Automatic material discharging control device

A technology of automatic control device and automatic control system, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems that the discharge volume cannot be automatically controlled, and cannot be automatically discharged, and achieves ingenious structural design, reasonable structural design, and good quality. The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0013] Example 1

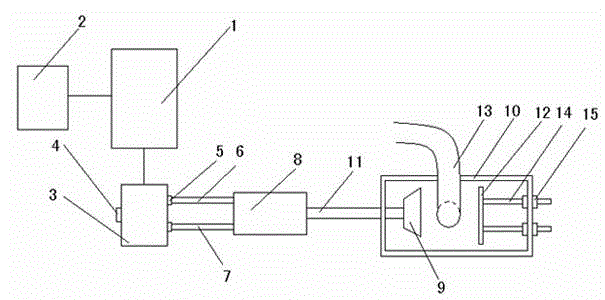

[0014] An automatic control device for discharging of this embodiment, refer to the attachment figure 1 , Including the automatic control system 1 installed on the rack, the automatic control system 1 is connected to the electronic scale 2, and the automatic control system 1 is also connected to the reversing valve 3. The reversing valve 3 is provided with an air inlet 4 and two There are two air outlets 5, and the two air outlets 5 are respectively connected to the air duct I6 and the air duct II7. The air duct I6 and the air duct II7 are both connected to the cylinder 8, and the output shaft 11 of the cylinder 8 is connected with a push plate 9. A square frame 10 is also installed on the frame. One side wall of the square frame 10 is provided with a through hole for passing the output shaft 11, and the opposite side wall of the square frame 10 is equipped with a stopper for use with the push plate 9. The plate 12 and the discharge hose 13 are arranged between t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap