Gasket for high-temperature joint and method of fabricating the same

a high-temperature joint and gasket technology, applied in the direction of sealing, cable termination, other chemical processes, etc., can solve the problems of b>2/b> not being durable, combustible graphite sheet, heat-resistant sheet b>, etc., to enhance heat resistance, strength and corrosion resistance of the reinforcing member, and reduce the flowability of the aqueous solution of heat-resistant anti-friction material. , the effect o

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

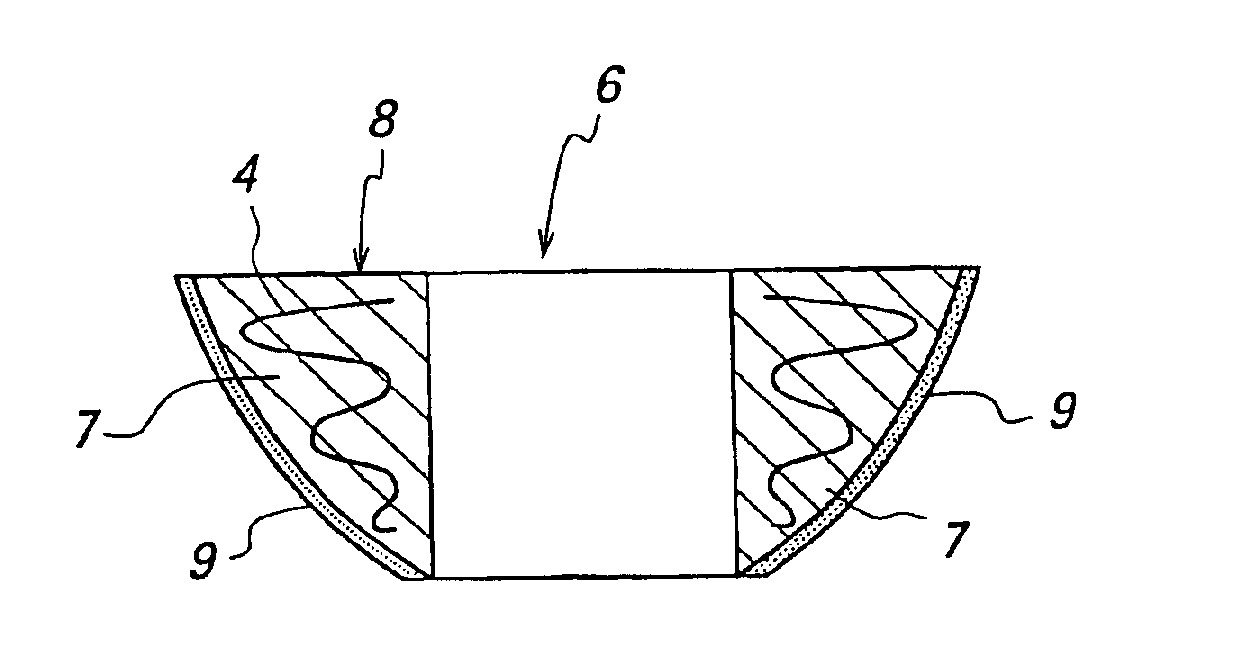

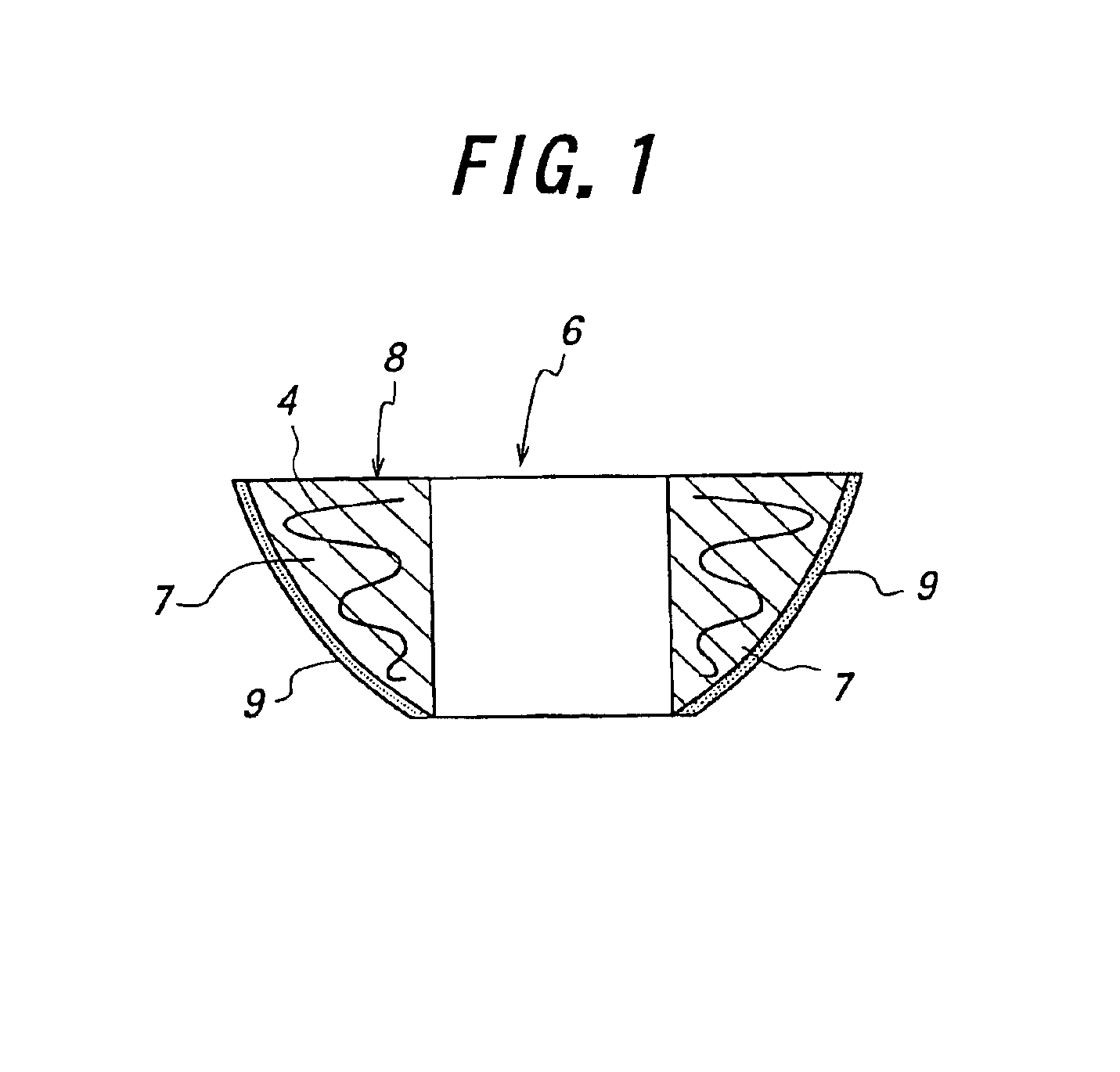

[0028]Now, embodiments of this invention will be described in detail based on the accompanying drawings. Here, FIG. 1 is a cross-sectional view showing one embodiment of a gasket for a high-temperature joint of this invention. In the drawing, similar parts to the conventional example will be denoted by the same reference numerals.

[0029]A gasket 6 of this embodiment includes a gasket basic substance 8 formed by filling a heat-resistant filler 7 mainly composed of diatomaceous earth into gaps of a meshed metallic reinforcing member 4, and coverture 9 made of a heat-resistant antifriction material mainly composed of a mixture of boron nitride and polytetrafluoroethylene resin for covering a surface of the gasket basic substance 8.

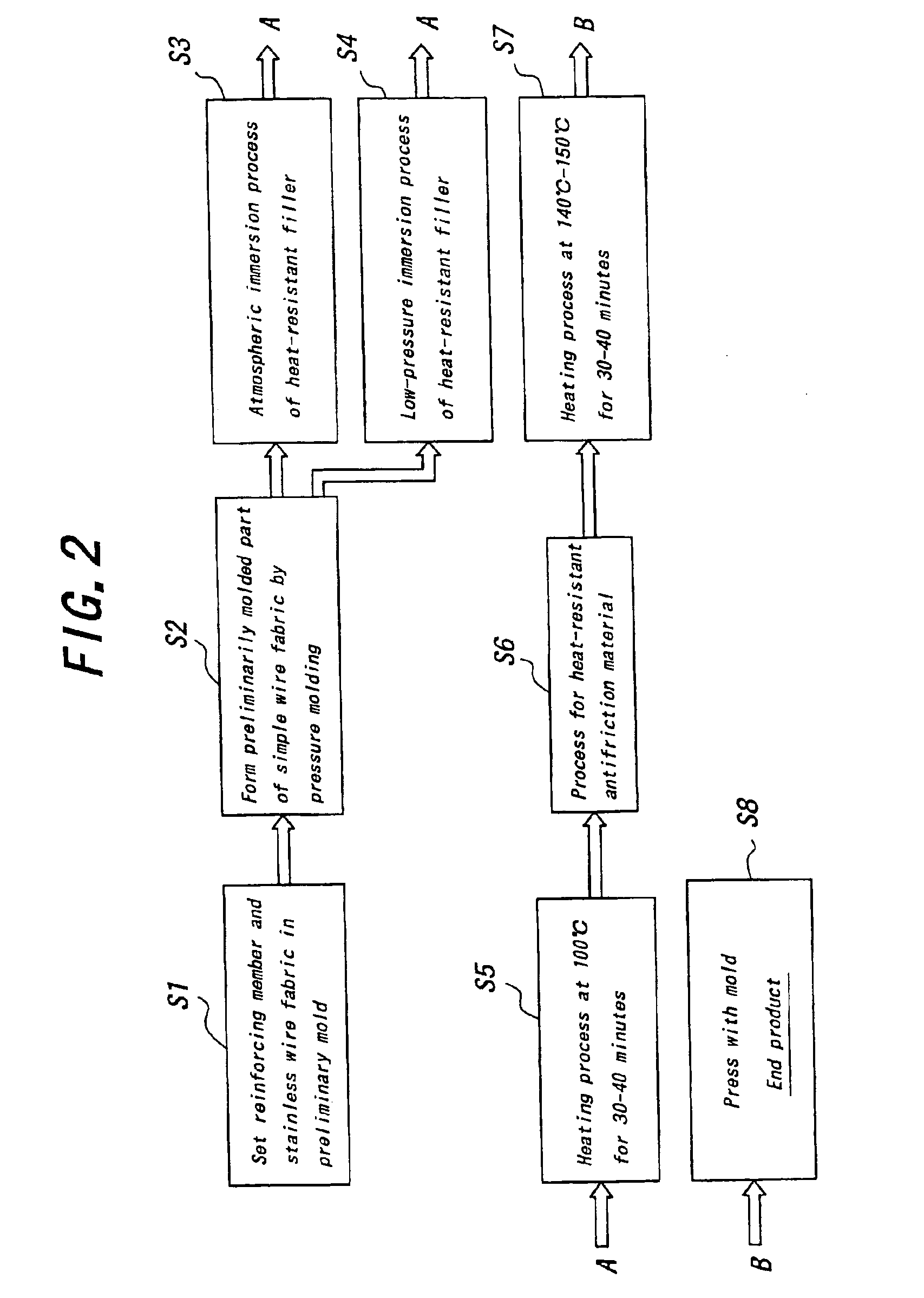

[0030]The gasket 6 of this embodiment is fabricated as described below in accordance with a fabricating method as shown in FIG. 2, which is one embodiment of a fabricating method of this invention. Specifically, here in Step S1 as shown in FIG. 2, a tubularly wou

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap