Multi-pin micro-Newton colloid thrustor

A thruster and gel technology, applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problem of few research units, the impact of thruster structural parameters on thruster performance is not considered, and the detailed design of gel thrusters Unpublished reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The multi-needle microcolloid thruster of the present invention will be described in detail below in conjunction with the accompanying drawings.

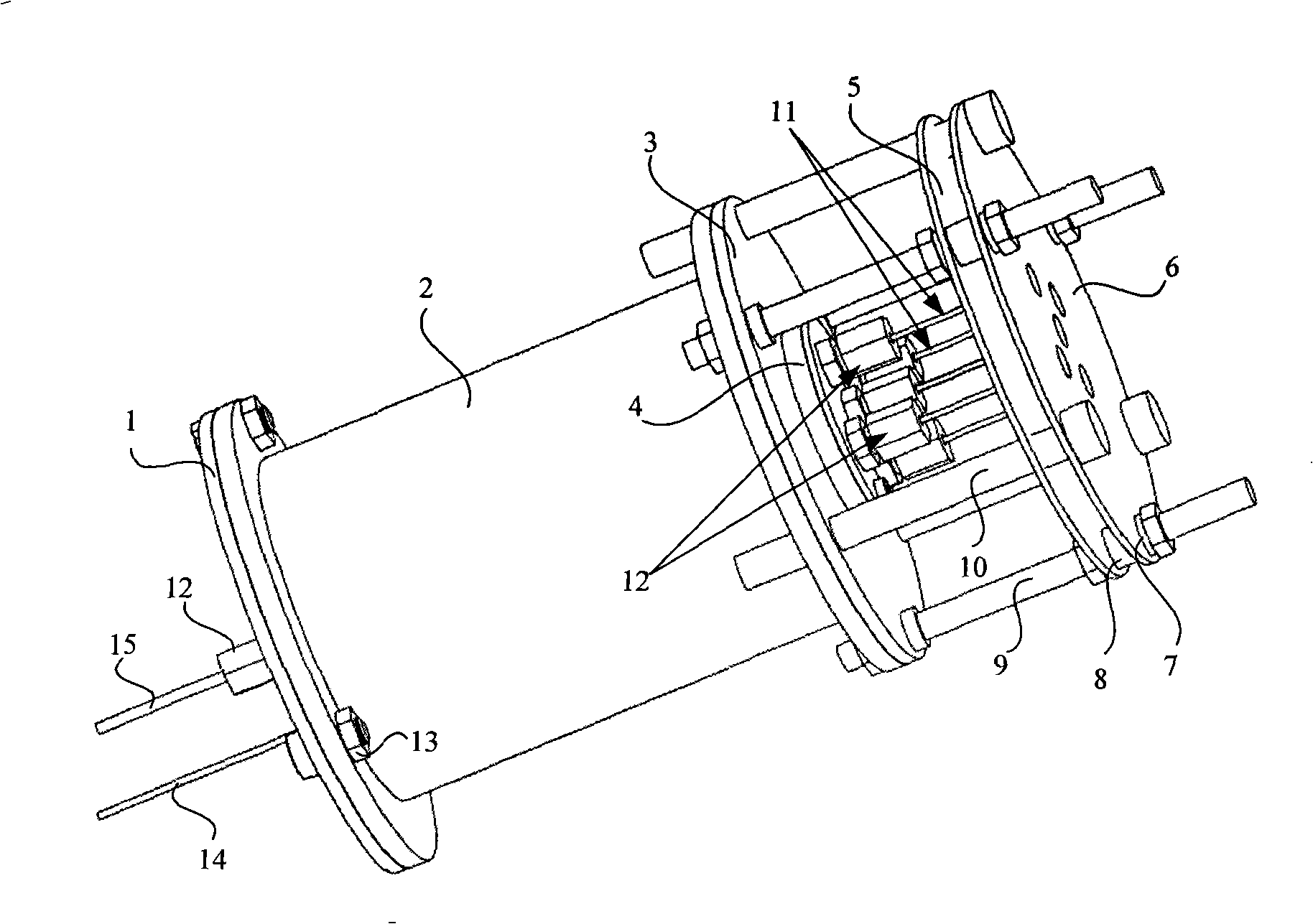

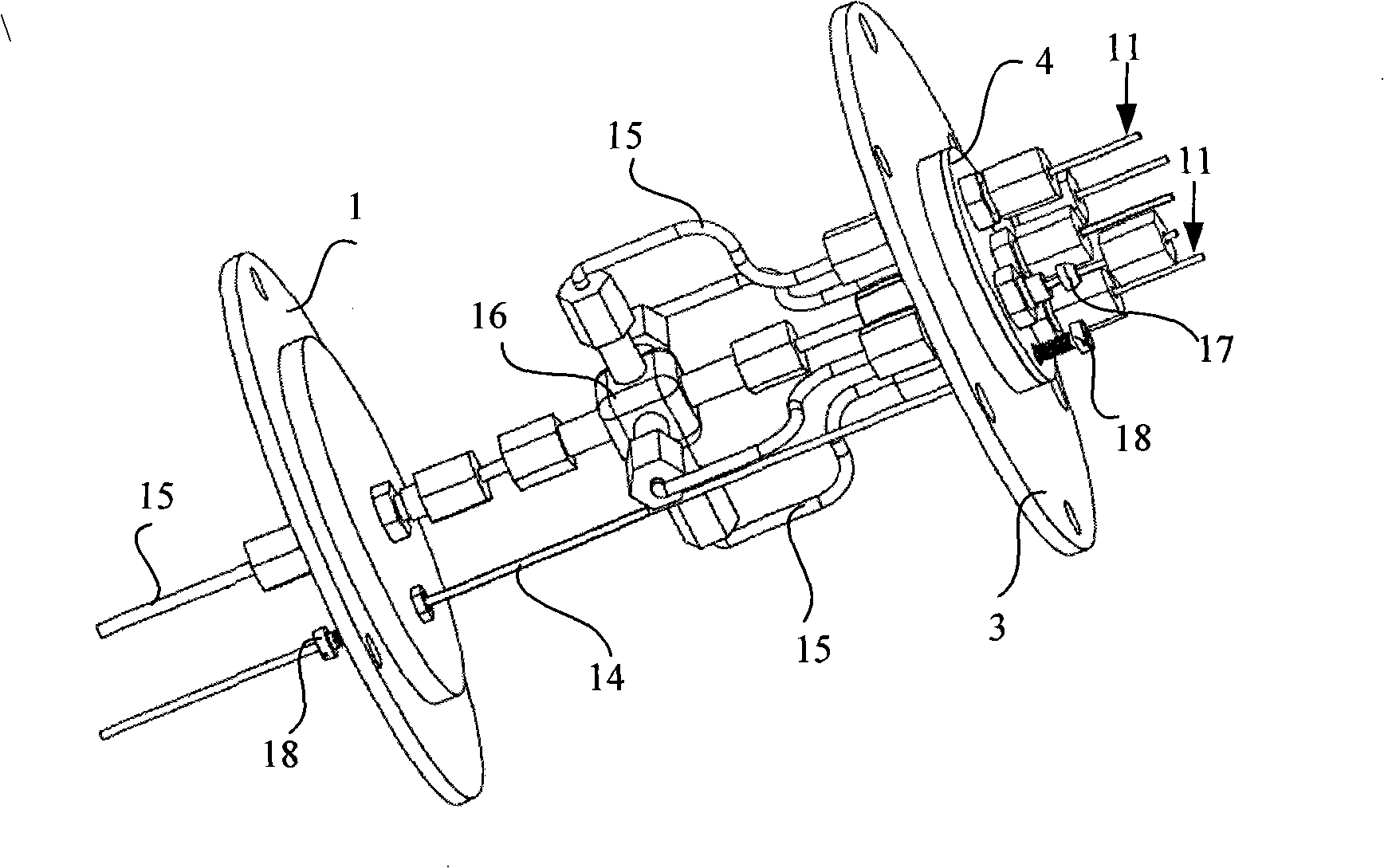

[0030] A kind of multi-needle microcolloid grade colloid thruster of the present invention, as figure 1 , figure 2 As shown, it includes insulating envelope 1, sleeve 2, through-wall joint 12, multi-way 16, capillary line 15, insulating base 3, metal gasket 4, extraction pole 5, accelerating pole 6, insulating gasket 7, insulation Collar 8 , insulating stud 9 , emitter 11 and wire 14 .

[0031] One of the capillary lines 15 is connected to the through-wall joint 12, and is connected to the multi-way 16 inside the sleeve 2 through the insulating envelope 1. The multi-way 16 is connected to a plurality of capillary lines 15 for propellant output. , which can realize single inflow and multiple outflow of propellant. The multiple capillary pipelines 15 for output are respectively connected to the through-wall joints 12 on the in

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap