Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

18 results about "Supporting system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Support system. Formal or informal network of goods, services, personnel, and organizations that sustains an entity in its survival and growth.

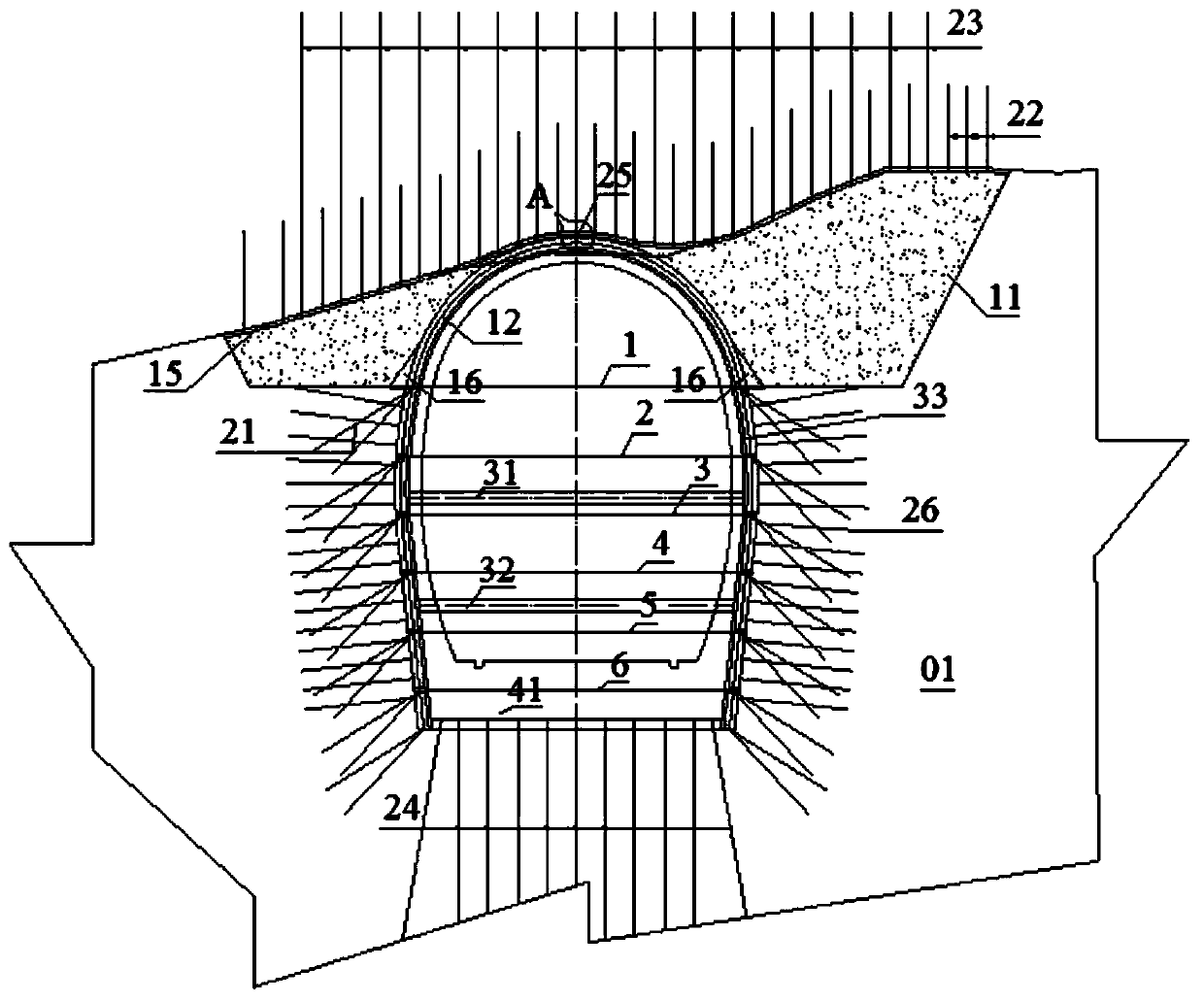

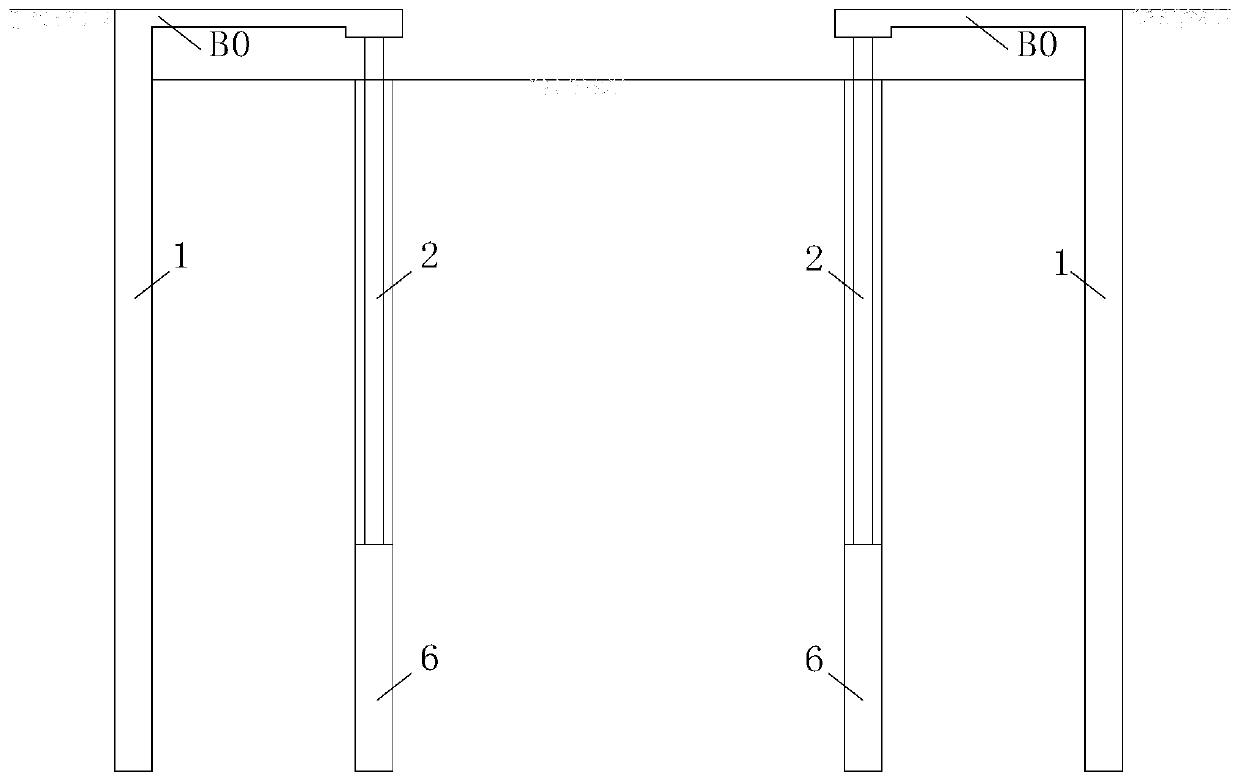

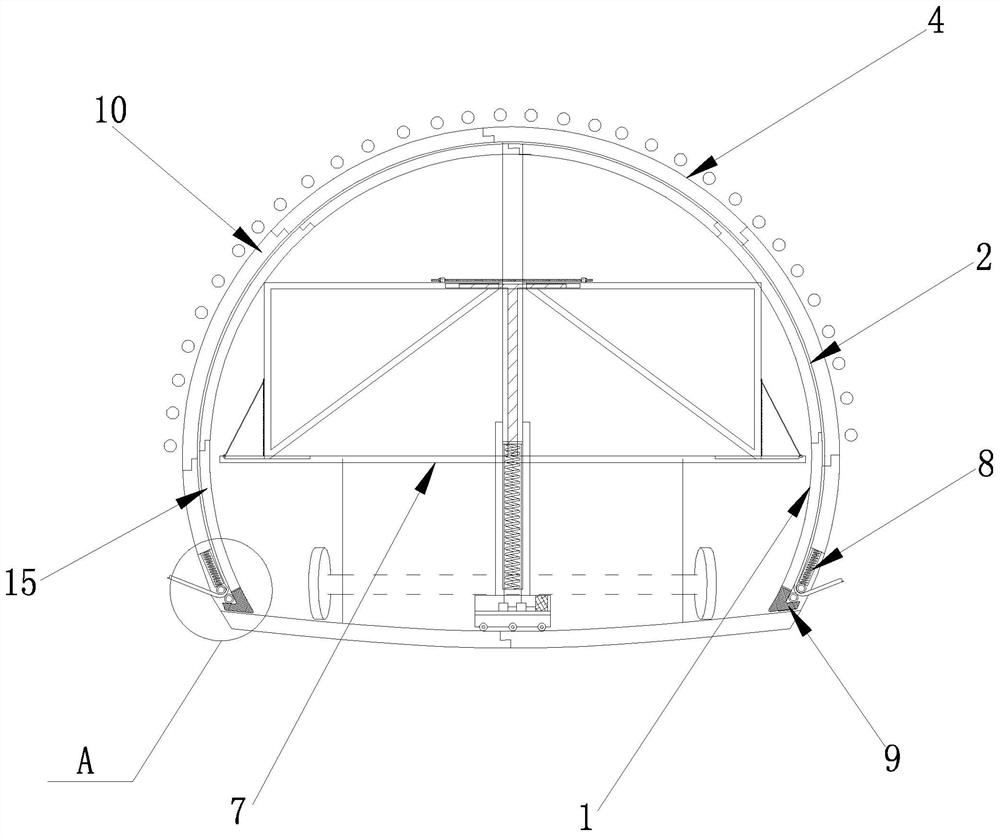

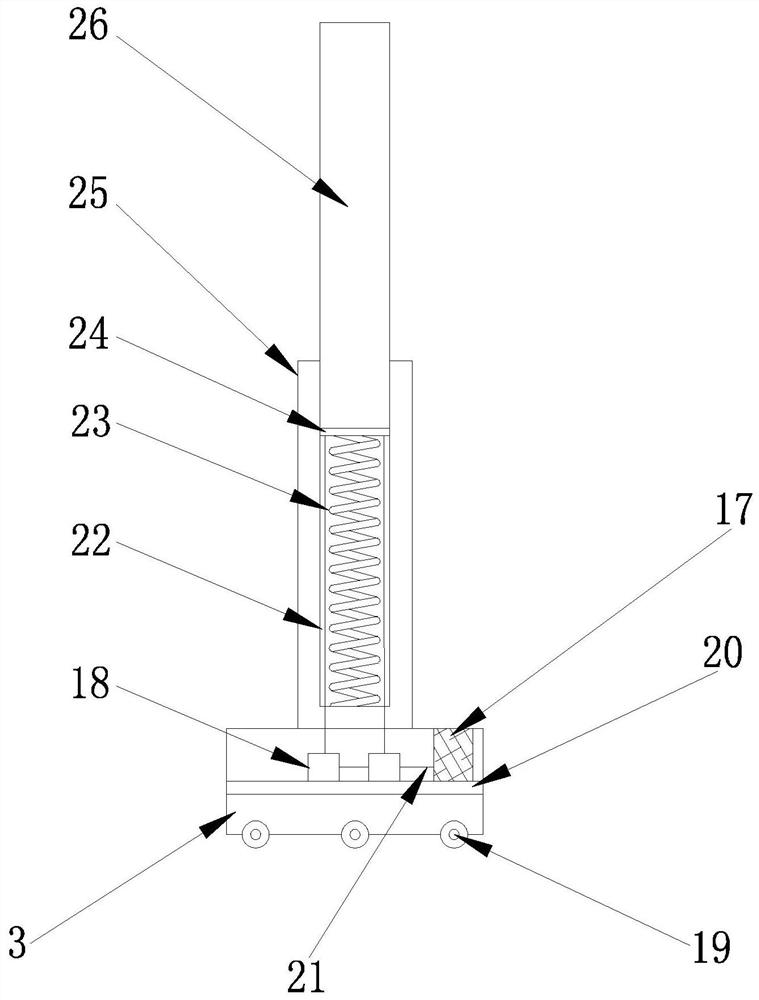

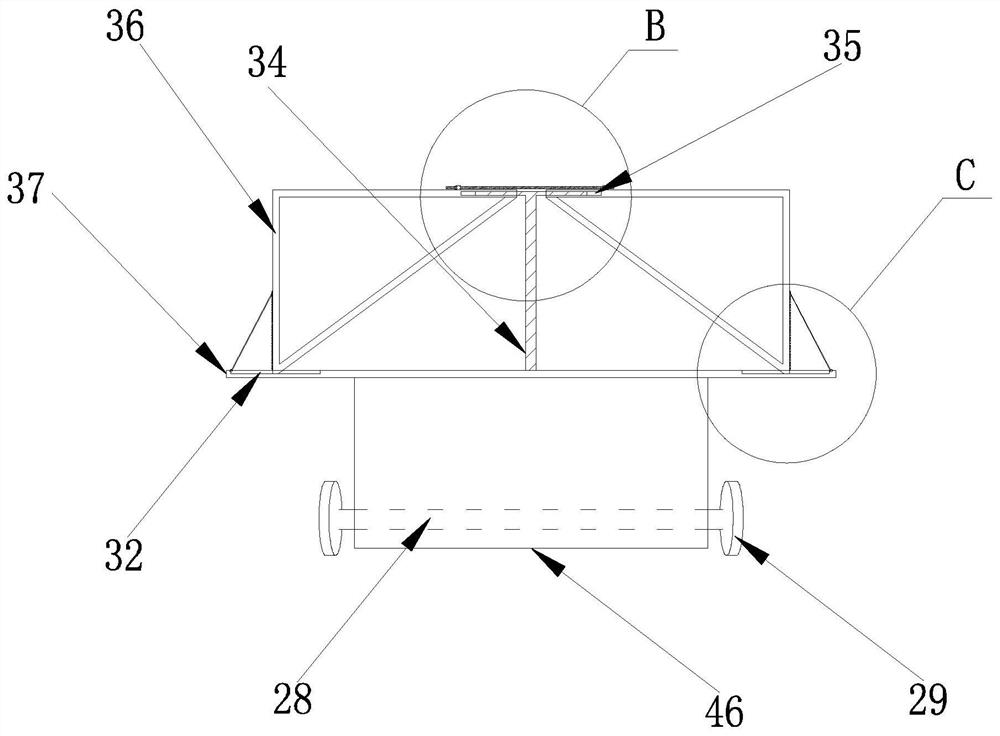

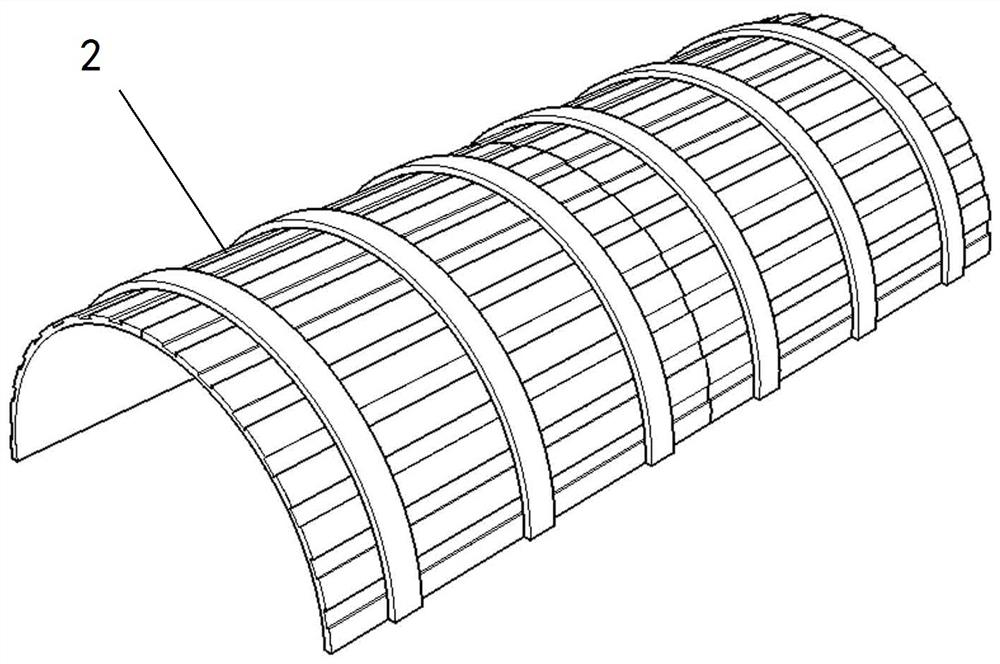

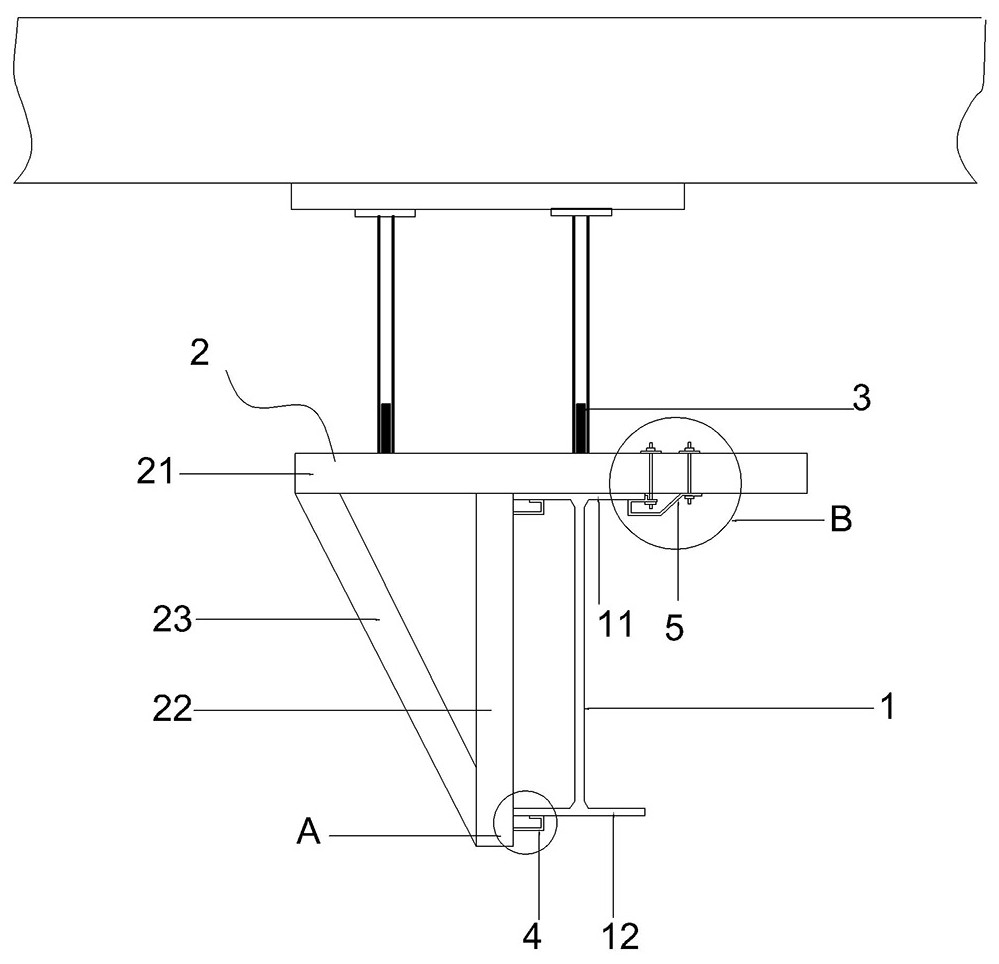

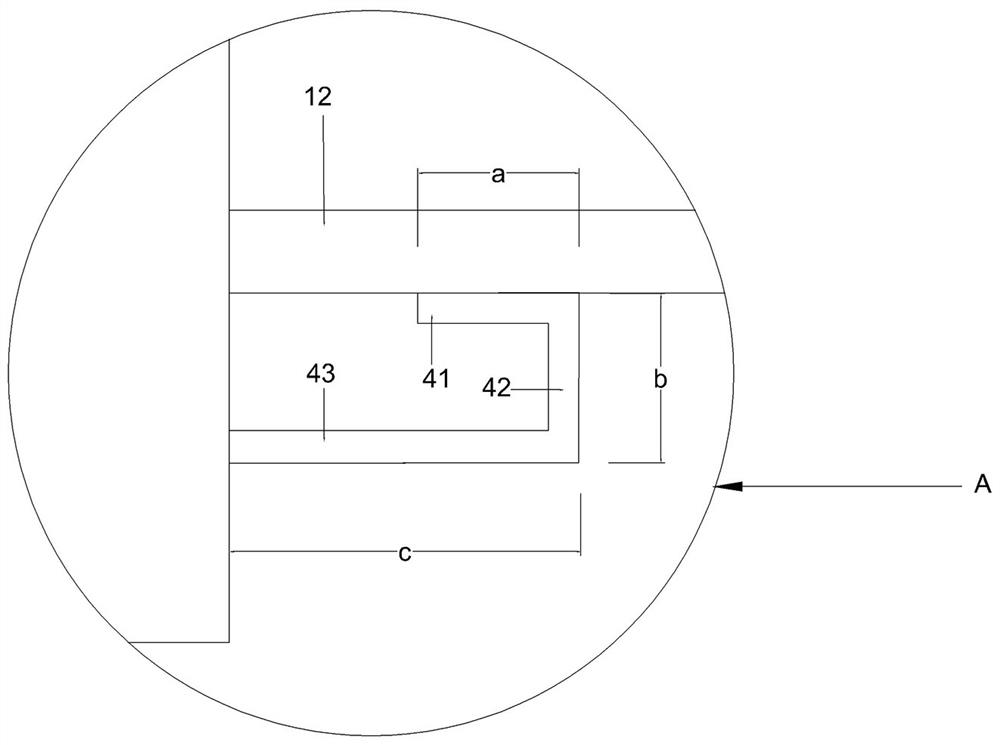

Large-section tunnel supporting system penetrating through giant karst cave hall and construction method thereof

PendingCN111411993AAvoid delayAvoid economic lossUnderground chambersMaterial fill-upSupporting systemArchitectural engineering

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

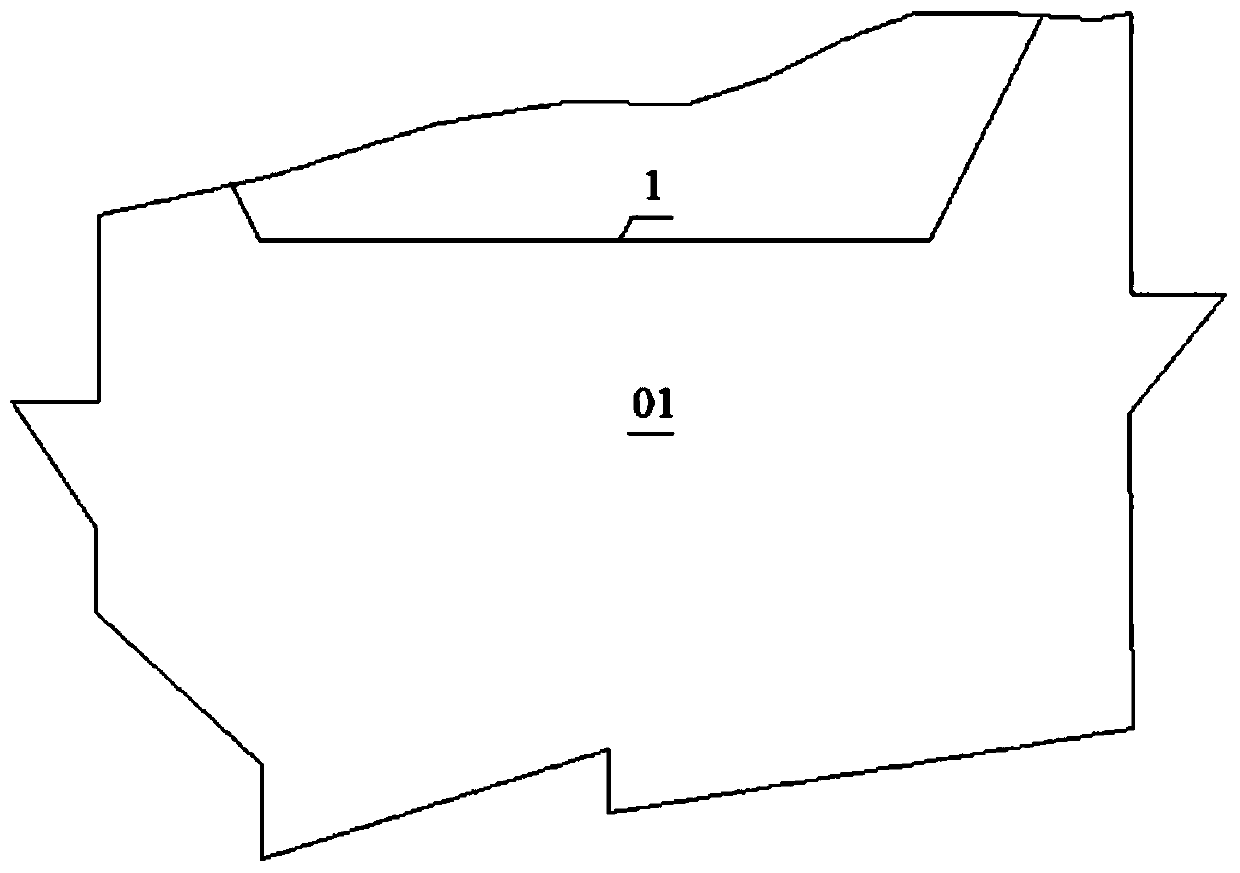

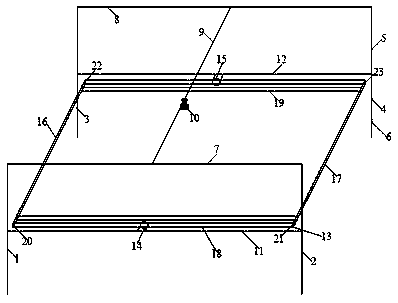

Retractable load support system

InactiveUS7189041B1Eliminate needPreventing unwanted cargo movementVehicle with removable loadingSupporting systemBraced frame

A retractable load support system for selectively raising a load from the bed of a trailer for allowing the usage of a forklift for loading and unloading the load. The retractable load support system includes a trailer having a bed, a plurality of openings within the bed, a plurality of supports extendable through the openings, a plurality of support members attached to the supports, and at least one actuator attached to the trailer and the support members for selectively lowering and raising the plurality of supports. A locking bar is extendable through locking apertures within the support members and a support frame of the trailer for locking the supports in a raised position.

Owner:POWELL MITCHELL E

Breast support system for recumbent woman and methods of use

ActiveUS20120208435A1BrassieresSupporting systemObstetrics

A breast support system for a recumbent female human includes medial and lateral supports for each breast.

Owner:HAWORTH RANDAL

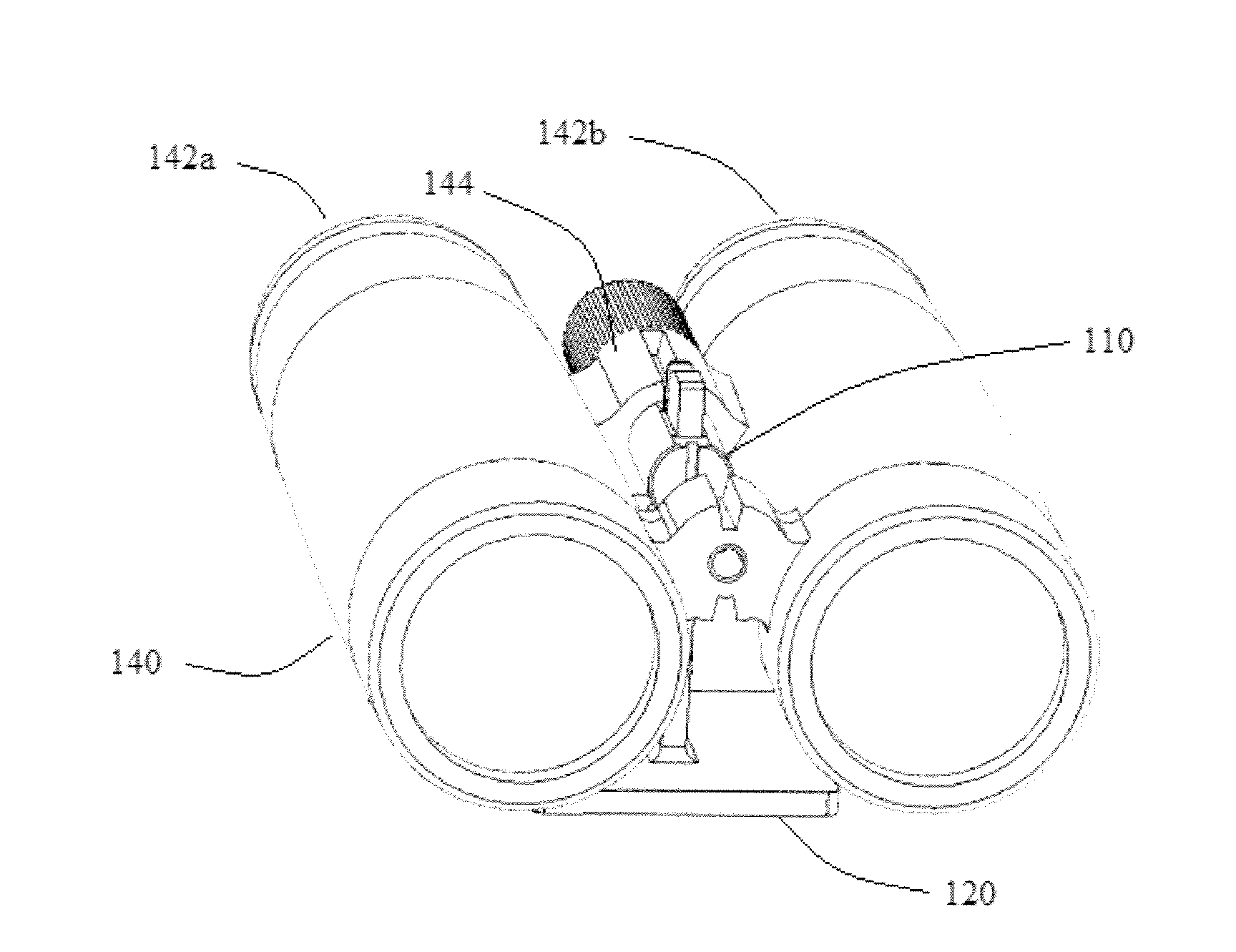

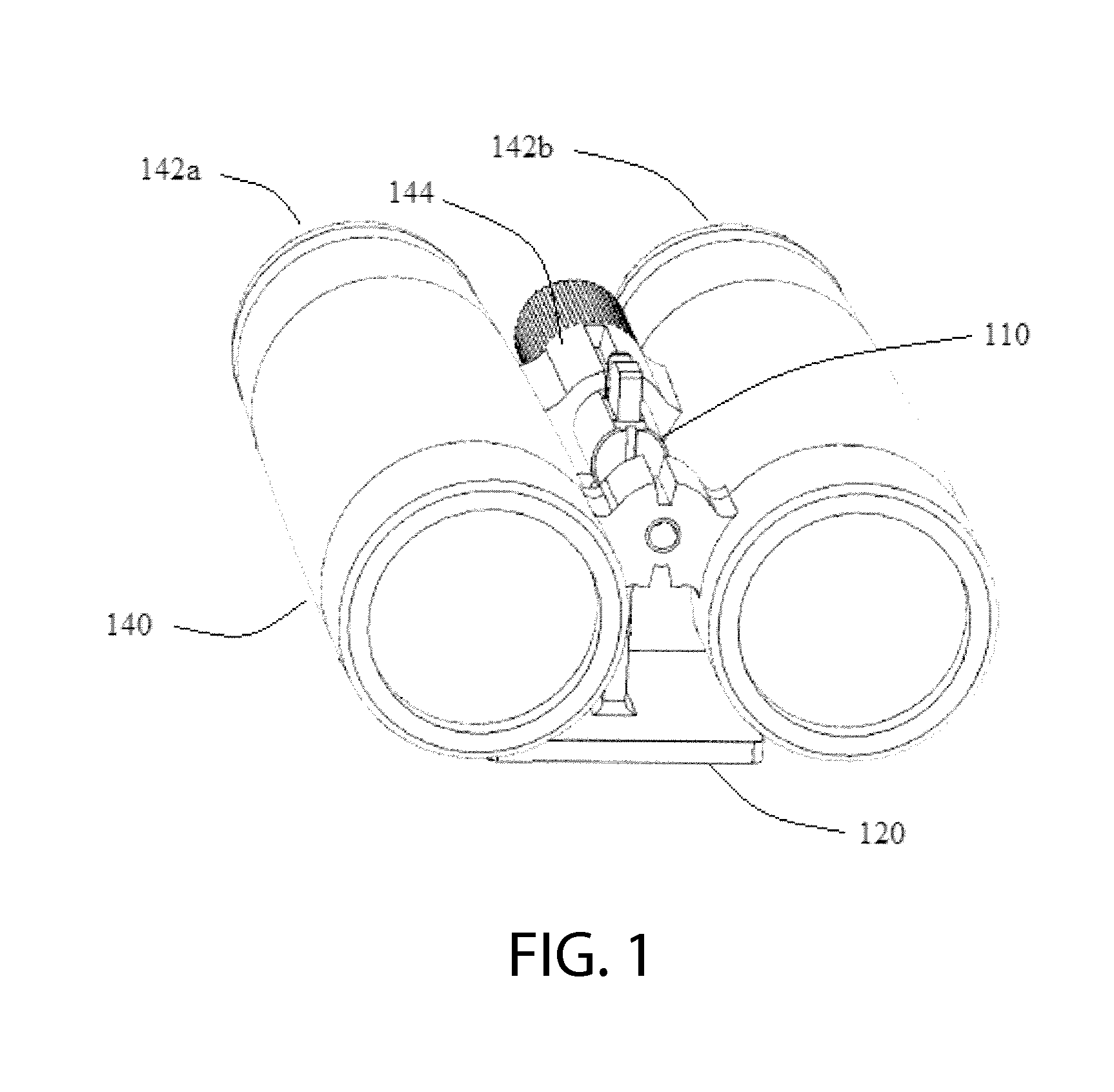

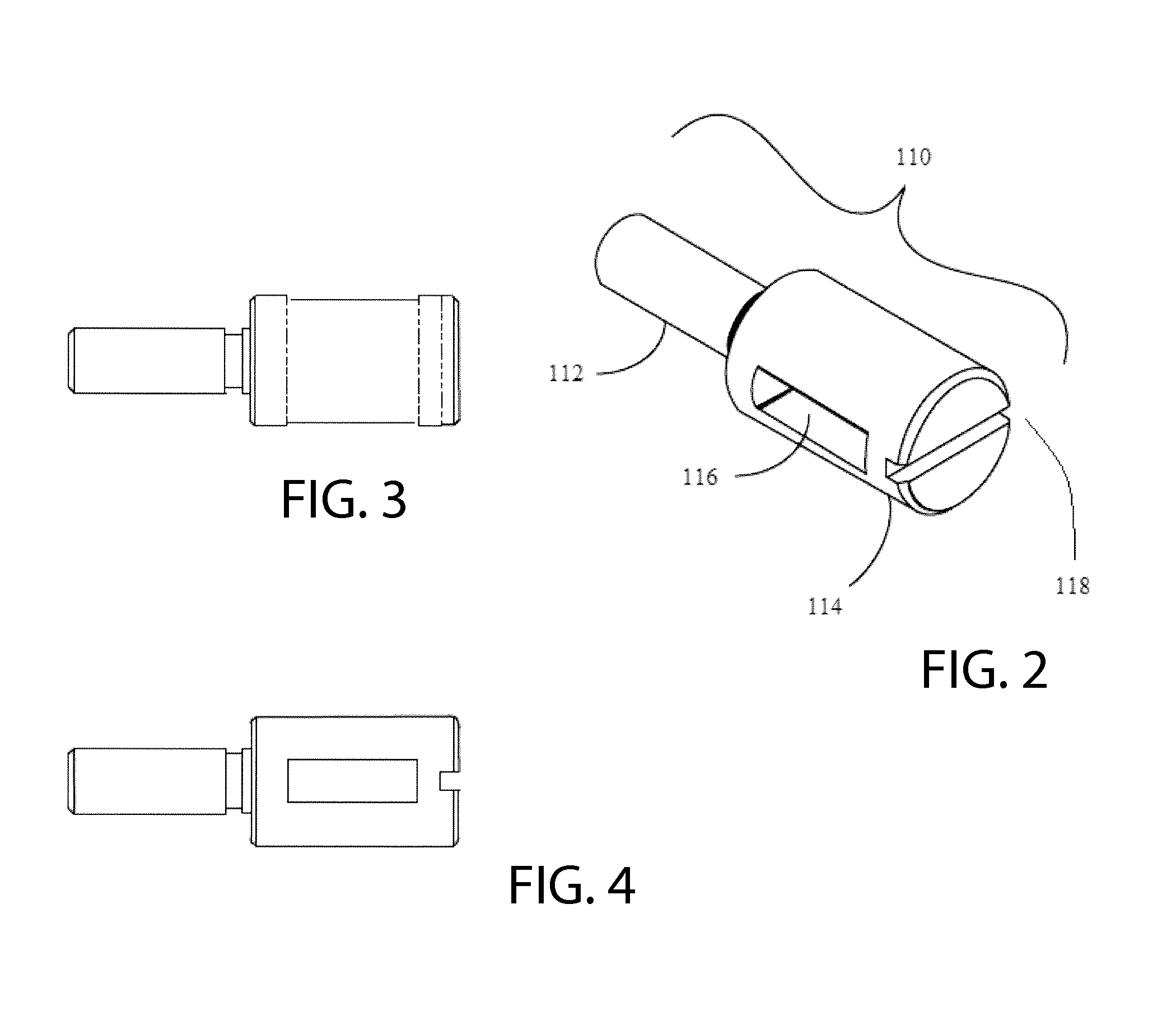

Article Supports and Adapters Therefor

Owner:FIELD OPTICS RES

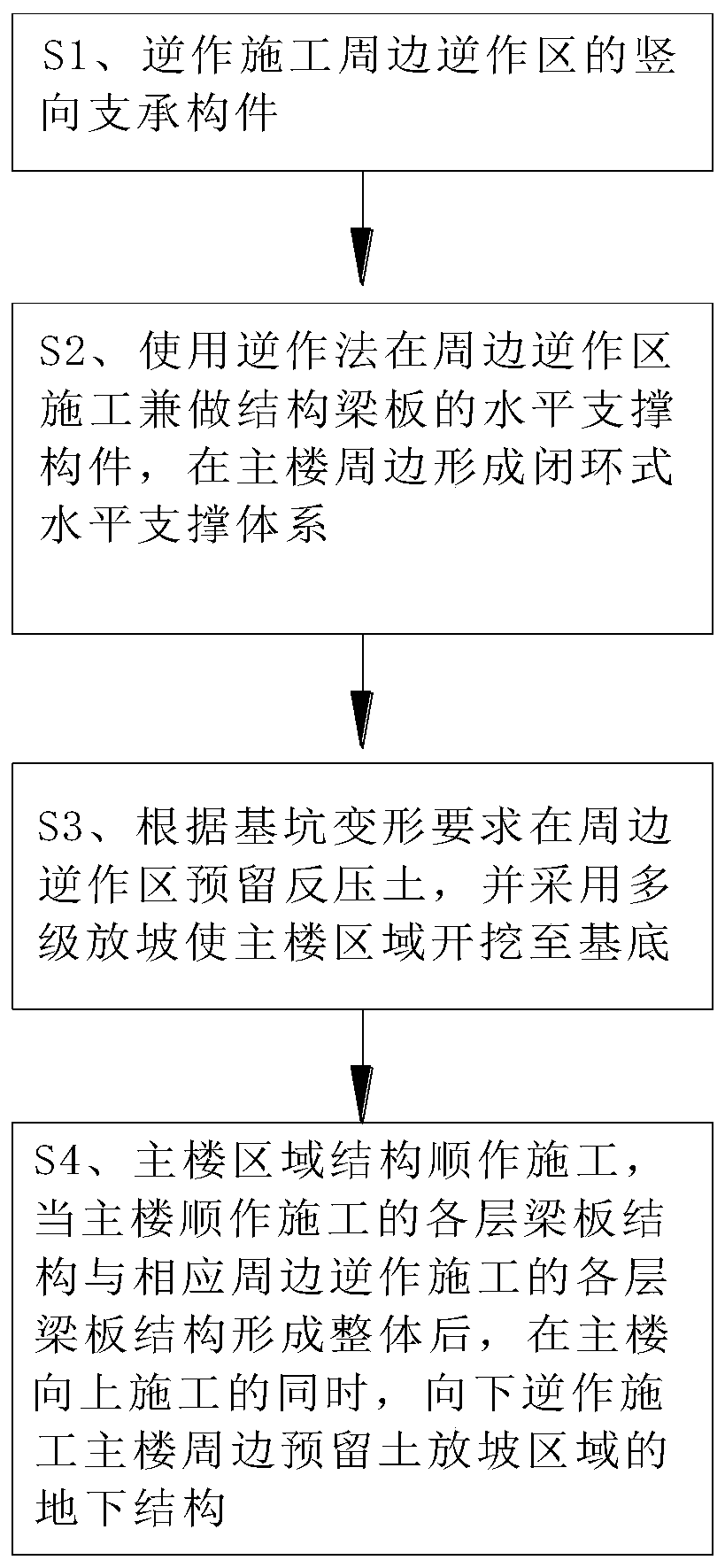

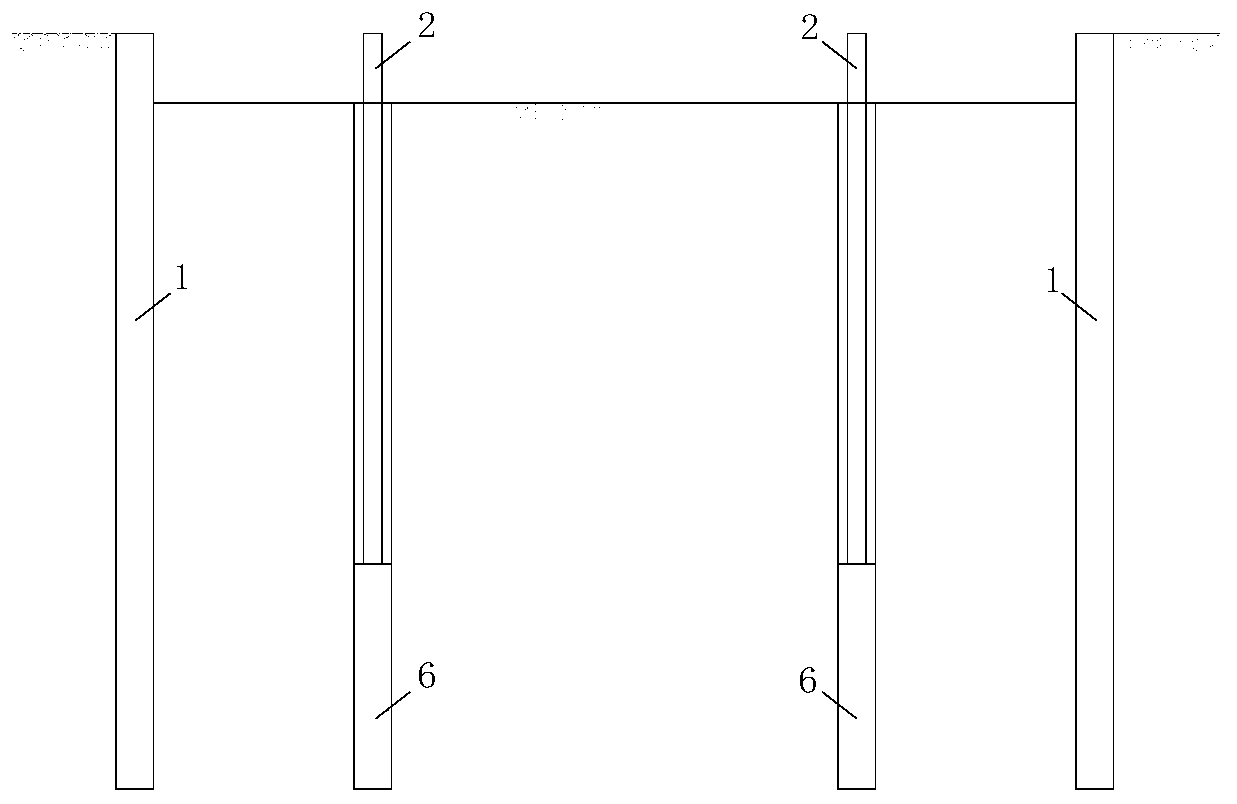

Building construction method adopting stepwise implementation of forward construction and reverse construction

InactiveCN111485578AImprove ventilationOptimizationArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

Owner:ANHUI INST OF BUILDING RES & DESIGN

Sleeve assembly capable of improvinganti-shearing performance of anchor rod and anchor rod comprising sleeve assembly

PendingCN109578038AGood connection flexibilityReduce lateral shearAnchoring boltsSupporting systemBiochemical engineering

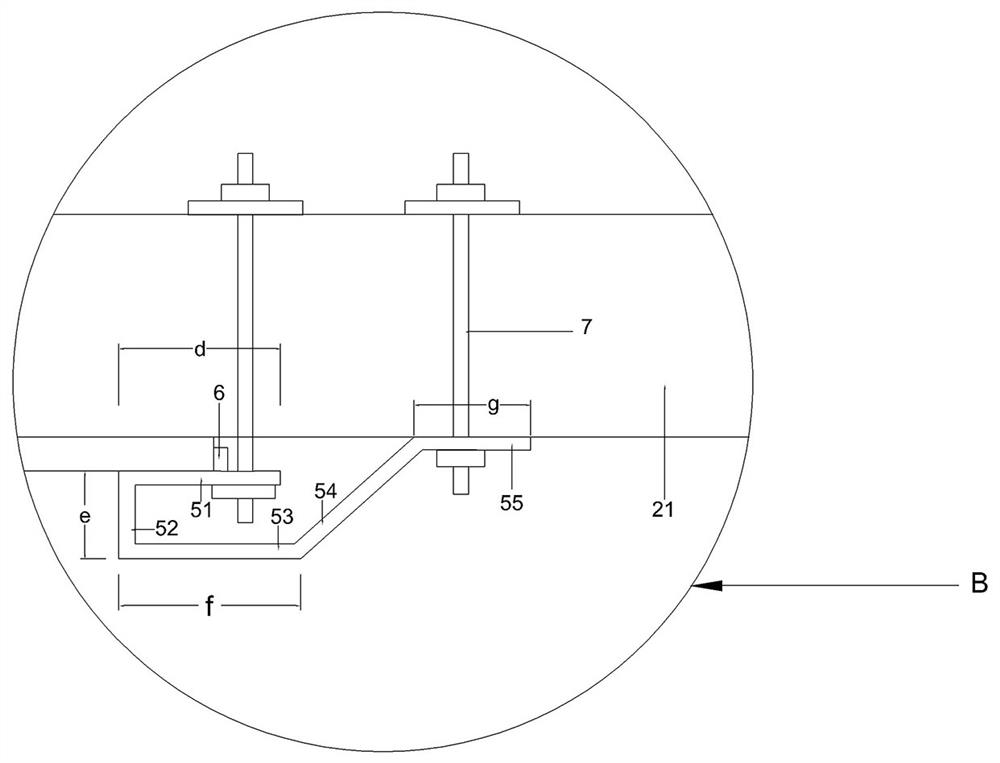

The invention belongs to the field of auxiliary components of anchor rods, and particularly relates to a sleeve assembly capable of improving the anti-shearing performance of an anchor rod and the anchor rod comprising thesleeve assembly. The sleeve assembly comprises a sleeve (2), the sleeve (2) is arranged at the inner side end, provided with a tray (4), of an anchor rod body (1), and an O-shaped sealing ring (3) is arranged between the sleeve (2) and the anchor rod body (1); the sleeve assembly further comprises an iron spacer (7) arranged at the outer side end of the tray (4) of the anchorrod body (1), a plastic washer (6) and a ball pad (5), and a fixed damping nut (8) is arranged at the outer end of the ball pad (5). The whole design can effectively reduce the amount of anchor rod fracturing caused by staggering of holes and surrounding rock, improve the anti-shearing capacity of an anchor rod supporting system, reduce cost of supplementary driving of anchor rods, reduce manuallabor of workers, improve the supporting effect of the anchor rods, and improve the safety ofroadway supporting.

Owner:TAIAN TAISHUO STRATUM CONTROL SCI & TECH CO LTD

Construction method for existing supporting system connected into subway in complex geology and environment

ActiveCN105155578AImprove adaptabilityReasonable useArtificial islandsUnderwater structuresSupporting systemAngular point

The invention discloses a construction method for an existing supporting system connected into a subway in the complex geology and environment. The construction method comprises the following steps that a point is selected from an underground diaphragm wall system to be built as a first axis point, and two intersecting surfaces of an original underground diaphragm wall supporting system of an original subway station and the underground diaphragm wall system to be built are set; a new underground diaphragm wall is built from the first axis point to the first connection surface to form a closed structure; an angular point closest to the first connection surface and the second connection surface is selected from the closed structure as a second axis point, and then two rows of third three-axis mixing piles are driven on the left side and the right side of a set third new underground diaphragm wall to be built from the second axis point to the second connection surface; and cement is poured into the spaces among first three-axis mixing piles, second three-axis mixing piles and the third three-axis mixing piles in sequence to form the first new underground diaphragm wall, the second new underground diaphragm wall and the third new underground diaphragm wall. By means of the method, the structural stability and the waterproof effect are improved.

Owner:CHINA CONSTR SIXTH ENG BUREAU CIVILENG +1

Construction support system and construction method for tunnel water burst

ActiveCN112412499APrevent water leakageSimple construction methodUnderground chambersHydro energy generationSupporting systemWater leakage

Owner:魏良帅

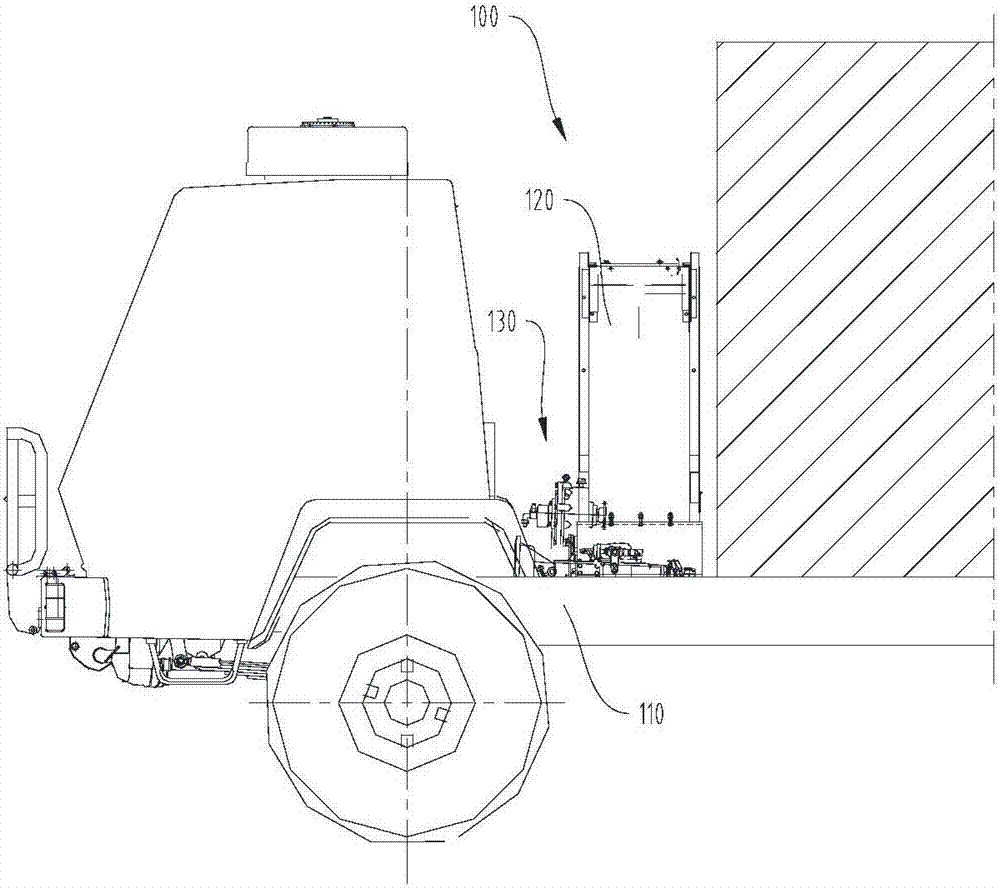

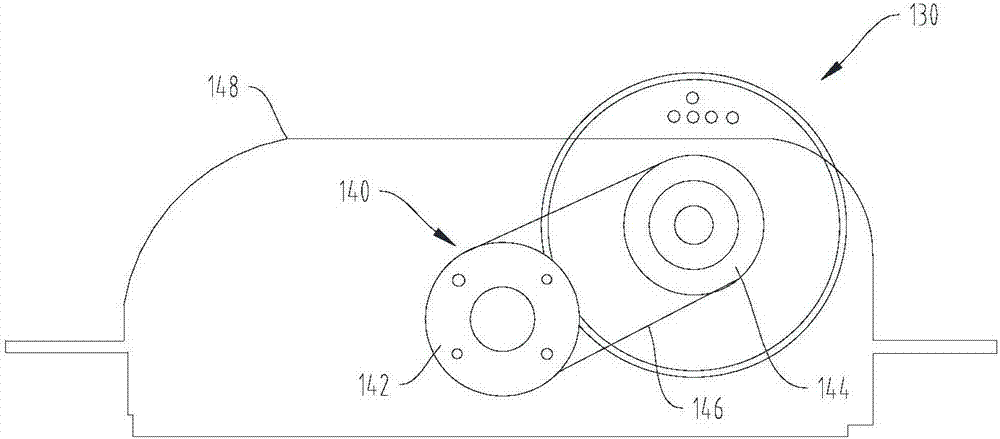

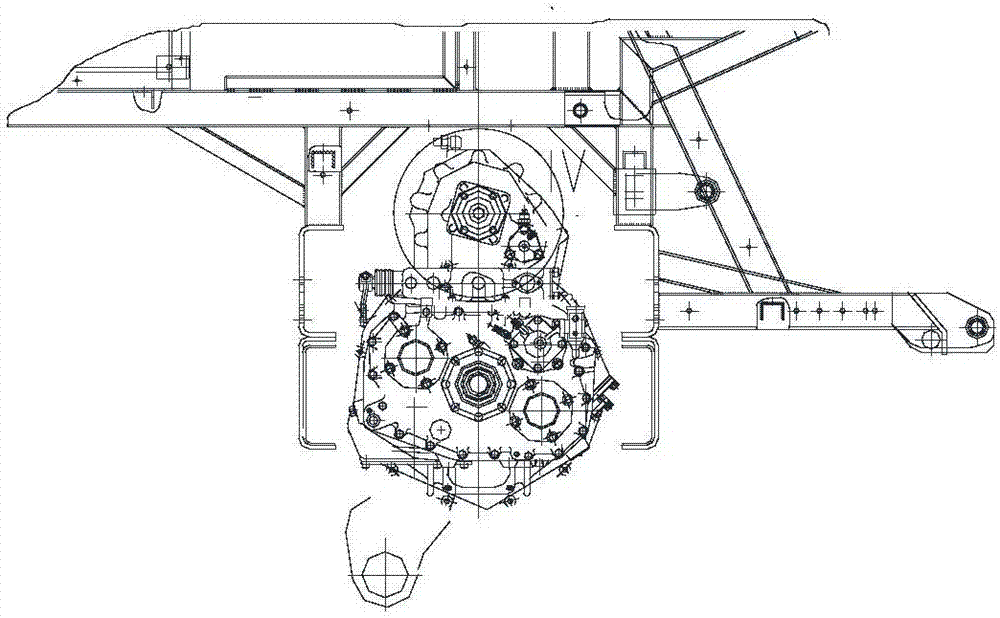

Power generation system and carrier device

Owner:TELLHOW SCI TECH CO LTD

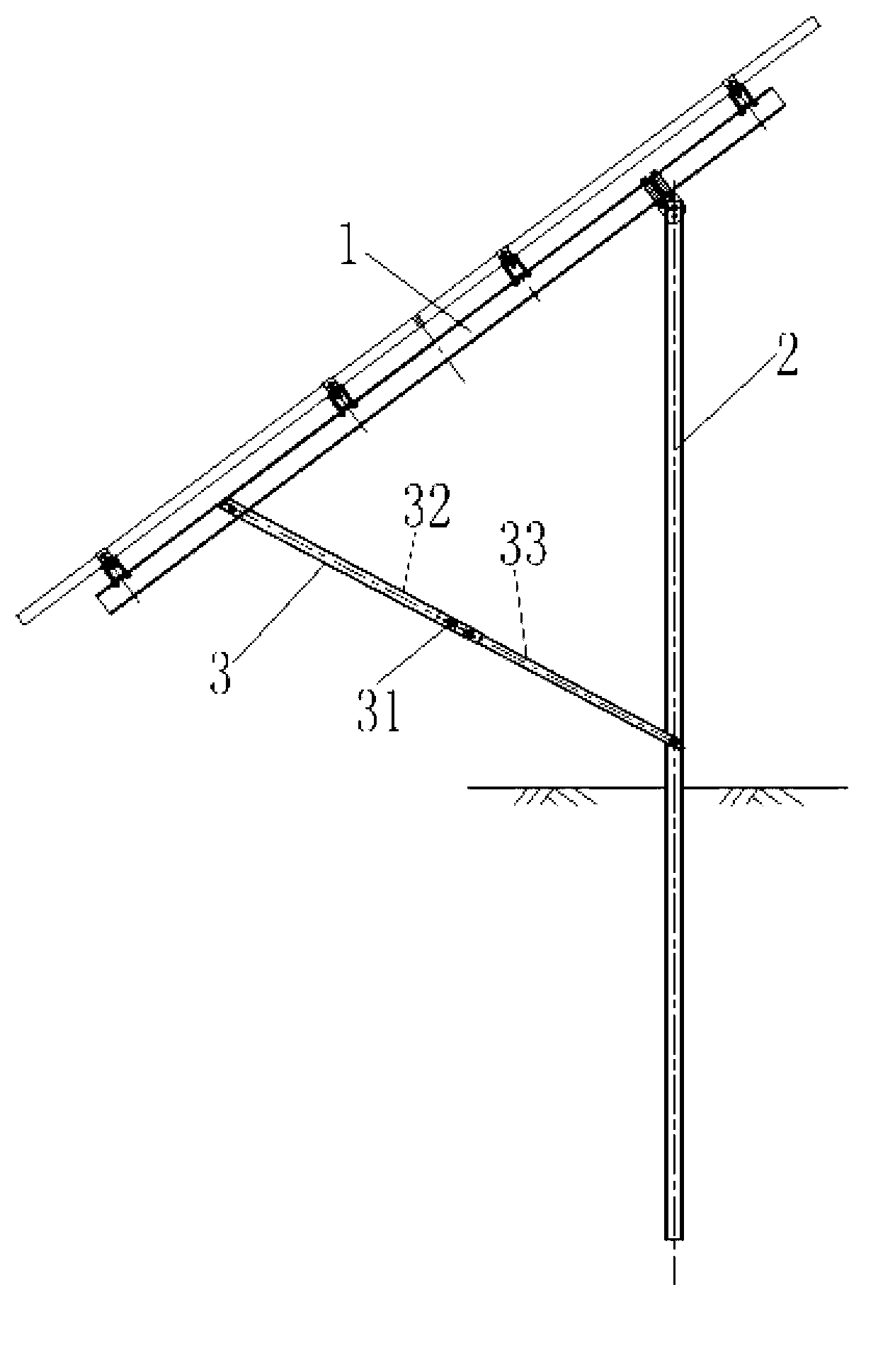

Integrated fine-adjustable fixing photovoltaic support system for ground independent column

InactiveCN103022186AEffective regulationWill not cause secondary pollutionPhotovoltaic supportsPhotovoltaic energy generationSupporting systemEngineering

Owner:SHANGHAI INTELLIGENCE POWER ENG CO LTD

Electromagnetic field resistant support garment

InactiveUS20180130564A1Increased riskReduce and eliminate breast exposureGarmentsBrassieresSupporting systemEngineering

A system and method are disclosed for a support system that can work with a variety of different garments. A support garment that has a non-conductive support wire is described. The non-conductive support wire is capable of shielding the body of the wearer from potentially harmful electromagnetic fields. A method of manufacturing a support garment is also described, which includes adding the non-conductive support wire to the support garment.

Owner:HARDMAN BRENNA ANN

Motorcycle part casting machining system

InactiveCN106607575AReduce labor intensityRealize continuous supplyMolten metal conveying equipmentsSupporting systemMachining system

Owner:重庆市巴南区龙亚机械厂

Medium front and back printing device and printing method

InactiveCN109177520AFlipReduce complexityTypewritersOther printing apparatusSupporting systemMotor drive

Owner:合肥经新科技有限公司

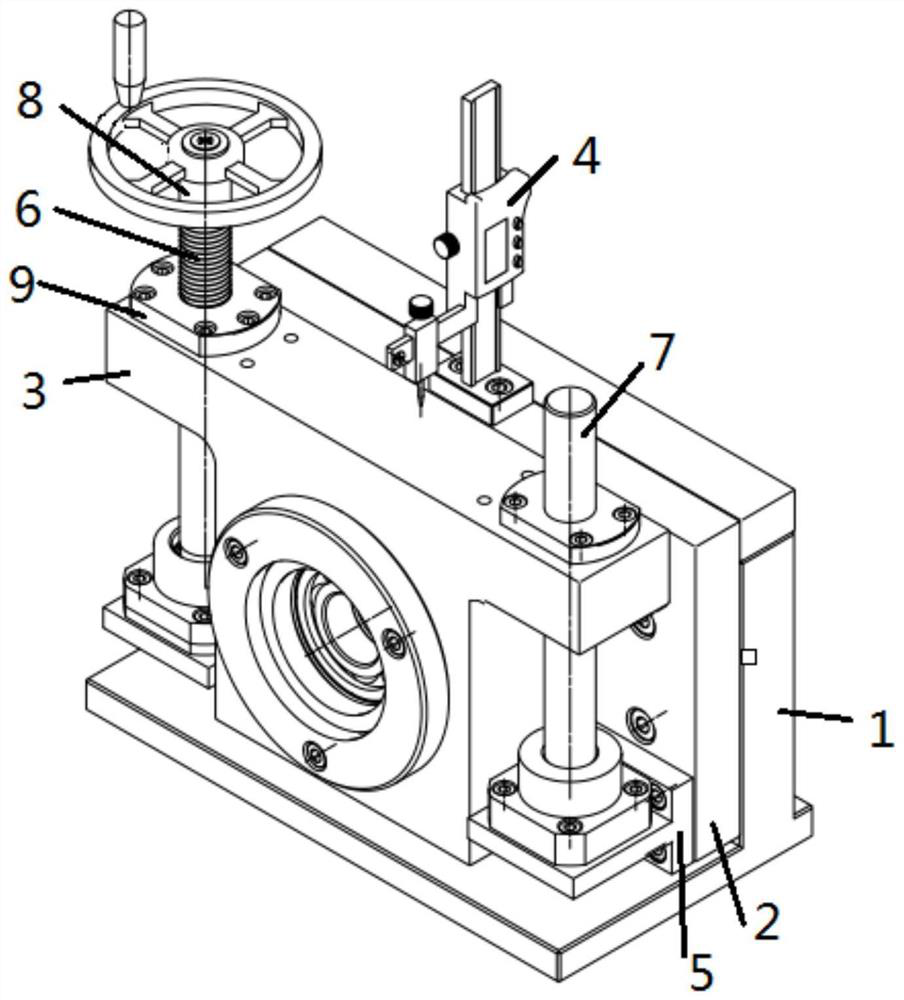

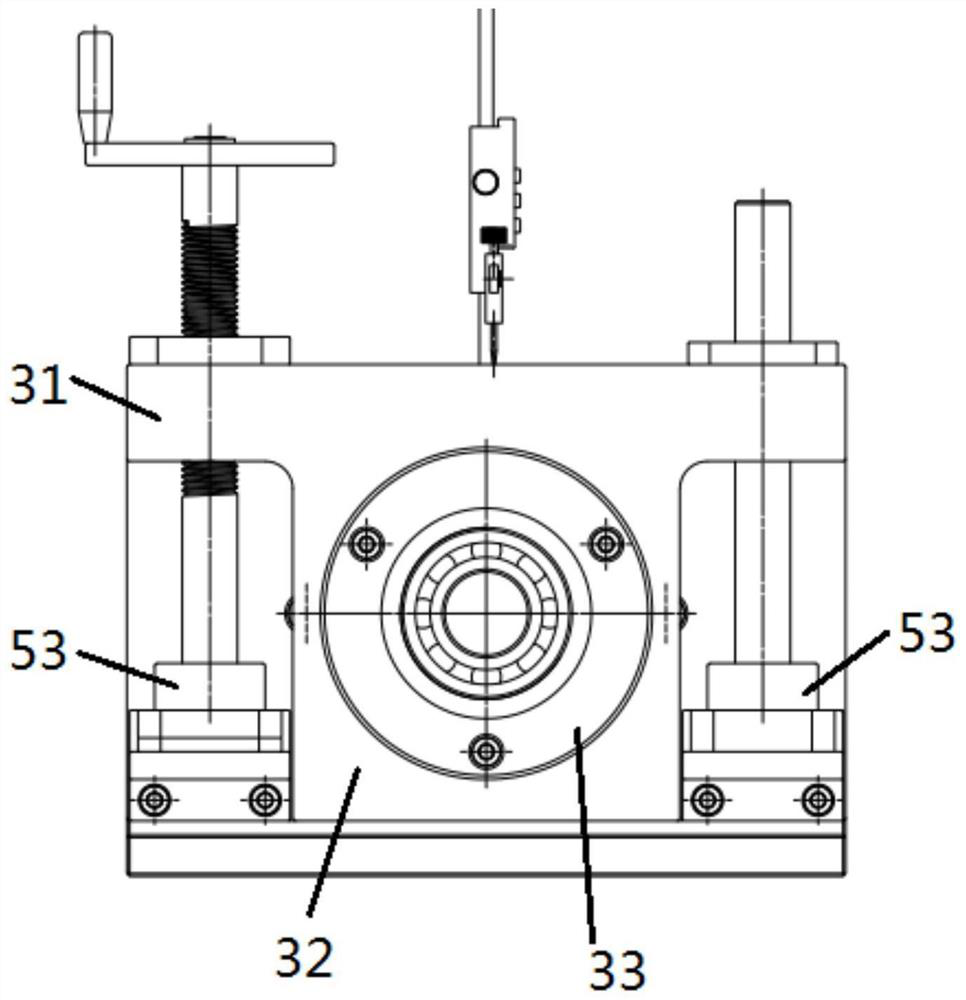

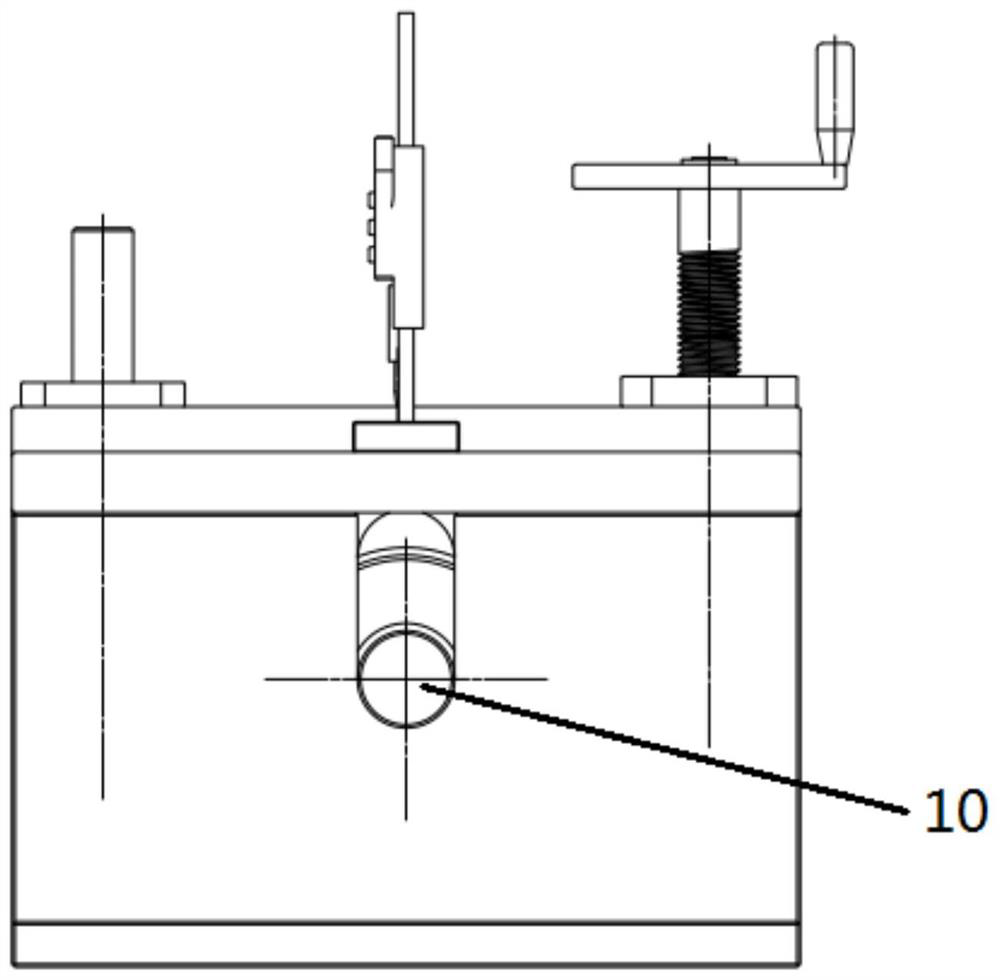

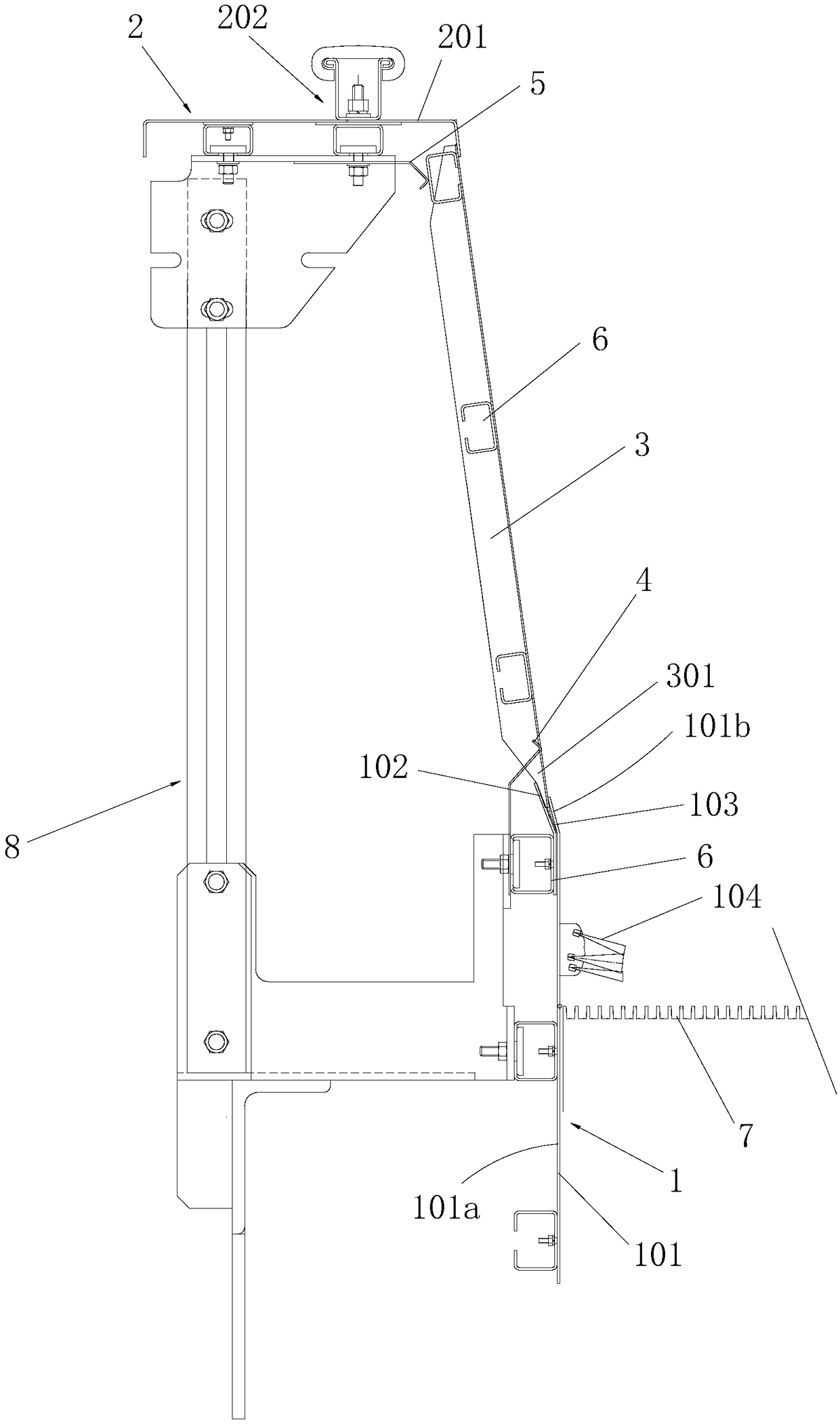

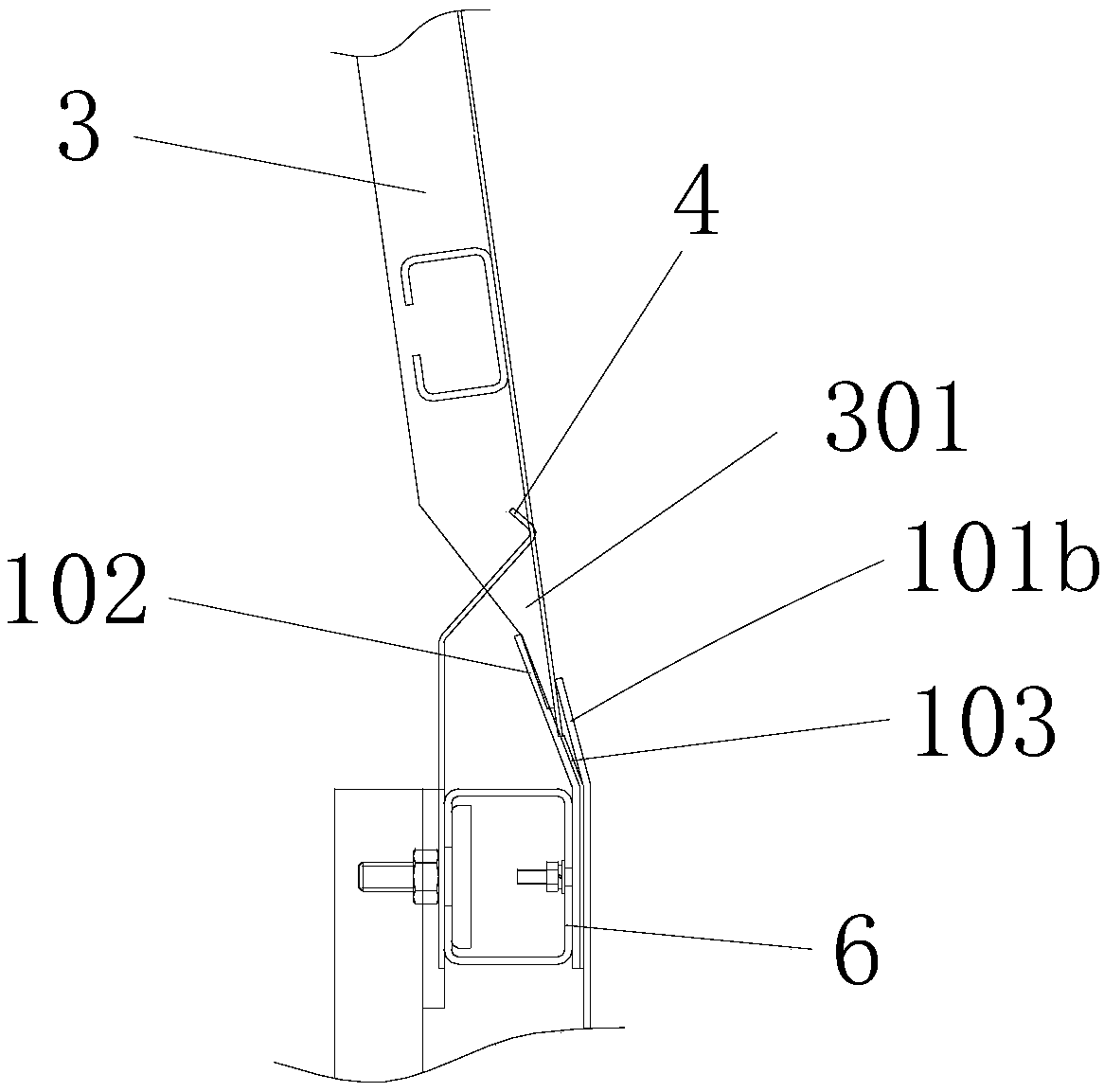

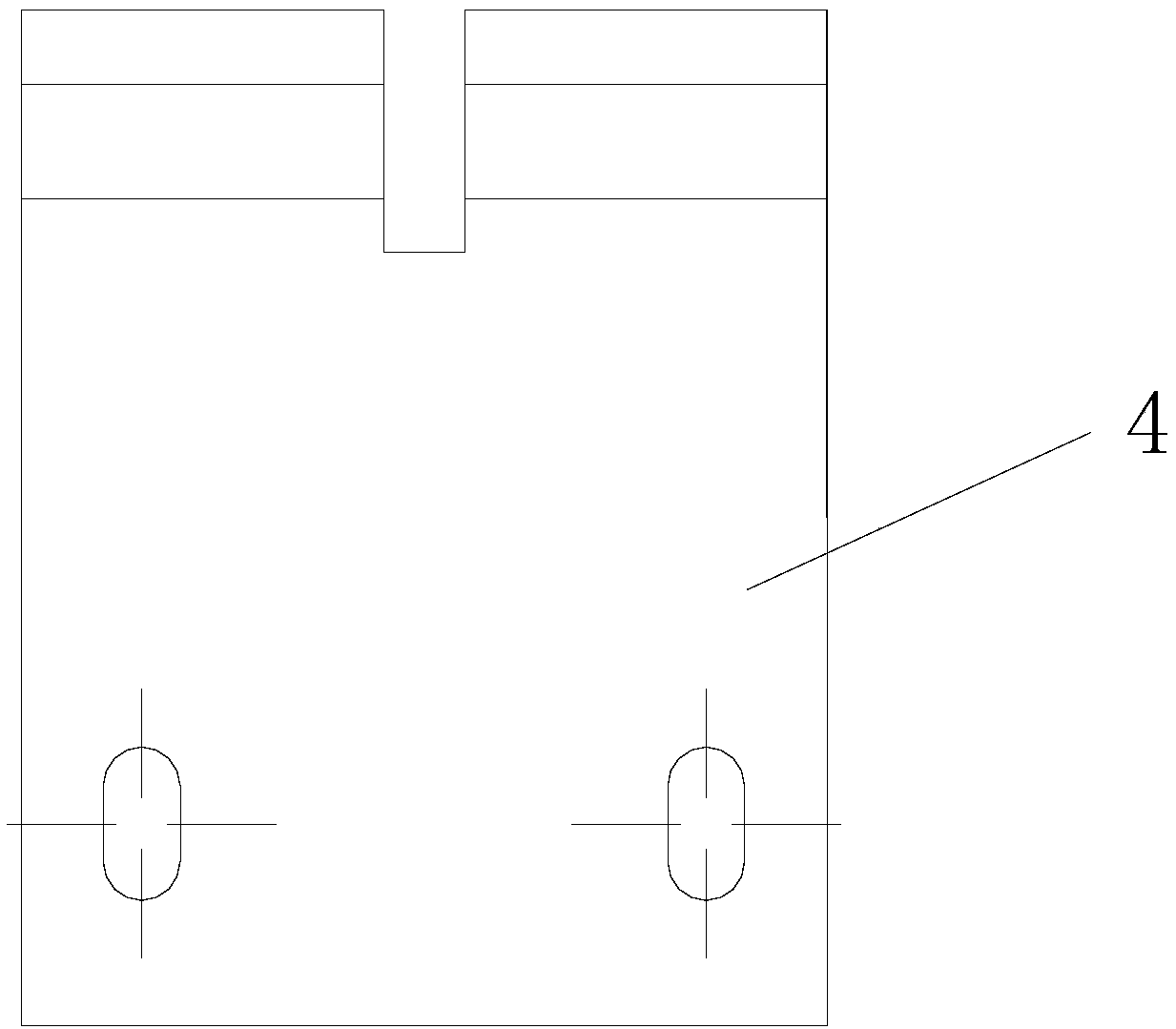

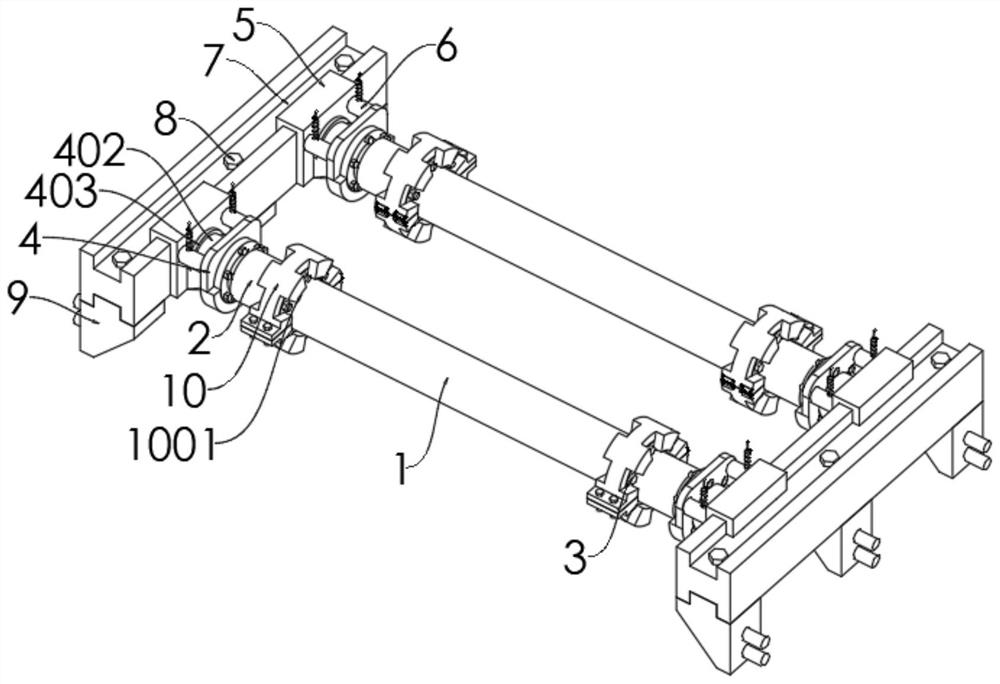

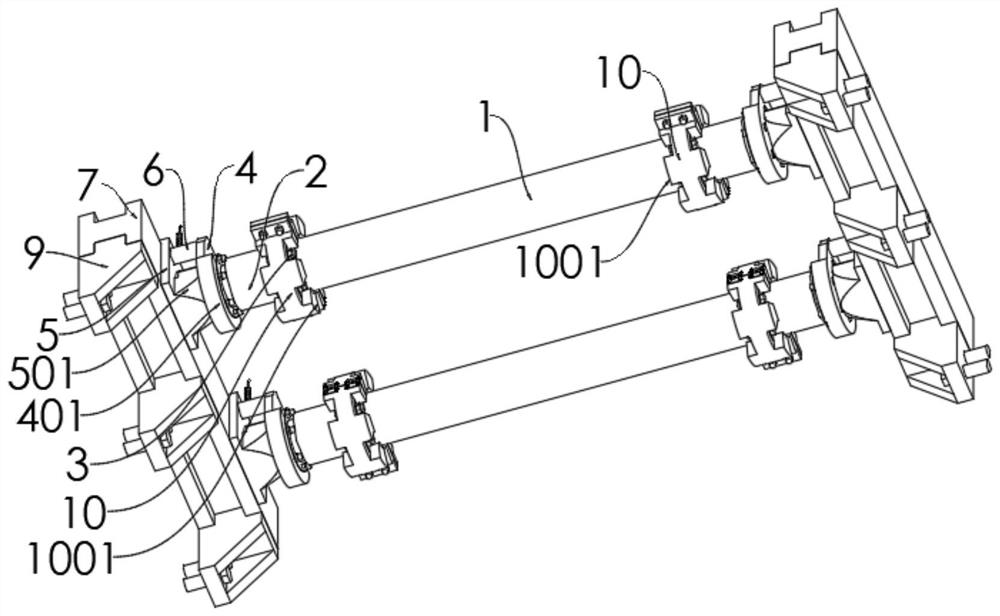

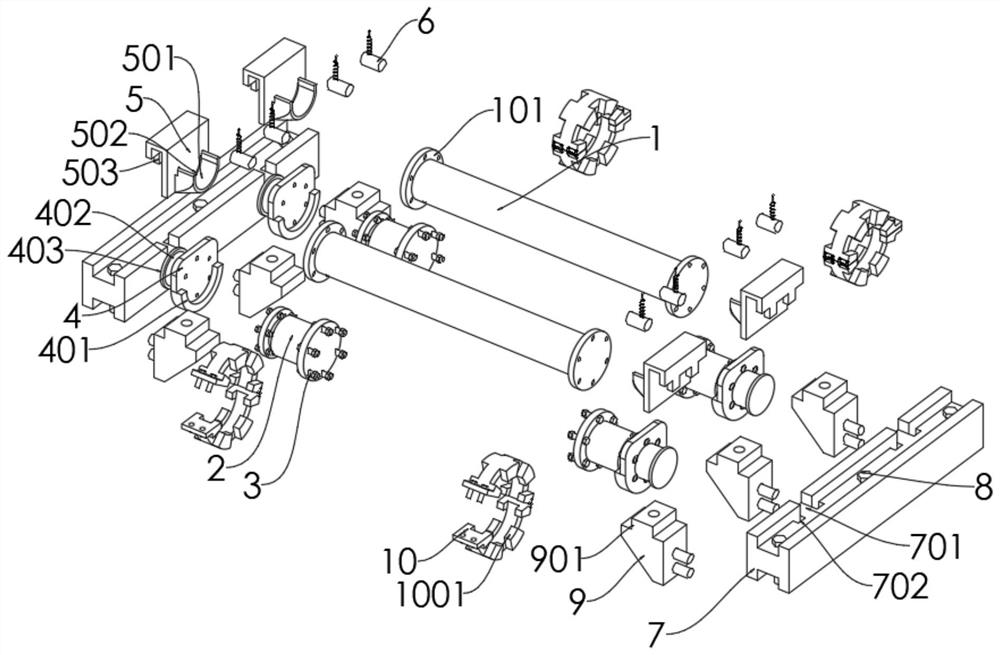

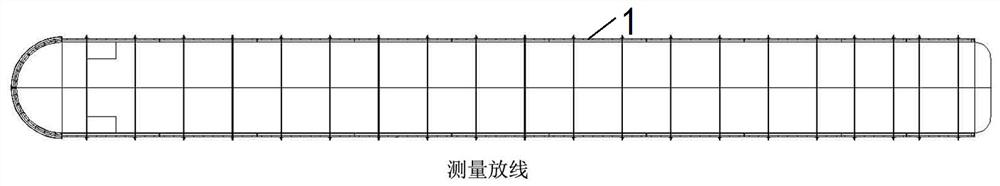

Drill rod supporting piece and supporting system for deep hole machining machine tool

PendingCN112222473AReduce straightness errorBoring/drilling componentsBoring/drilling machinesSupporting systemClassical mechanics

Owner:YANCHENG INST OF TECH

Guardrail device of escalator

PendingCN108861989AEasy to installEasy to assemble and disassembleEscalatorsSupporting systemEngineering

Owner:DONGNAN ELEVATOR

Intelligent practical deep foundation pit steel support

PendingCN114855814AHigh strengthImprove securityExcavationsPhotovoltaic energy generationSupporting systemArchitectural engineering

Owner:CHINA RAILWAY 14TH BUREAU GRP 1ST ENG CO LTD

Rapid construction method for gate pier concrete high and large formwork

InactiveCN112900442AImprove construction efficiencyShorten the construction periodFoundation engineeringSupporting systemArchitectural engineering

Owner:GEZHOUBA GROUP FOUND ENG

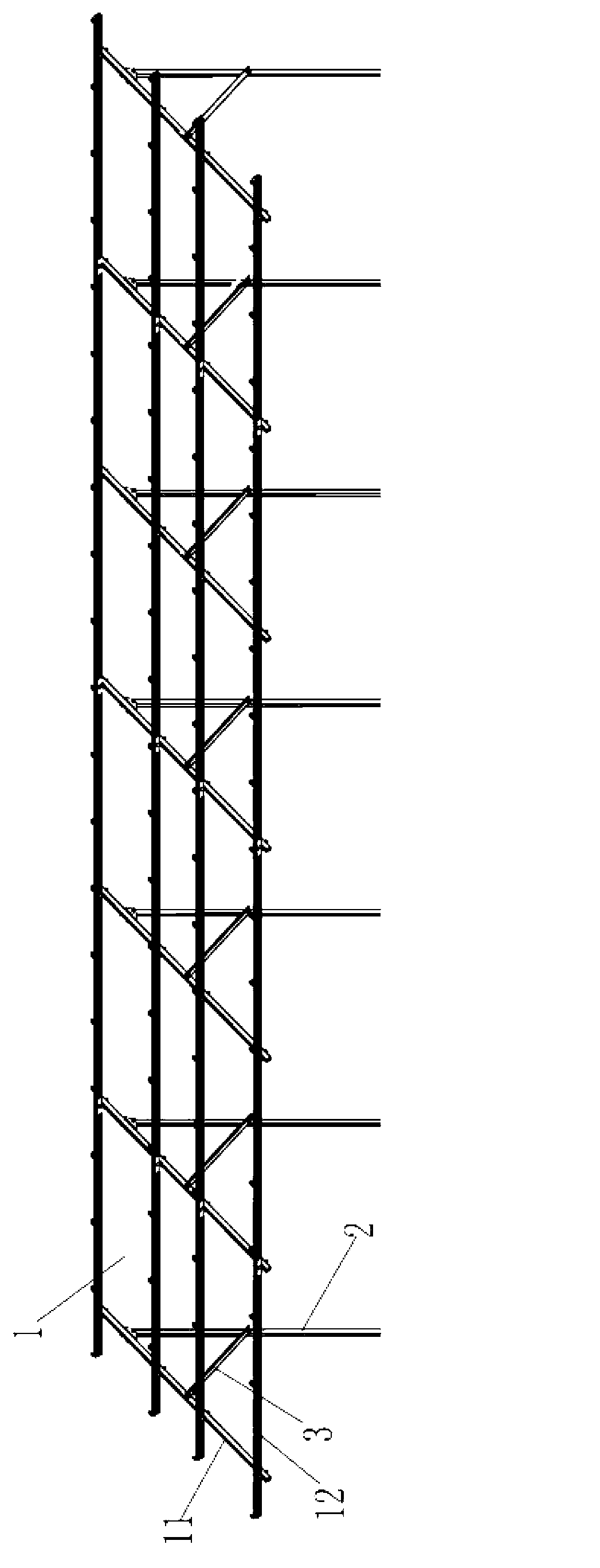

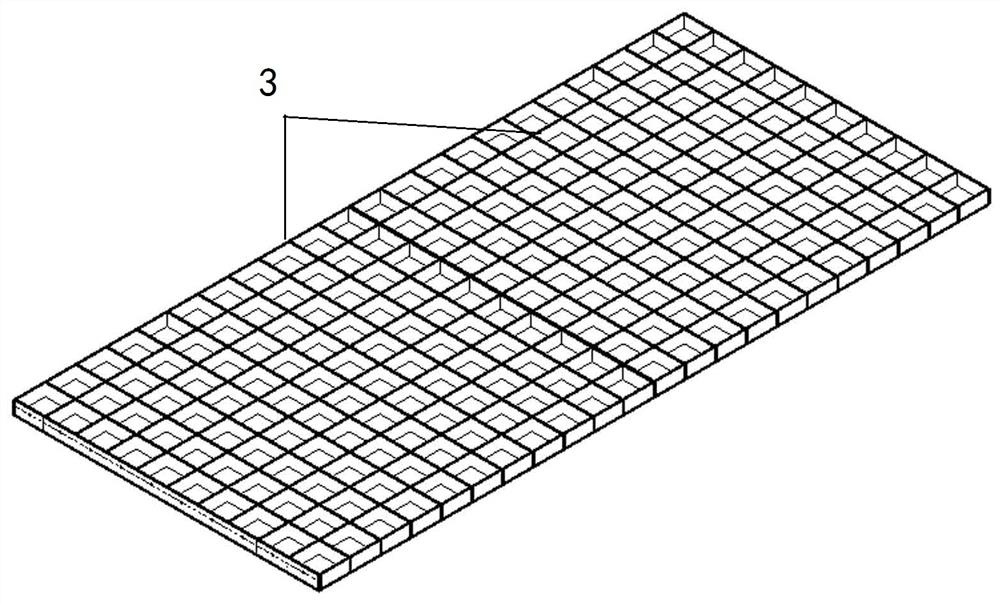

Steel embracing beam supporting system of formwork supporting frame and construction method of steel embracing beam supporting system

ActiveCN113668850AAvoid wastingStable supportForms/shuttering/falseworksShoresSupporting systemIndustrial engineering

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap