Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

12 results about "Spray tower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A spray tower (or spray column or spray chamber) is gas-liquid contactor used to achieve mass and heat transfer between a continuous gas phase (that can contain dispersed solid particles) and a dispersed liquid phase. It consists of an empty cylindrical vessel made of steel or plastic, and nozzles that spray liquid into the vessel. The inlet gas stream usually enters at the bottom of the tower and moves upward, while the liquid is sprayed downward from one or more levels. This flow of inlet gas and liquid in opposite directions is called countercurrent flow.

Industrial gas purification dust removal equipment

InactiveCN106731372ASimple structureEasy to useHuman health protectionCombination devicesParticulatesHEPA

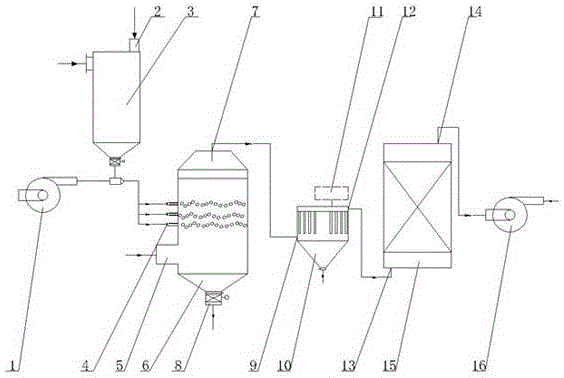

The invention discloses industrial gas purification dust removal equipment, which comprises an air inlet pipeline, a cyclone separation tower, an electrostatic dust removal tower, a spraying tower, an activated carbon adsorption device and an air outlet pipeline, wherein the air inlet pipeline is arranged on an air inlet of the cyclone separation tower; a first centrifugal fan is arranged on the air inlet pipeline; an air outlet of the cyclone separation tower is connected with the air inlet of the cyclone separation tower; the air outlet of the cyclone separation tower communicates with an air inlet of the electrostatic dust removal tower; an HEPA (high efficiency particulate air) filtering net is arranged inside a pipeline for connecting the cyclone separation tower and the electrostatic dust removal tower; an air outlet of the electrostatic dust removal tower communicates with an air inlet of the spraying tower. The industrial gas purification dust removal equipment has the advantages that the structure is simple; the use is convenient; effective purification and dust removal can be performed on industrial waste gas; the purification effect is good; in addition, the environment pollution can be reduced; a protection effect is achieved on environment; meanwhile, industrial dust can be removed, so that the work environment of workers is more comfortable and healthy.

Owner:HEFEI QIFEI INFORMATION TECH CO LTD

Waste liquid and waste gas treatment system

PendingCN109821397AAchieve couplingWater contaminantsDispersed particle separationSpray towerEnvironmental resistance

The invention provides a waste liquid and waste gas treatment system, which comprises a spraying tower and a biological filtering bed connected with the spraying tower, wherein a sensing device and acentral control part which are connected with each other are mounted in the system; a preliminary filtering component is arranged inside the spraying tower; a water inlet path and an air inlet path are connected to the spraying tower; the spraying tower is communicated with the reaction groove through a water outlet path and an air outlet path; and a depth filtering component is arranged in the biological filtering bed. The combination of the spraying tower and the biological filtering bed to realize the coupling of waste gas treatment process and wastewater spraying treatment process is an innovative technology in the field of environmental protection, so that the system has a wide application prospect.

Owner:广州益禄丰生态环保科技有限责任公司 +1

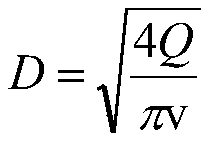

Method for removing acid gas in fume gas using a spray tower

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

Treatment system of smoke organic waste gas produced in circuit board disassembly

Owner:SOUTH CHINA UNIV OF TECH

Microbiological deodorization method

InactiveCN112246097AReduce governance costsNatural degradationGas treatmentDispersed particle separationSpray towerEnvironmental chemistry

The invention discloses a microbiological deodorization method, which belongs to the technical field of disinfection and deodorization, and comprises the following steps: S1, preparing a microbial preparation, S2, pre-stirring a strain combination; S3, preparing a deodorant from the prepared composite microbial preparation according to the mass; and S4, putting a prepared deodorant into an ultrasonic atomizer or a spray tower. According to the invention, the microbial preparation is creatively adopted to perform spray deodorization on the odor source, so that the deodorization efficiency is high, the effect is good, the treatment cost of the odor source and odor is effectively reduced, the overall operation difficulty is low, only the polluted area is atomized, the odor is effectively controlled before volatilization, the odor pollution spreading can be effectively controlled, and the influence on the operation environment is avoided; the microbial inoculum is non-toxic, can be naturally degraded, has no residue after deodorization, does not need additional neutralization and filtration, has higher environmental adaptability, and meets the deodorization requirements of small and medium-sized farms and small and medium-sized garbage collection stations.

Owner:福建元景之态生物科技有限公司

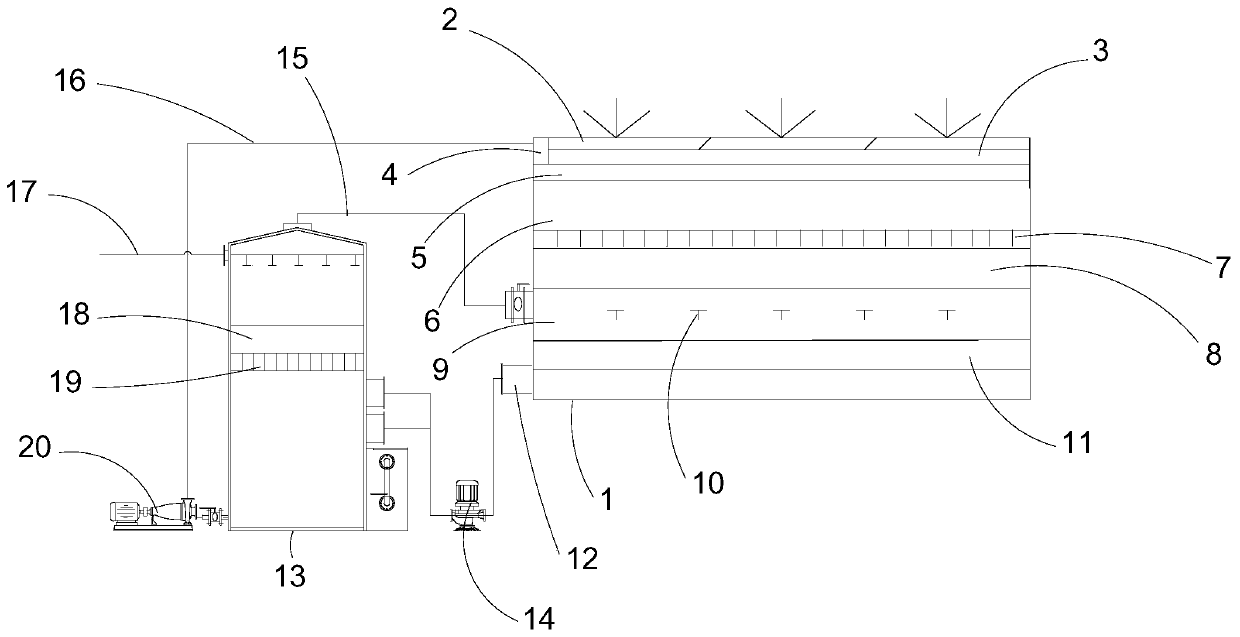

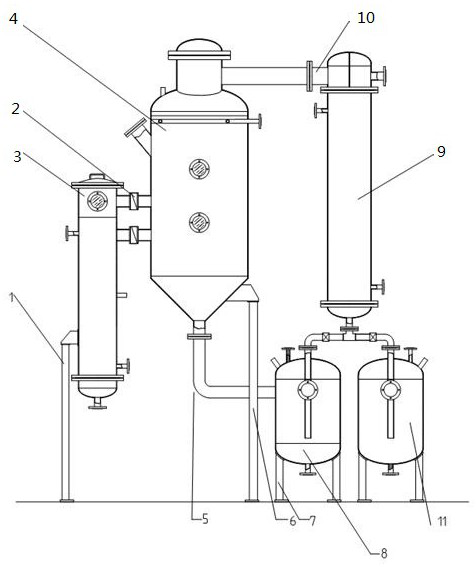

Ammonia distillation and dephenolization coupling device for semi-coke production wastewater and process thereof

InactiveCN112299513AImprove the heating effectAccelerate evaporationWater contaminantsSteam generation using pressureCombustion chamberThermodynamics

The invention relates to the technical field of semi-coke wastewater treatment, in particular to an ammonia distillation and dephenolization coupling device for semi-coke production wastewater. The device comprises a heating mechanism, a spray tower is erected above the heating mechanism, a heat exchange mechanism is installed on the side wall of the spray tower, a preheating mechanism is arrangedon the side, away from the heat exchange mechanism, of the spray tower, and the preheating mechanism is connected with the heating mechanism; and an air conveying mechanism is mounted on the heatingmechanism. Through the arranged heating mechanism, water vapor containing phenol can be combusted, then the combusted phenol is decomposed into water and carbon dioxide, formed water vapor performs heat exchange in the heat exchange mechanism, the heating mechanism can further heat phenol-containing liquid entering a heating chamber, the phenol-containing liquid is vaporized and then conveyed intoa combustion chamber through the air conveying mechanism to be combusted, water in a water guide pipe can be preheated through the arranged preheating mechanism, and a large amount of water can be saved.

Owner:INNER MONGOLIA LANHUOYAN TECH & ENVIRONMENTAL PROTECTION CO LTD

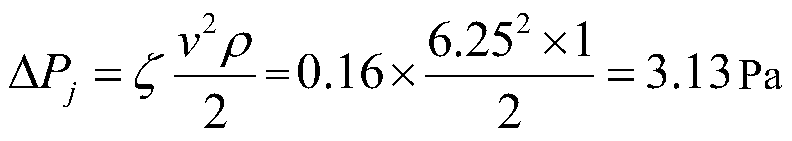

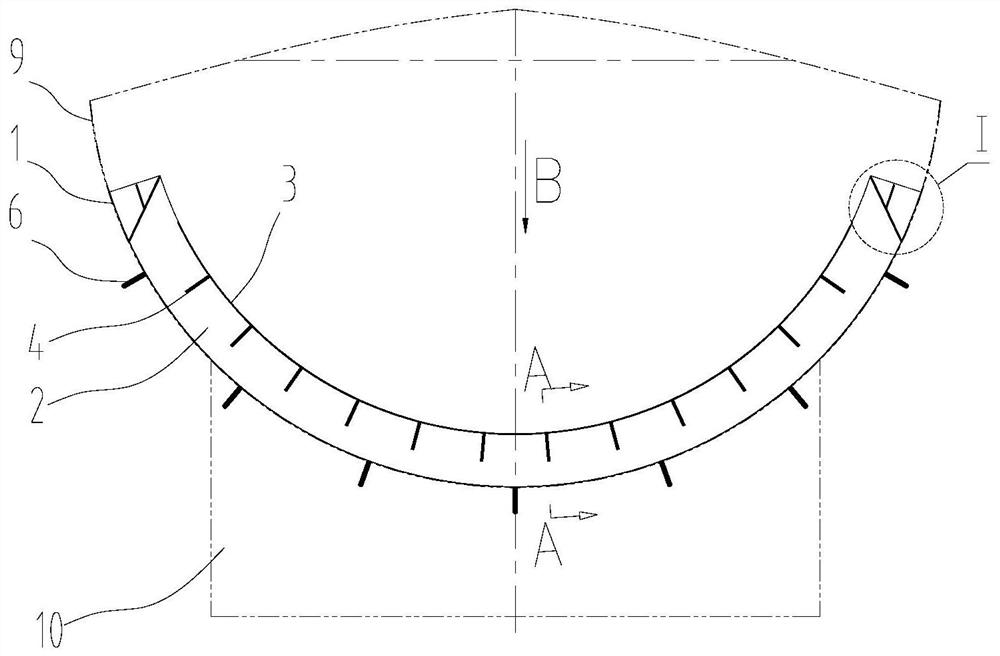

Energy-saving device of wet desulphurization spray tower

Owner:浙江菲达环保科技股份有限公司

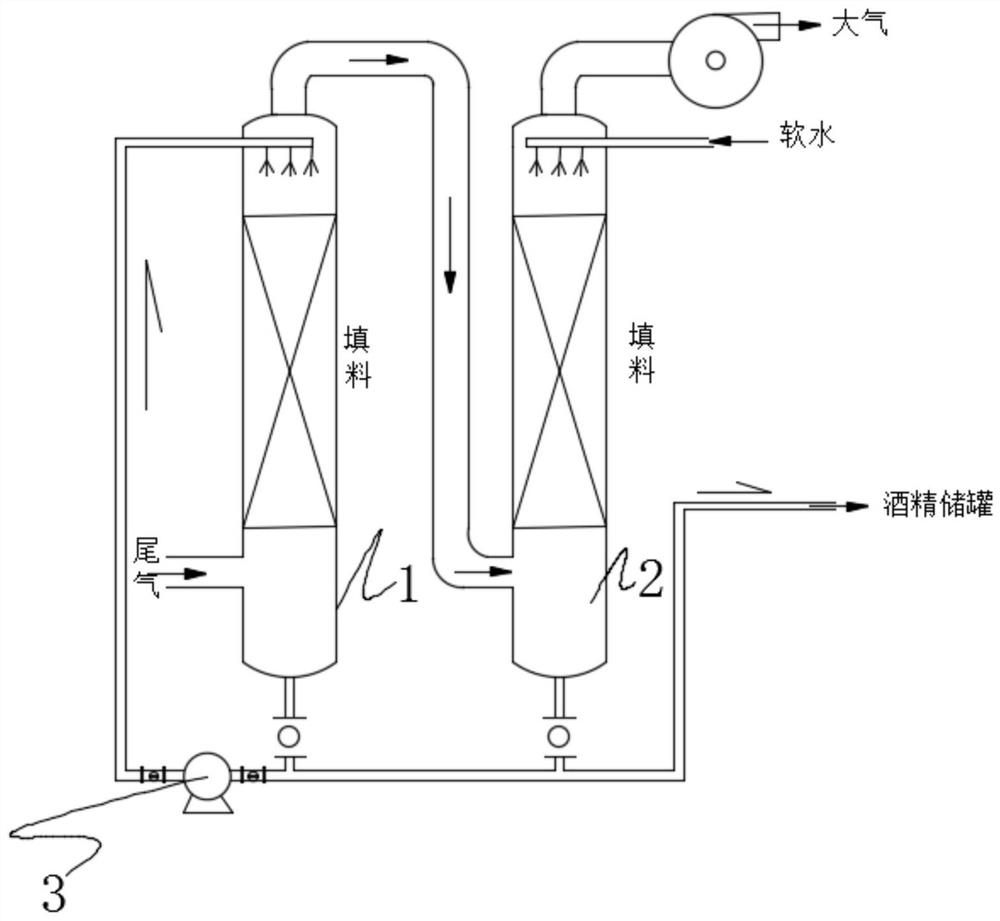

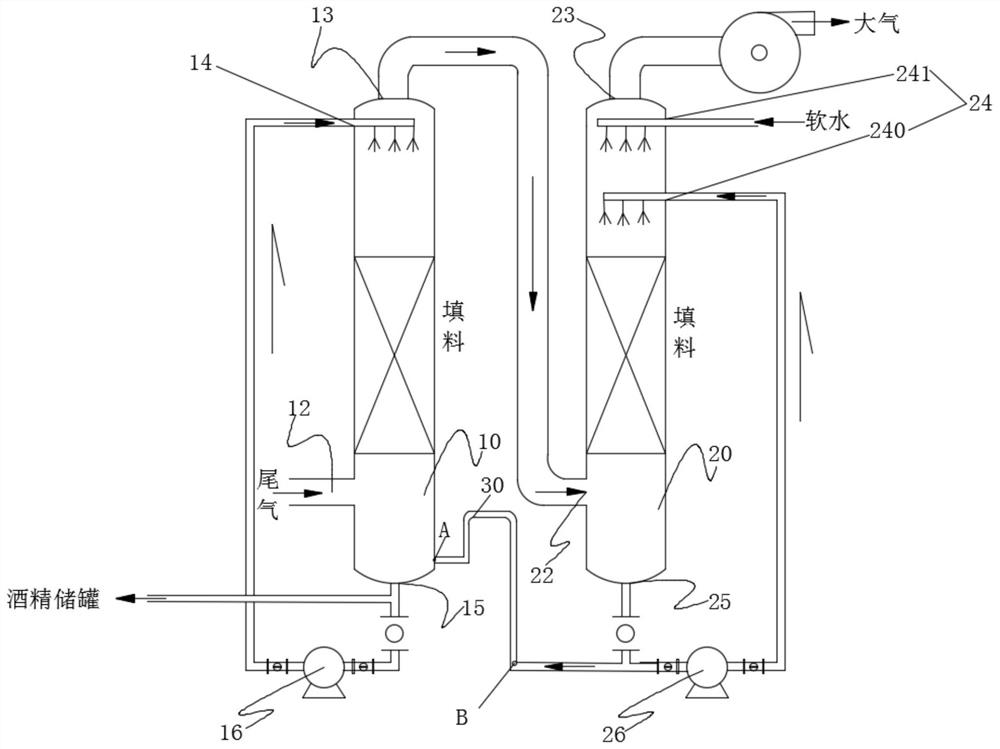

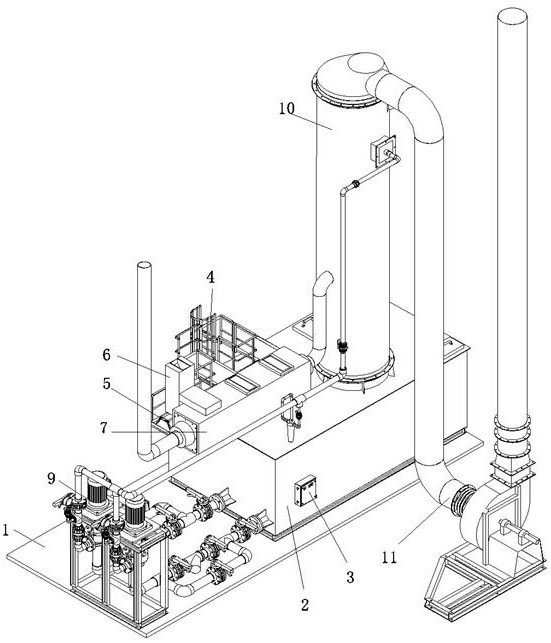

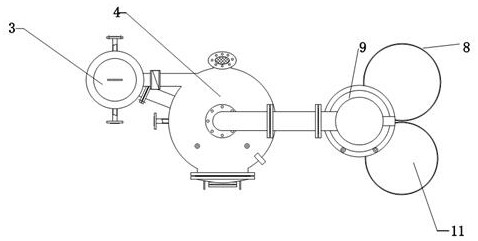

Ethanol recovery system

Owner:益海(防城港)大豆工业有限公司

Waste gas treatment device for thermosensitive adhesive production

Owner:滁州都铂新材料科技有限公司

Refrigerating device

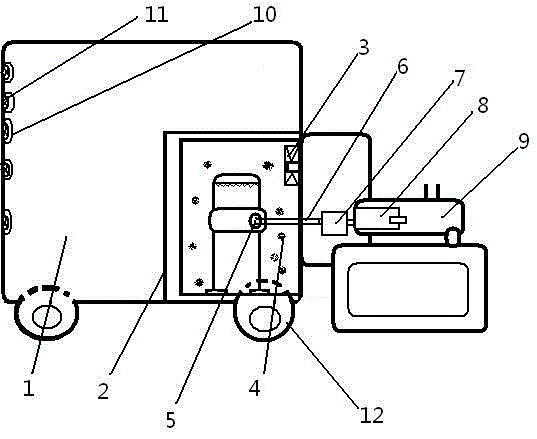

InactiveCN105423467ADomestic cooling apparatusLighting and heating apparatusSpray towerWater cycling

Owner:丁巧娜

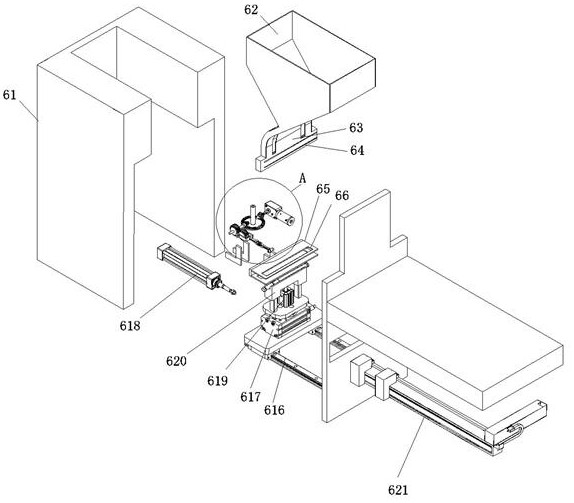

Solvent recovery device of isoprene rubber device

PendingCN114768482AIncrease unit adsorption areaImprove adsorption efficiencyGas treatmentDispersed particle separationSpray towerComposite material

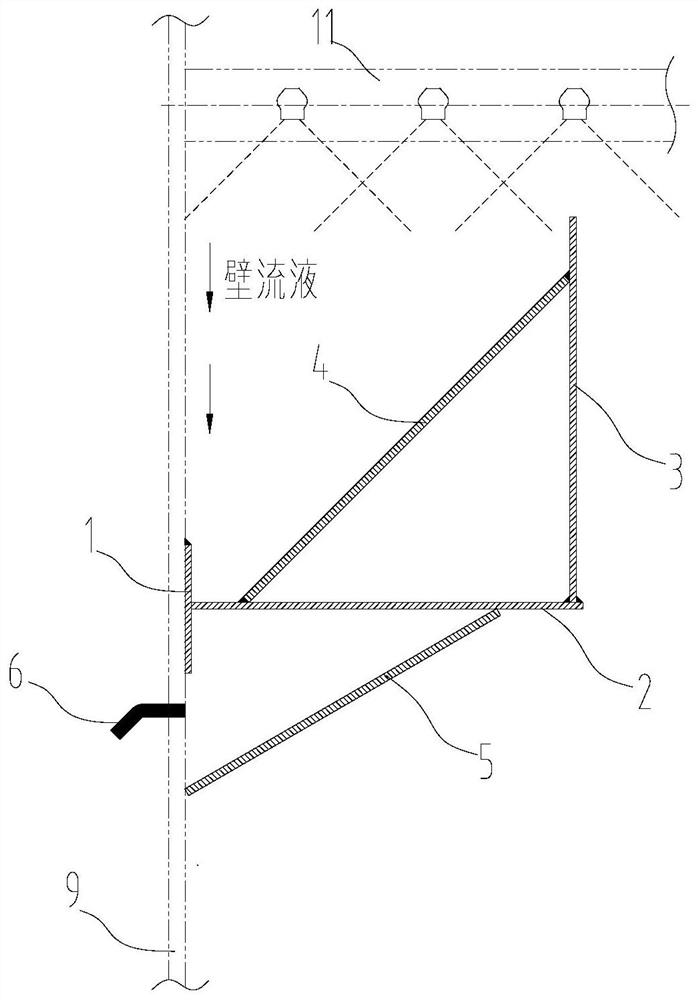

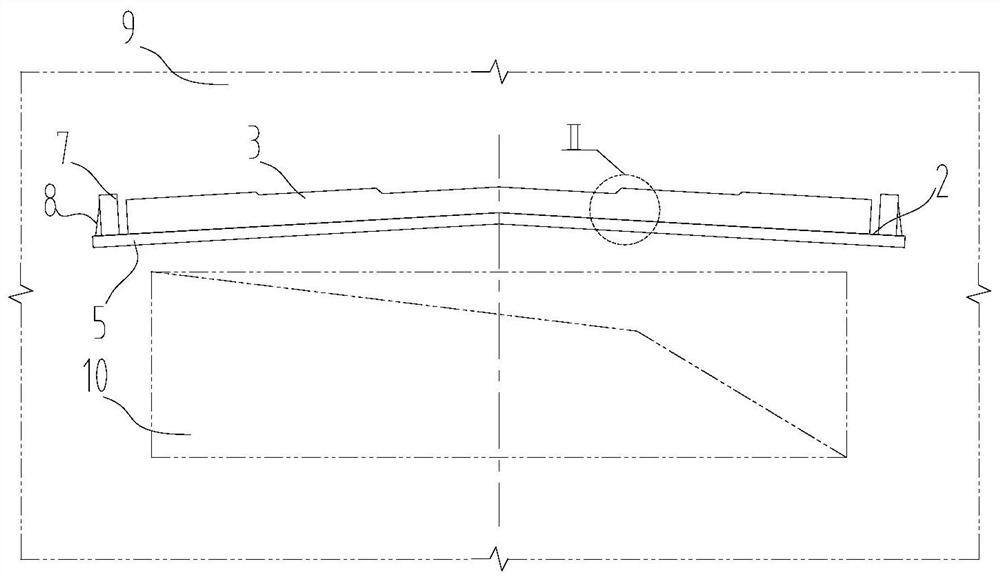

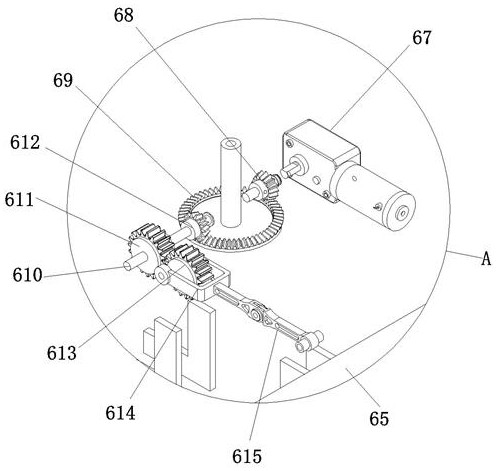

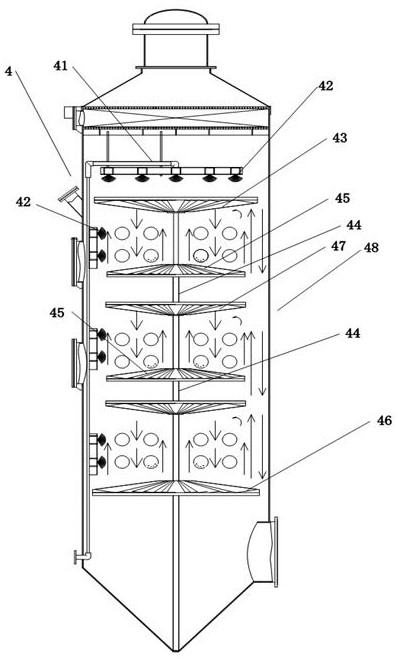

The invention discloses a solvent recovery device of an isoprene rubber device, which belongs to the field of chemical equipment and comprises a gas storage tank communicated with a spray tower. The spray tower is communicated with an adsorption tower, the spray tower comprises a spray tower shell, and a spray device is arranged in the spray tower shell; three groups of rotational flow devices are sequentially arranged in the spray tower shell from top to bottom in the vertical direction; a rotational flow plate rotating shaft is arranged in the spray tower shell; the rotational flow device comprises a rotational flow plate, the rotational flow plate is fixedly arranged on a rotational flow plate rotating shaft, the rotational flow plate can rotate along with the rotational flow plate rotating shaft, and the solvent recovery device of the isoprene rubber device can improve the recovery efficiency of hexane and increase the adsorption of VOCs, so that a better discharge effect is achieved.

Owner:SHANDONG SHENCHI PETROCHEM

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap