Method for machining duplicate gears

A technology of double gears and processing methods, which is applied to components with teeth, metal processing equipment, gear tooth manufacturing devices, etc., can solve the problems of low production efficiency of double gear hobbing, achieve high production efficiency, reduce The influence of machining accuracy and the effect of enhancing the strength of positioning and clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

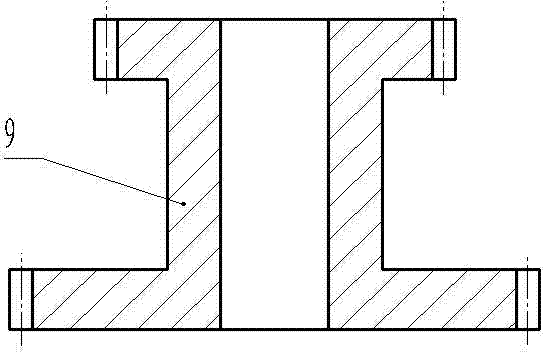

[0015] Such as figure 2 The gear hobbing fixture of a double gear shown includes a clamp body 1, on which a mandrel 6 for wearing two double gears 9 is mounted, and a nut 8 and a pressure plate 7 are installed on the upper end of the mandrel 6, The lower end of the mandrel 6 has a cone part that cooperates with the clamp body 1, and a bolt and a backing plate that are fixedly connected with the clamp body 1 are installed under the cone part; a washer 2 is installed on the outside of the mandrel 6 at the upper end of the clamp body 1 , The gasket 2 is a copper pad, and the outer side of the gasket 2 is equipped with an inner positioning sleeve 3 and an outer positioning sleeve 4 successively, and an open sleeve 5 which is offset against the inner side of the outer positioning sleeve 4 is installed on the top of the inner positioning sleeve 3 .

[0016] Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap