Construction support system and construction method for tunnel water burst

A technology for tunnels and water gushing, applied in tunnels, tunnel linings, temporary shields, etc., can solve the problems of unsecured tunnels, dredging, high drainage costs, and large economic losses, so as to improve connection reliability and waterproofing. performance, saving the workload of erection and dismantling, and preventing water leakage in the tunnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

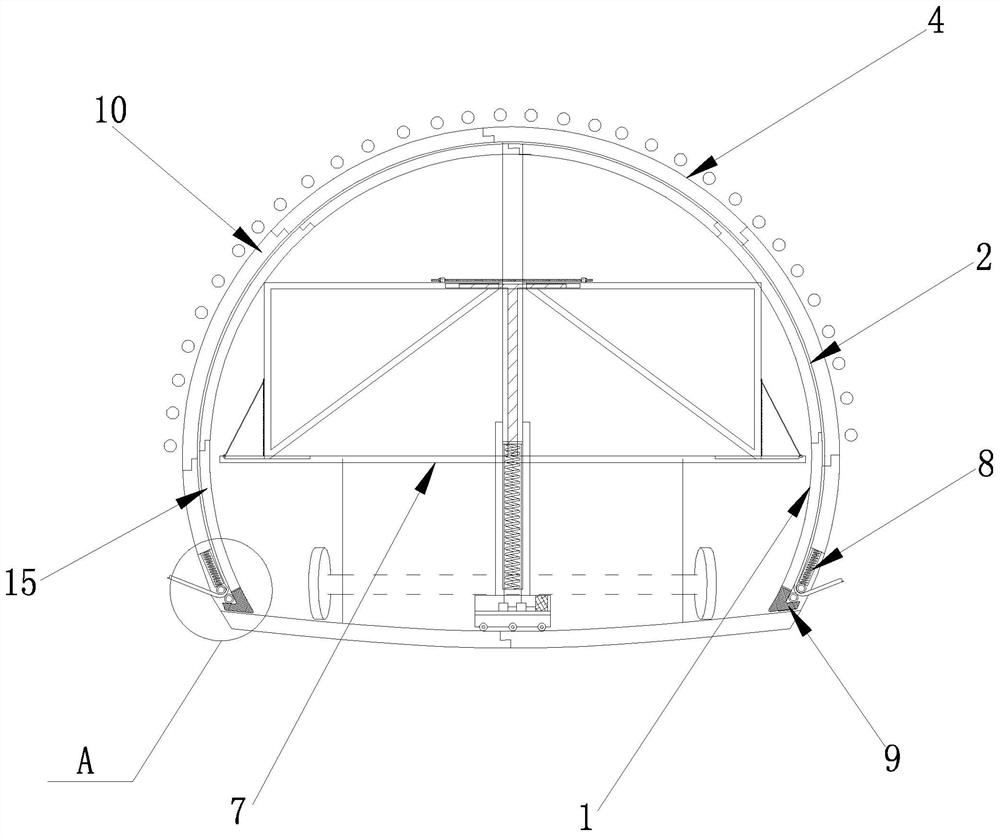

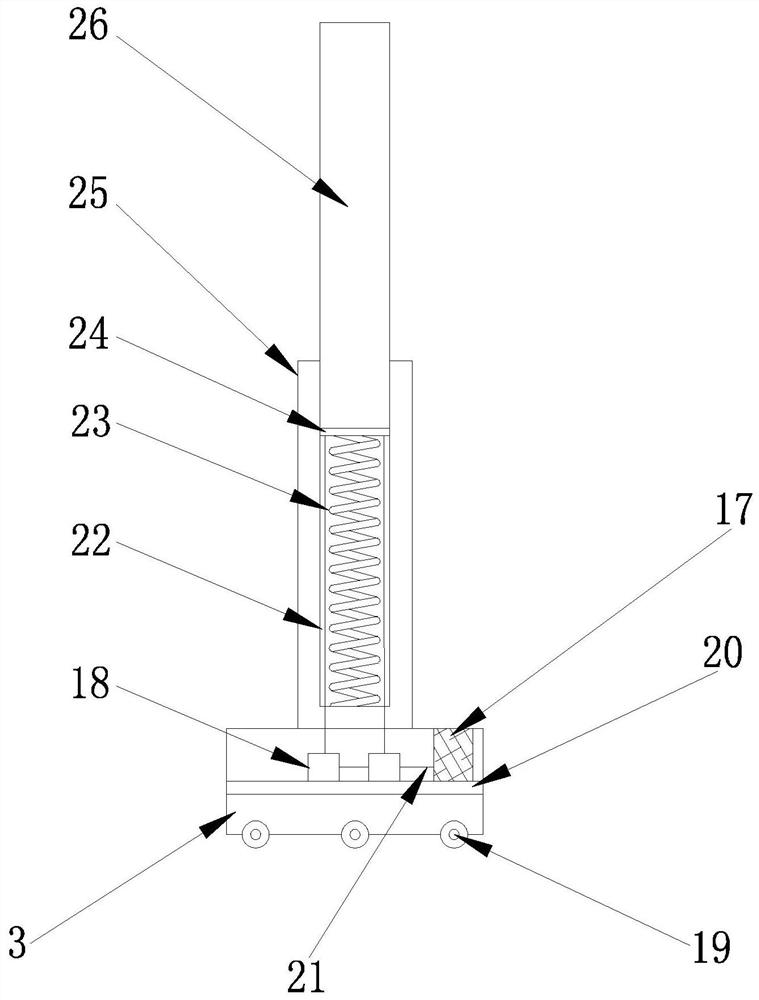

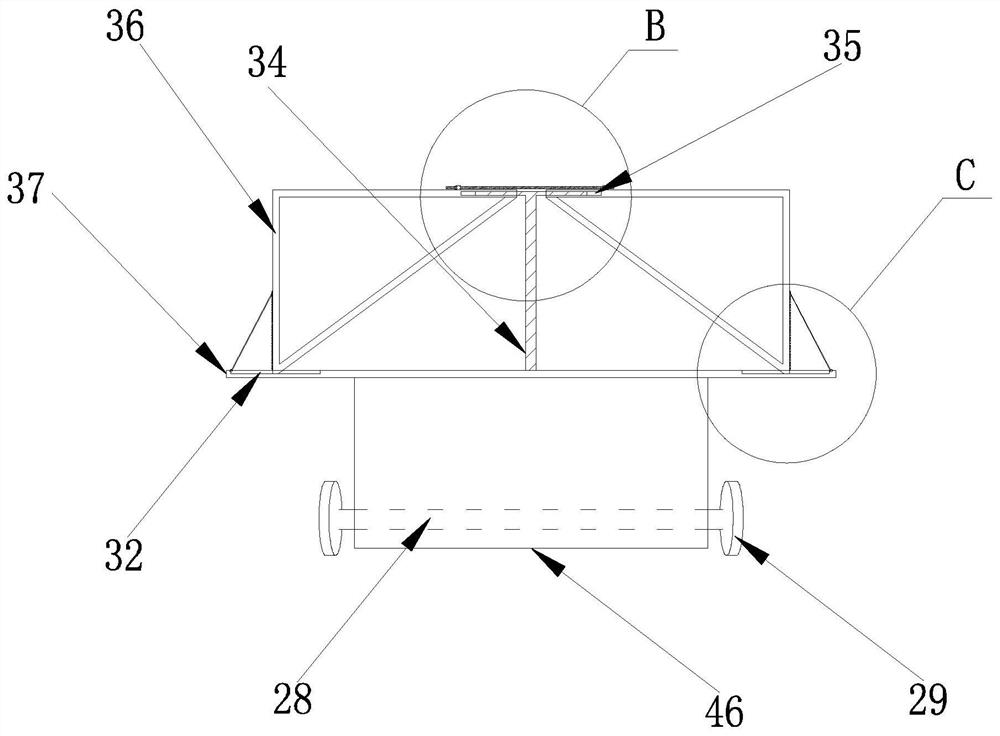

[0043] Example: such as Figure 1-6 As shown, a construction support system for tunnel water gushing, including supporting ring arch device 1, waterproof mechanism 2, top support device 7 and upper ring arch device 4, the upper ring arch device 4 is close to the tunnel excavation contour line , the waterproof mechanism 2 is assembled between the supporting ring arch device 1 and the upper ring arch device 4; the supporting device 7 abuts on the supporting ring arch device 1; Form an upper annular inner support ring arch; the support ring arch device 1 is connected by a plurality of support ring arch units 15 to form a lower annular inner support ring arch; the connection between adjacent upper ring arch units 10 and the adjacent support ring arch The joints of the units 15 are arranged in a staggered manner; the upper ring-shaped inner support ring arch designed by the present invention is formed by connecting multiple upper ring arch units; the lower ring-shaped inner support ri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap