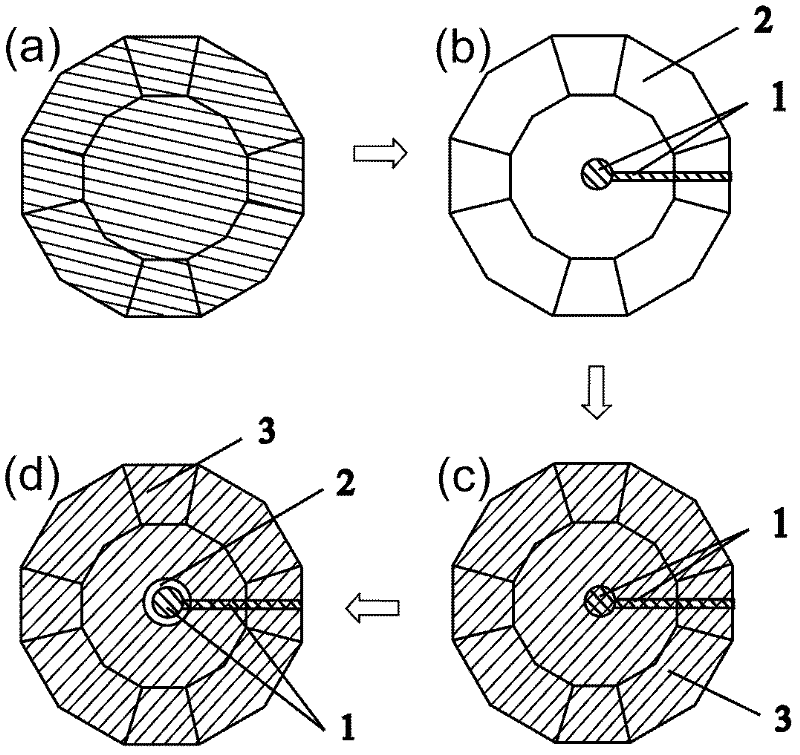

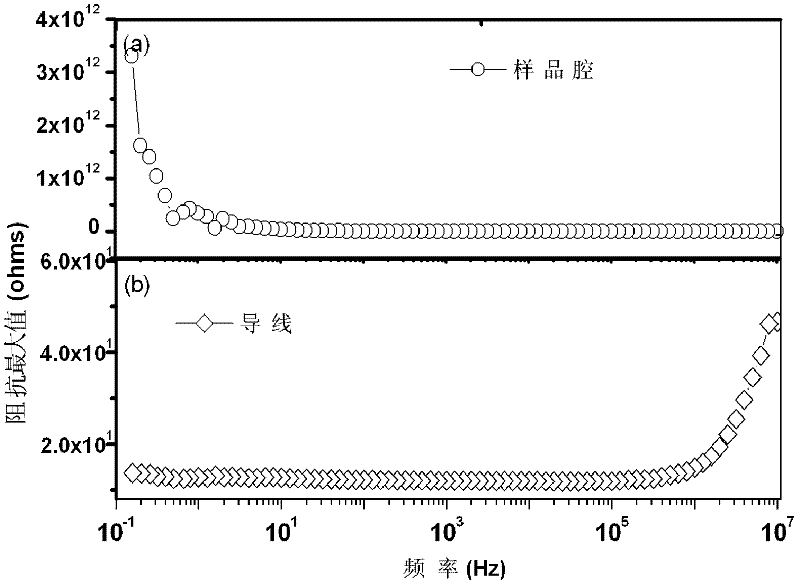

Electrode for high-voltage in-situ impedance spectroscopy measurement and its preparation method and application

InactiveCN102288824AFix fixitySolve insulation problemsResistance/reactance/impedenceEtchingInsulation Problem

Owner:JILIN UNIV

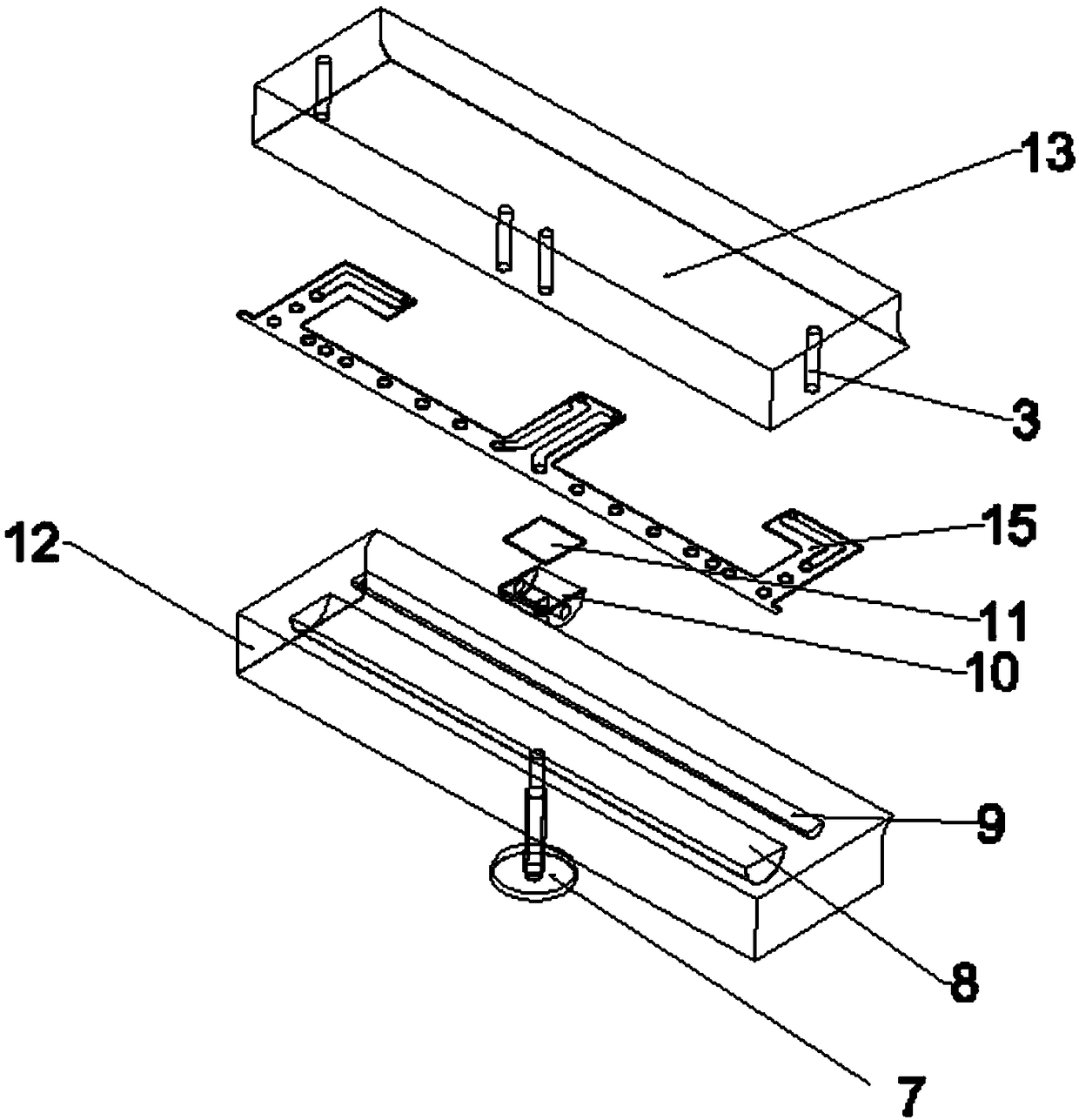

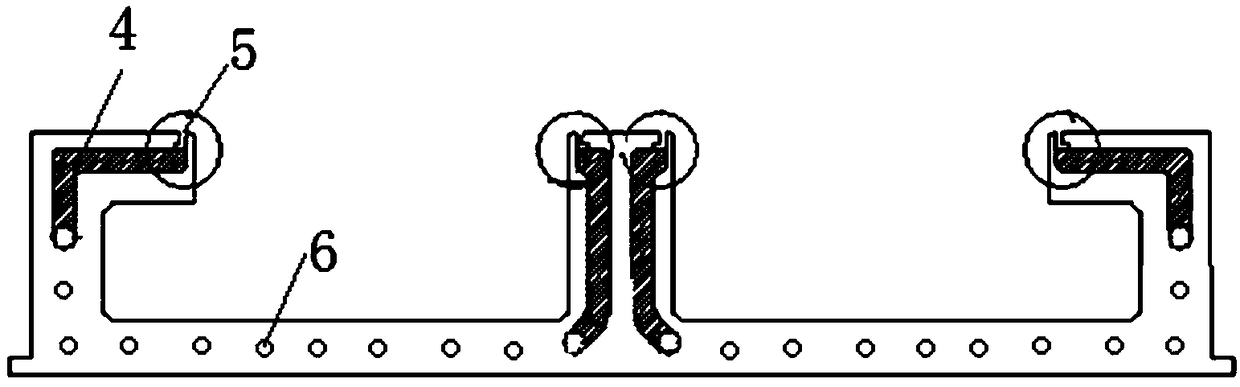

Construction spacer

InactiveUS20060137289A1Reduce and eliminate distortionReduce distortion problemsProtective foundationBuilding componentsEngineeringCHEEK DIMPLES

The present invention is related to spacers that can create fluid flow space at a variety of structural interfaces, particularly in building construction. The spacers of the present invention include unique hinges that can physically couple one panel of the spacer to another panel of the spacer in a manner that substantially distortionally separates the two panels. Preferred embodiments include a folded hinge having at least two folds. The spacers of the present invention also include unique panel dimples that help control the rigidity of the panel. In preferred embodiments, elongated dimples are used to help control rigidity.

Owner:COTTEN KENNETH K

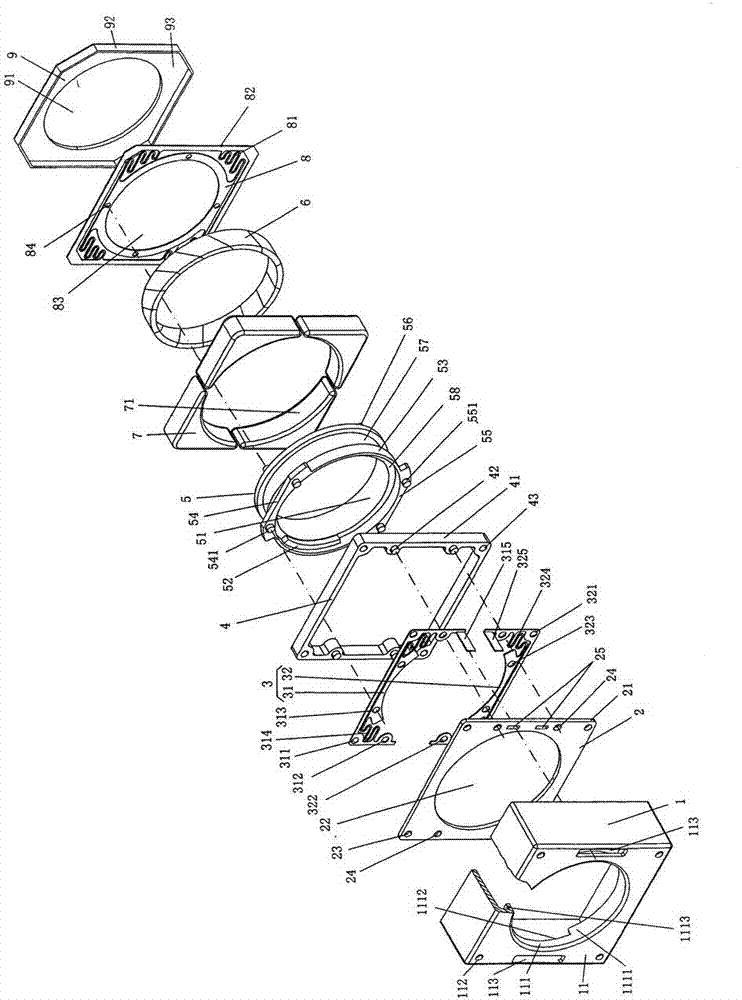

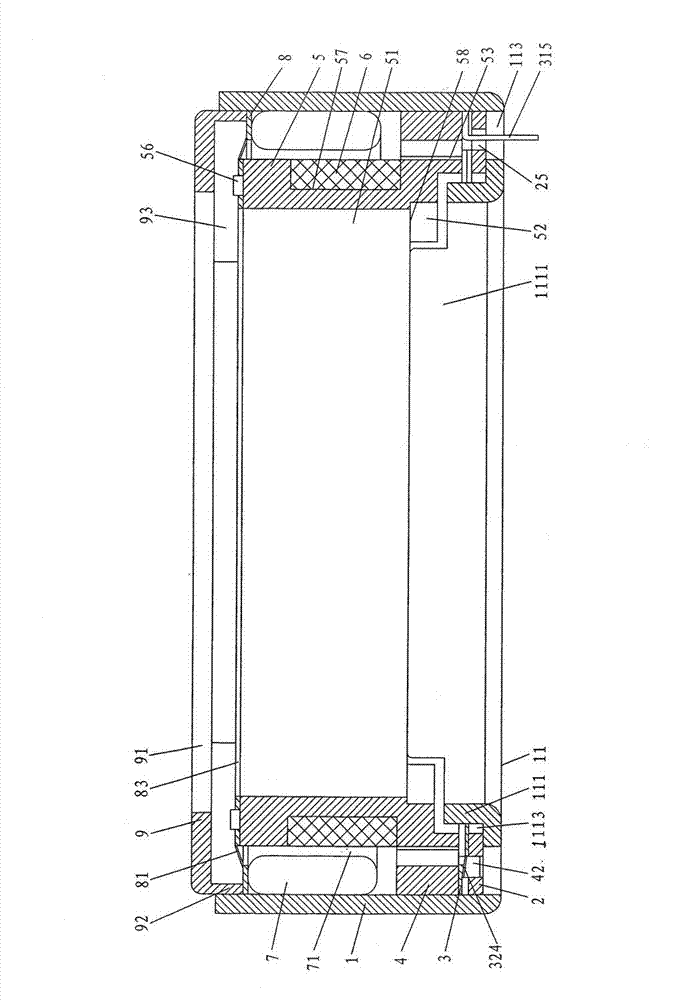

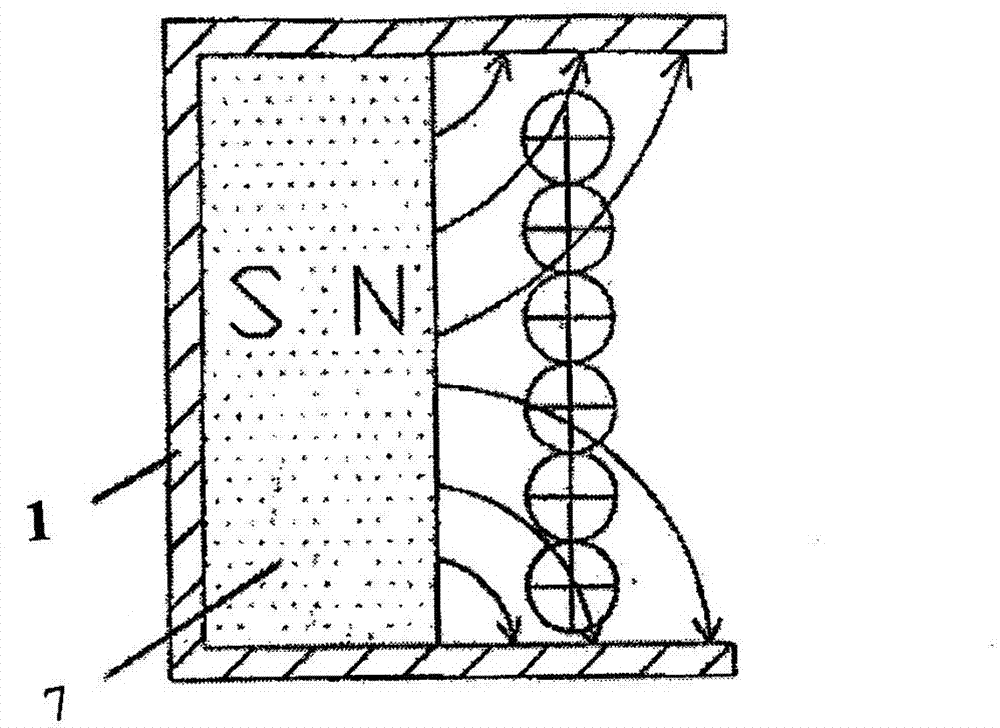

Lens driving device

ActiveCN103091813AIncreased electromagnetic induction forceImprove distributionProjector focusing arrangementCamera focusing arrangementImaging qualityOptical axis

Owner:山东润蒙应急救援装备有限公司

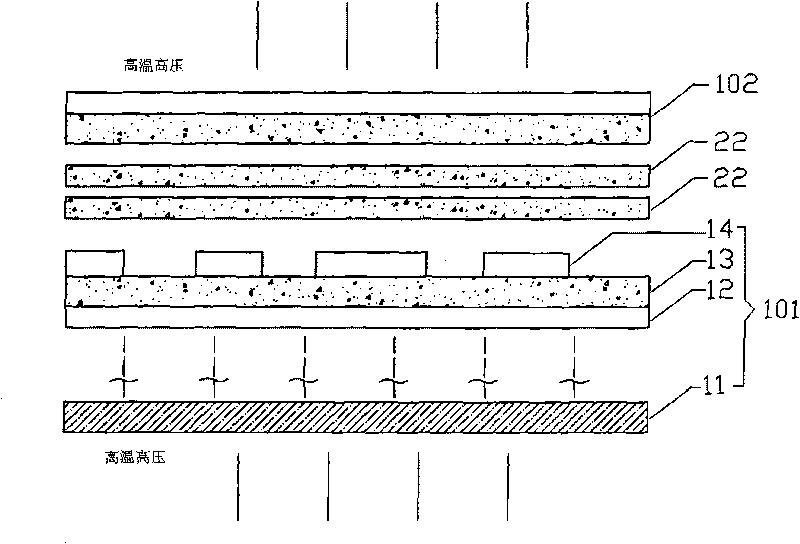

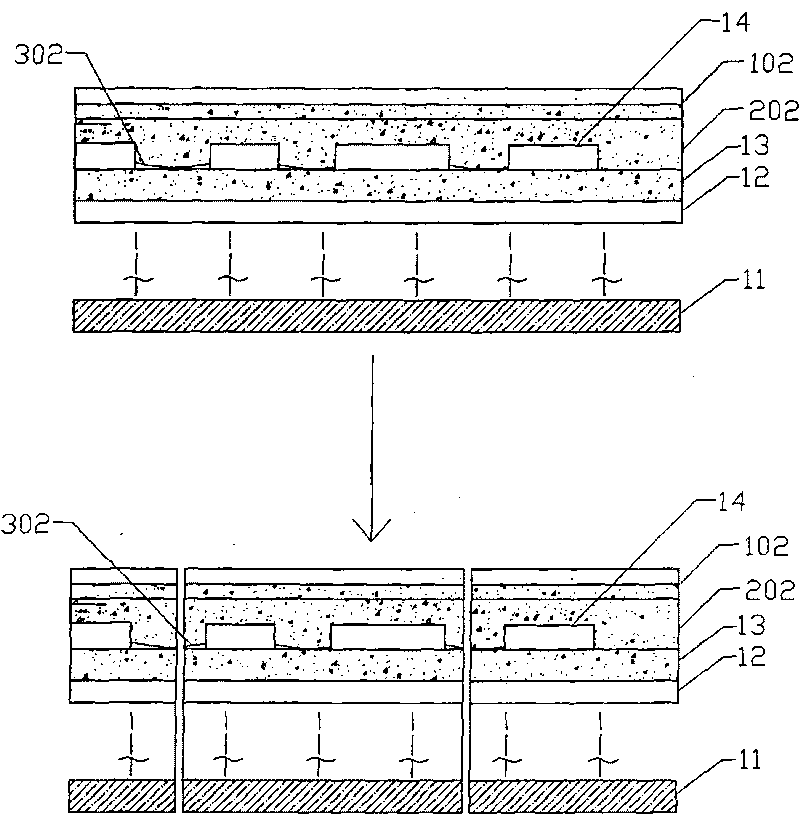

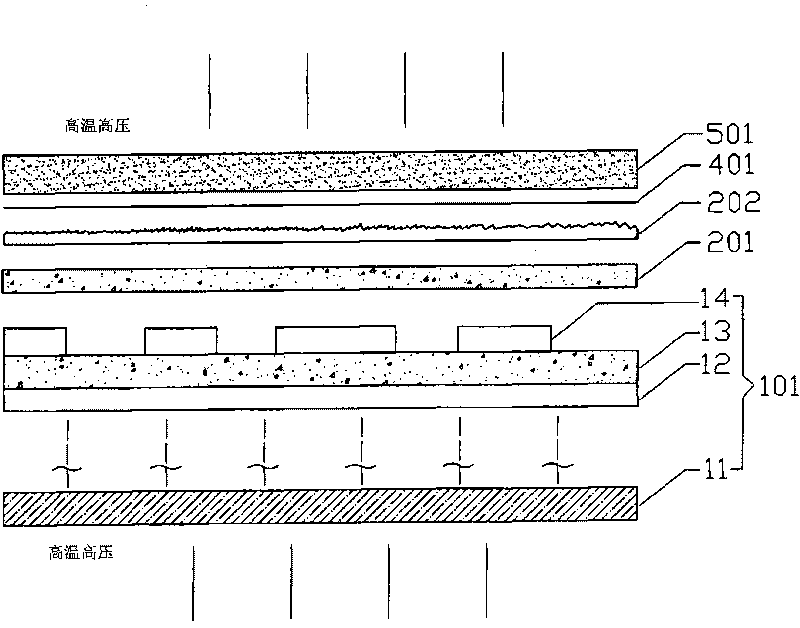

Process for pressing galvanized PCB boards and multi-layer PCB board

InactiveCN101711101APrevent glue shortageAvoid quality problemsPrinted circuit detailsMultilayer circuit manufactureEngineeringWork in process

Owner:SHENNAN CIRCUITS

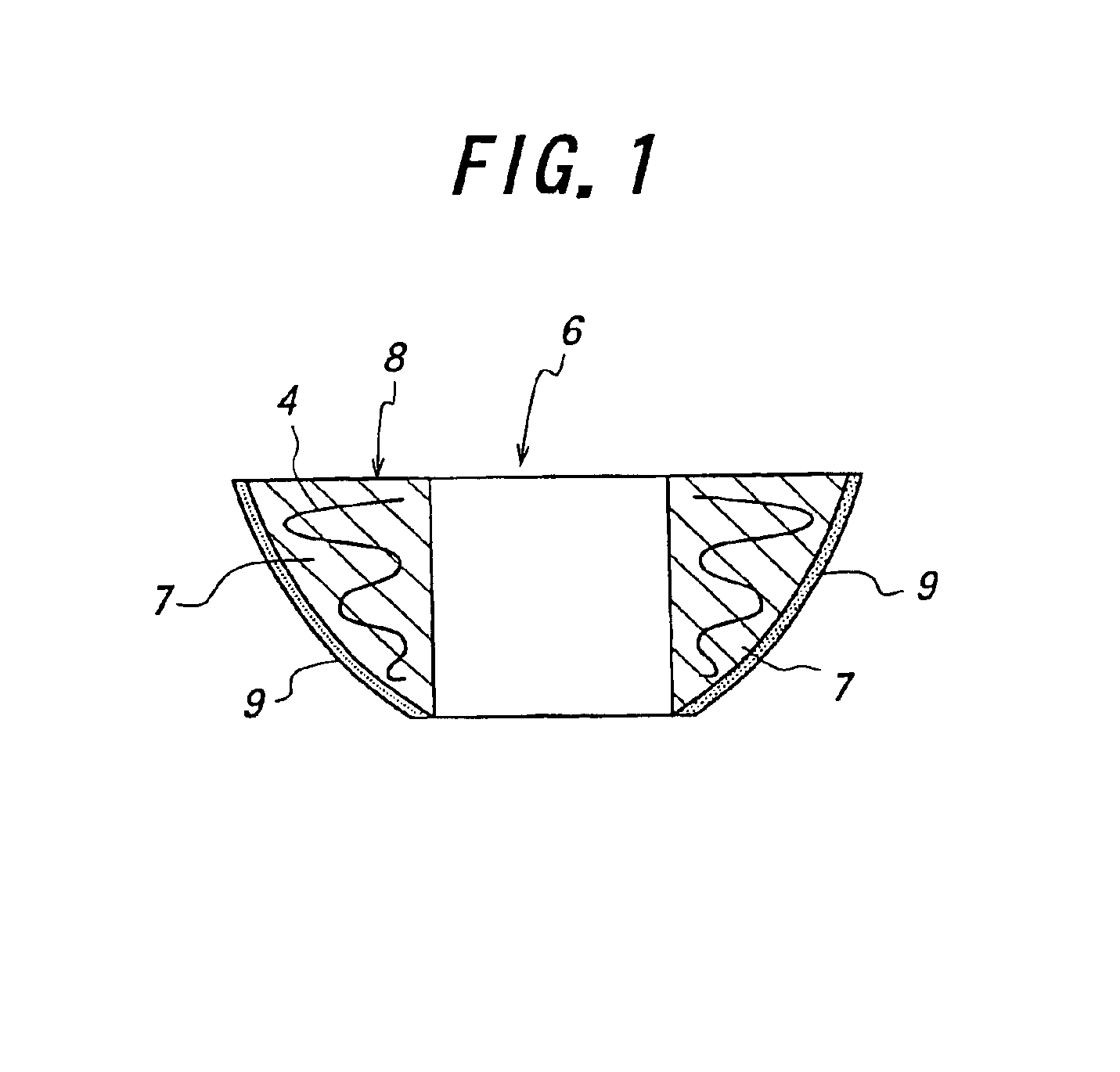

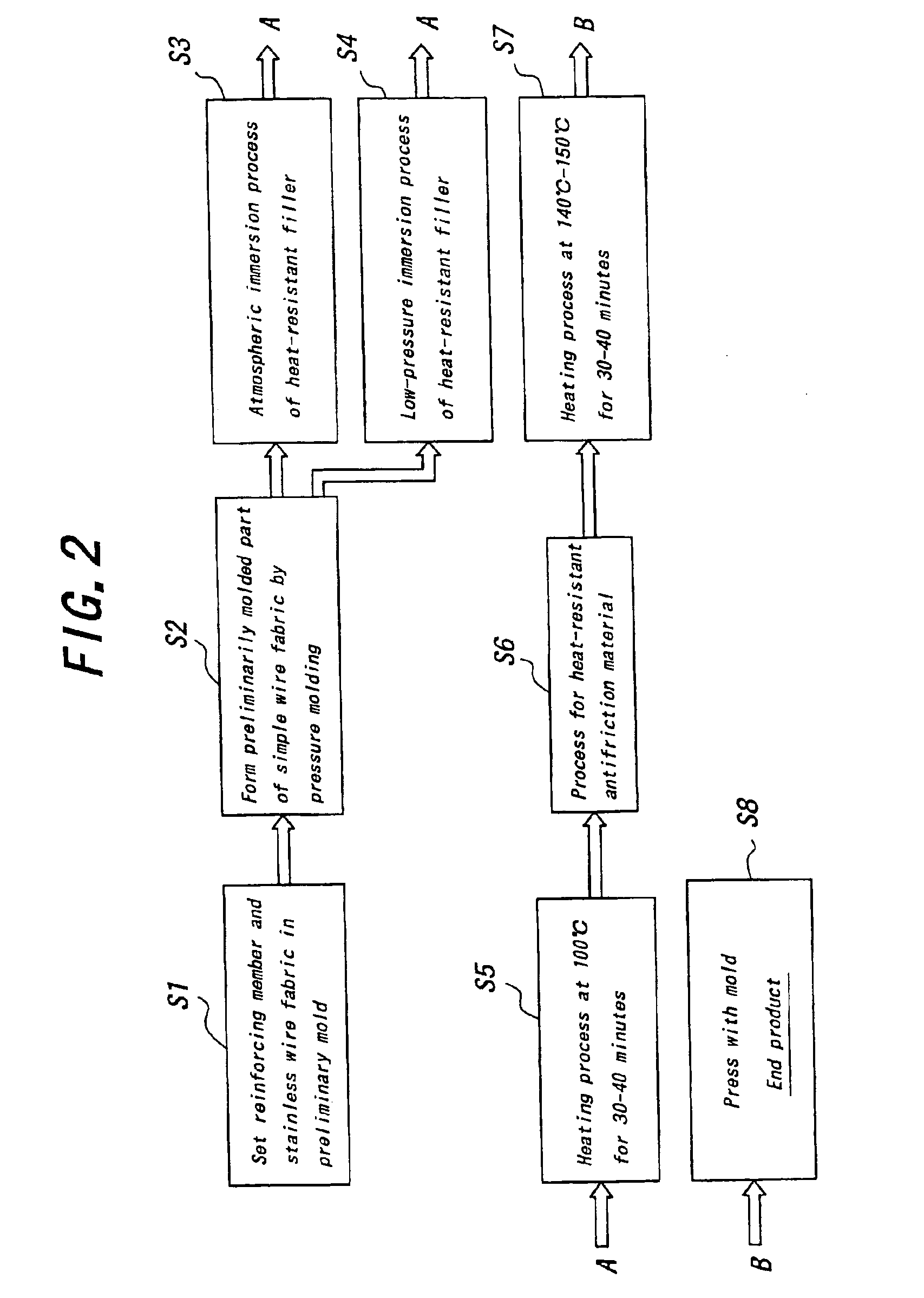

Gasket for high-temperature joint and method of fabricating the same

InactiveUS6889983B2Flowability of solution is reducedHigh strengthEngine sealsFlanged jointsBoron nitridePolytetrafluoroethylene

Owner:HONDA MOTOR CO LTD +1

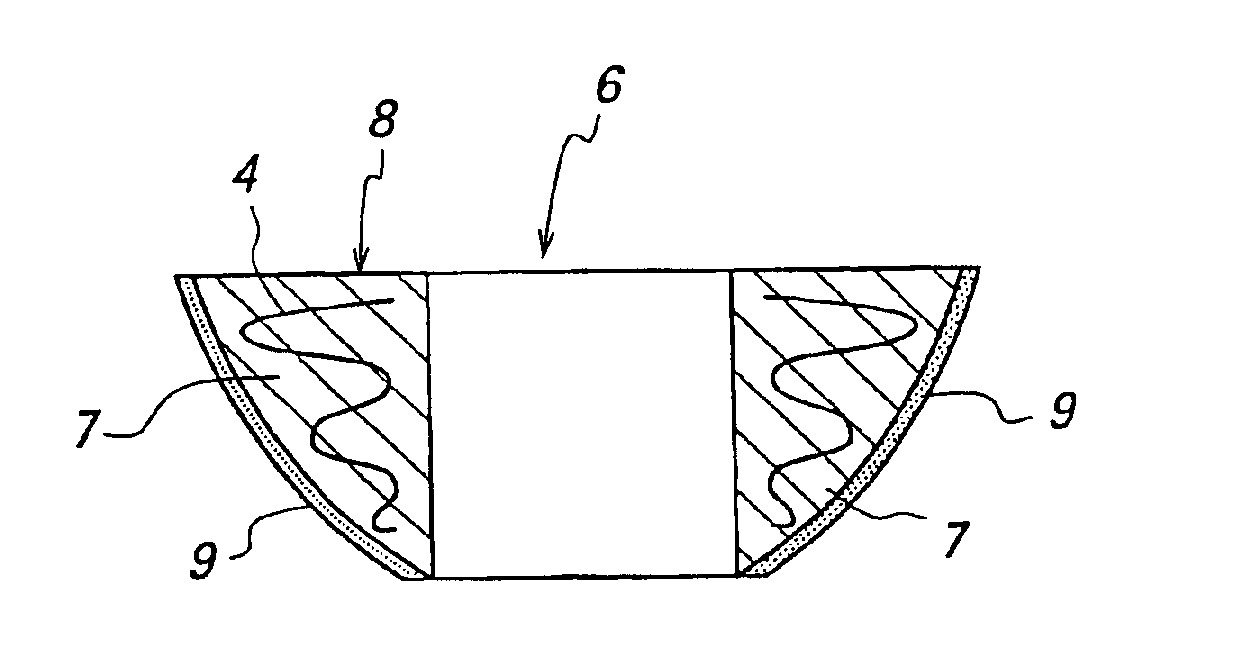

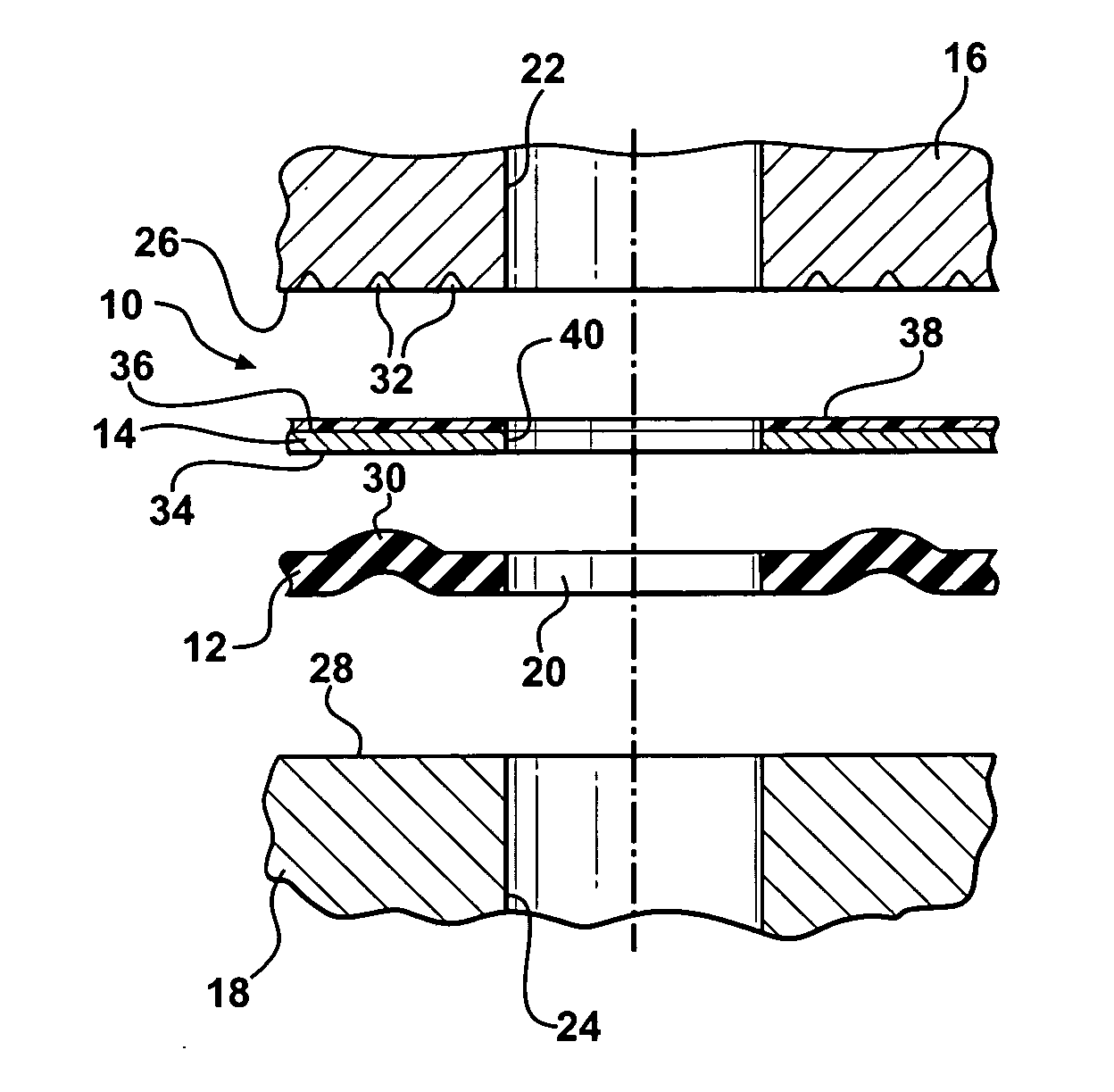

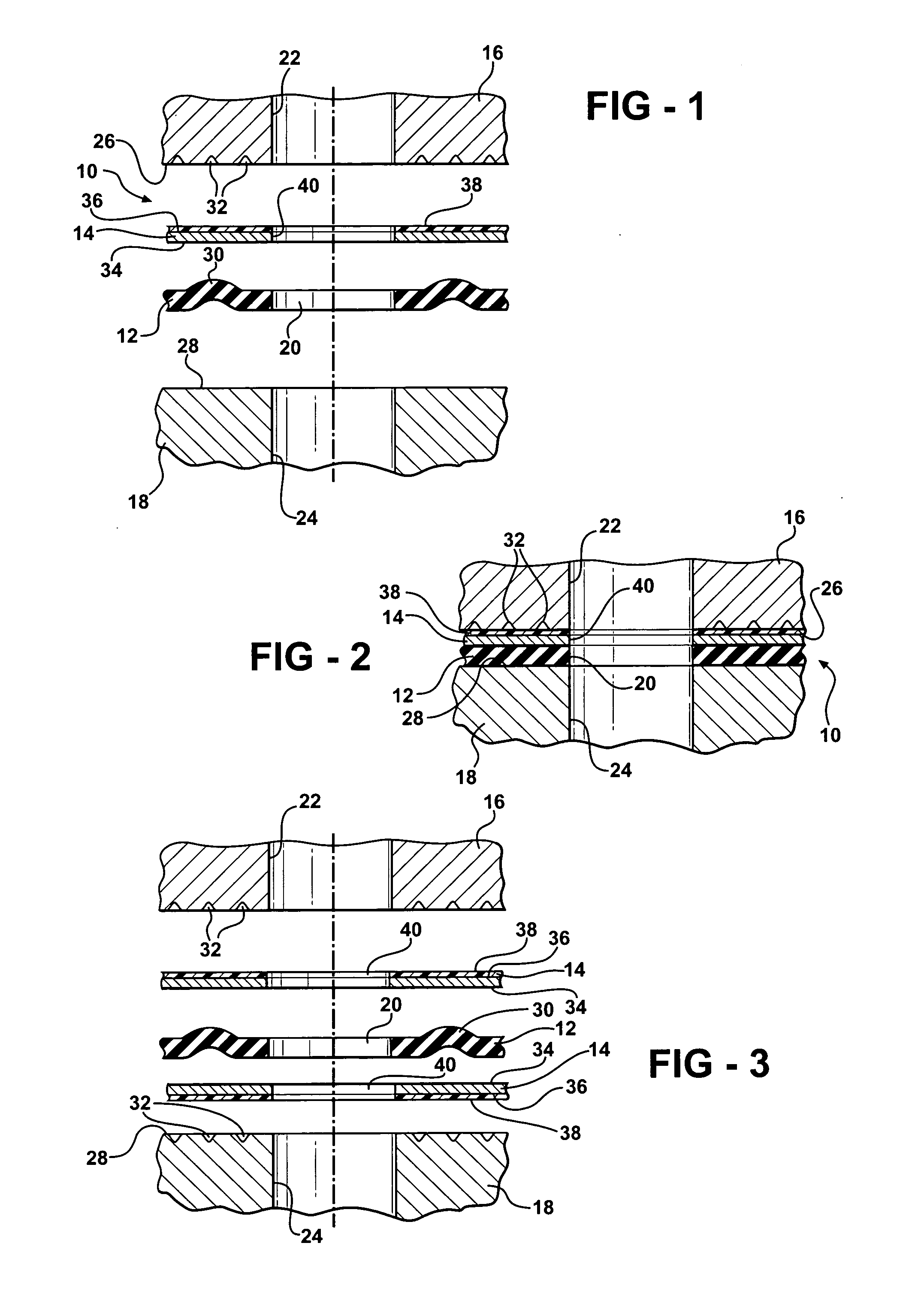

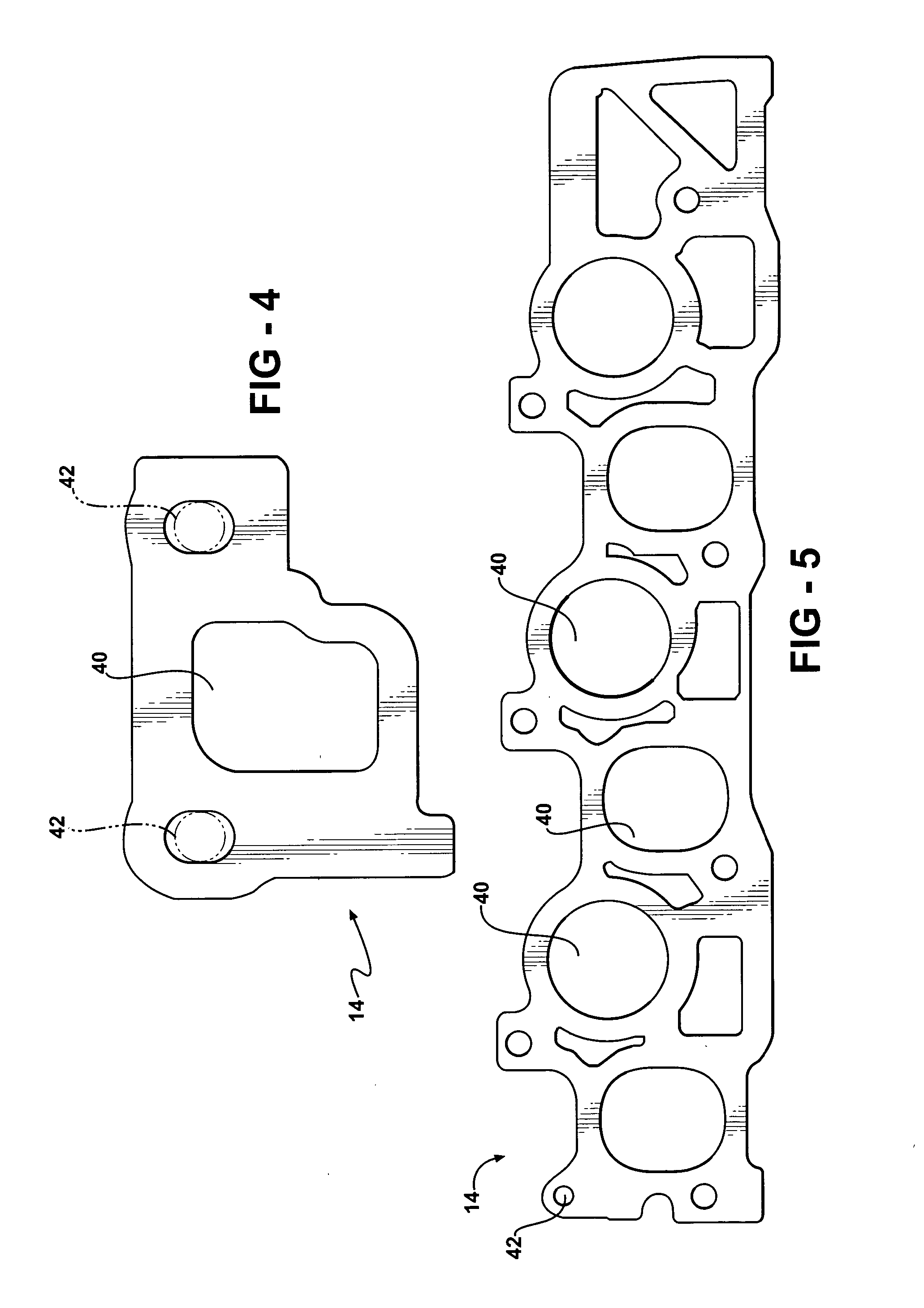

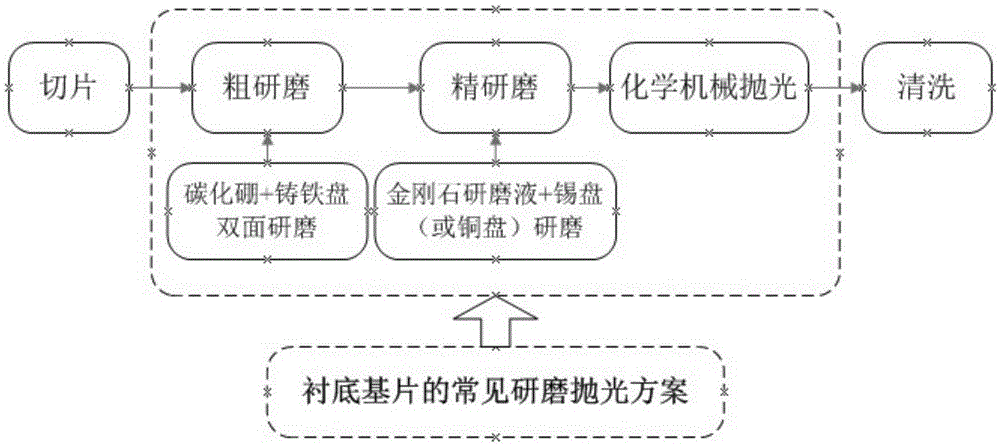

Gasket assembly

InactiveUS20070024009A1Simple and low-costReduce maintenance costsEngine sealsSealing arrangements for enginesElectrical and Electronics engineeringGasket

Owner:FEDERAL MOGUL WORLD WIDE

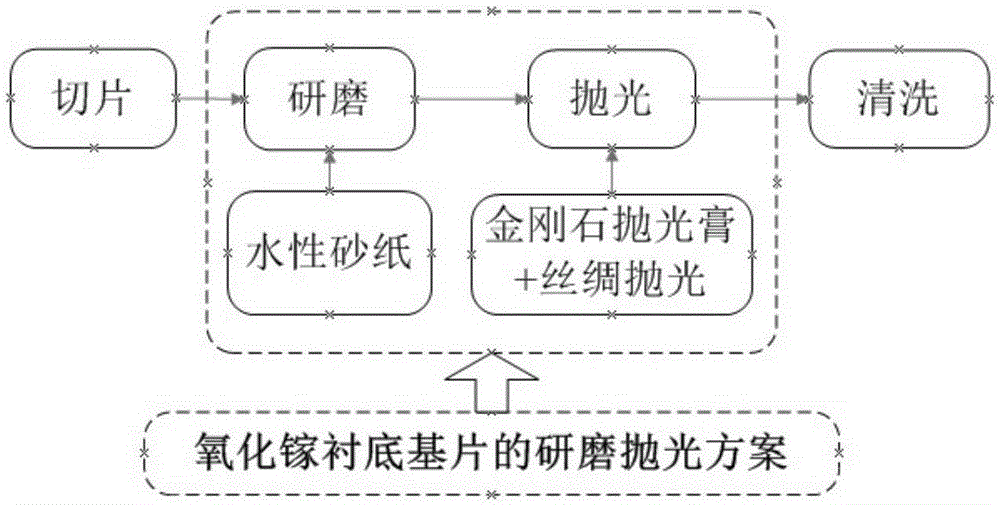

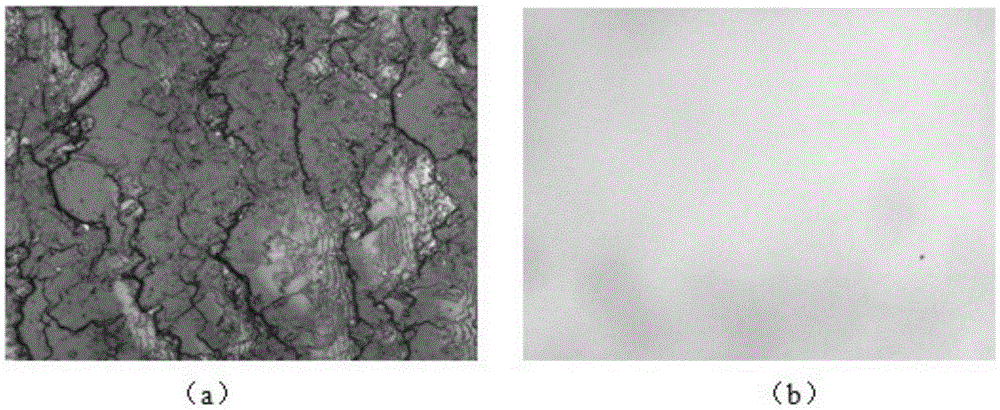

Ultra-precision machining method for gallium oxide substrate

Owner:南京大劲精密机械有限公司

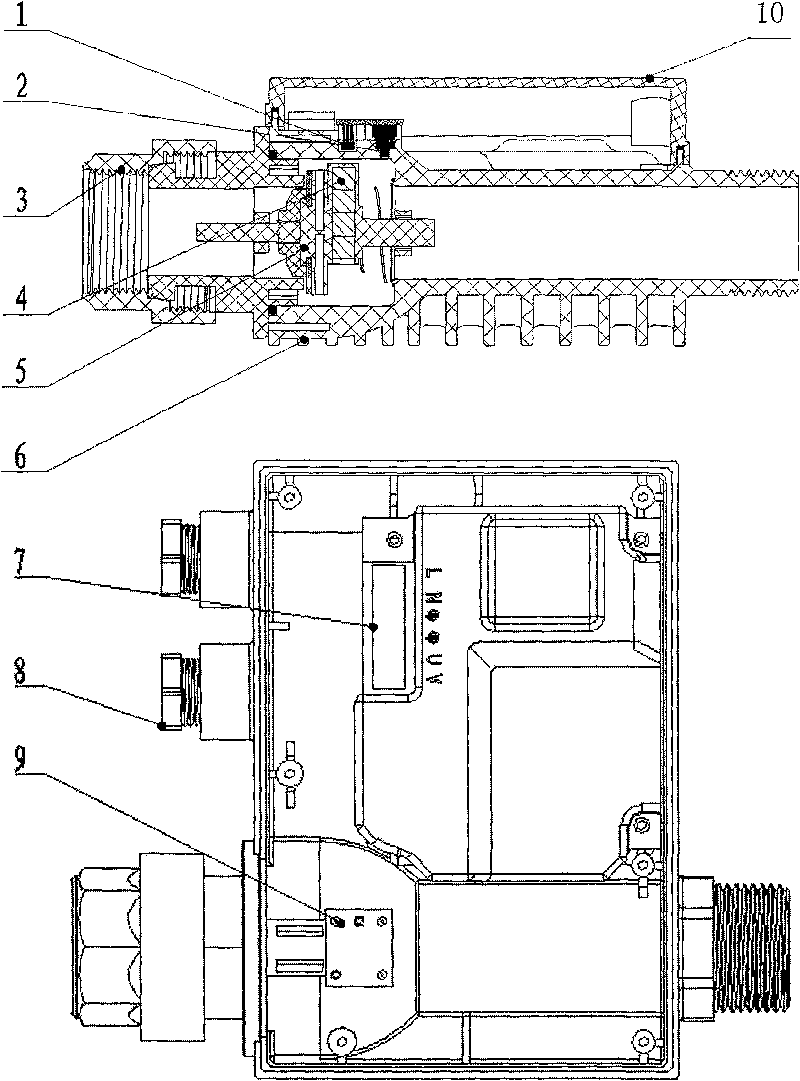

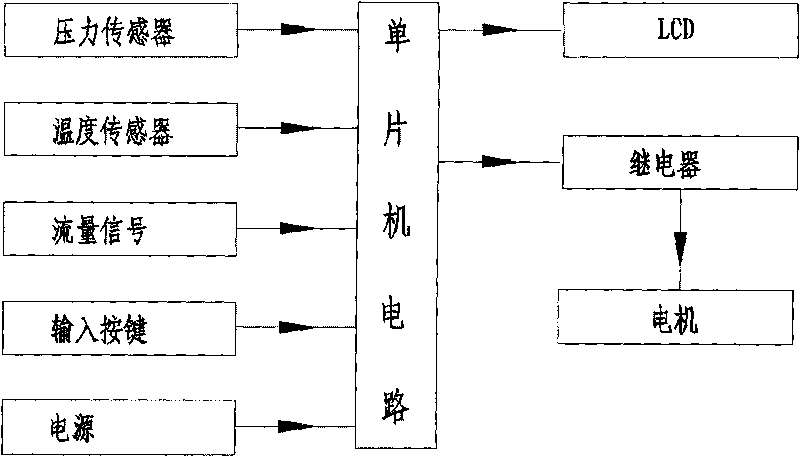

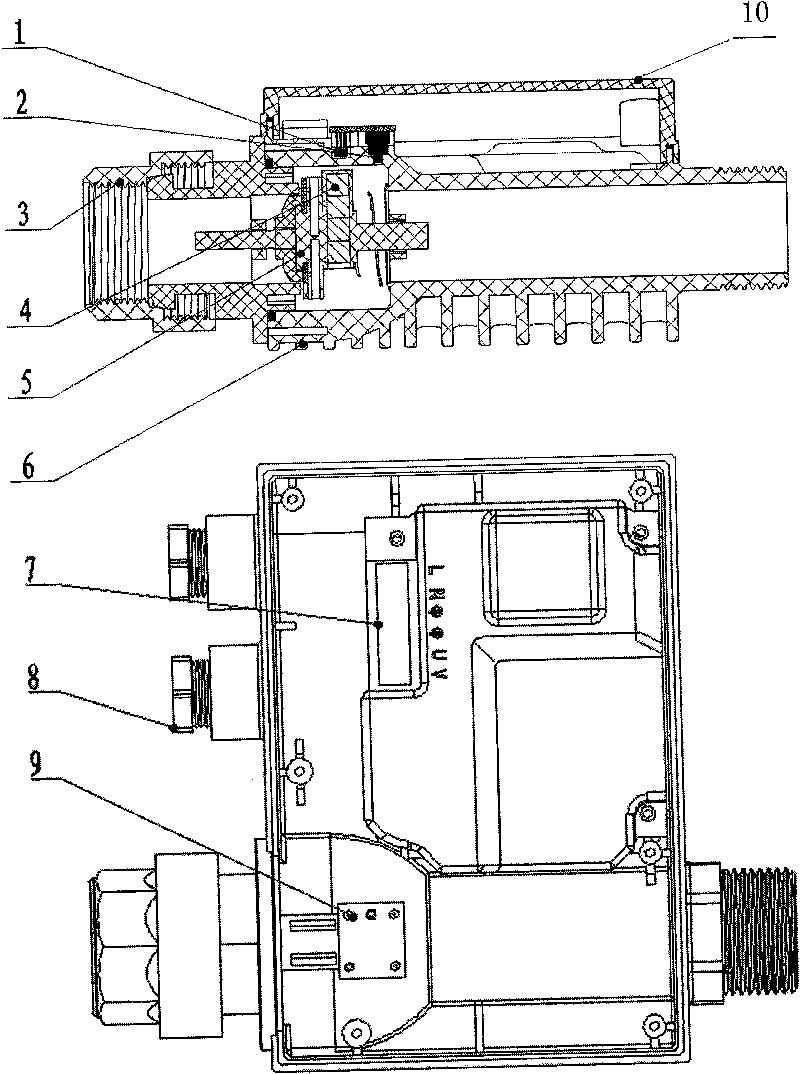

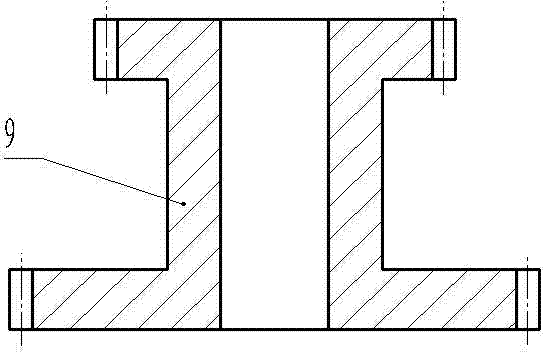

Electronic pressure controller

InactiveCN101727110AEasy to installExtend your lifeFluid pressure control with auxillary non-electric powerFluid pressure control using electric meansTemperature controlLED display

Owner:JIANGSU HUANLI TECH DEV CO LTD

Method for machining duplicate gears

Owner:钦州市铭盛自动化设备有限公司

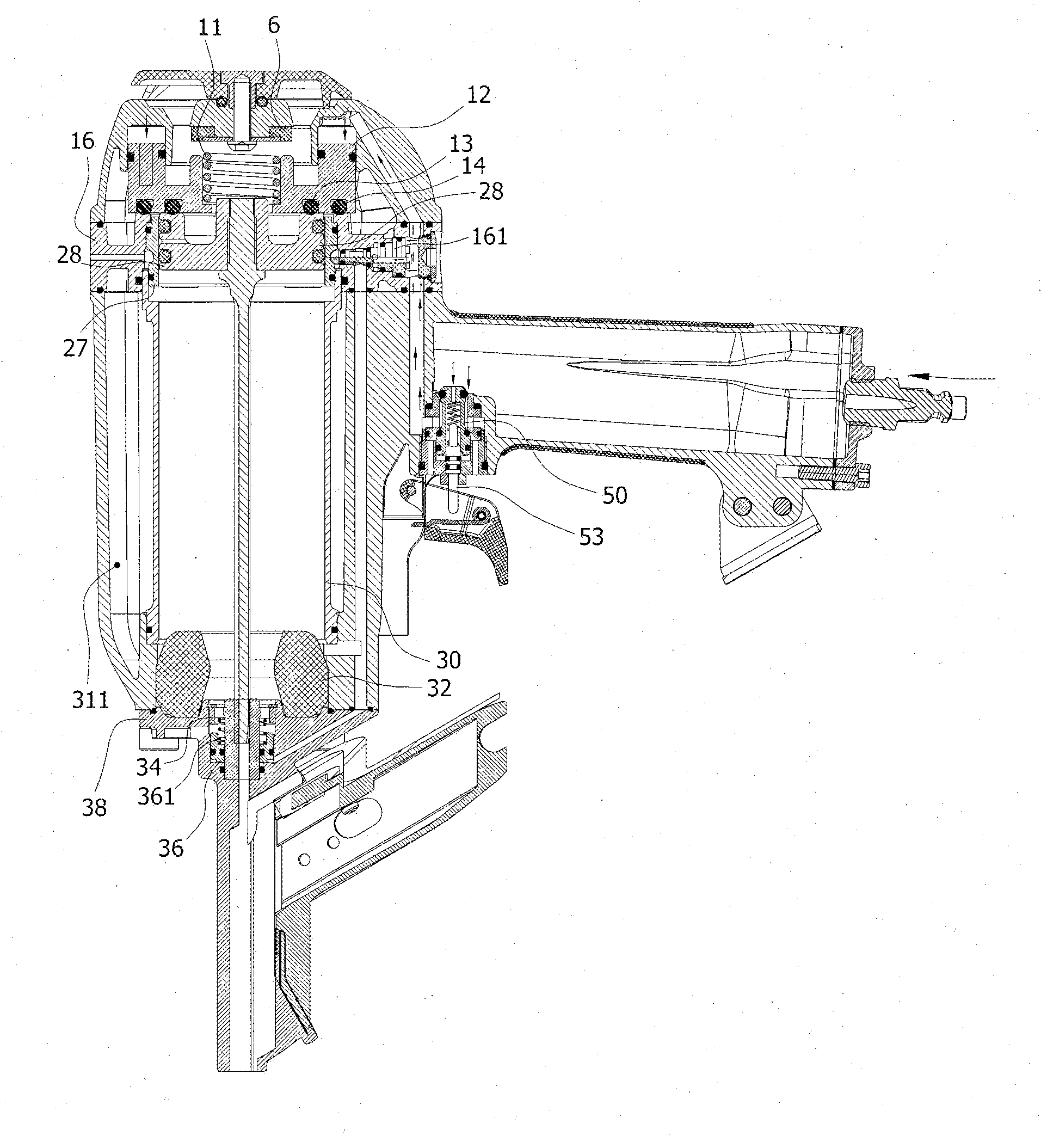

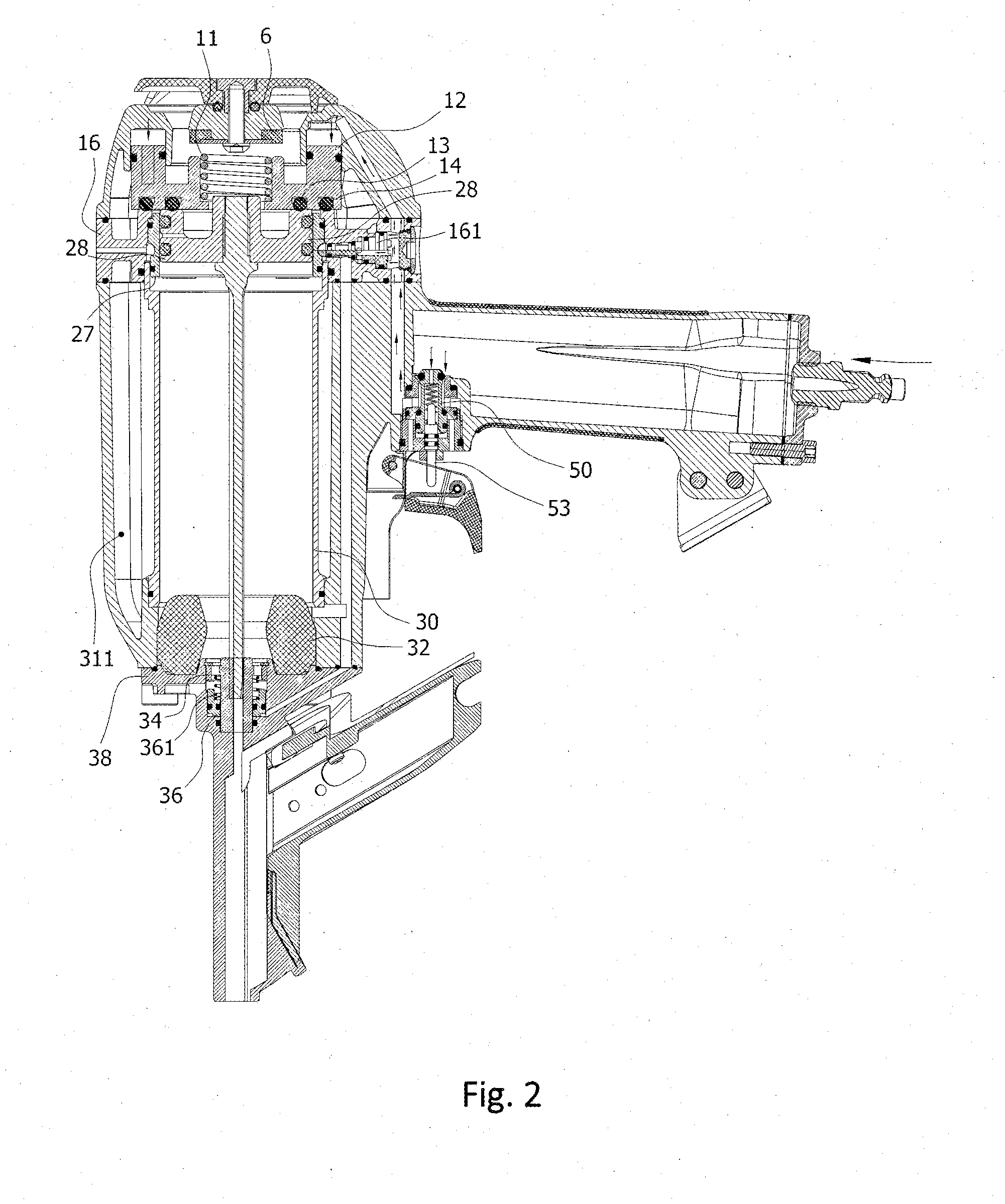

Pneumatic nail gun

ActiveUS20150197001A1Reduce pressure oscillationsImprove efficiencyStapling toolsNailing toolsEngineeringControl valves

Owner:ZHEJIANG RONGPENG AIR TOOLS

Position-regulatable external pressure fixator for reating kneecap fracture without wound

Owner:ZHEJIANG UNIV

Waterproof boot to pant connection

An article includes a first garment, a second garment, and a waterproof fastener system configured to join the first garment to the second. The waterproof fastener includes: a first annular gasket, coupled to the first garment, the first annular gasket including a flexible substrate and a continuous groove radially oriented on the first garment such that an engagement direction thereof is oriented 90 degrees relative to a longitudinal direction of the first garment, and a second annular gasket coupled to the second garment, the second annular gasket including a second flexible substrate and a continuous rib radially oriented on the second garment such that an engagement direction thereof is oriented 90 degrees relative to a longitudinal direction of the second garment. The continuous groove is configured to receive the continuous rib to form a waterproof interference fit.

Owner:WL GORE & ASSOC INC

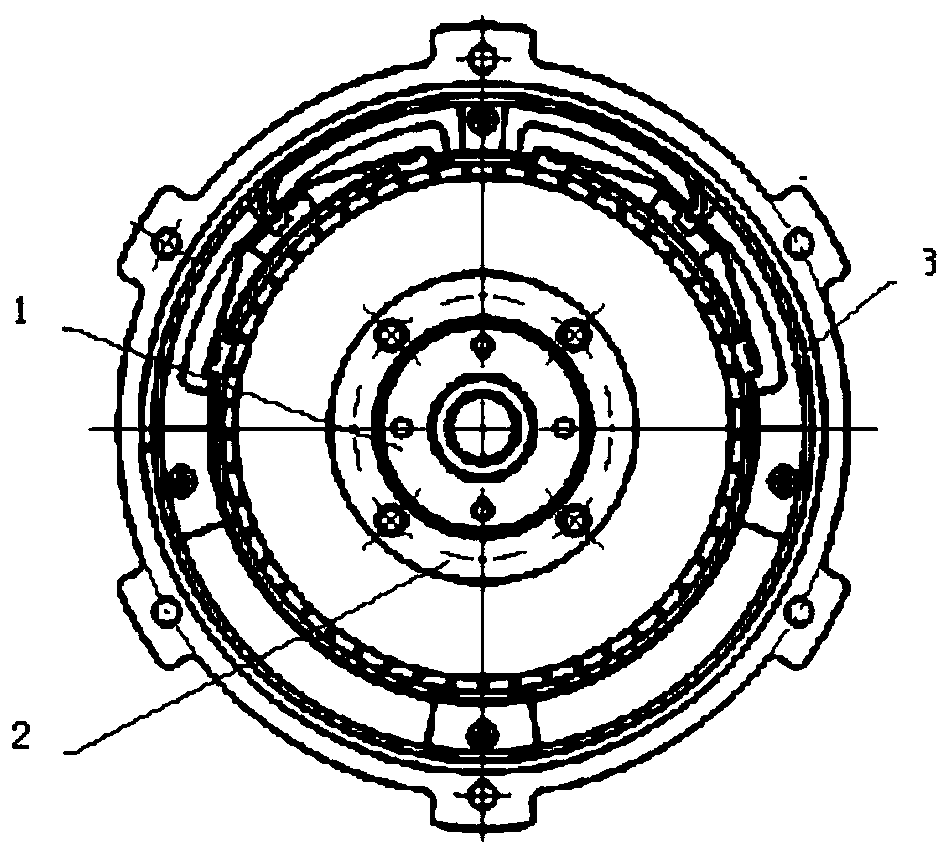

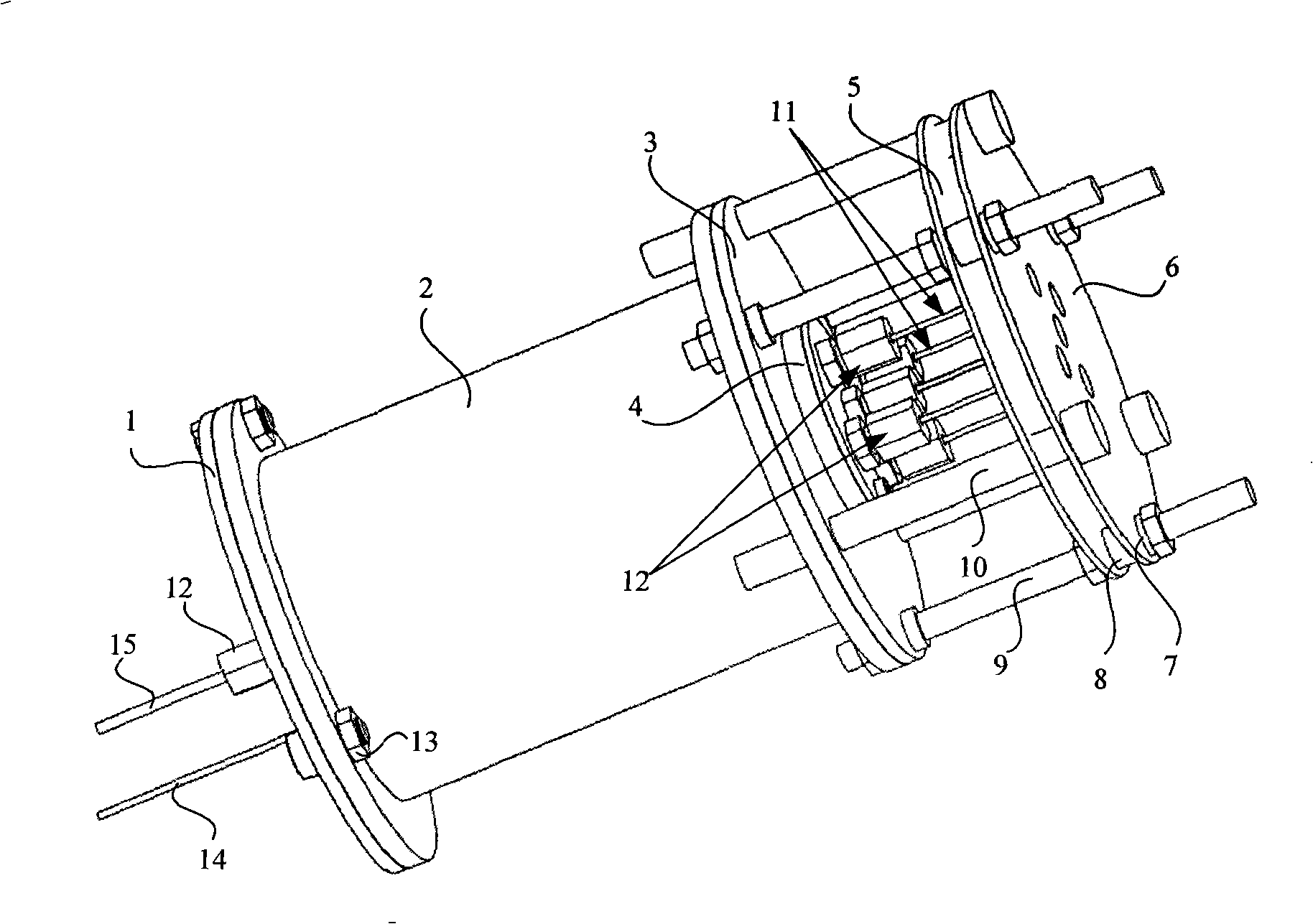

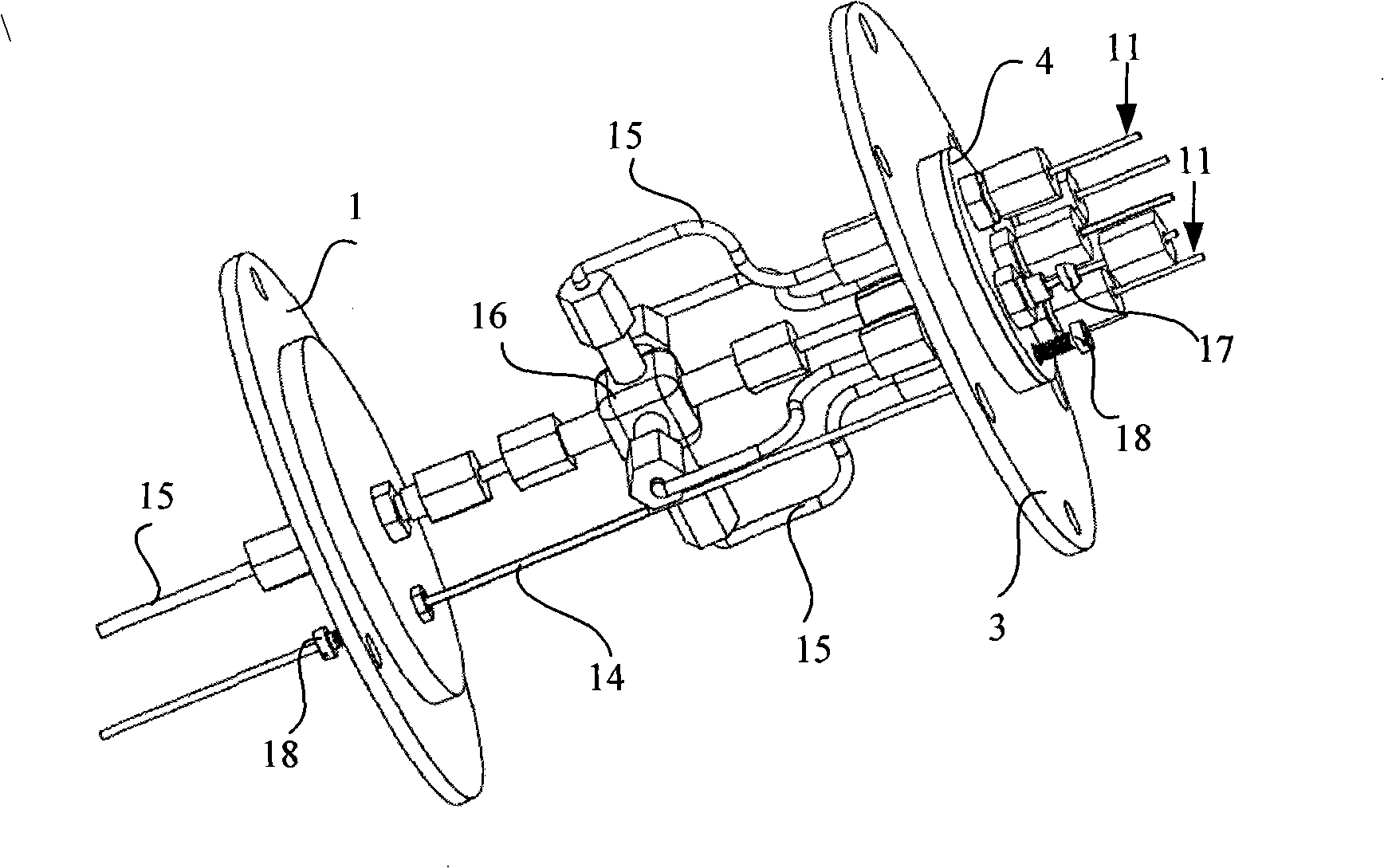

Bearing preload adjusting and locking structure for a small and special electrical machine and implementation method

ActiveCN110867984ARealize imposingRealize mass productionMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machineMachine

Owner:TIANJIN NAVIGATION INSTR RES INST

Antibacterial heating graphene shoes and preparation method thereof

InactiveCN106954912AFast heat conductionImprove cooling efficiencyAntifouling/underwater paintsLiquid surface applicatorsGraphene coatingOrganic solvent

Owner:泉州信和石墨烯研究院有限公司

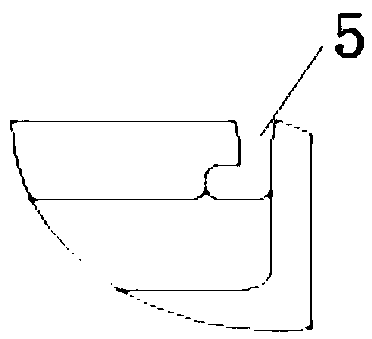

Selftightening compound sealing pad

InactiveCN101387345AImprove sealingStrong ability to withstand pressureEngine sealsMedia accessMaterials science

Owner:马志刚

Multi-pin micro-Newton colloid thrustor

InactiveCN101539073ASimple compositionIncrease or decrease quantityRocket engine plantsEngineeringColloid

Owner:BEIHANG UNIV

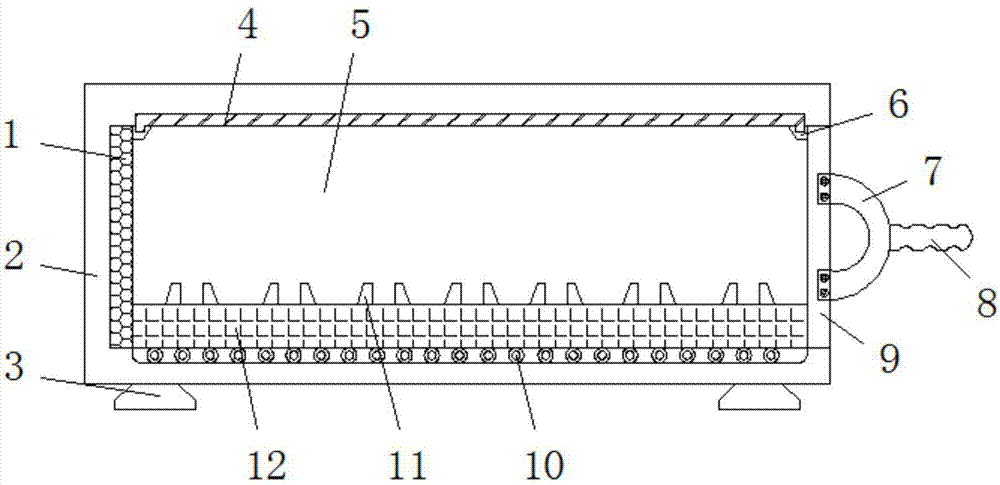

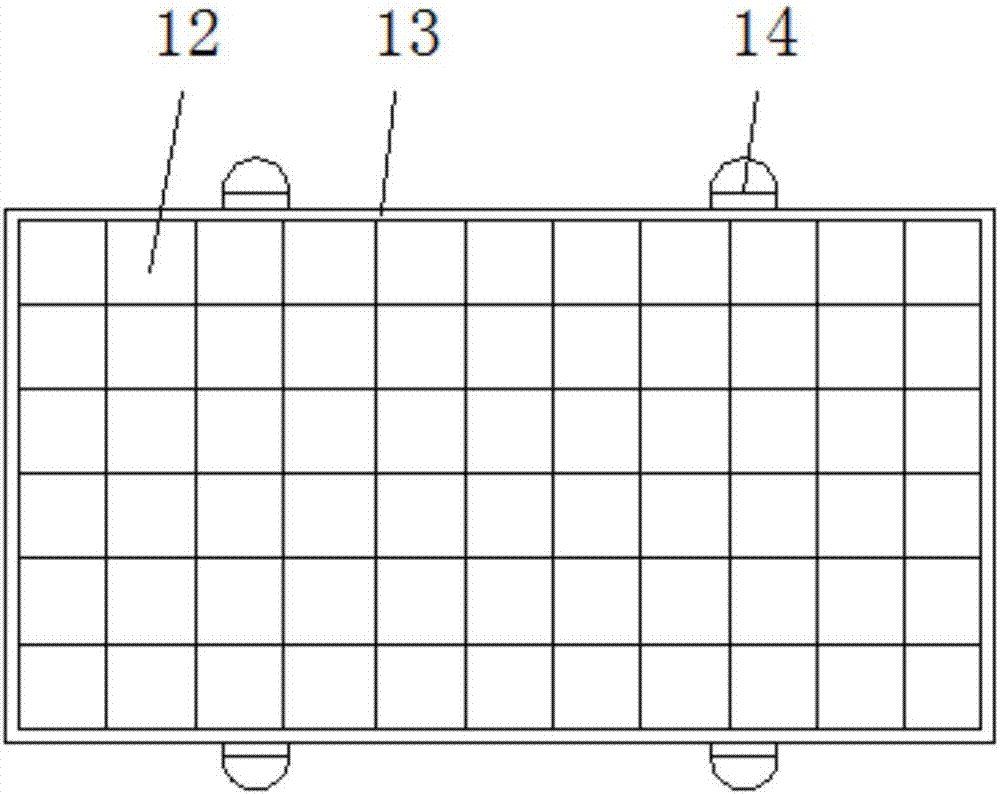

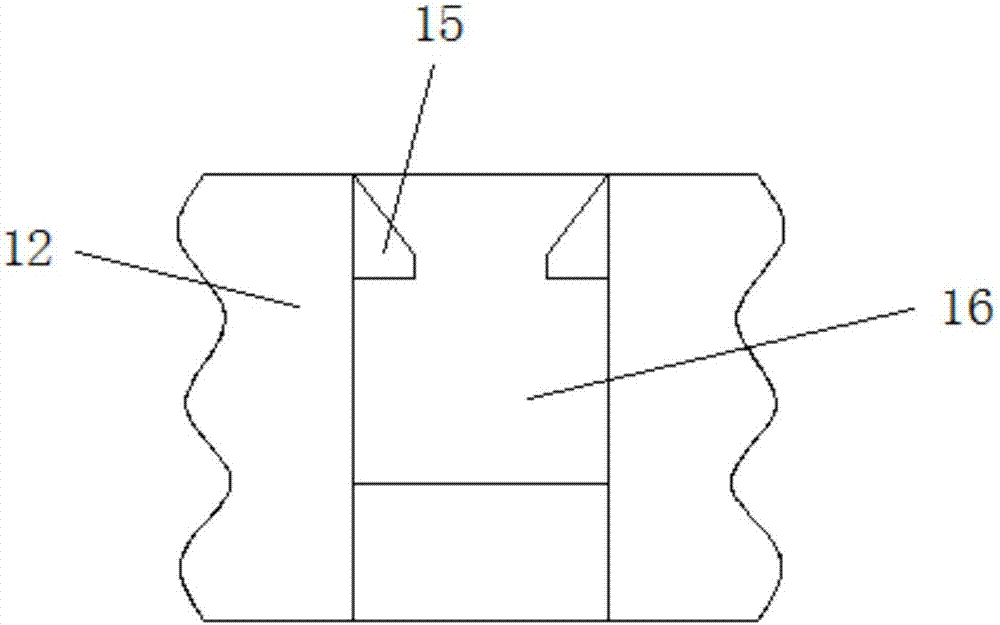

Novel grid-type cryopreservation box made of mixed material

InactiveCN107416359AEffective shock absorption and bufferingReduce the impact of vibrationDomestic cooling apparatusLighting and heating apparatusMixed materialsEngineering

Owner:ZHENGZHOU QISHUO ELECTRONICS TECH CO LTD

Adjustable eccentric sleeve

InactiveCN102767573AEnough contact surfaceMeet regulatory needsBearing unit rigid supportEngineeringLantern

The present invention relates to an adjustable eccentric sleeve which can be adjusted according to eccentricity, and solves problems of an existing eccentric sleeve, such as narrow adaptability and incapability to meet the accommodation of different eccentric errors. The device comprises a lantern ring with a round hole in the middle, which is characterized in that a circumferential outer wall of the lantern ring is uniformly provided with at least three regulating blocks; the regulating blocks are fixed with the lantern ring through adjusting screws; and a detachable and replaceable gasket is arranged between each regulating block and the outer wall of the lantern ring. The invention adopts a form of detachable gasket to realize an adjustable structure of the eccentric sleeve, so as to meet adjusting demands of different eccentric errors; and during the adjustment process, the eccentric sleeve and a mounting hole maintain adequate contact surface to ensure the strength of support.

Owner:HANGZHOU NANFANGTONGDA GEARS CO LTD

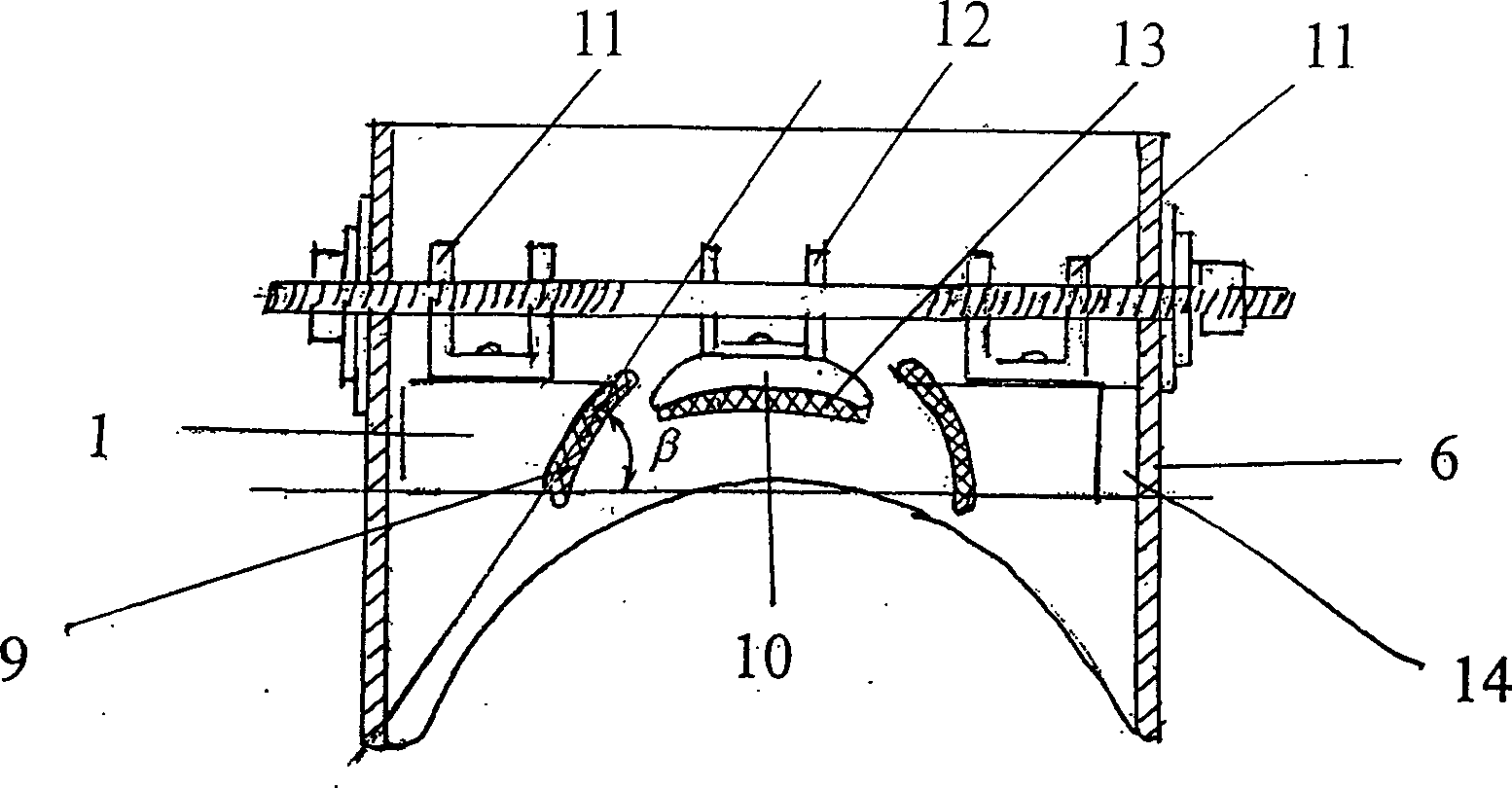

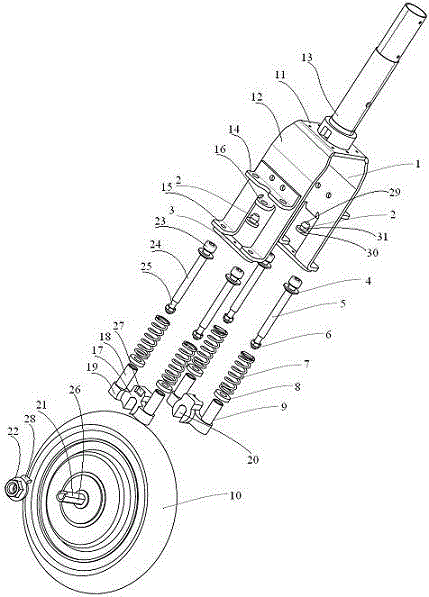

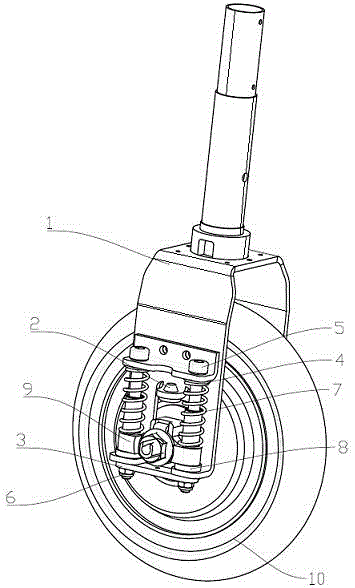

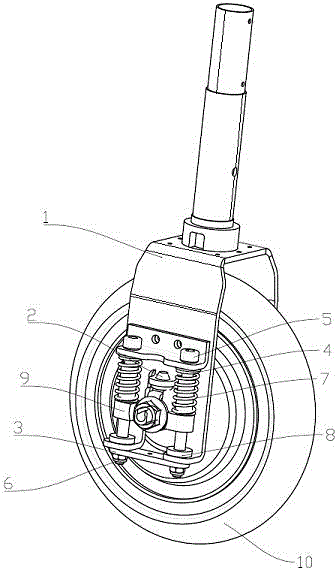

Front damping system applied to scooter

InactiveCN106741521AIngenious structural designCompact structureAxle suspensionsEngineeringSoft materials

Owner:NANJING KUAILUN INTELLIGENT TECH CO LTD

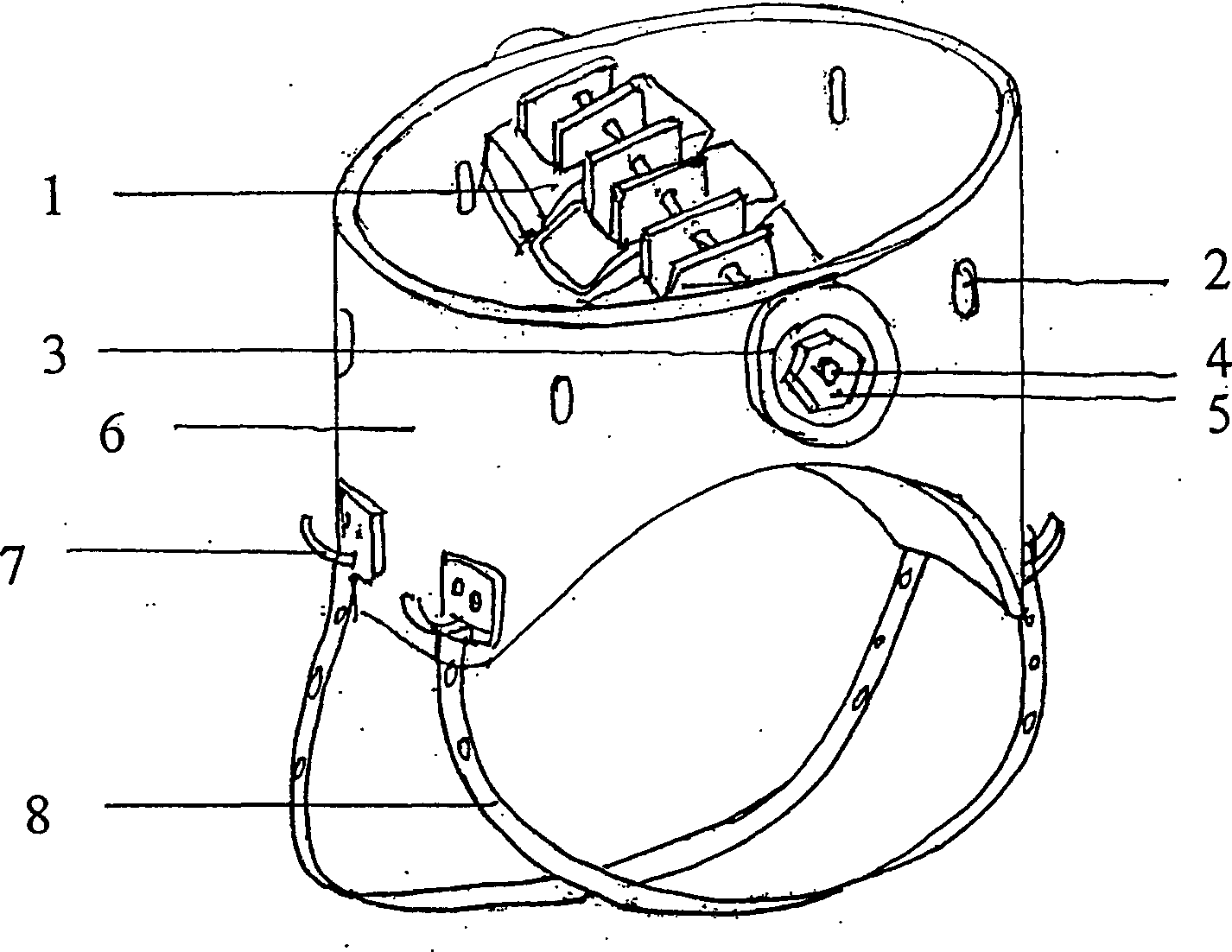

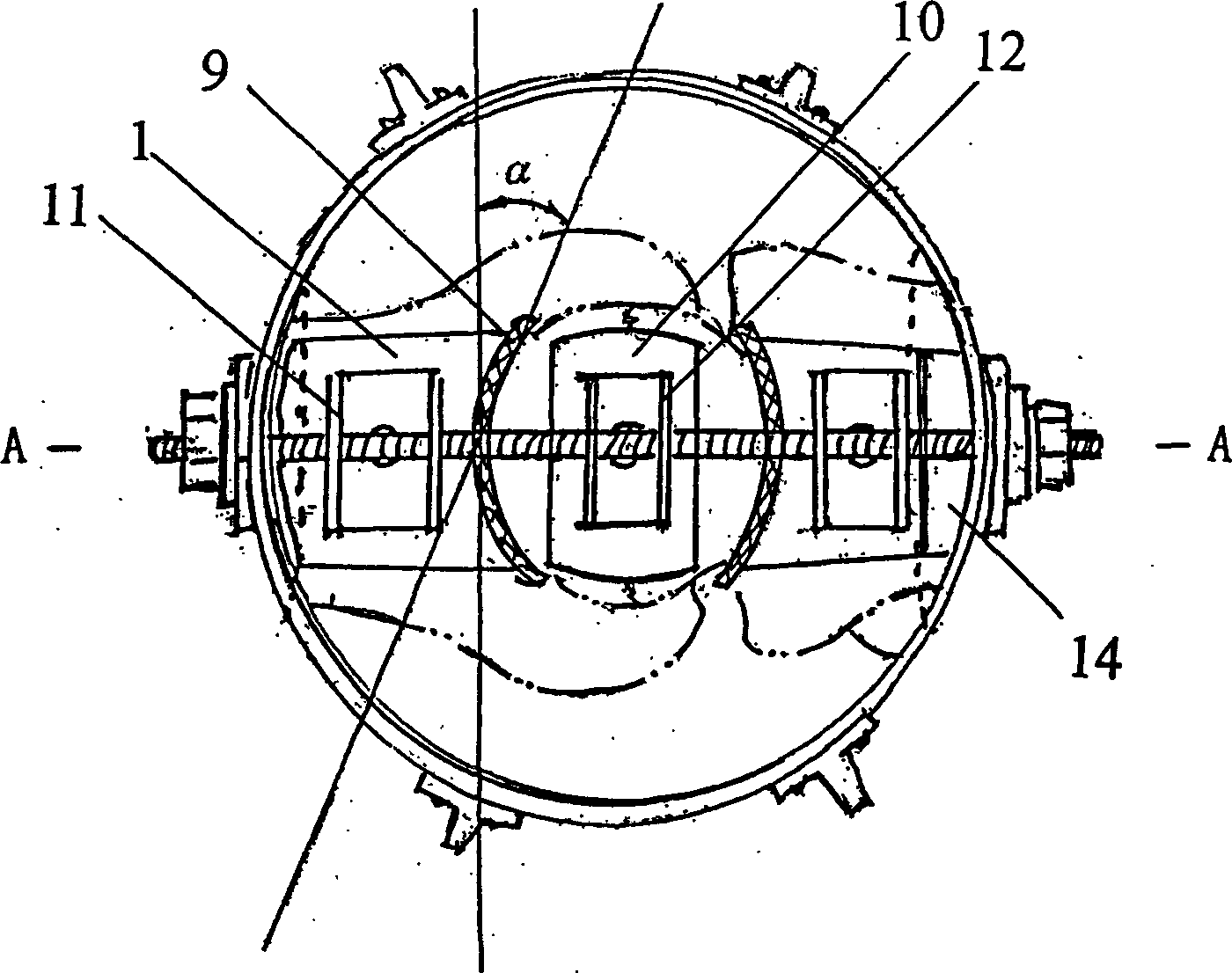

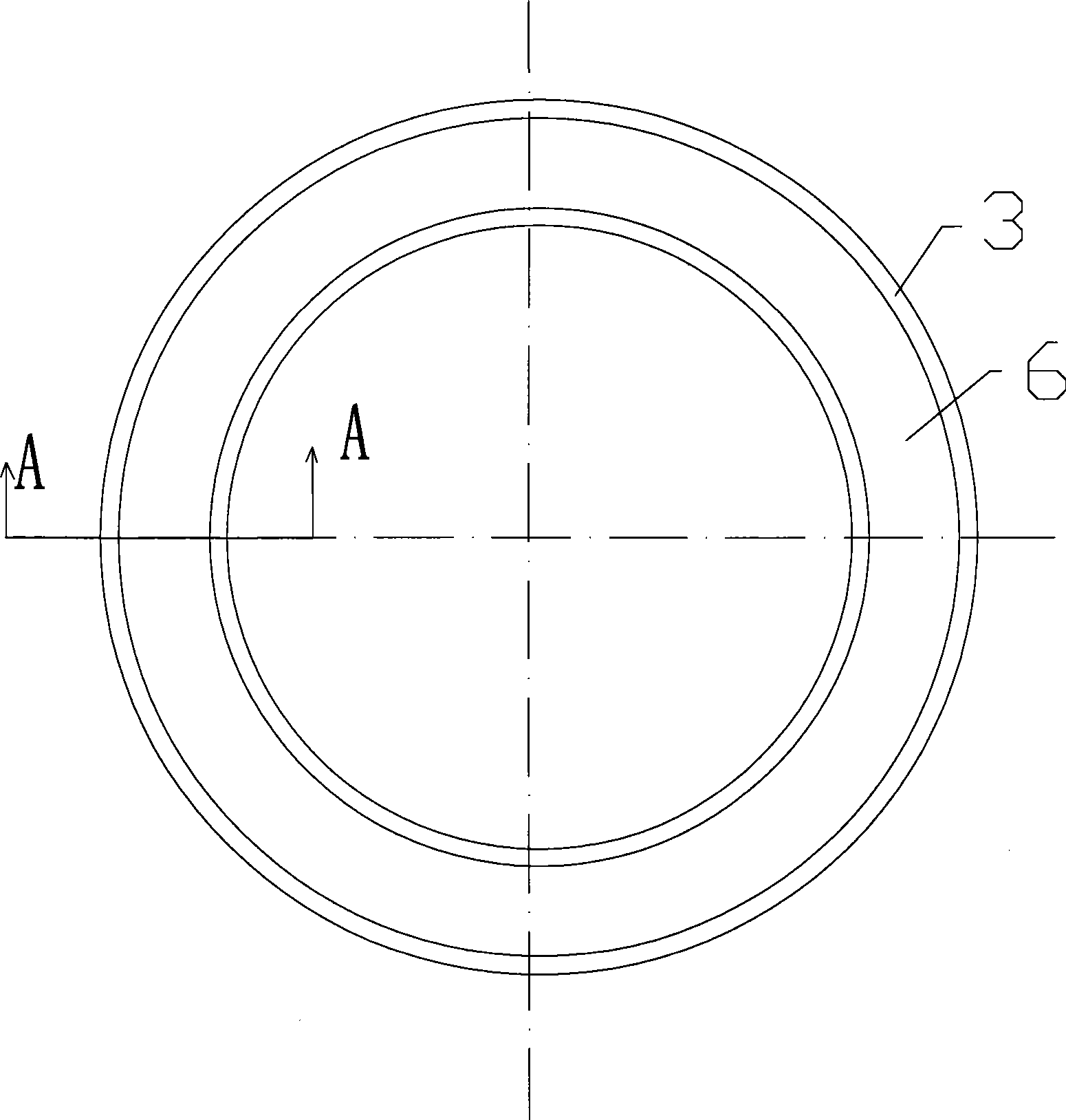

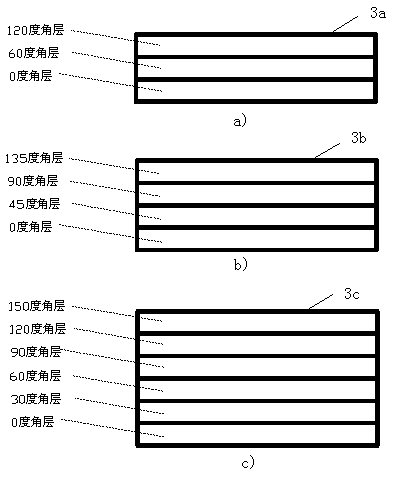

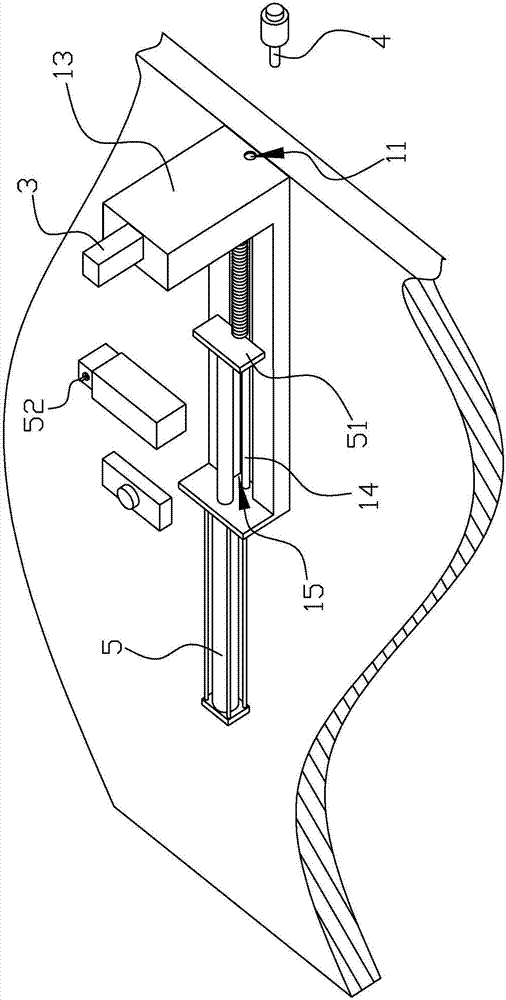

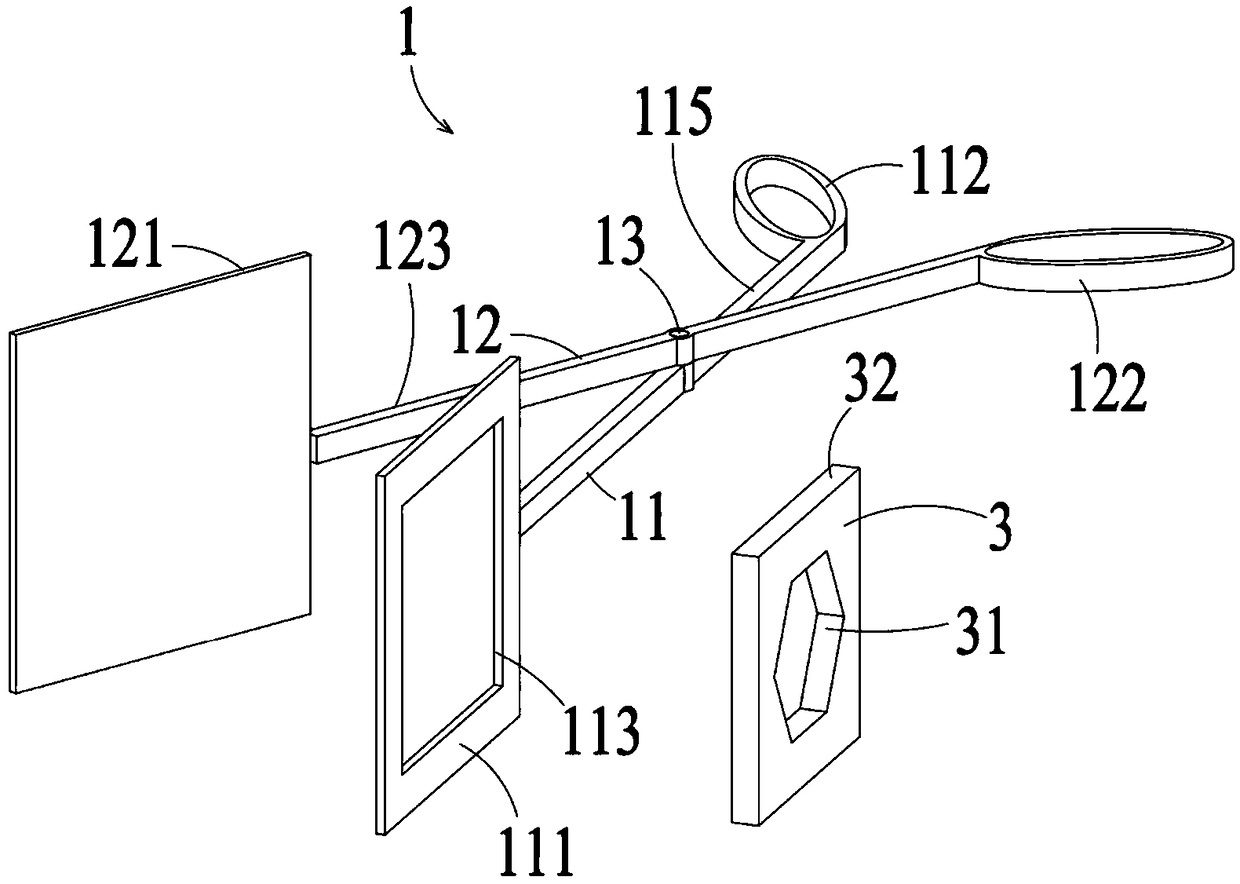

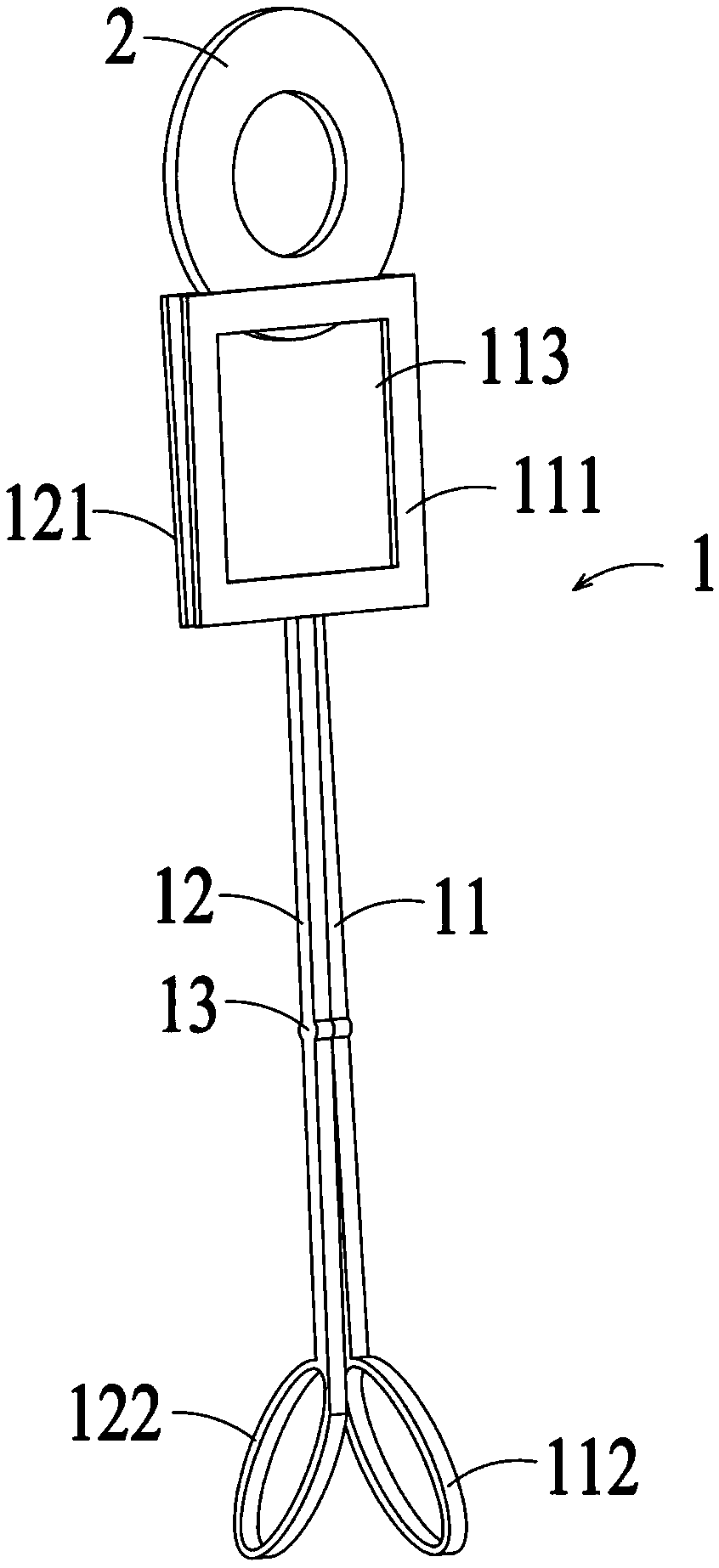

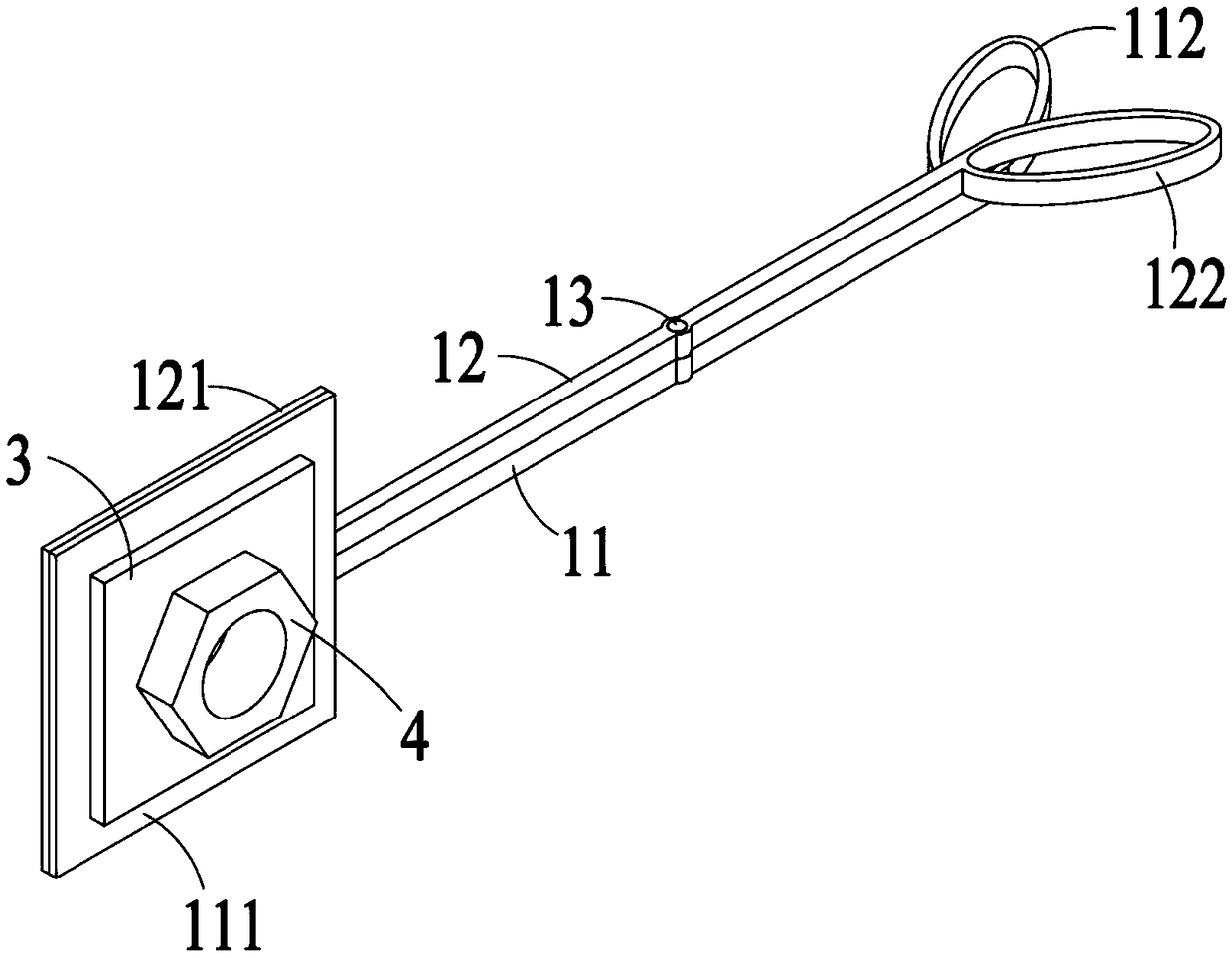

Steel pipe welding gasket installation auxiliary device

ActiveCN113714726AFit tightlyEase of welding workWelding/cutting auxillary devicesAuxillary welding devicesPipe weldingSteel tube

The invention provides a steel pipe welding gasket installation auxiliary device, and relates to the field of welding gasket installation devices. The steel pipe welding gasket installation auxiliary device comprises a main rod, a movable ring, an adjusting ring, at least three supporting legs and connecting rods, wherein the movable ring and the adjusting ring can move along the main rod, the supporting legs are arranged at intervals in the circumferential direction of the main rod, and the connecting rods are in one-to-one correspondence with the supporting legs; the bottoms of the supporting legs are hinged to the bottom of the main rod and are configured to be capable of rotating in the direction close to or away from the main rod, and the two ends of the connecting rods are hinged to the middles of the corresponding supporting legs and the movable ring respectively; and a rotating cylinder capable of rotating around the main rod is arranged at the top of the main rod in a sleeved mode, one end of the rotating cylinder is connected with an operating rod, the other end of the rotating cylinder is connected with a welding gasket abutting roller through a telescopic assembly, and the axis of the welding gasket abutting roller is parallel to the axis of the main rod. According to the steel pipe welding gasket installation auxiliary device, a welding gasket can be quickly and tightly attached to the inner wall of a steel pipe so as to facilitate welding machine operation.

Owner:CHINA FIRST METALLURGICAL GROUP +1

Adhesive-dispensing ceramic coating device and method for preventing material mixture

InactiveCN108816565AAvoid mixingImprove pass rateSpraying apparatusSpecial surfacesAdhesiveCeramic coating

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

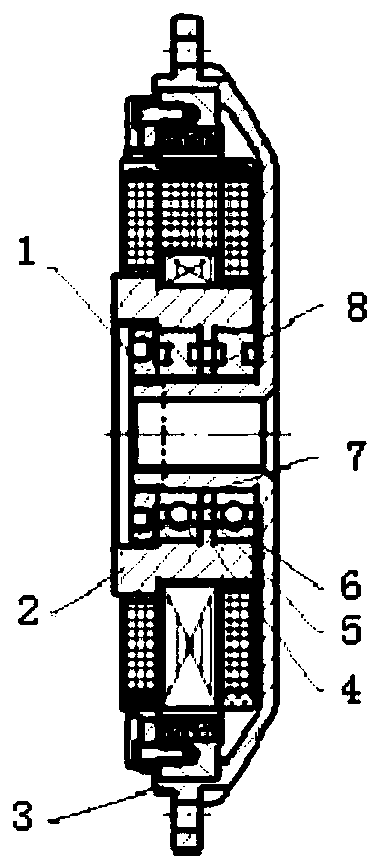

Sleeve assembly capable of improvinganti-shearing performance of anchor rod and anchor rod comprising sleeve assembly

PendingCN109578038AGood connection flexibilityReduce lateral shearAnchoring boltsSupporting systemBiochemical engineering

The invention belongs to the field of auxiliary components of anchor rods, and particularly relates to a sleeve assembly capable of improving the anti-shearing performance of an anchor rod and the anchor rod comprising thesleeve assembly. The sleeve assembly comprises a sleeve (2), the sleeve (2) is arranged at the inner side end, provided with a tray (4), of an anchor rod body (1), and an O-shaped sealing ring (3) is arranged between the sleeve (2) and the anchor rod body (1); the sleeve assembly further comprises an iron spacer (7) arranged at the outer side end of the tray (4) of the anchorrod body (1), a plastic washer (6) and a ball pad (5), and a fixed damping nut (8) is arranged at the outer end of the ball pad (5). The whole design can effectively reduce the amount of anchor rod fracturing caused by staggering of holes and surrounding rock, improve the anti-shearing capacity of an anchor rod supporting system, reduce cost of supplementary driving of anchor rods, reduce manuallabor of workers, improve the supporting effect of the anchor rods, and improve the safety ofroadway supporting.

Owner:TAIAN TAISHUO STRATUM CONTROL SCI & TECH CO LTD

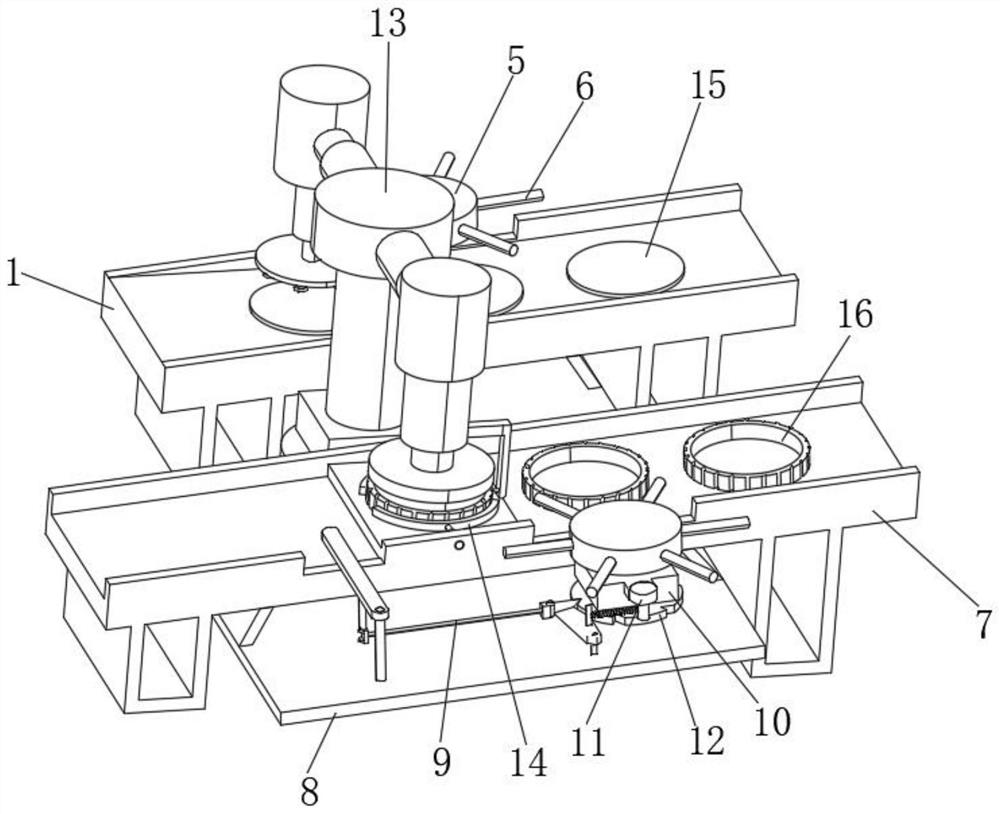

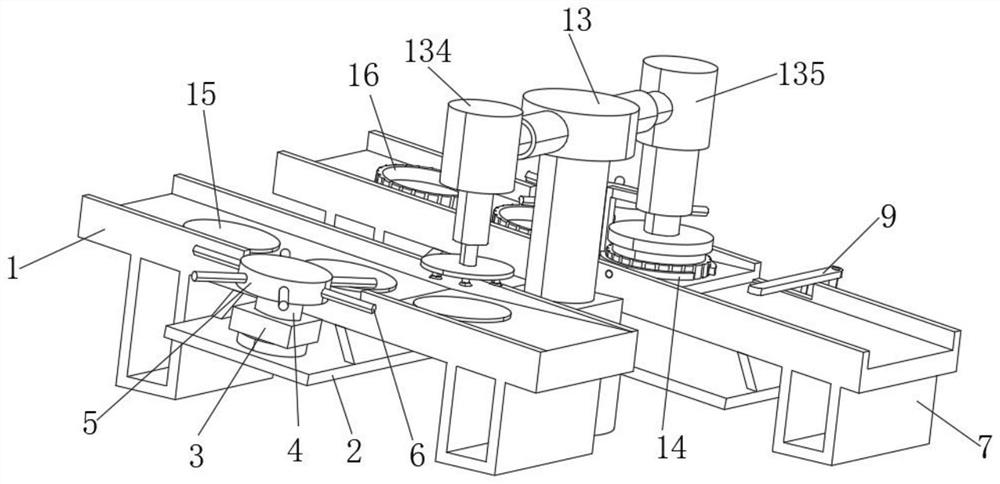

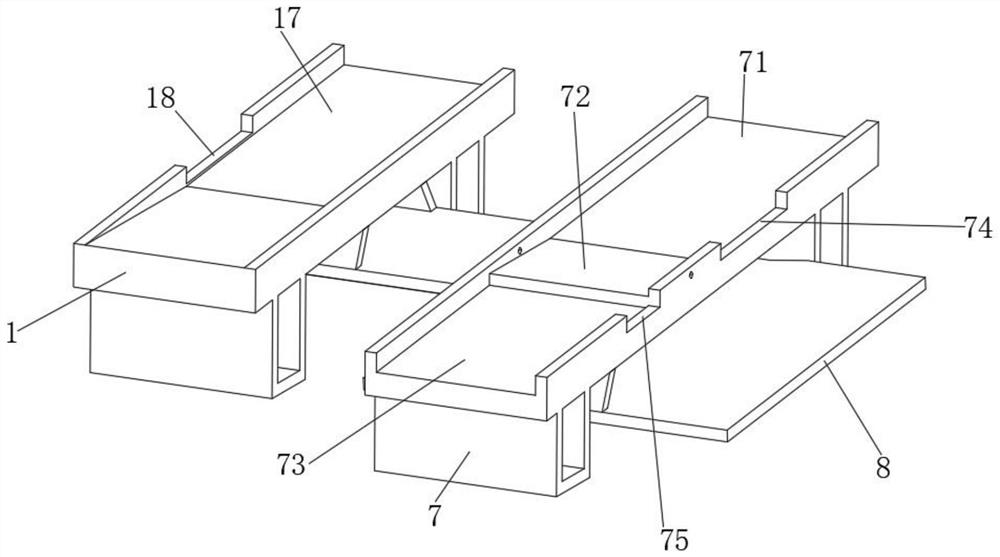

Bottle cap gasket plugging machine

PendingCN114751001ASmooth transmissionProduction rhythm is tightPackagingElectric machineControl engineering

Owner:HEFEI UNIV OF TECH

Marking face piece of hard seal with electronic recognition function, and making method of marking face piece

The invention discloses a marking face piece of a hard seal with the electronic recognition function, and a making method of the marking face piece. The marking face piece of the hard seal with the electronic recognition function, and the making method of the marking face piece are used for solving the problem that a hard seal in the prior art lacks in the technical measures for hiding an electronic chip in a seal gasket, and a worker can only carry out carving on the whole assembled seal because the electronic chip is hidden outside the seal gasket. According to the technical scheme, the marking face piece of the hard seal with the electronic recognition function is characterized in that the marking face piece is composed of a plastic marking face piece body, an electronic chip unit and aplastic closed part, a concave area is formed in the plastic marking face piece body, the wall of the concave area extends downwards and inclines inwards, a concave groove is formed in the bottom surface of the concave area, the electronic chip unit is arranged in the concave area, and forming is carried out in the manner that the concave area is filled through a secondary molding technology. Themaking method of the marking face piece is continuously carried out with the successive following technological steps, on a multi-station automatic making assembly line, of molding a plastic markingface piece body on a first molding station, tightly and fixedly bonding the electronic chip unit to the concave area on an installation station, carrying out filling to close the concave area on the secondary molding station, and removing the protruding parts through finishing on a finishing station.

Owner:SHANTOU SPECIAL ECONOMIC ZONE XIEQIN STATIONERY CO LTD

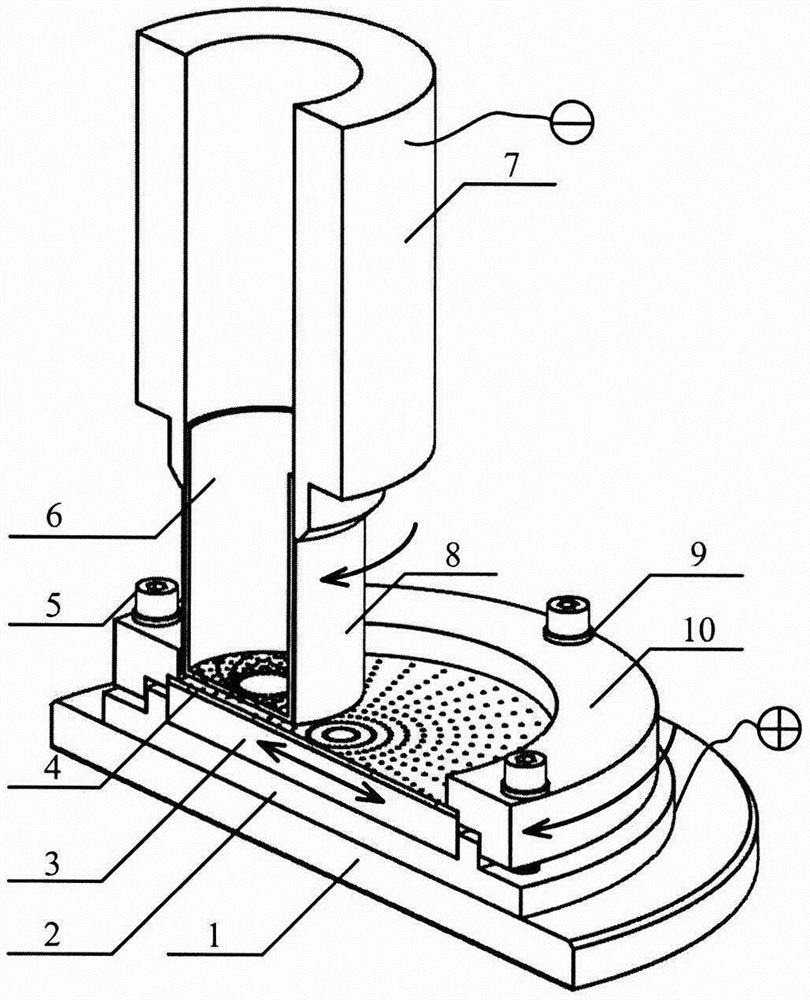

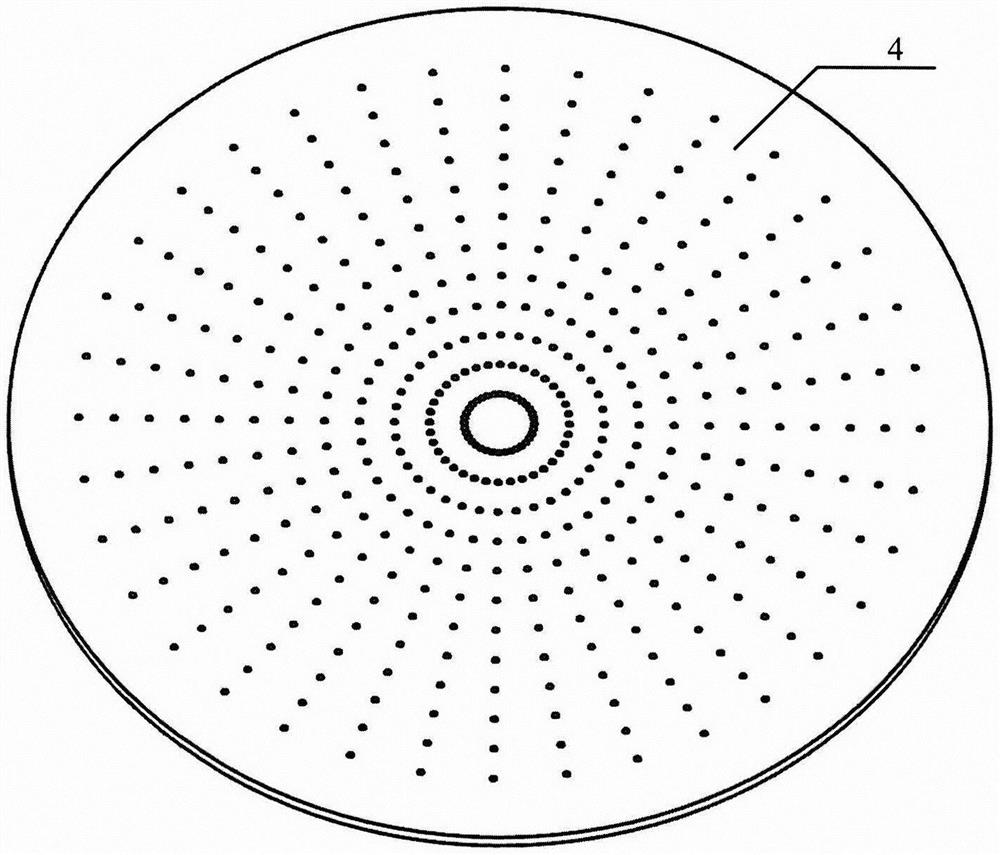

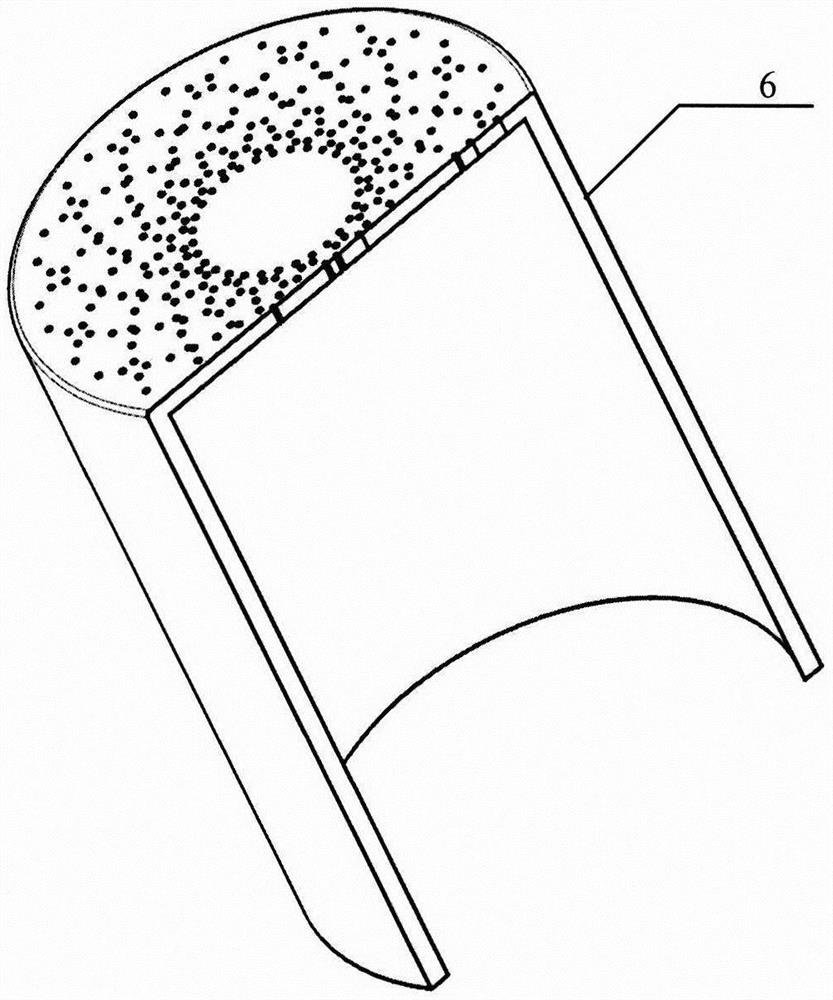

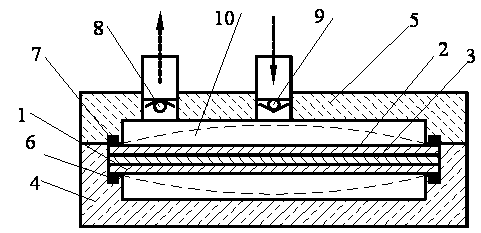

Internal liquid-spraying rotating cathode mask electrolytic machining method and implementation device

ActiveCN113878185AEliminate intermittent dissolutionEliminate warpingMachining working media supply/regenerationElectrical-based auxillary apparatusElectrolytic agentEngineering

Owner:NANJING AGRICULTURAL UNIVERSITY

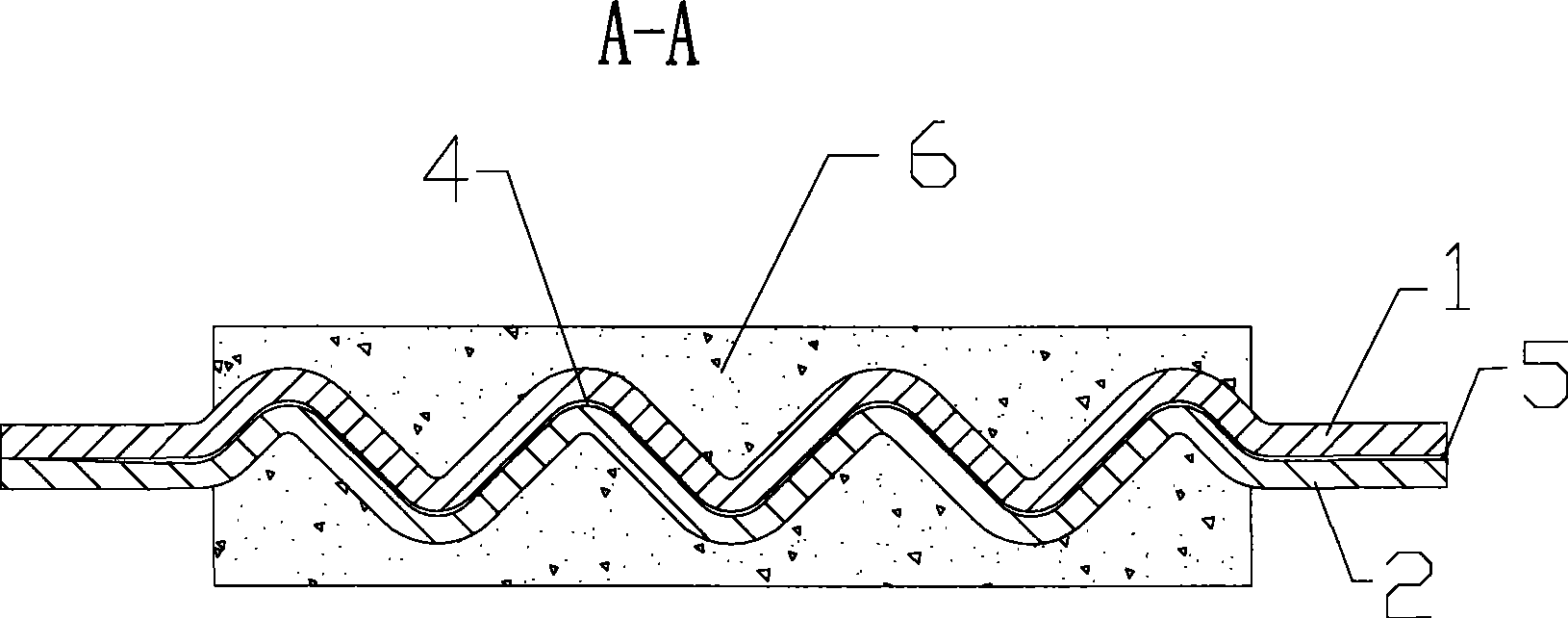

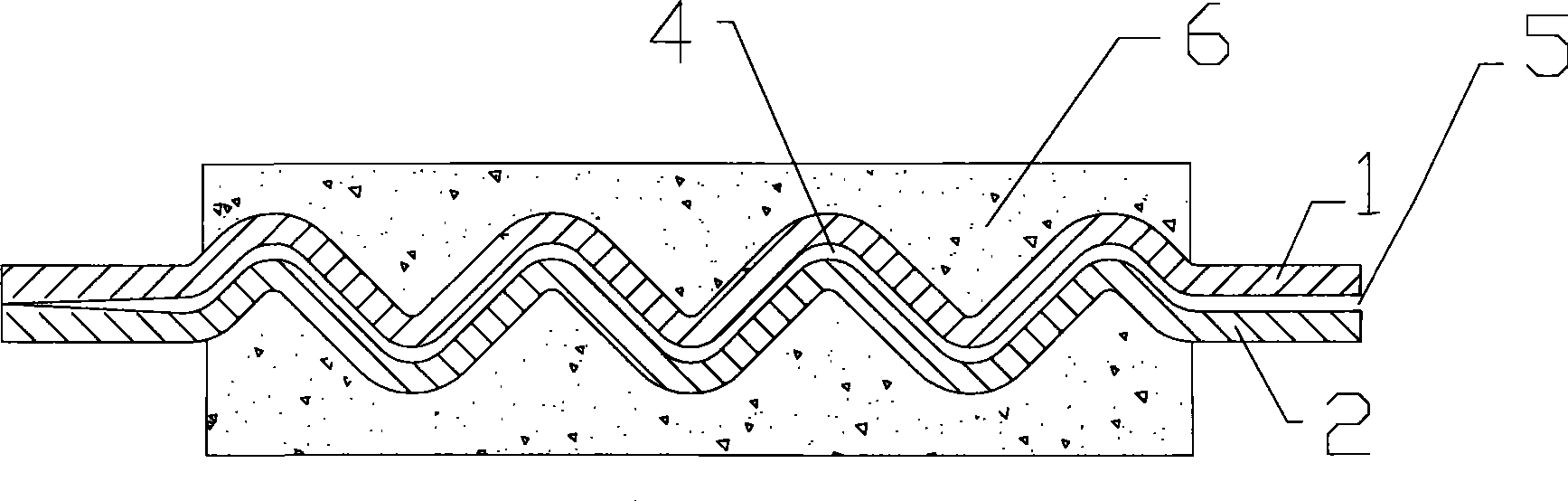

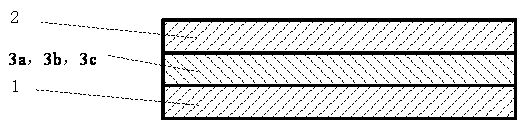

Piezoelectric pump vibrator with multiaxial fiber-reinforced resin gasket

InactiveCN103321881ALong repeated fatigue lifeHigh strengthFlexible member pumpsPositive-displacement liquid enginesGlass fiberCarbon fibers

Owner:CHONGQING ZHONGLEI SCI & TECH

Gasket combination device for screw

InactiveCN107138932AImprove combination efficiencyNot easy to looseMetal working apparatusVertical planeEngineering

Owner:ZHOUSHAN CHENGUANG ELECTRIC APPLIANCE

Clamping device for confined space in shelter power station

Owner:郑州佛光发电设备股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap