Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Effluent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Effluent is an outflowing of water or gas to a natural body of water, from a structure such as a wastewater treatment plant, sewer pipe, or industrial outfall. Effluent, in engineering, is the stream exiting a chemical reactor.

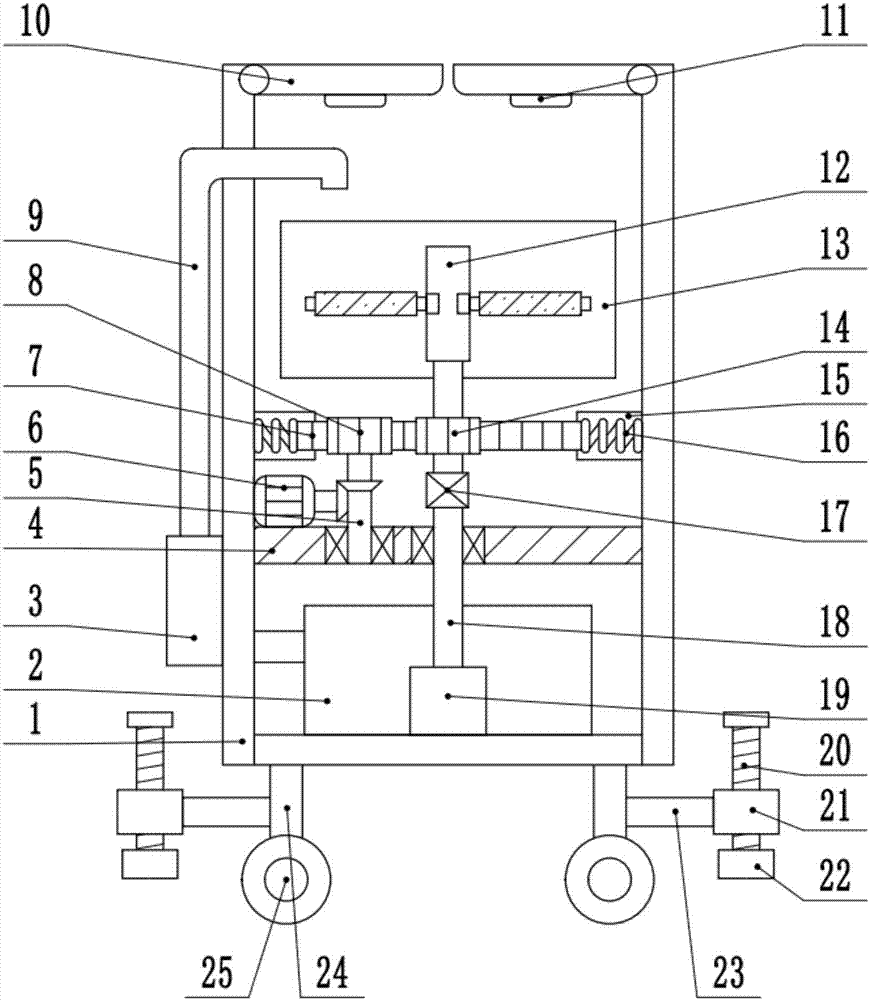

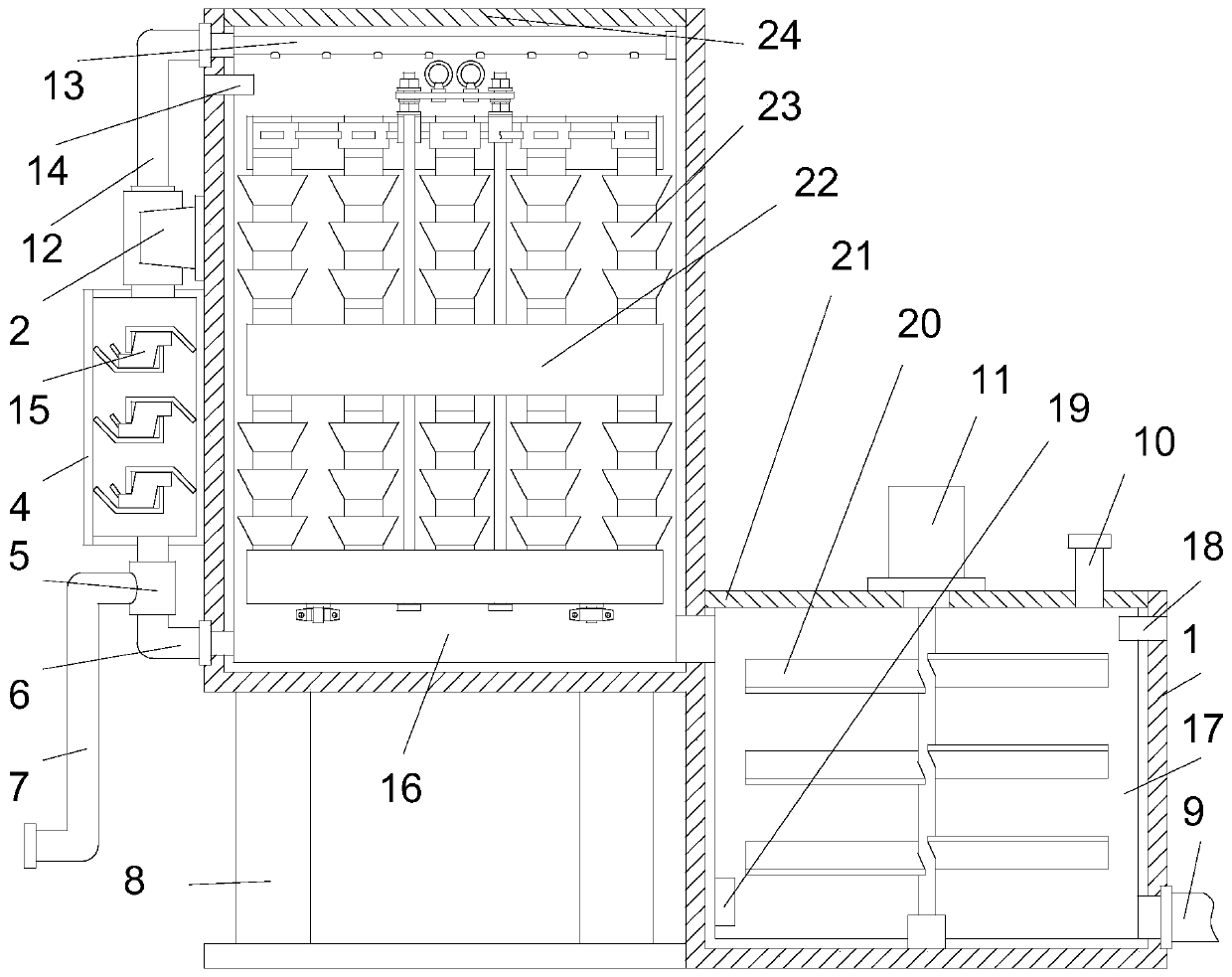

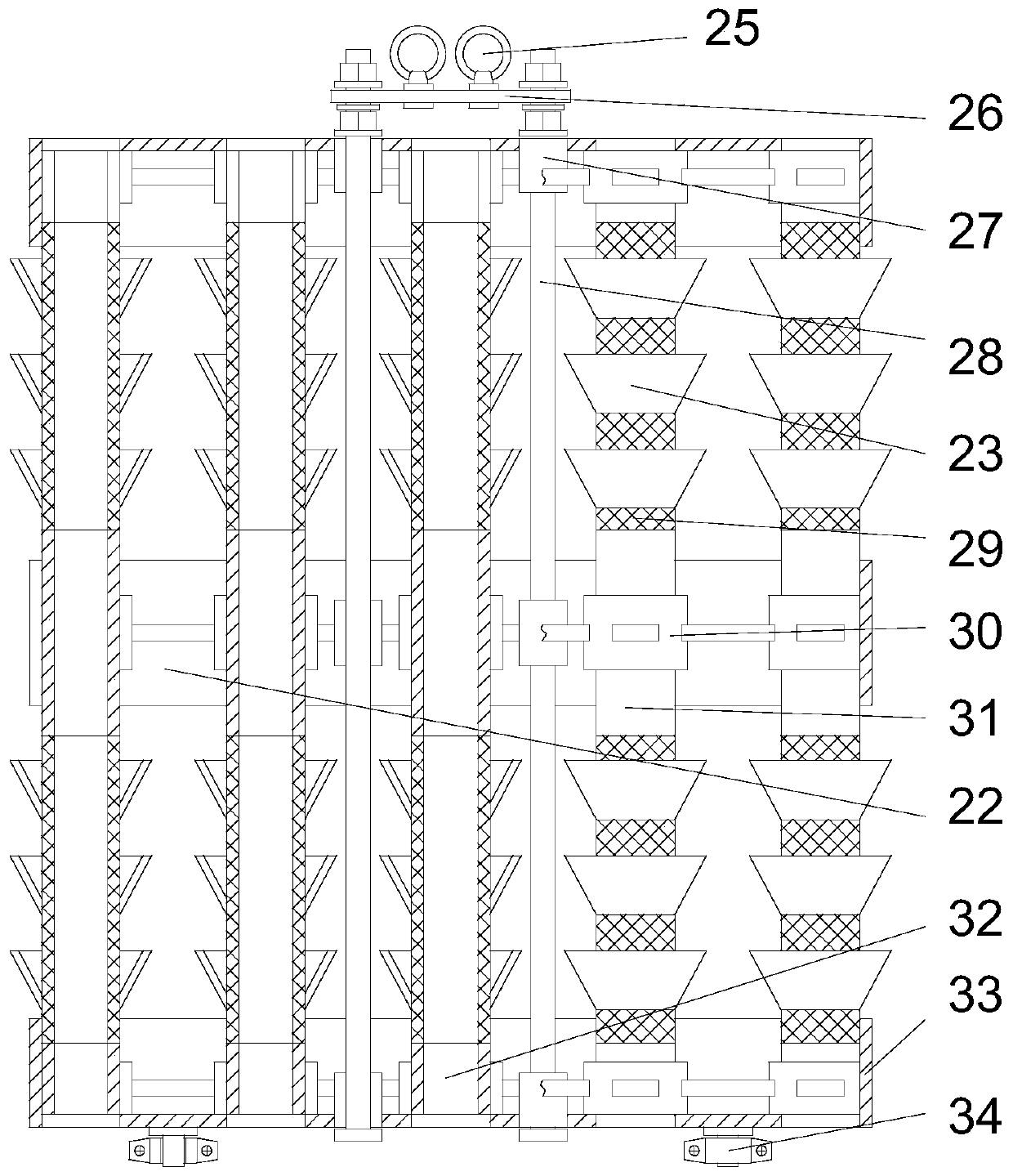

Moving type washing and disinfecting device for medical instruments

InactiveCN107486425AFully cleanedEasy to moveCleaning using toolsCleaning using liquidsWater storage tankElectromagnetic valve

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

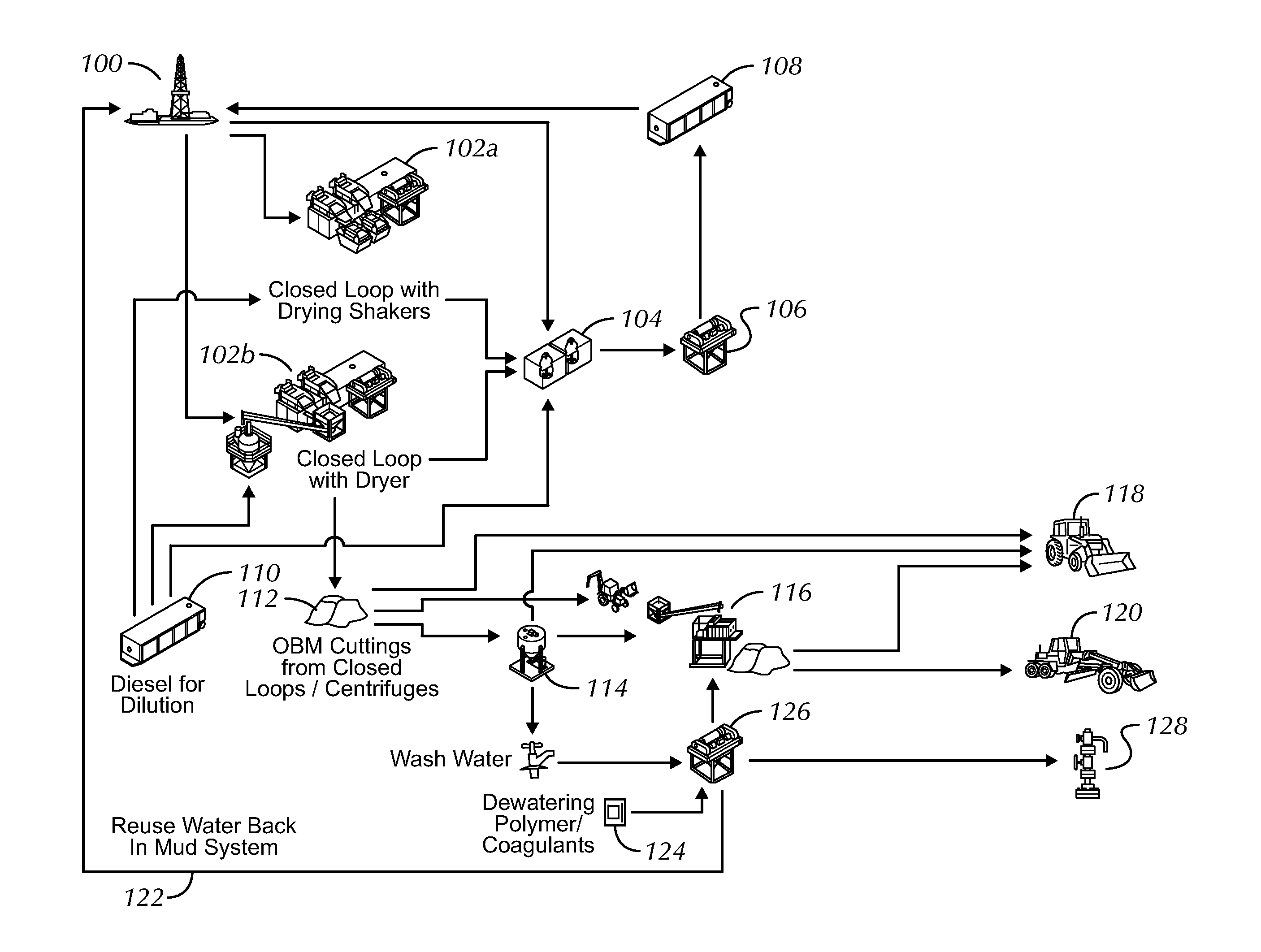

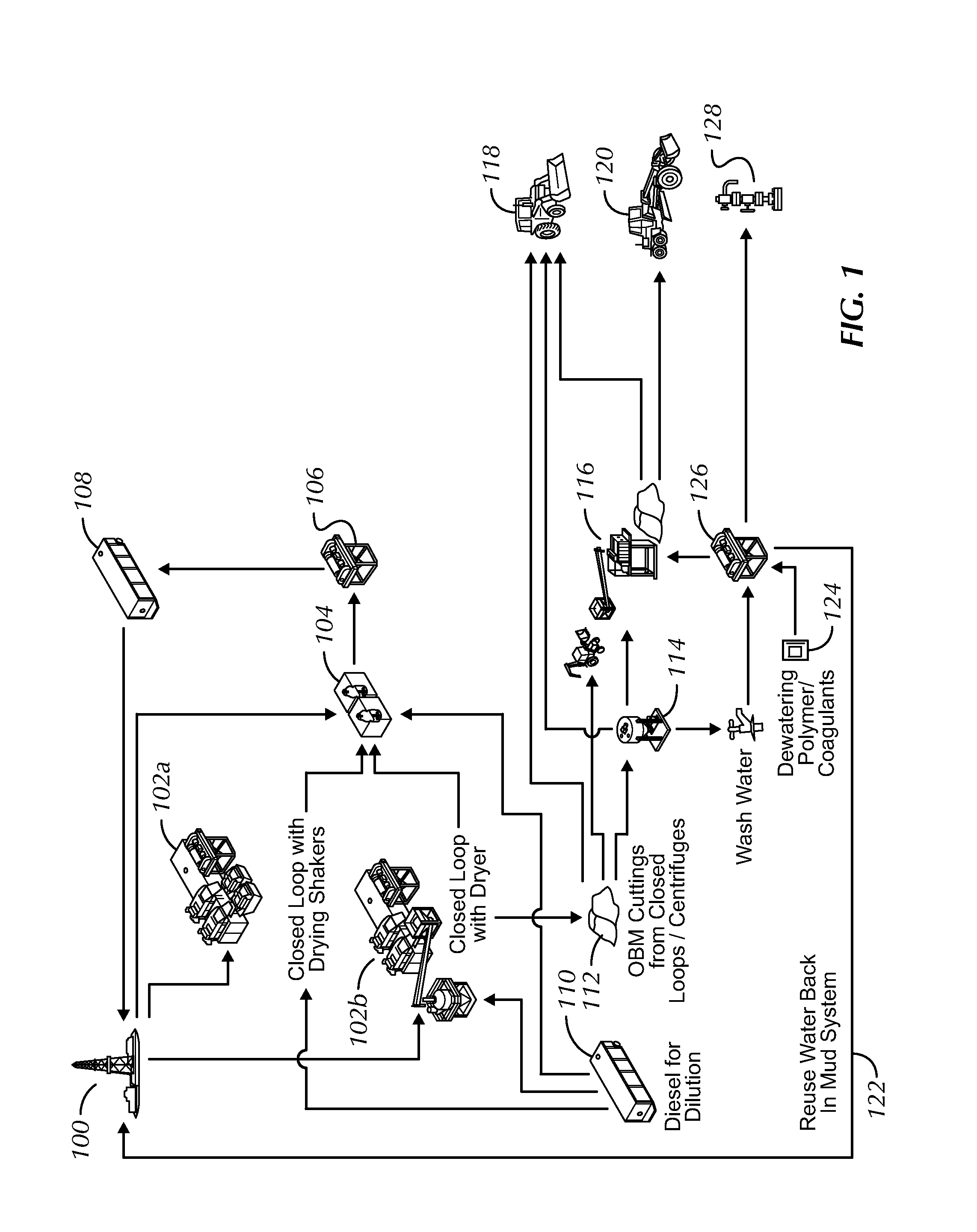

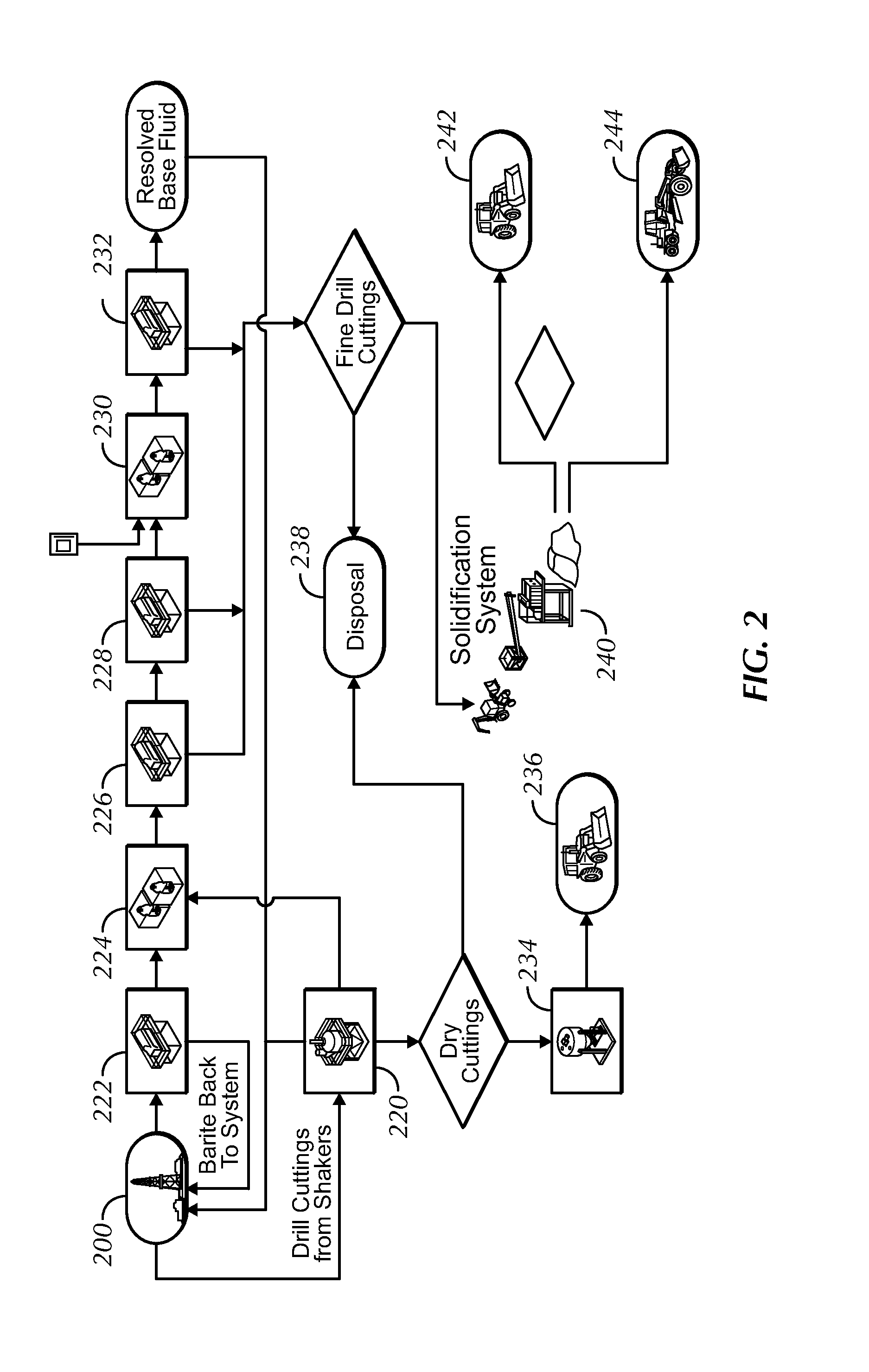

Drilling fluid processing

ActiveUS20140371113A1Water/sewage treatment by centrifugal separationSolid sorbent liquid separationFluid phaseWash water

Owner:MI

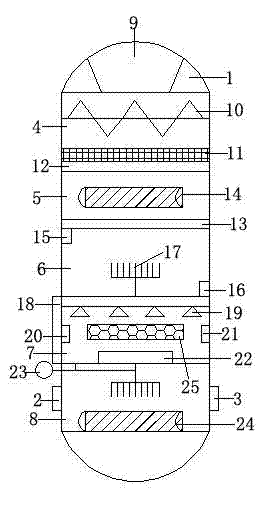

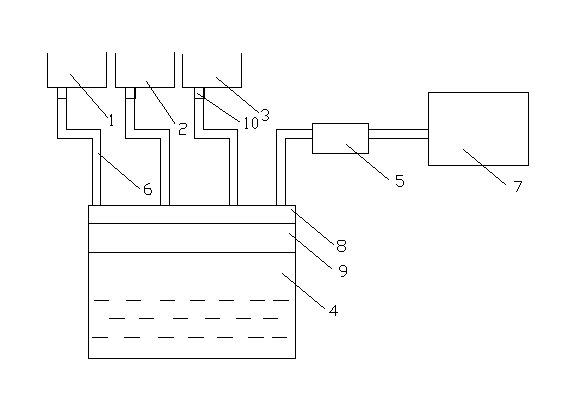

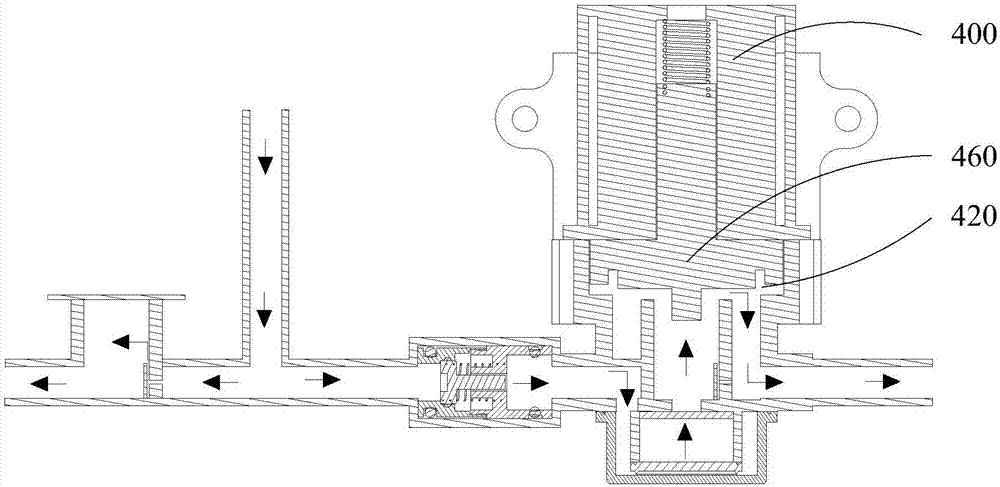

Automatic control system and method for emission monitoring of radioactive airborne effluents

InactiveCN103076816AReduce labor intensityImprove work efficiencyFlow control using electric meansProgramme control in sequence/logic controllersAutomatic controlProgrammable logic controller

The invention discloses an automatic control system and an automatic control method for mission monitoring of radioactive airborne effluents. According to the automatic control system, an emission flow monitoring sensor is connected with a flow monitoring PLC (Programmable Logic Controller) through a cable; the flow monitoring PLC is connected with an automatic control unit through a signal line; the automatic control unit is connected with a flow adjusting valve, an electromagnetic valve, sampling monitoring equipment, a mass flow meter, a pressure gauge and a pump respectively through a signal control line; and an airborne substance sampling head is connected with a tail gas emission pipe after being connected with the flow adjusting valve, the electromagnetic valve, the sampling monitoring equipment, the mass flow meter, the pressure gauge and the pump respectively in sequence through a sampling pipe. Due to the adoption of the automatic control system and the automatic control method disclosed by the invention, the sample representativeness of effluent monitoring under the conditions of separate or simultaneous emission, large differences among airborne substance source items and scattered emission in a plurality of radioactive operating places can be enhanced, the labor intensity of effluent monitoring can be relieved, and the working efficiency is increased; and the system and the method have the characteristics of stability, reliability, intelligent regulation and control, and unattended operation.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

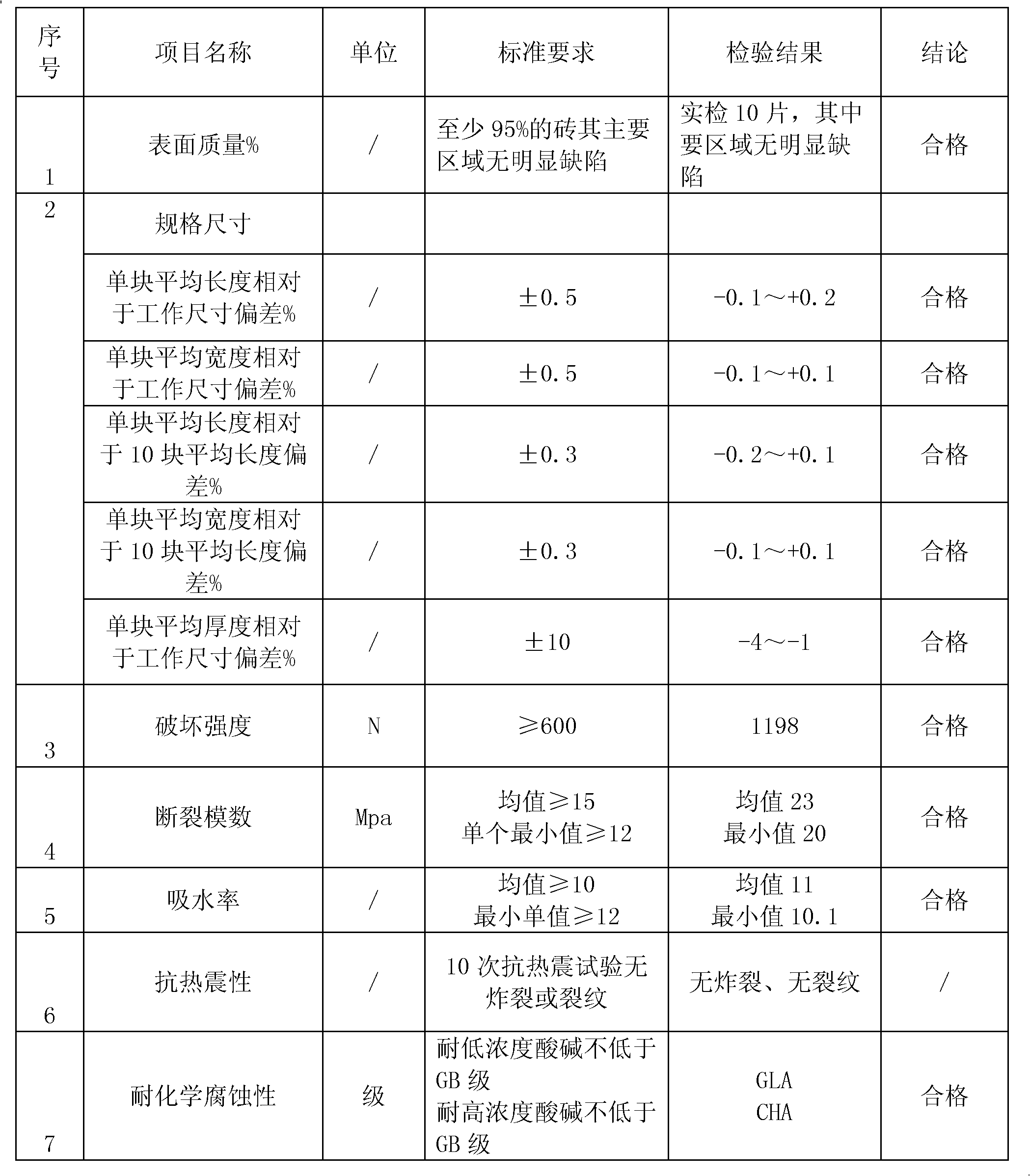

New process for preparing powder by dry method of ceramic tiles

InactiveCN101857421AReduce pollutionReduce energy consumptionClaywaresEnergy consumptionMaterials science

Owner:淄博新空间陶瓷有限公司

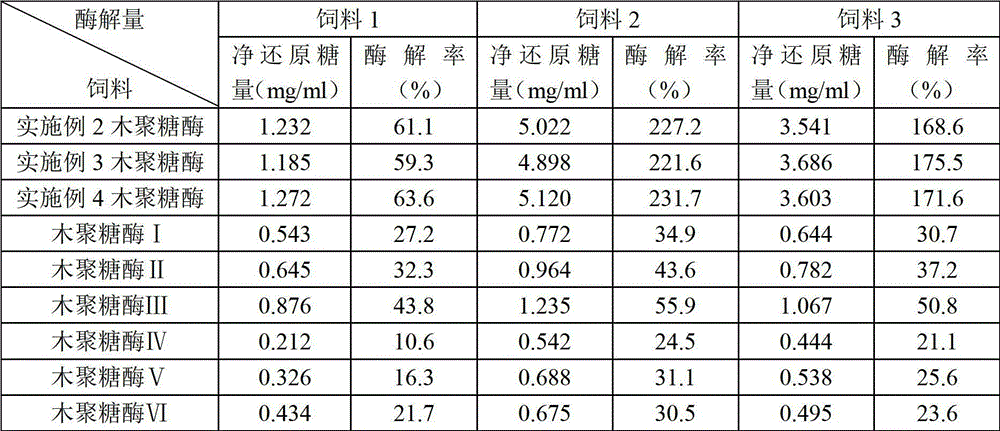

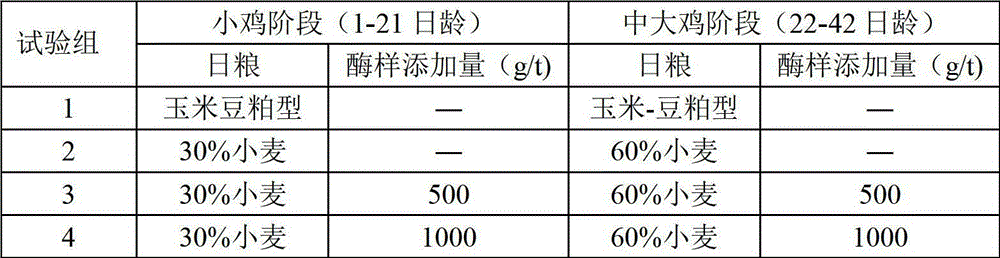

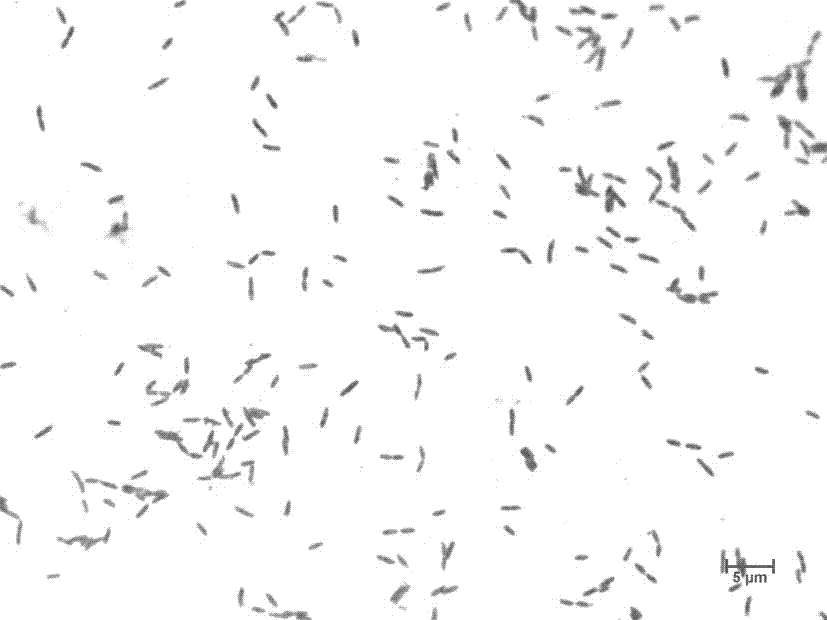

Method for procuding aspergillus oryzae of xylanase capable of efficiently degrading feed substrate and xylanase

ActiveCN103060202AGood enzymatic effectEfficient degradationFungiAnimal feeding stuffAquatic productAspergillus oryzae

Owner:GUANGDONG VTR BIO TECH

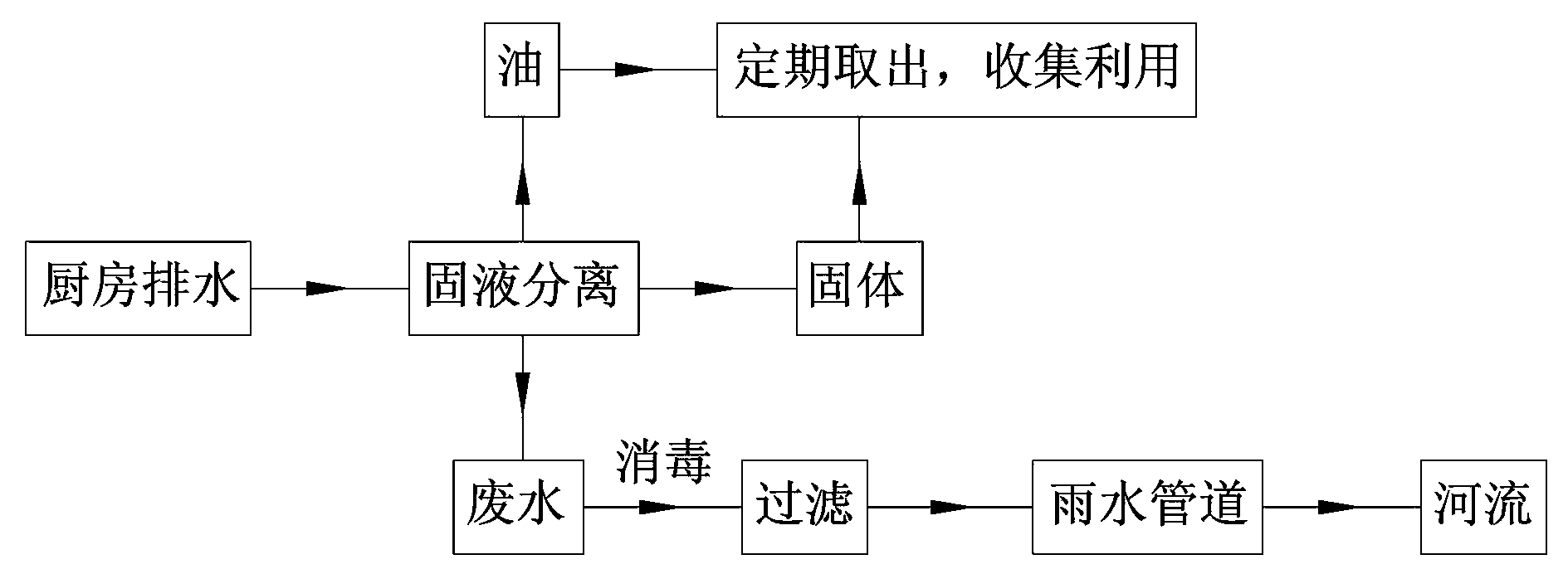

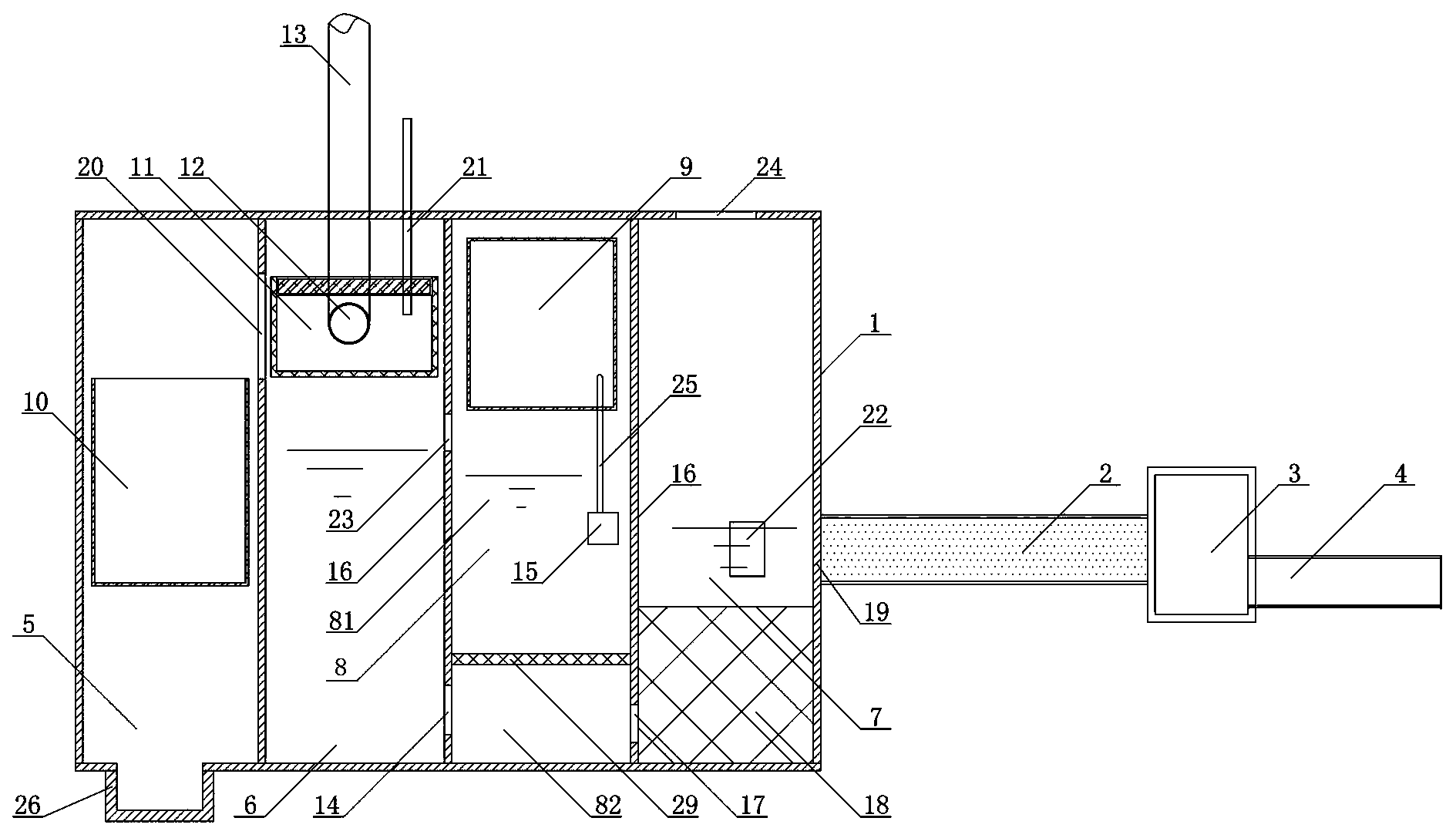

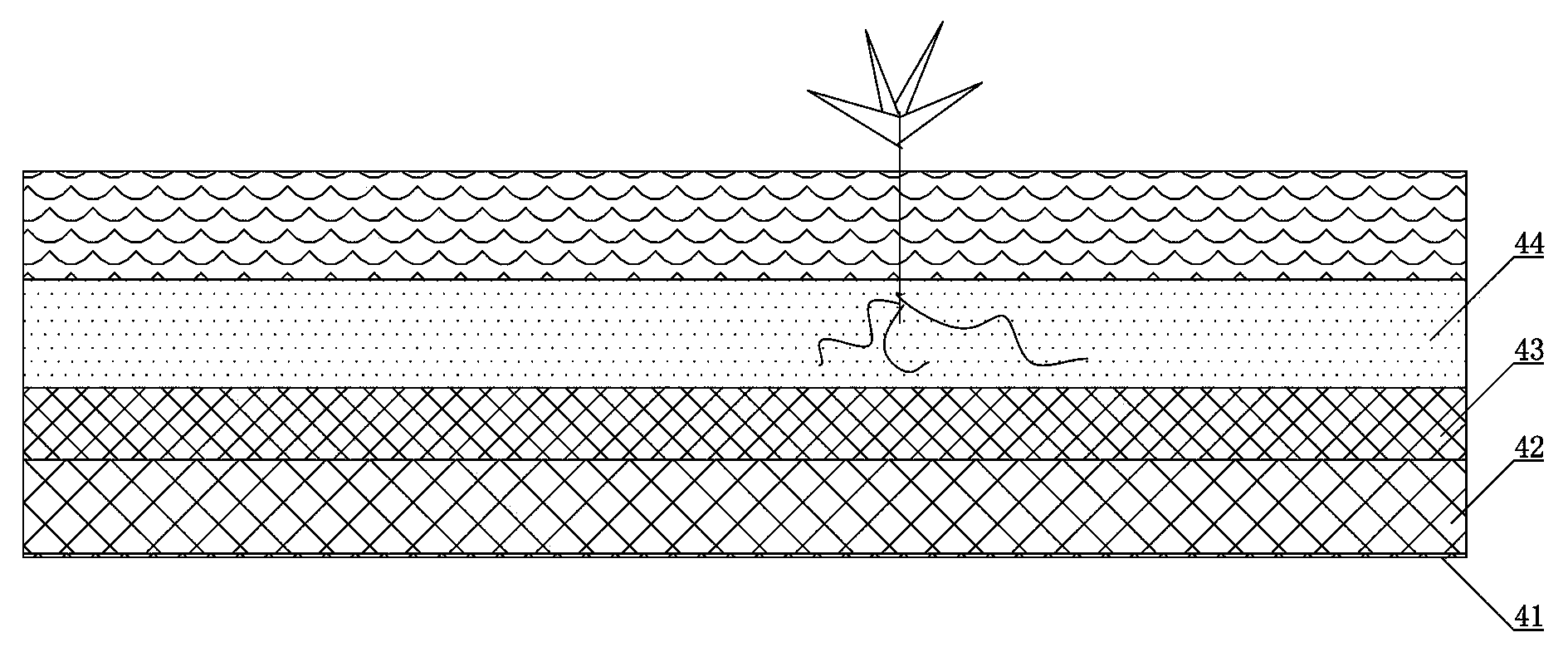

Kitchen effluent treatment method and kitchen effluent treatment device

ActiveCN103708683ARealize the way of civilized water useRealize the collectionMultistage water/sewage treatmentWater storageFiltration

Owner:王凤蕊

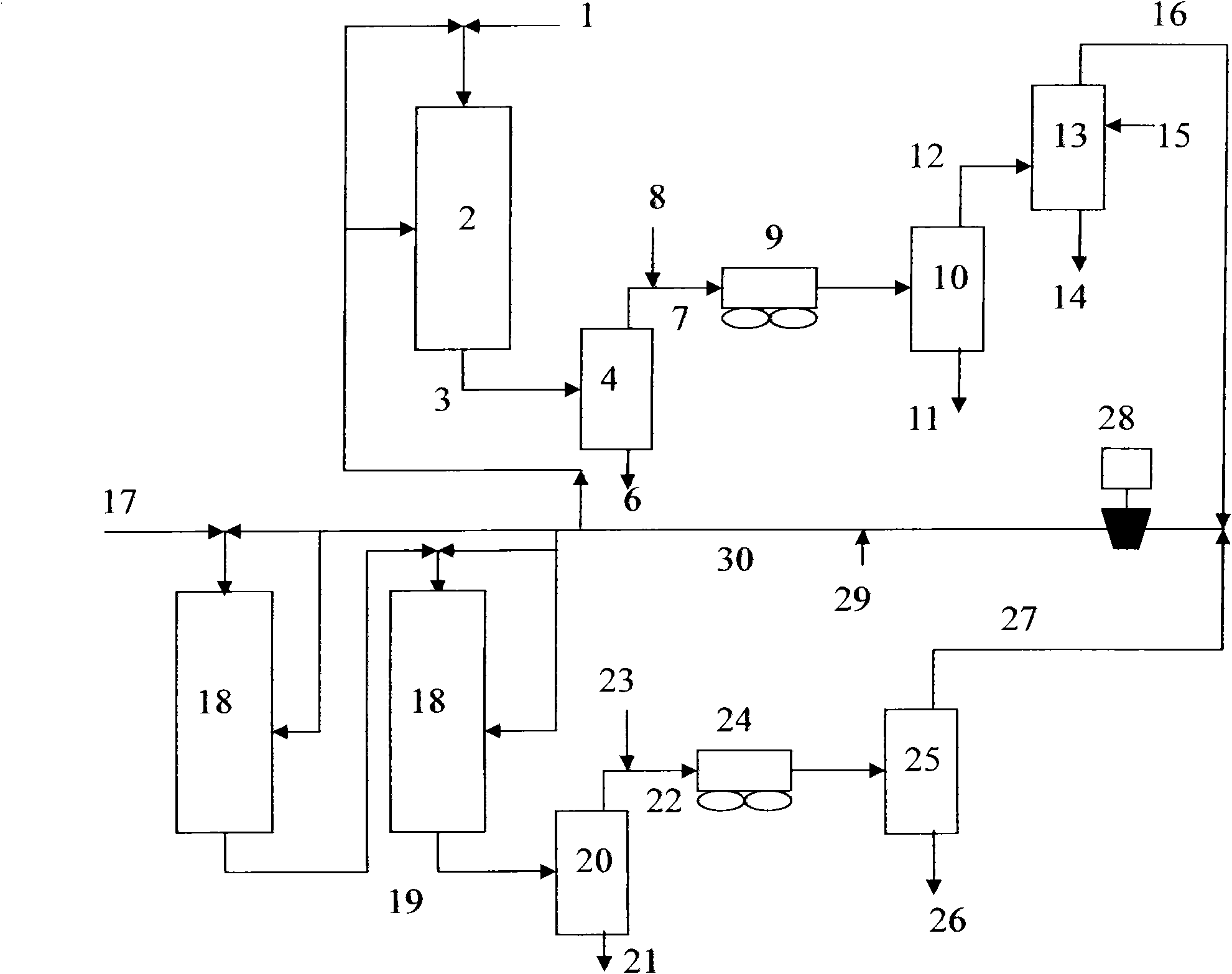

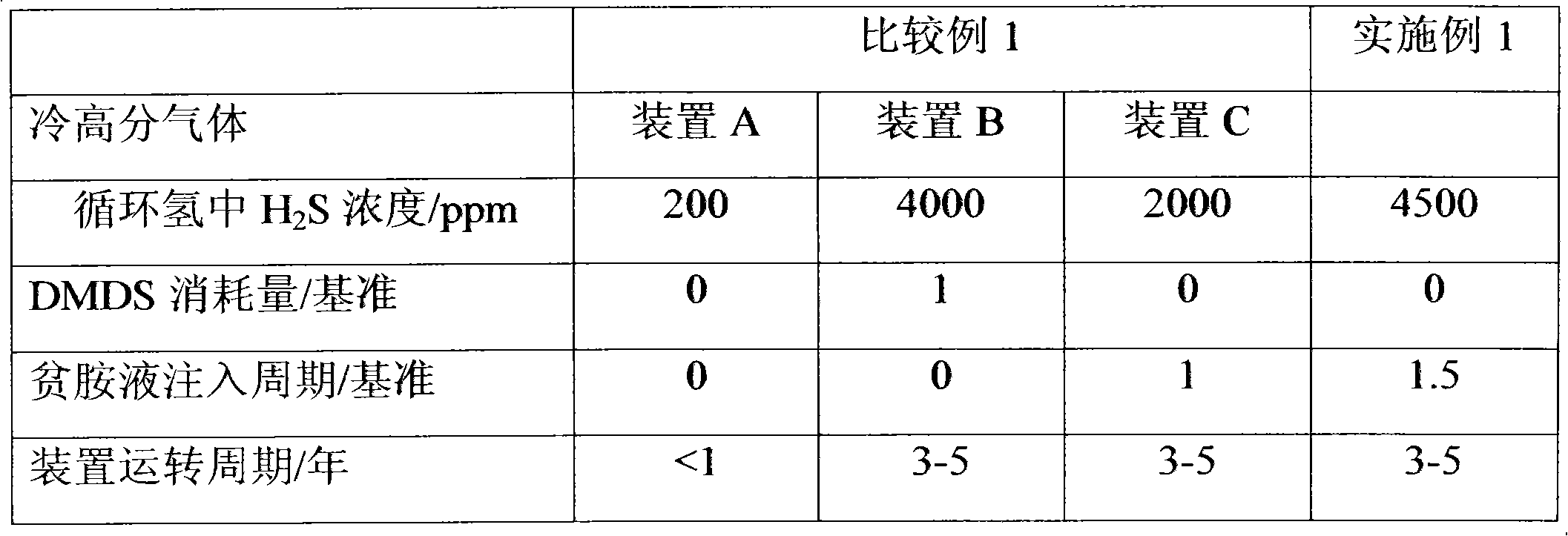

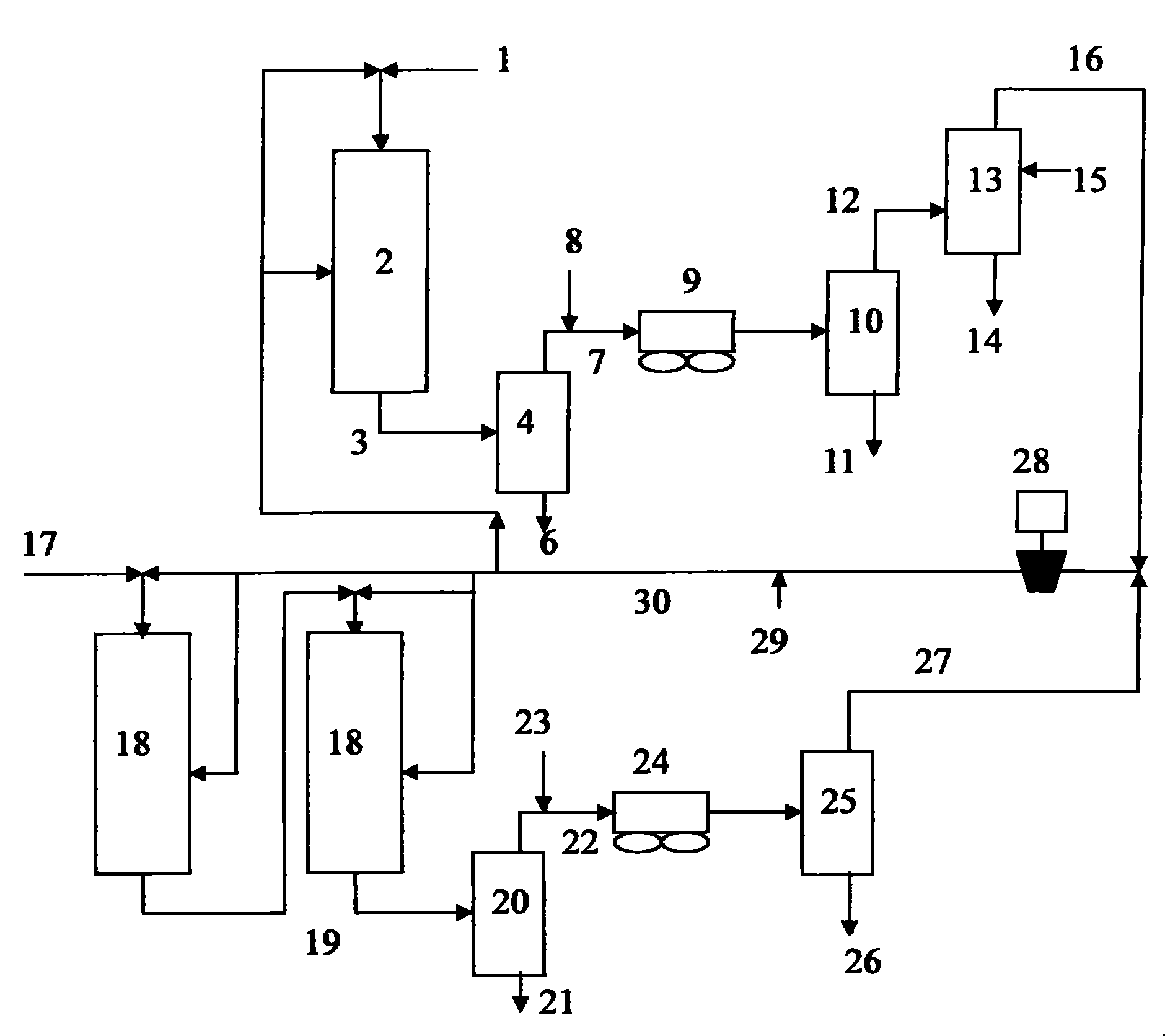

Hydrocracking method for processing low-sulfur raw material

ActiveCN102465014AImprove product qualityIdeal comprehensive processing effectTreatment with hydrotreatment processesHydrogenTotal investment

Owner:CHINA PETROLEUM & CHEM CORP +1

Iodine reducing laminar material and method for processing iodine-enrichment water

InactiveCN1768960AIodine reduction effect is goodInorganic anion exchangersWater/sewage treatment by ion-exchangeMaterials scienceSodium hydroxide

Owner:BEIJING UNIV OF CHEM TECH

Method for further reclamation of L-tyrosine from effluent of L-cystine production

ActiveCN101182297AHigh purityReduce lossOrganic compound preparationAmino-carboxyl compound preparationTyrosineProteolysis

Owner:湖北新生源生物工程有限公司

Reverse-osmosis water purifier purging method

InactiveCN102527243APrevent scalingExtended service lifeSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisStopped workSolenoid valve

The invention discloses a reverse-osmosis water purifier purging method, which includes: when water making of a water purifier is finished, a water pump continues to work in delay mode, and a purging solenoid valve is started for purging membrane elements in delay working of the water pump until waste water concentrated in the previous water making is fully discharged outside a membrane element container; and then the purging solenoid valve is closed, and the water pump continues to work to purge sludge and crystals in a waste water proportioner out through high-speed water under effect of pressure. The reverse-osmosis water purifier purging method has the advantages of timely discharging the concentrated waste water out of the membrane elements before the water purifier stops working, preventing crystals from depositing on surfaces of membranes and in the waste water proportioner, avoiding pollution of the membrane elements and prolonging surface life of the membrane elements.

Owner:A O SMITH (SHANGHAI) ENVIRONMENTAL PRODUCTS CO LTD

Method for treating dinitro-diazophenol (DDNP) primary explosive production wastewater

ActiveCN102003715AHandling safety and environmental protectionZero emissionGeneral water supply conservationEnergy based wastewater treatmentHigh concentrationSolid fuel

Owner:山东圣世达化工有限责任公司

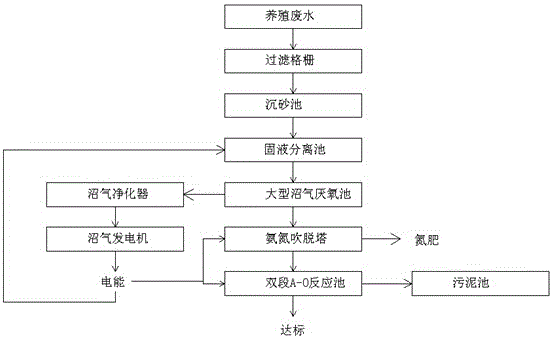

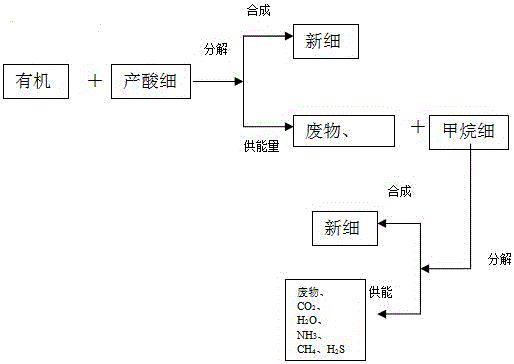

Culture waste water energy self circulation disposal system and method thereof

InactiveCN105152473AIncrease productionImprove electricity consumptionGaseous fuelsWaste based fuelSludgePollution

Owner:GUANGXI YINENG ENVIRONMENTAL PROTECTION ENG CO LTD

Method for producing ethanol by recycling anaerobic digestion effluent and vinasse clear liquid

ActiveCN108841873AIncrease the reuse ratioEmission reductionBiofuelsFermentationFiltrationWater treatment

The invention discloses a method for producing ethanol by recycling anaerobic digestion effluent and vinasse clear liquid and belongs to the technical fields of waste water treatment and ethanol fermentation industry. The method comprises the following steps: mixing and blending membrane filtrate obtained after membrane filtration of anaerobic digestion effluent, part of vinasse clear liquid, other material mixing water and crushed cereal raw materials, and performing processes of liquefying, saccharifying, fermenting and distilling to obtain ethanol, wherein the membrane filtrate accounts for30 to 90 percent of the total weight of the blending water, the vinasse clear liquid accounts for 10 to 40 percent of the total weight of the blending water, and the rest is other material mixing water; and the concentration of volatile acid of the blending water is controlled to be 100 to 1200 mg / L (based on acetic acid) by adjusting the proportion of the membrane filtrate, the vinasse clear liquid and other material mixing water or adding the acetic acid. By the method, discharge of ethanol production waste water is greatly reduced and water resources are saved; meanwhile, the problem thatthe ethanol is fermented to generate acid is effectively avoided, the alcohol yield is significantly increased, the utilization rate of the raw materials is increased by 1 to 5 percent, and the production energy consumption and cost of the ethanol are reduced.

Owner:JIANGNAN UNIV

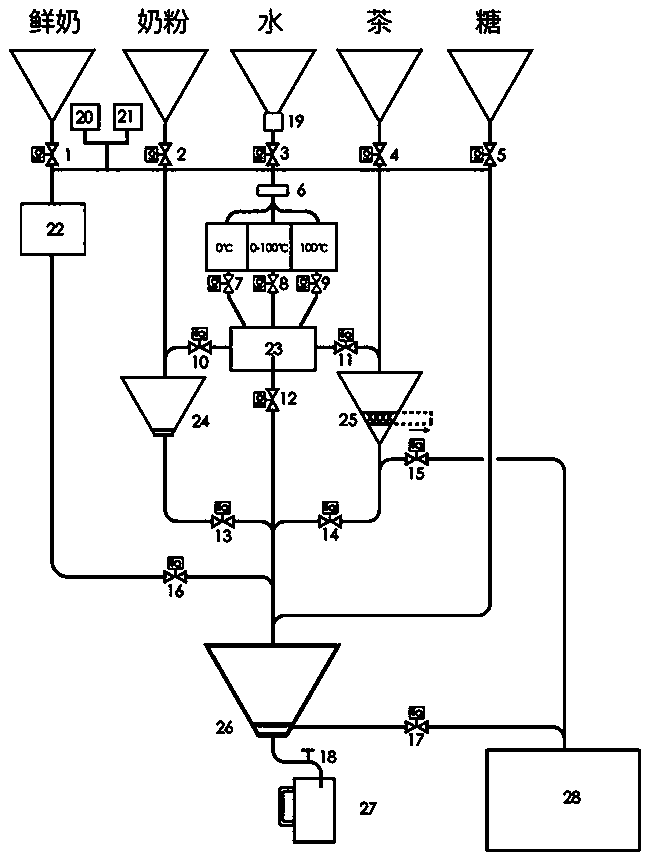

Domestic multifunctional automatic milk tea machine device

InactiveCN108814301ANo heat lossReduce heat lossBeverage vesselsControl systemAgricultural engineering

Owner:ZHANGJIAGANG INST OF IND TECH SOOCHOW UNIV +1

High-ammonia-nitrogen and high-hardness waste water pretreatment device, treatment system and treatment method

InactiveCN110078263AHigh total hard removal rateReduce turbidityWater aerationWater softeningNitrogenHardness

The invention provides a high-ammonia-nitrogen and high-hardness waste water pretreatment device, a treatment system and a treatment method. The pretreatment device comprises a buffer blowoff pool, aeration equipment and a coagulation pool; the buffer blowoff pool is provided with an alkaline regulator inlet, a waste water inlet and a buffer blowoff pool water outlet; the aeration equipment is arranged at the bottom of the buffer blowoff pool; the coagulation pool comprises a coagulant inlet, a coagulation pool water inlet and a coagulation pool water outlet; the buffer blowoff pool water outlet is communicated with the coagulation pool water inlet. The aeration equipment is arranged at the bottom of the buffer blowoff pool, the alkaline regulator added from the alkaline regulator inlet and high-annomia-nitrogen and high-hardness waste water are subjected to completely mixed reaction, part of calcium and magnesium ions in the waste water can be converted into precipitate by the alkaline regulator to be removed, and ammonia nitrogen can be removed preliminarily, so that the efficiency of removing the total hardness by the device is high, and the influence on the subsequent biochemical treatment and underwater equipment scaling is greatly reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Improved coconut shell and method thereof for reducing vanadium in water body

InactiveCN107617425ALarge specific surface areaEasy to prepareOther chemical processesWater contaminantsSocial benefitsAlcohol

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

Highland barley biological control disease-resistant and growth promoting method

InactiveCN104620817APromote decompositionNo emissionsBio-organic fraction processingOrganic fertiliser preparationBiotechnologyDisease

Owner:ZHEJIANG UNIV

Dialkene-containing gasoline fraction hydrotreating method

InactiveCN102559261AEasy to removeSolve cokingTreatment with hydrotreatment processesFluid phaseReaction temperature

The invention provides a dialkene-containing gasoline fraction hydrotreating method. The method comprises the following steps: (1) directly mixing a dialkene-containing gasoline fraction raw material with a hot hydrogen-donor solvent, and feeding the mixture into a hydropretreating reactor for dialkene-removing reaction when the temperature of the mixture reaches the dialkene-removing reaction temperature; (2) mixing reaction effluent of the hydropretreating reactor with hydrogen gas, feeding the mixture into a heating furnace, heating the mixed material until the temperature of the mixed material reaches the temperature required by the inlet of the hydrotreating reactor, feeding the mixed material into a separator, separating the mixed material into a gas phase and a liquid phase, wherein the liquid phase is mainly the hydrogen-donor solvent and is circulated to the step (1) for use, and the separated gas phase is fed into the hydrotreating reactor so as to be subjected to hydrogenation impurity-removal reaction; and (3) feeding the reaction effluent of the hydrotreating reactor into a separation system, separating out the hydrotreated gasoline fraction and a gas phase, wherein the gas phase is mainly the hydrogen gas and is recycled. Compared with the prior art, the method provided by the invention can be used for effectively solving the coking problem of a dialkene-containing gasoline fraction hydrotreater.

Owner:何裕松

Fluid extraction of metals of metalloids

InactiveCN1265160AEfficient extractionEfficient separationSolid waste disposalSeparation devicesSolventPhosphine

Owner:IDAHO RESARCH FOUNDATION INC

Device for treating high-concentration ammonia nitrogen in coking wastewater by using surfactant

InactiveCN103570085AAvoid secondary pollutionSimple structureWater contaminantsWater/sewage treatmentHigh concentrationPrimary standard

Owner:CHANGZHOU UNIV

Preparation method of pyrite tailing ceramsite proppant

ActiveCN105801162AHigh strengthLight weightCeramic materials productionCeramicwareHigh pressureLow density

Owner:GONGYI CITY GUANGMING CHEM

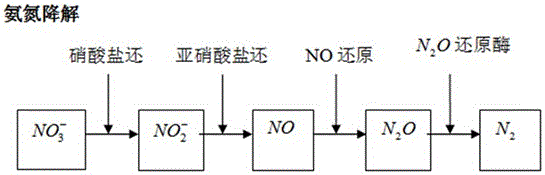

Method for improving removal effect of nitrogen pollutants in sewage

ActiveCN106927576AReduce processing costsNovel structural designBacteriaWater contaminantsHigh concentrationActivated sludge

Owner:FUDAN UNIV

Ultrahigh-filtering-speed IV-class water upgrading standard transformation nitrogen and phosphorus removal device and a treatment process thereof

PendingCN111170590ASolve easy blockageSolve the blockageTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsInorganic phosphateNitrogen removal

Owner:安徽绿衡环保科技有限公司

Filtering and purifying device for chemical wastewater treatment

ActiveCN111533222AAvoid accumulationConvenient and fast delegatingSpecific water treatment objectivesWater contaminantsStructural engineeringProcess engineering

Owner:YUNCHENG UNIVERISTY

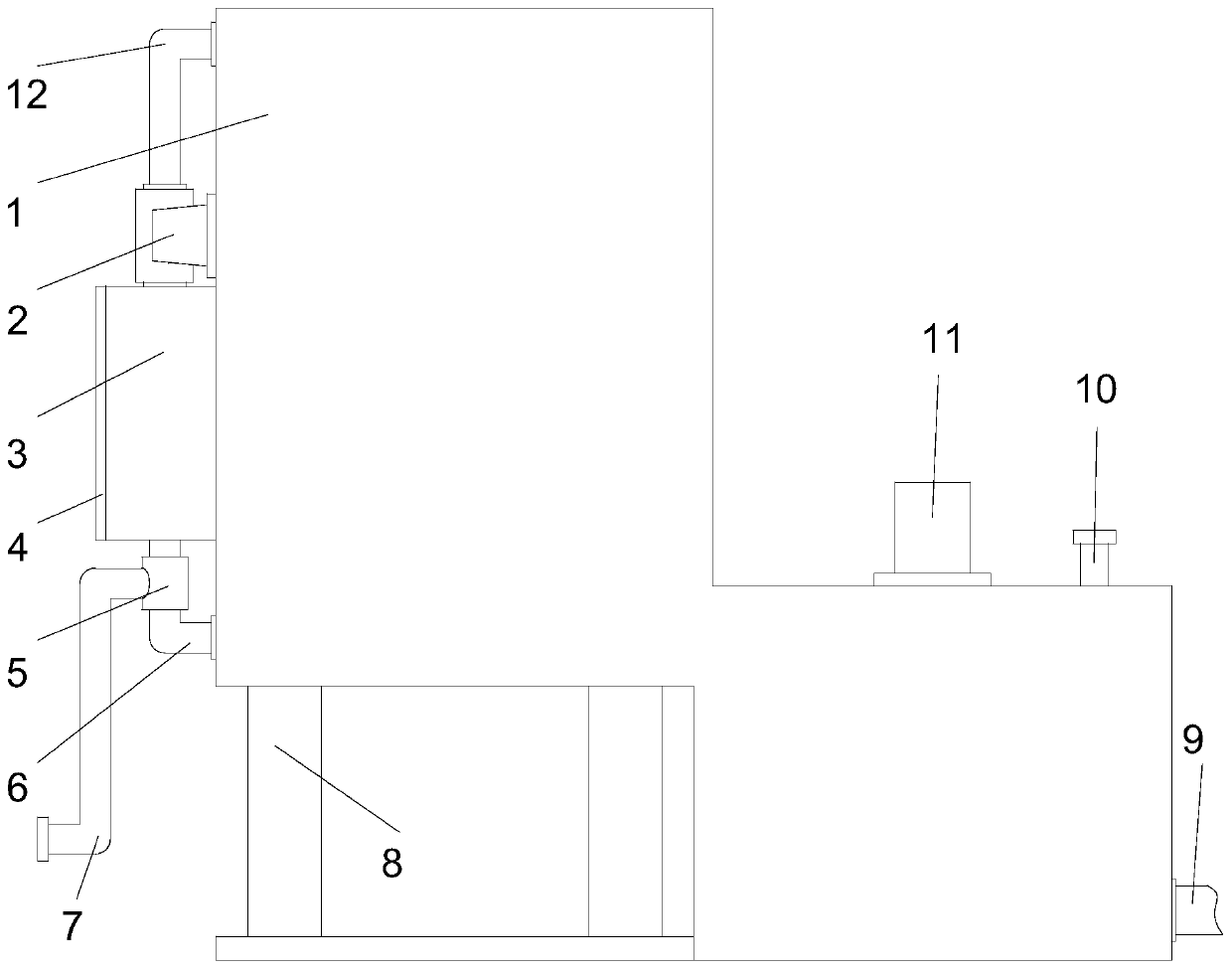

Ammonia distillation and dephenolization coupling device for semi-coke production wastewater and process thereof

InactiveCN112299513AImprove the heating effectAccelerate evaporationWater contaminantsSteam generation using pressureCombustion chamberThermodynamics

The invention relates to the technical field of semi-coke wastewater treatment, in particular to an ammonia distillation and dephenolization coupling device for semi-coke production wastewater. The device comprises a heating mechanism, a spray tower is erected above the heating mechanism, a heat exchange mechanism is installed on the side wall of the spray tower, a preheating mechanism is arrangedon the side, away from the heat exchange mechanism, of the spray tower, and the preheating mechanism is connected with the heating mechanism; and an air conveying mechanism is mounted on the heatingmechanism. Through the arranged heating mechanism, water vapor containing phenol can be combusted, then the combusted phenol is decomposed into water and carbon dioxide, formed water vapor performs heat exchange in the heat exchange mechanism, the heating mechanism can further heat phenol-containing liquid entering a heating chamber, the phenol-containing liquid is vaporized and then conveyed intoa combustion chamber through the air conveying mechanism to be combusted, water in a water guide pipe can be preheated through the arranged preheating mechanism, and a large amount of water can be saved.

Owner:INNER MONGOLIA LANHUOYAN TECH & ENVIRONMENTAL PROTECTION CO LTD

Sewage recycling and reusing apparatus

InactiveCN103233500AEmission reductionReduce deteriorationDomestic plumbingWater supply installationSewageEnvironmental degradation

Owner:SUZHOU GREEN BUILDING TECH RES CENT

Waste water valve, and reverse osmosis water purifier

ActiveCN107998888ASimple waterwaySimple structureReverse osmosisWater/sewage treatment bu osmosis/dialysisReverse osmosisWater purification filter

Owner:FOSHAN SHUNDE MIDEA WATER DISPENSER MFG +1

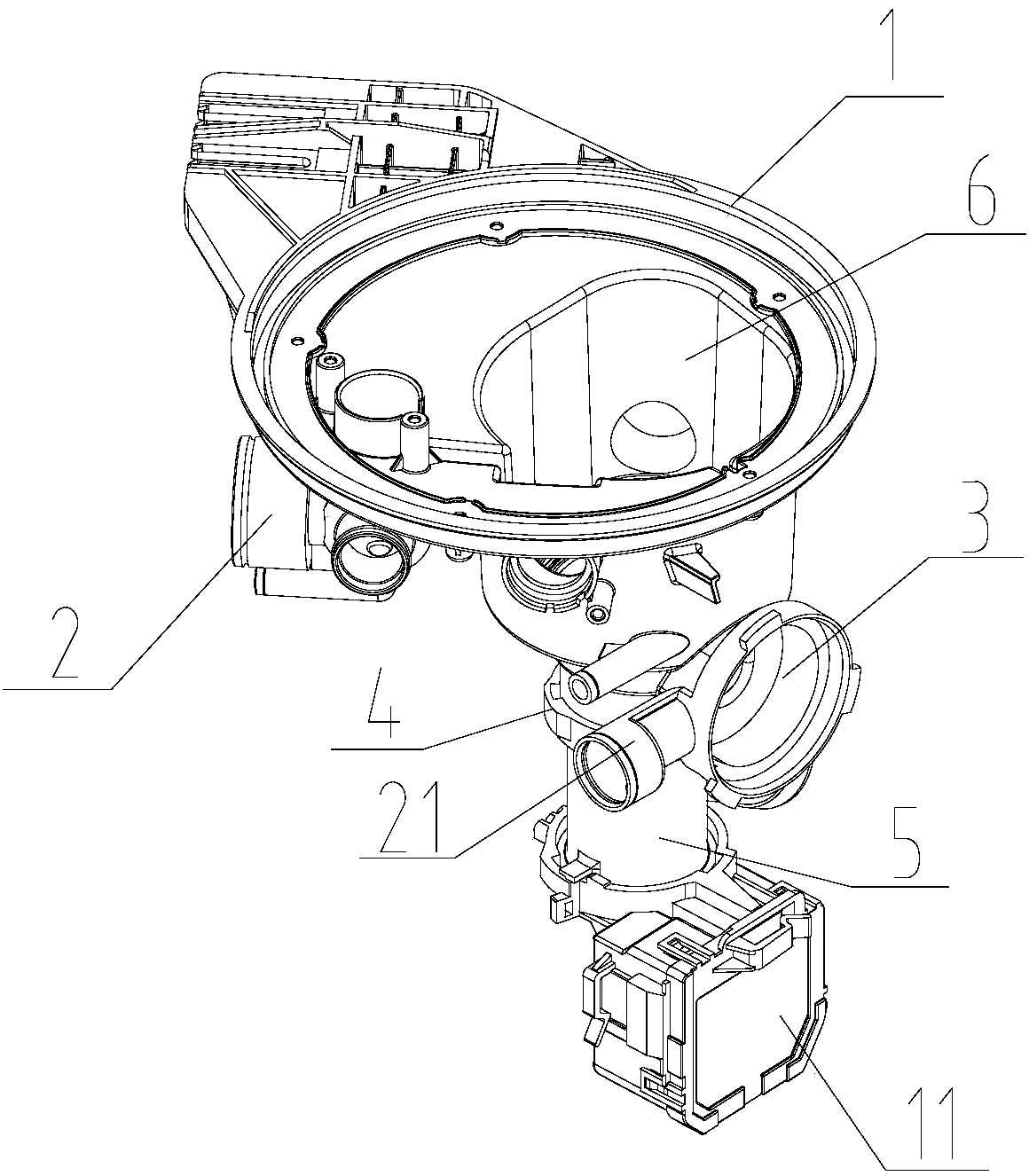

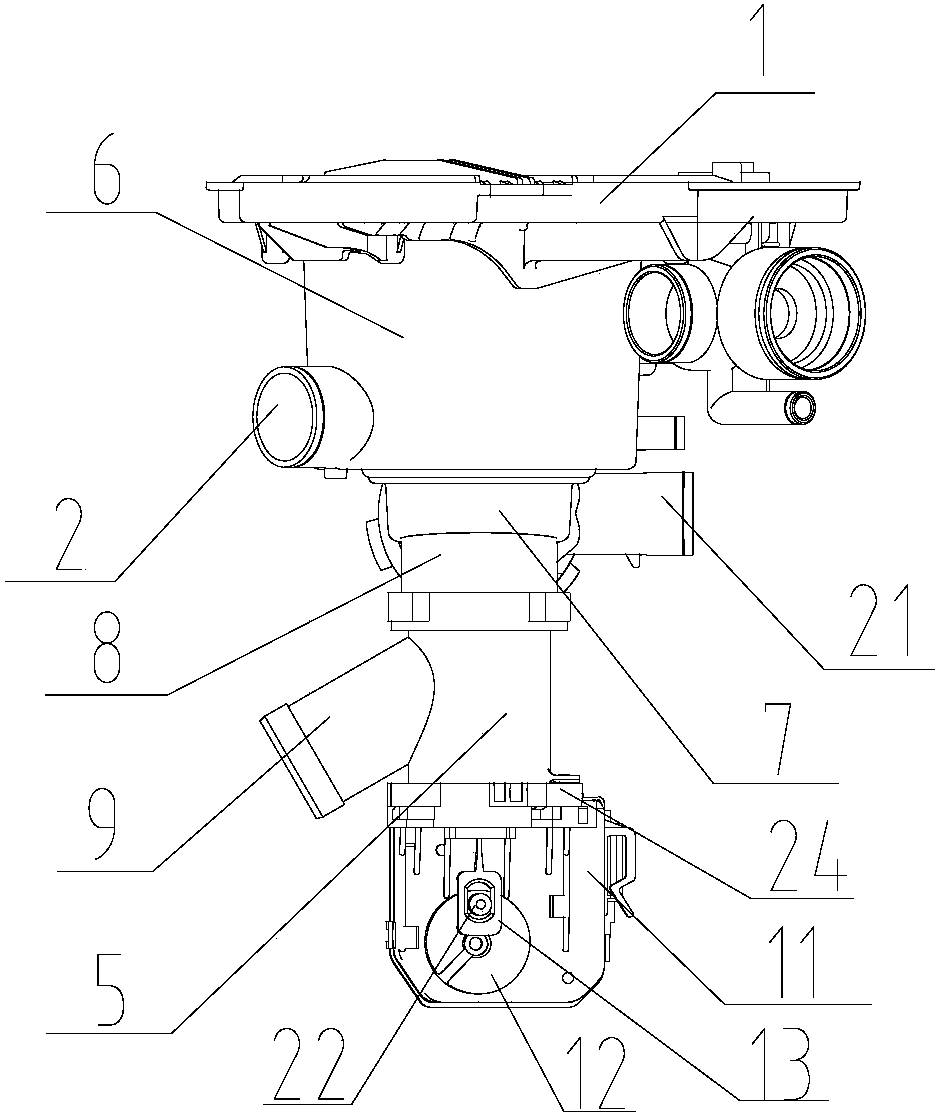

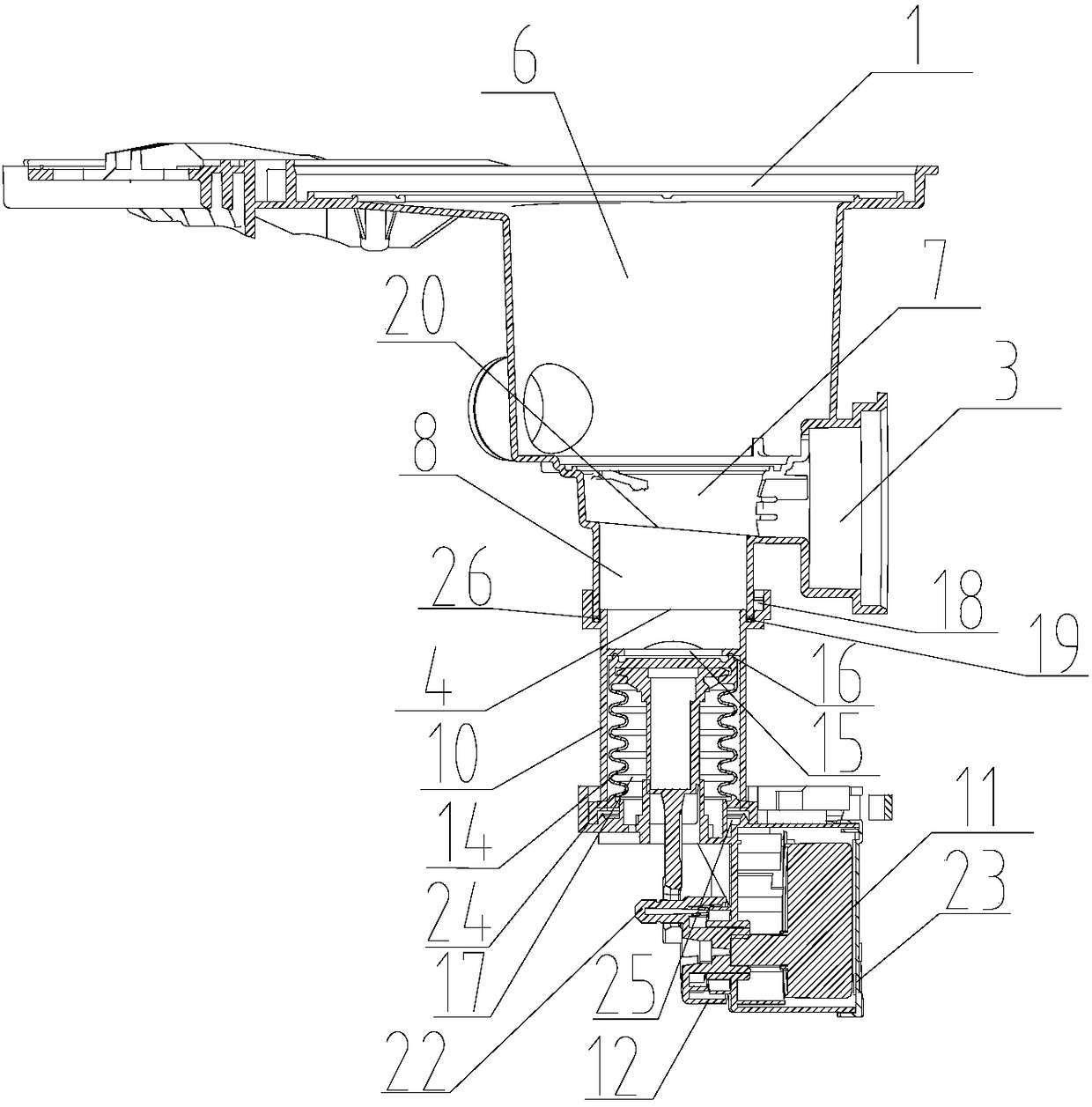

Dishwasher sink drainage method, drainage structure and dishwasher

PendingCN108420383ANoise Reduction IndexImprove water efficiencyTableware washing/rinsing machine detailsWater dischargeEngineering

Owner:QINGDAO HAIER DISHWASHER

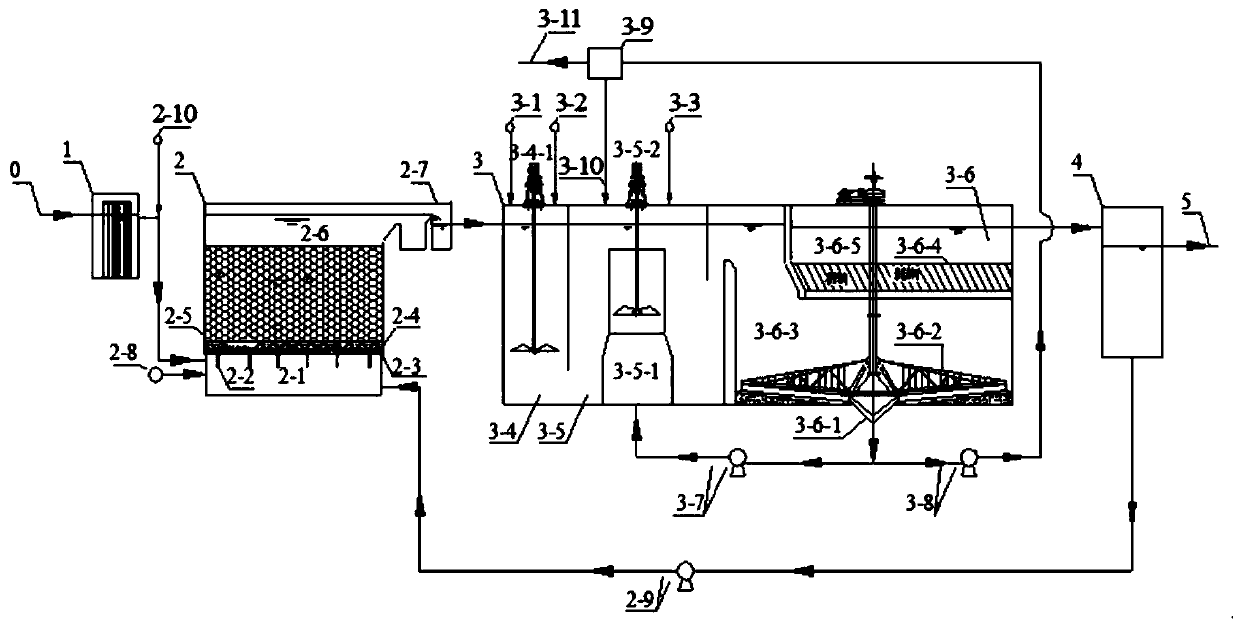

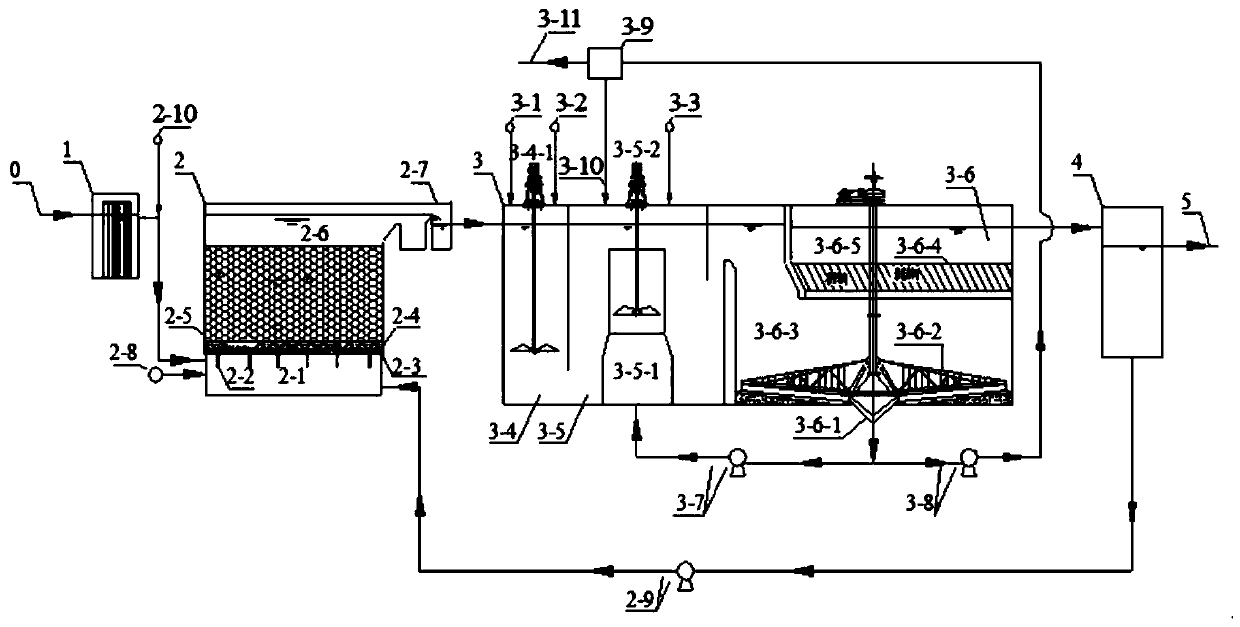

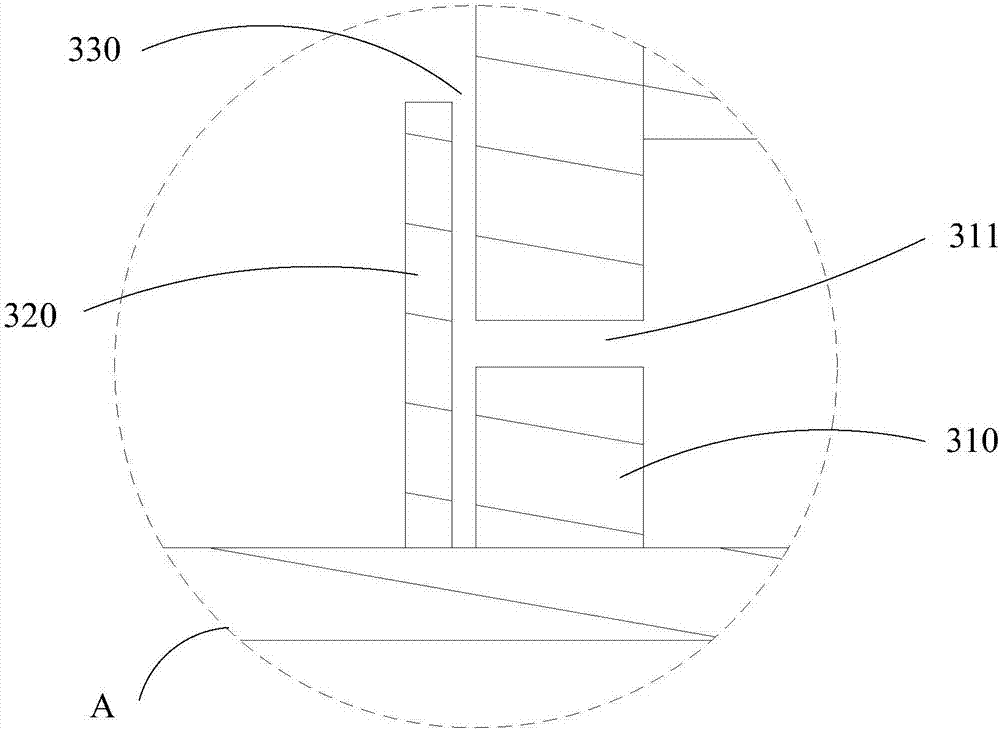

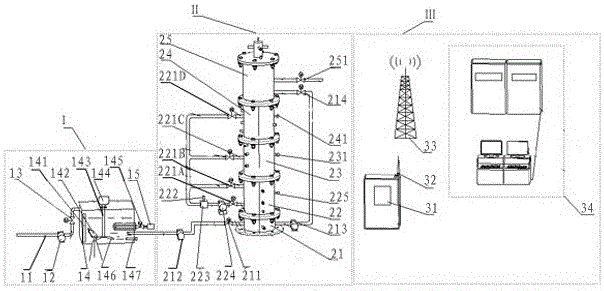

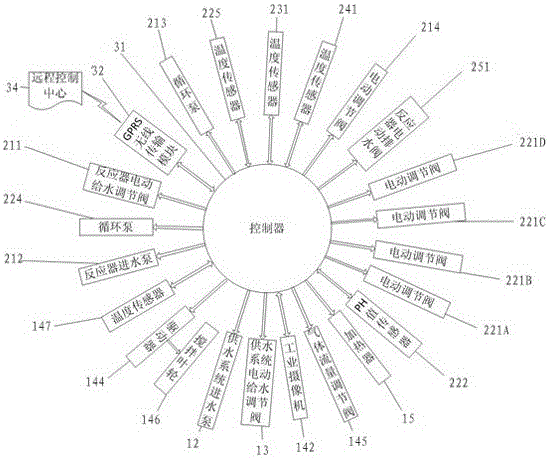

Automatic detection and control system for spiral symmetrical flow anaerobic reactor

ActiveCN105116945AReduce usageReduce manufacturing costTreatment with anaerobic digestion processesSimultaneous control of multiple variablesWireless transmissionRemote control

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Water purifier for production of rubber accelerator DZ and wastewater treatment method

InactiveCN105967449AImprove water qualityEmission reductionWater/sewage treatmentMultistage water/sewage treatmentChemical treatmentMicrobial agent

The invention belongs to the technical field of rubber chemical wastewater treatment and particularly relates to a water purifier for production of a rubber accelerator DZ and a wastewater treatment method. The water purifier for production of the rubber accelerator DZ comprises a solid adsorption material, a microbial water purifier and an enzyme preparation. The solid adsorption material is prepared from, by weight, 10-25 parts of medical stone, 5-20 parts of active coke and 5-15 parts of slag; the microbial water purifier is prepared from, by weight, 0.5-2.0 parts of phosphorus-accumulating bacteria powder, 0.4-1.4 parts of geotrichum candidum powder, 0.2-0.8 part of white rot fungi powder and 0.3-1.2 parts of microbacterium powder; the enzyme preparation comprises, by weight, 0.05-0.1 part of manganese catalase, 0.04-0.12 part of oxidoreductase, 0.03-0.08 part of streptomyces protease and 0.02-0.1 part of nitrile hydratase. By joint action of the solid water purifier, the composite microbial agent and the enzyme preparation to wastewater, secondary pollution caused by chemical treatment is avoided, sewage discharging amount is decreased, and quality of treated wastewater is improved. In addition, by the wastewater treatment method, CODcr discharging amount reaches national specified standards.

Owner:SHANDONG YONGTAI CHEM GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap