Medium front and back printing device and printing method

A technology for printing devices and media, applied in printing devices, printing, typewriters, etc., to achieve the effect of reducing complexity and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

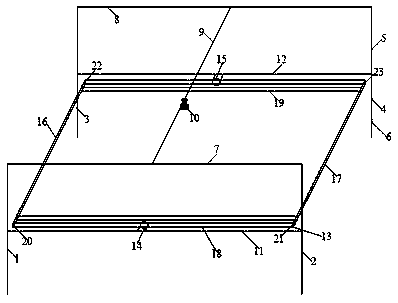

[0009] Depend on figure 1As shown, a medium front and back printing device includes a support system. The support system includes a left front support vertical bar 1, a right front support vertical bar 2, a left rear support vertical bar 3, a right rear support vertical bar 4, a left front support vertical bar, a right front support vertical bar, and a right front support vertical bar. The structures of the support vertical bar, the left rear support vertical bar and the right rear support vertical bar are exactly the same, and the left front support vertical bar, the right front support vertical bar, the left rear support vertical bar, the right rear support vertical bar include the lower support vertical bar 6 and the upper support Vertical bar 5, lower supporting vertical bar is the vertical bar of fixed length, upper supporting vertical bar is the vertical bar of telescopic variable length, left front supporting vertical bar, right front supporting vertical bar, left rear supp

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap