Front damping system applied to scooter

A front shock absorption and scooter technology, which is applied to bicycle accessories, axle suspension devices, transportation and packaging, etc., can solve the problems that the front shock absorption system structure is not easy to be too large, stuck, and the shock absorption system is deformed, so as to achieve disassembly and assembly Easy maintenance and replacement, uniform force, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to deepen the understanding and recognition of the present invention, the present invention will be further described and introduced below in conjunction with the accompanying drawings.

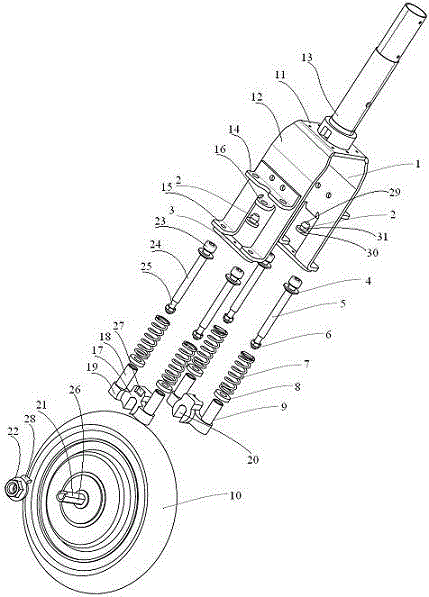

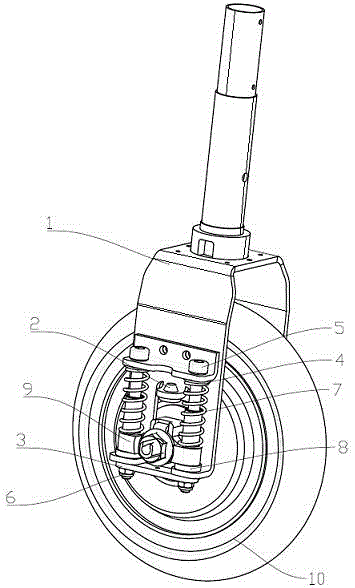

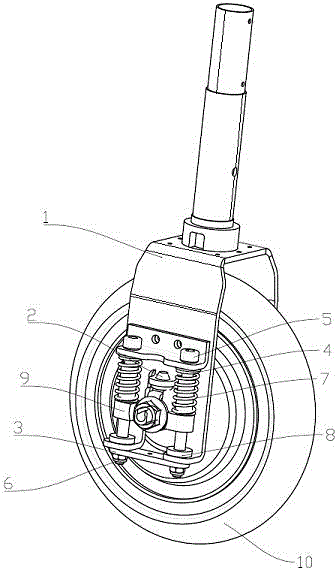

[0020] Such as figure 1 — image 3 The preferred embodiment of the present invention shown is a front damping system applied to an electric scooter, which specifically includes two damping sliders 9 fixedly mounted on the motor assembly 10, and a front fork 1 fixedly mounted on it. Four shock-absorbing slide rails 5 and shock-absorbing springs 7 sleeved on the shock-absorbing slide rails 5 . Two shock-absorbing sliders 9 are respectively arranged on both sides of the motor assembly 10, and the described shock-absorbing slide rails 5 are arranged symmetrically on both sides of the front fork 1, and all the shock-absorbing springs 7 have a pre-tightening force during installation, so that It can play a good shock-absorbing effect on the motor assembly 10 . Two damping sliders 9

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap