Drill rod supporting piece and supporting system for deep hole machining machine tool

A technology for processing machine tools and supports, applied in the components of boring machines/drilling machines, boring/drilling, metal processing equipment, etc. It can solve the problems of inconsistency of actual processing, no consideration of axial thrust, etc., and reduce straightness. effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in more detail below with reference to schematic diagrams, wherein preferred embodiments of the present invention are shown, and it should be understood that those skilled in the art can modify the present invention described herein while still achieving the advantageous effects of the present invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

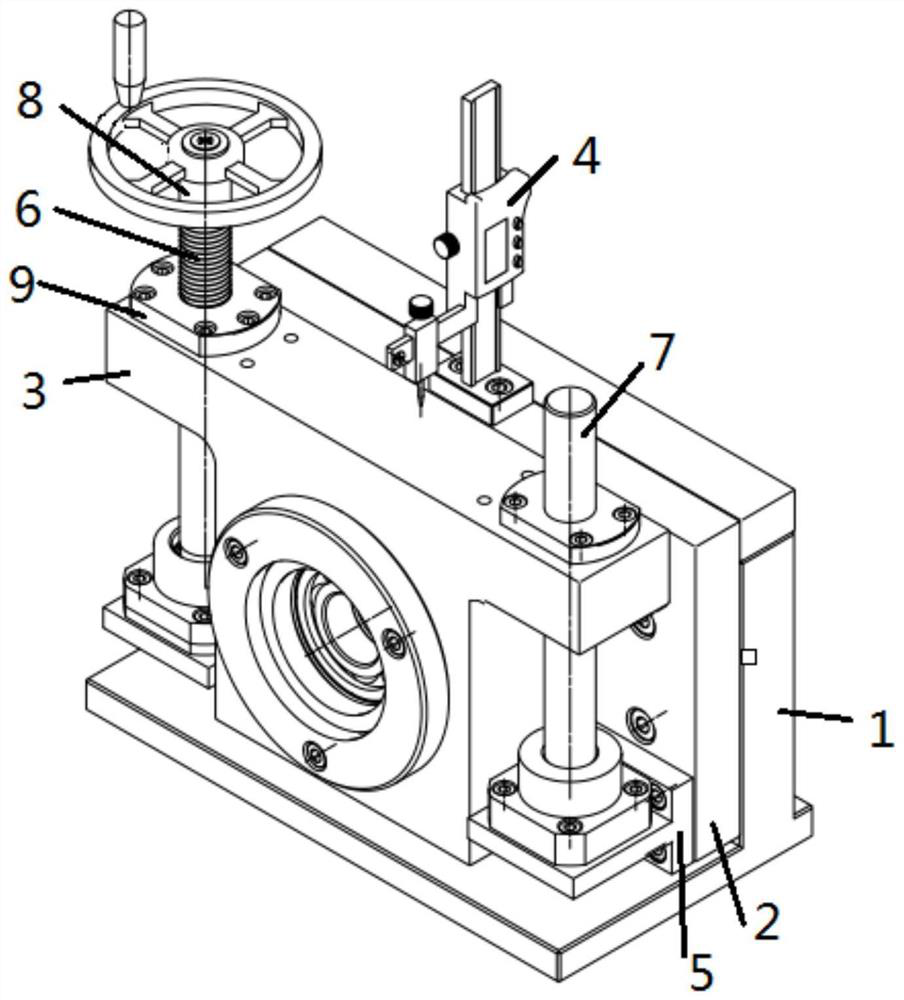

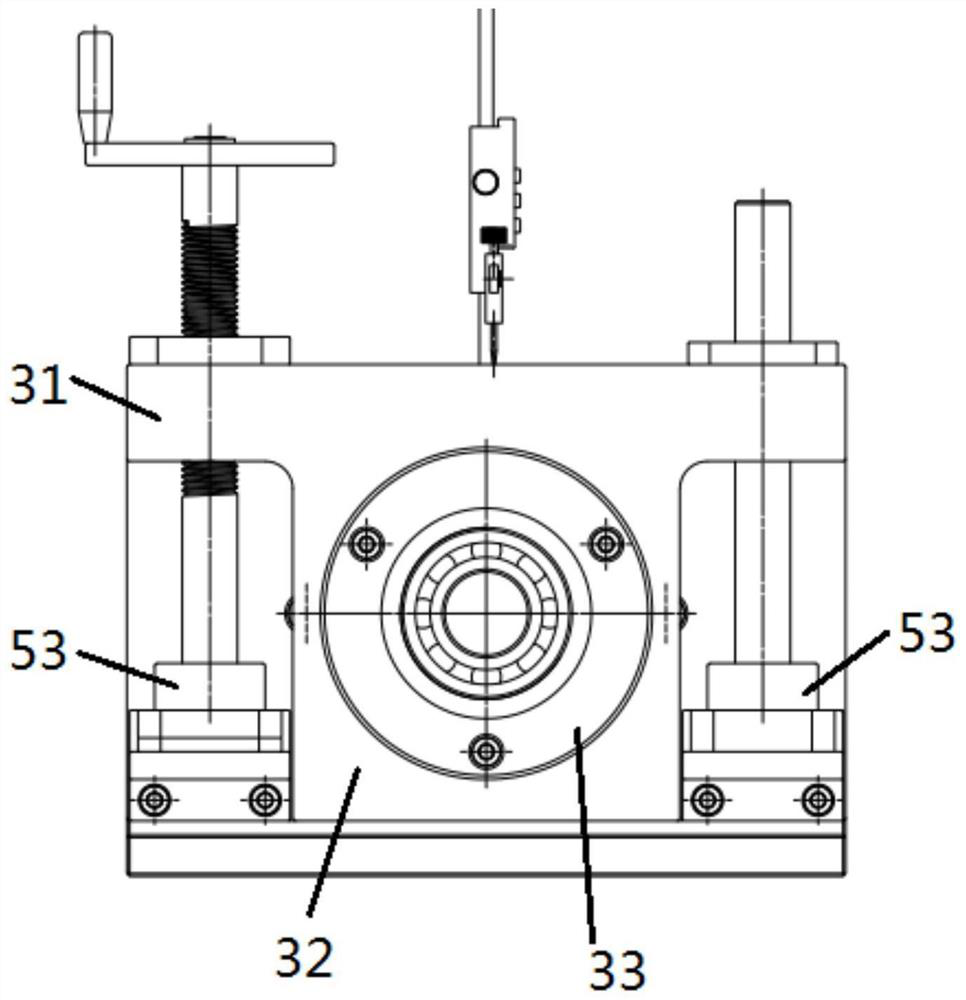

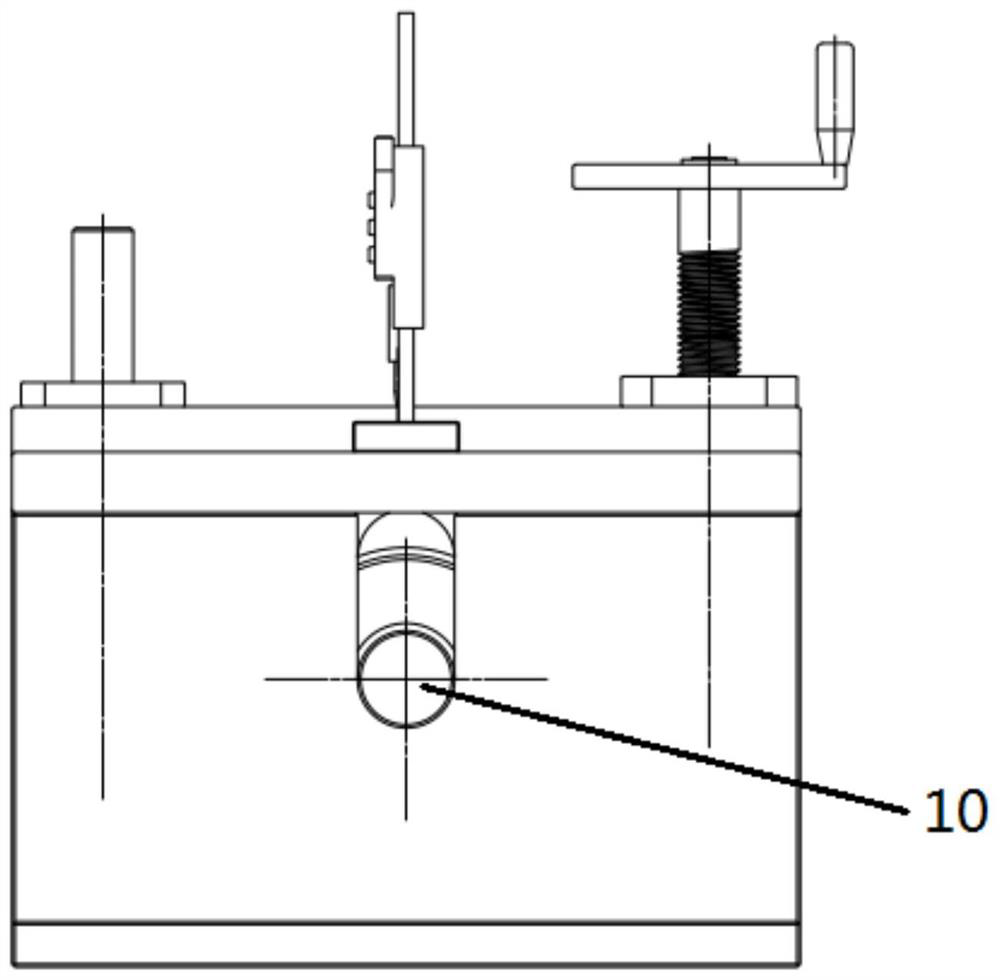

[0032] Such as Figure 1-7 As shown, a drill rod support for a deep hole processing machine tool includes a first support base 1, one side of the first support base 1 is sequentially connected to a support plate 2 and a drill rod support member 3; the first support base 1 1. The support plate 2 and the drill pipe support member 3 are all provided with mounting holes 10 for the drill pipe to pass through; a screw micrometer 4 is fixed on the upper side of the support plate 2;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap