Energy-saving device of wet desulphurization spray tower

A technology of wet desulfurization and energy-saving devices, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of increasing flue gas resistance, not simple enough structure, increasing energy consumption of desulfurization fans, etc., to reduce flue gas resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

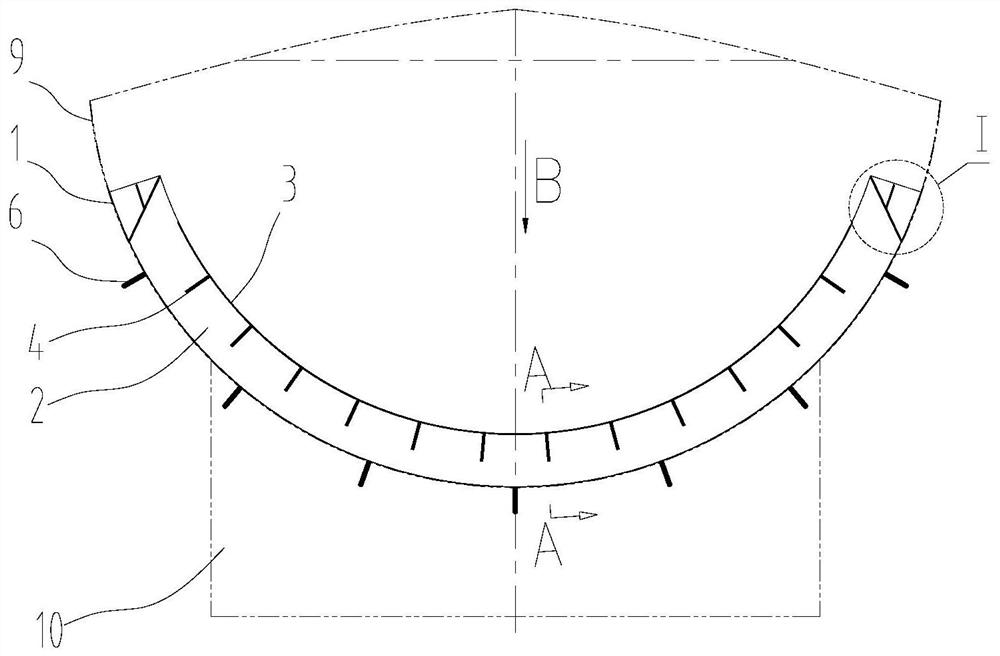

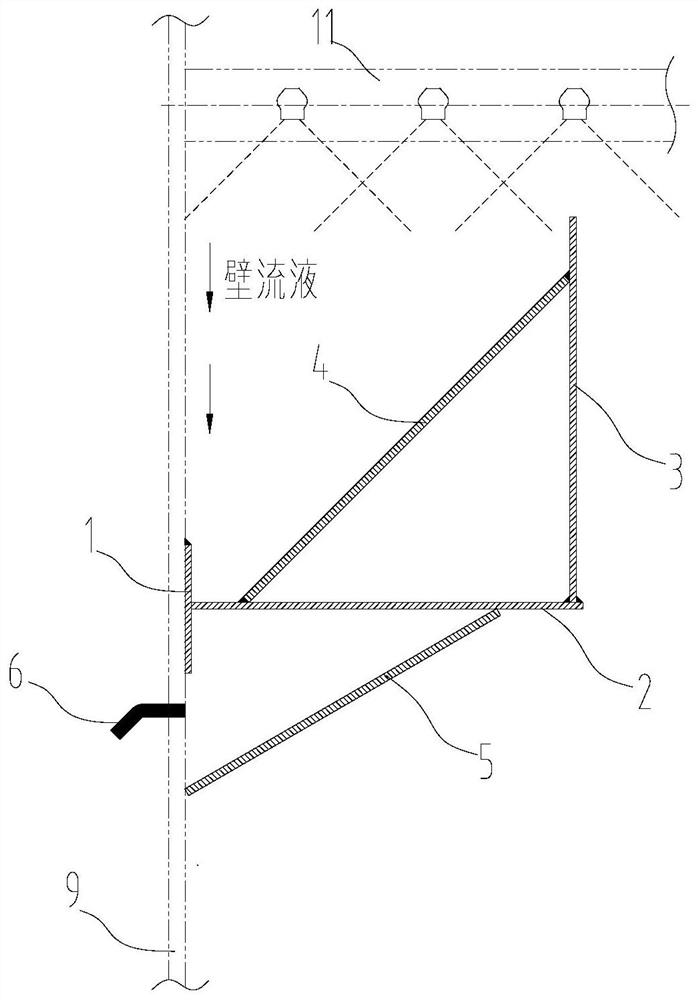

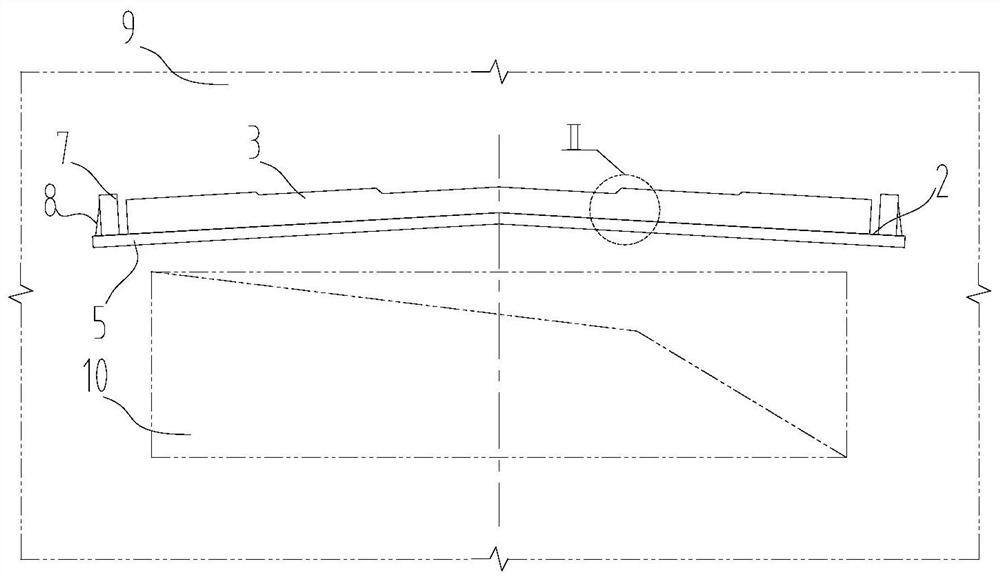

[0023] refer to Figure 1 to Figure 5 An energy-saving device for a wet desulfurization spray tower according to the present invention is installed on the tower wall 9 of the wet desulfurization spray tower between the entrance 10 of the wet desulfurization spray tower and the lowest spray layer 11, including 9 reinforcing plate 1 on the inner side, base plate 2 connected with reinforcing plate 1, side plate 3 installed on the inner side of base plate 2, pull rod 4, sealing plate 5, ventilation pipe 6 and deflector 7, said side plate 3 and At least two tie rods 4 are arranged between the bottom plates 2, and the two ends of the tie rods 4 are respectively connected with the inner wall of the side plate 3 and the upper wall of the bottom plate 2, and an inclined setting is welded between the lower bottom surface of the bottom plate 2 and the tower wall 9. The sealing plate 5 is used to support the bottom plate 2, the side plate 3, the pull rod 4 and the collected wall liquid; at t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap