Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Industrial waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial waste is the waste produced by industrial activity which includes any material that is rendered useless during a manufacturing process such as that of factories, industries, mills, and mining operations. Types of industrial waste include dirt and gravel, masonry and concrete, scrap metal, oil, solvents, chemicals, scrap lumber, even vegetable matter from restaurants. Industrial waste may be solid, liquid or gaseous. It may be hazardous or non-hazardous waste. Hazardous waste may be toxic, ignitable, corrosive, reactive, or radioactive. Industrial waste may pollute the air, the soil, or nearby water sources, eventually ending up in the sea. Industrial waste is often mixed into municipal waste, making accurate assessments difficult. An estimate for the US goes as high as 7.6 billion tons of industrial waste produced every year. Most countries have enacted legislation to deal with the problem of industrial waste, but strictness and compliance regimes vary. Enforcement is always an issue.

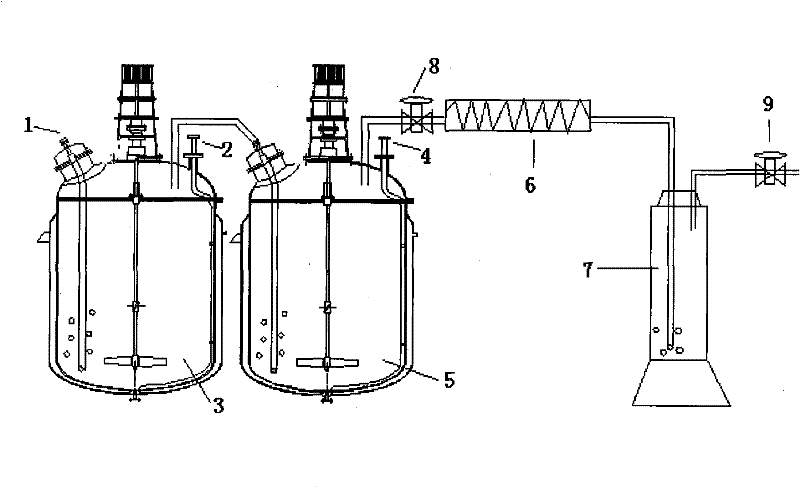

Comprehensive recycling treatment method of waste rare-earth fluorescent lamp

ActiveCN103627906AShort processReduce recycling costsProcess efficiency improvementLiquid wasteEconomic benefits

The invention discloses a comprehensive recycling treatment method of a waste rare-earth fluorescent lamp, which comprises the steps that S1, waste fluorescent powder, a waste glass tube and mercury-containing waste liquid are separated and recycled from the waste rare-earth fluorescent lamp; S2, the waste fluorescent powder is roasted; an obtained roasted ore is leached; a leaching solution and a leaching residue are obtained; S3, the leaching solution is subjected to extraction, reverse extraction and separation; alumina and rare-earth oxide are obtained; and S4, the leaching residue is subjected to digestion, extraction and purification; and a strontium-containing product is obtained. The waste rare-earth fluorescent lamp is separated, the obtained waste fluorescent powder and the obtained mercury-containing waste liquid are comprehensively recycled respectively by technologies of roasting, leaching, extraction, reverse extraction and the like, and then secondary valuable resources such as alumina, various rare-earth oxide and the strontium-containing product are comprehensively recycled from the waste fluorescent powder. The method is short in technological process and low in recycling cost, solves the problems of stockpiling, environmental pollution and the like caused by the industrial waste rare-earth fluorescent lamp, and has certain economic benefits and industrial significance.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Method for solidifying and cementing tannery sludge containing heavy metals by bacillus pasteurii

ActiveCN108675585AWater contaminantsWaste water treatment from animal processingChemistryIndustrial waste

Owner:ZHEJIANG UNIV OF TECH

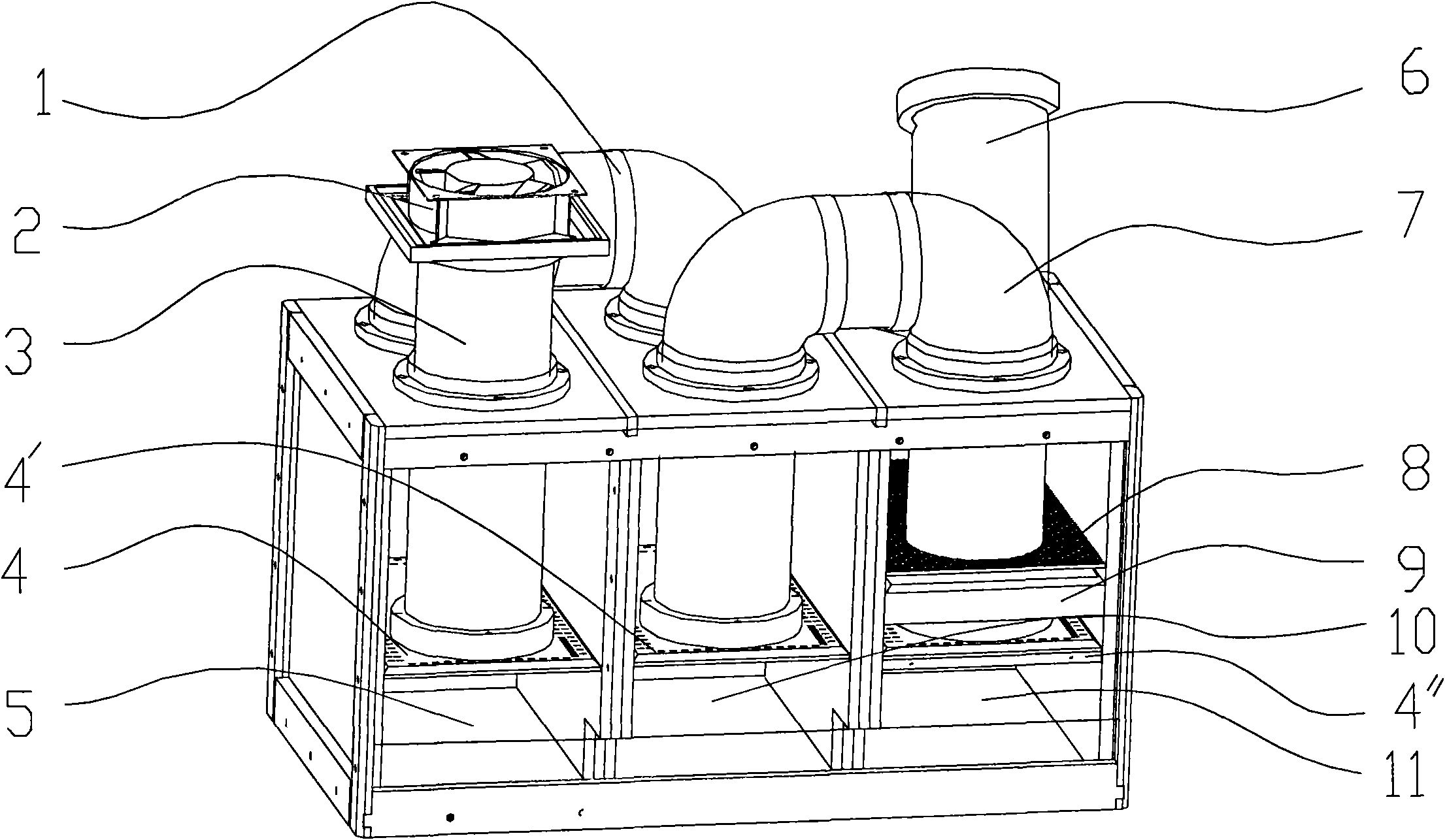

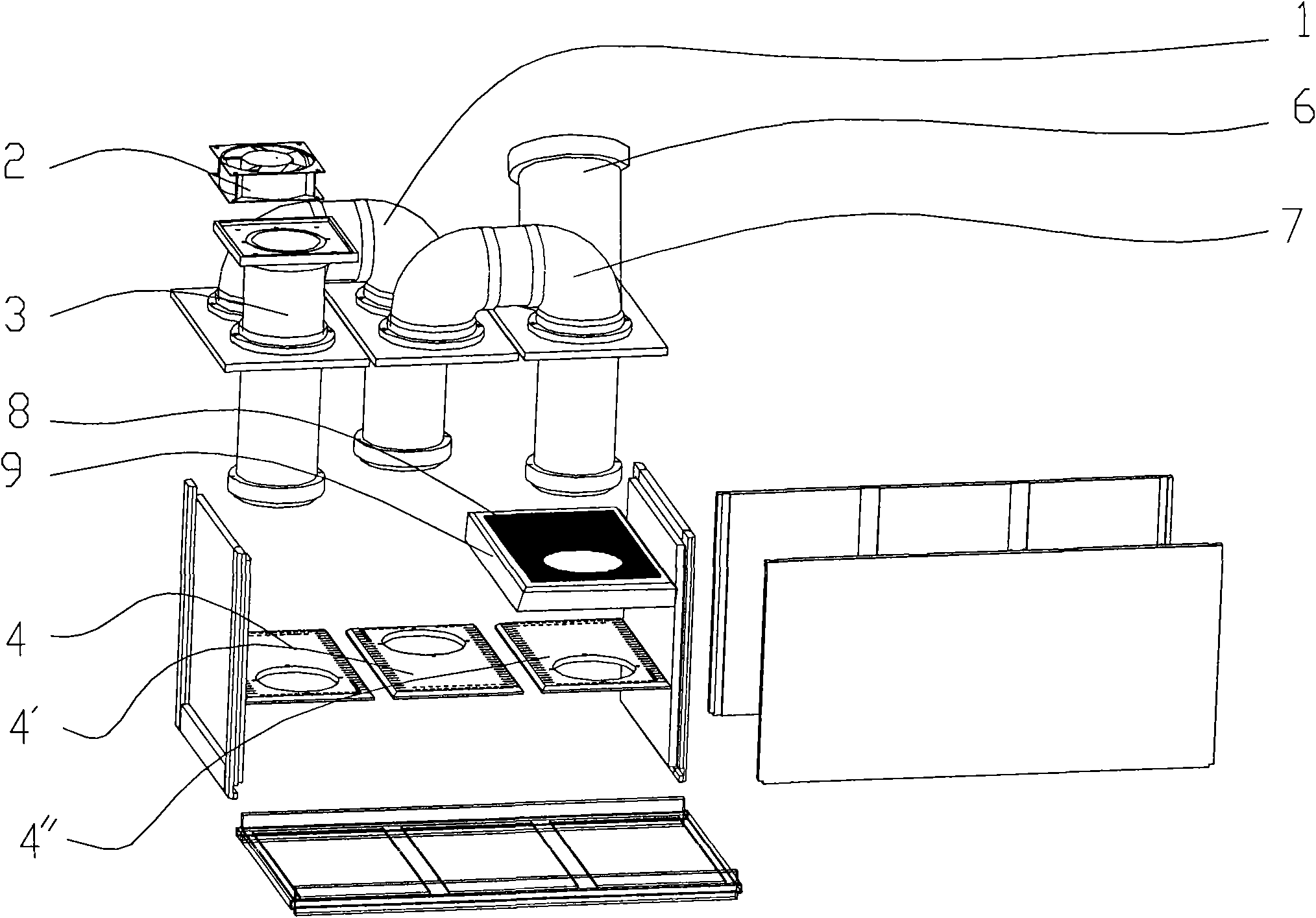

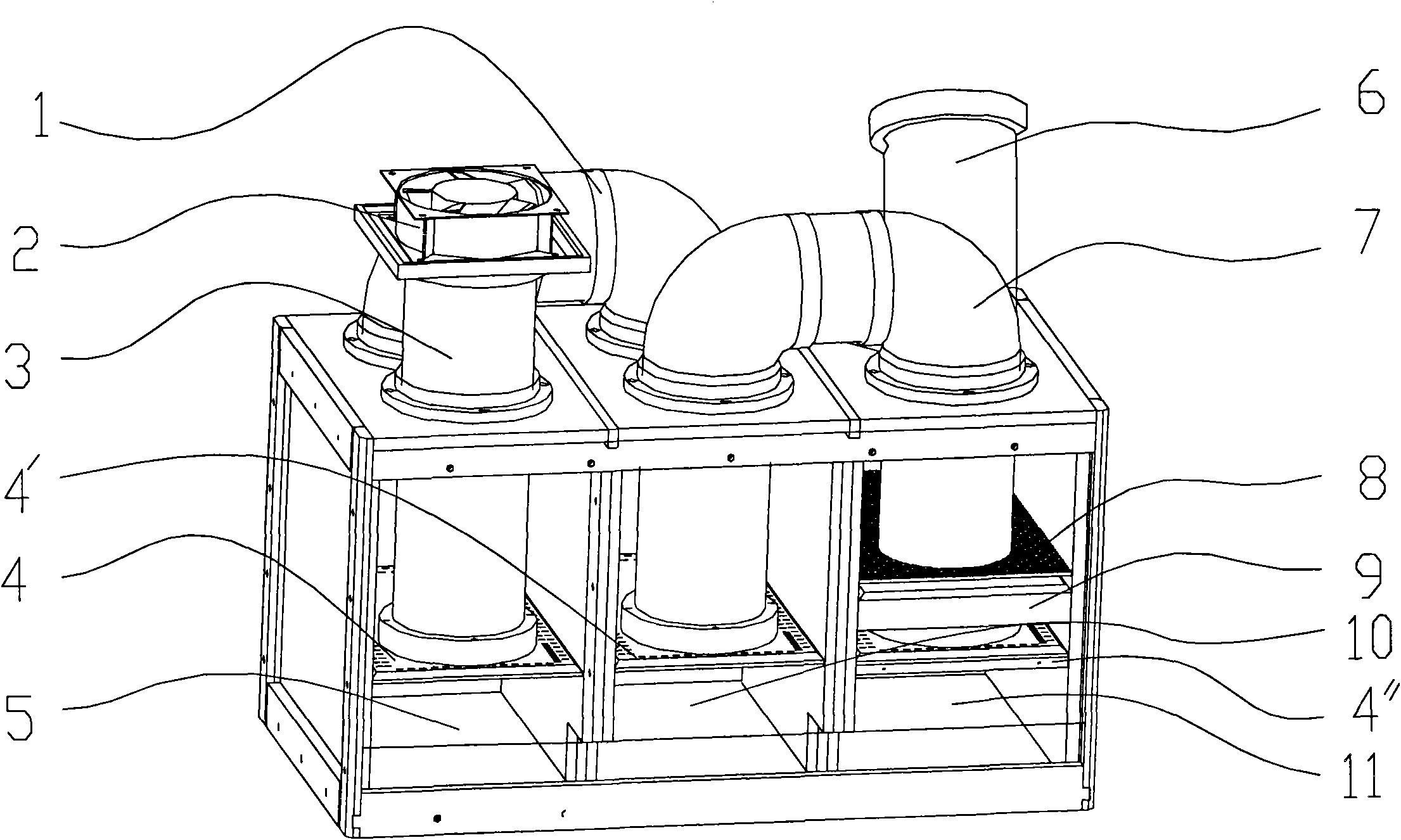

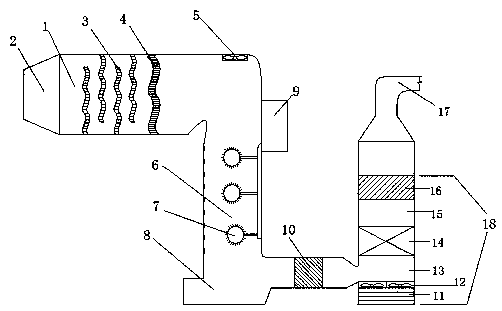

Industrial gas purification dust removal equipment

InactiveCN106731372ASimple structureEasy to useHuman health protectionCombination devicesParticulatesHEPA

The invention discloses industrial gas purification dust removal equipment, which comprises an air inlet pipeline, a cyclone separation tower, an electrostatic dust removal tower, a spraying tower, an activated carbon adsorption device and an air outlet pipeline, wherein the air inlet pipeline is arranged on an air inlet of the cyclone separation tower; a first centrifugal fan is arranged on the air inlet pipeline; an air outlet of the cyclone separation tower is connected with the air inlet of the cyclone separation tower; the air outlet of the cyclone separation tower communicates with an air inlet of the electrostatic dust removal tower; an HEPA (high efficiency particulate air) filtering net is arranged inside a pipeline for connecting the cyclone separation tower and the electrostatic dust removal tower; an air outlet of the electrostatic dust removal tower communicates with an air inlet of the spraying tower. The industrial gas purification dust removal equipment has the advantages that the structure is simple; the use is convenient; effective purification and dust removal can be performed on industrial waste gas; the purification effect is good; in addition, the environment pollution can be reduced; a protection effect is achieved on environment; meanwhile, industrial dust can be removed, so that the work environment of workers is more comfortable and healthy.

Owner:HEFEI QIFEI INFORMATION TECH CO LTD

Simple and convenient synthesis method and application of waste grease based polyhydric alcohol

InactiveCN104262561ALow costSolve pollutionFatty acid esterificationPolyureas/polyurethane adhesivesTransesterification reactionAlcohol products

Owner:ZHEJIANG HENGFENG NEW MATERIAL

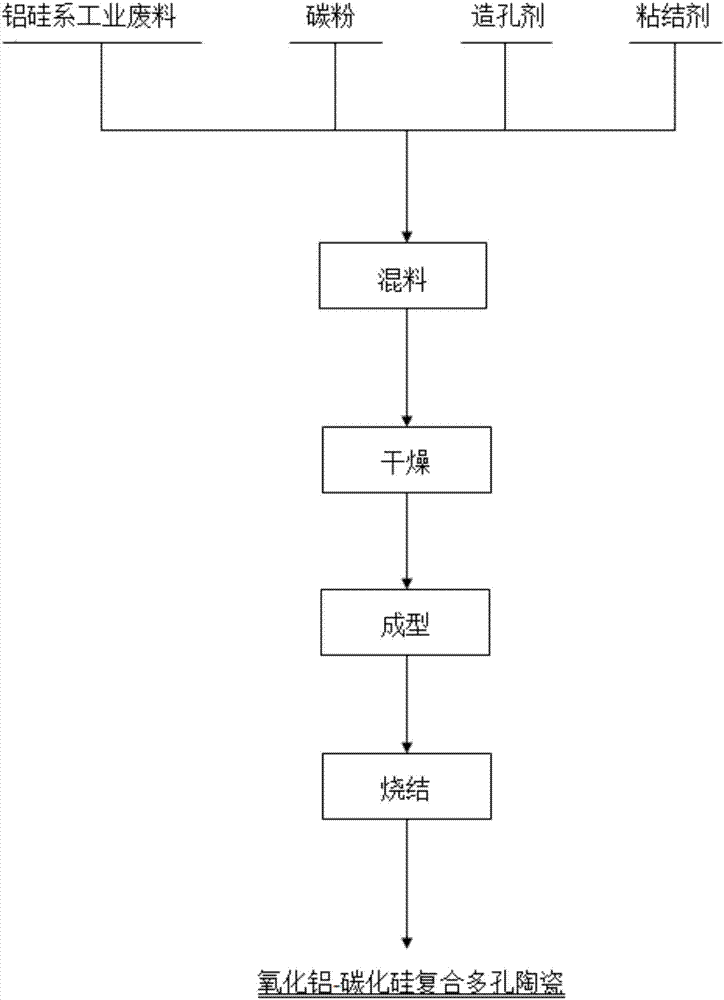

Method of preparing aluminum oxide-silicon carbide compound porous ceramic by aluminum-silicon industrial waste residues

ActiveCN107399988AModerate porosityExcellent strengthCeramic materials productionCeramicwareIndustrial wasteAdhesive

The invention discloses a method of preparing aluminum oxide-silicon carbide compound porous ceramic by aluminum-silicon industrial waste residues. The primary raw materials comprise industrial waste residues, carbon powder, a pore forming substance and an adhesive. The aluminum oxide-silicon carbide compound porous ceramic is prepared by the following steps of mixing, drying, forming and sintering to obtain a final product. Treatment and high additional value utilization of the industrial waste residues are achieved. The prepared porous ceramic is remarkable in performance, and can be applied to the fields of filtration, sound isolation, heat isolation, fire fighting and the like. The method is simple in process flow and convenient for industrialized promotion; and the cost is good to control and the method has extreme economical value.

Owner:NORTHEASTERN UNIV

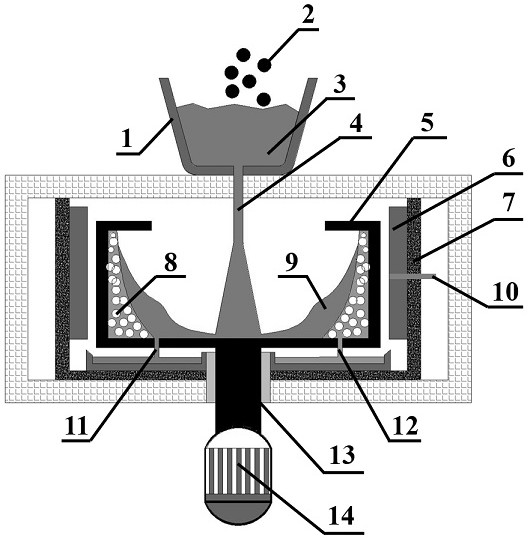

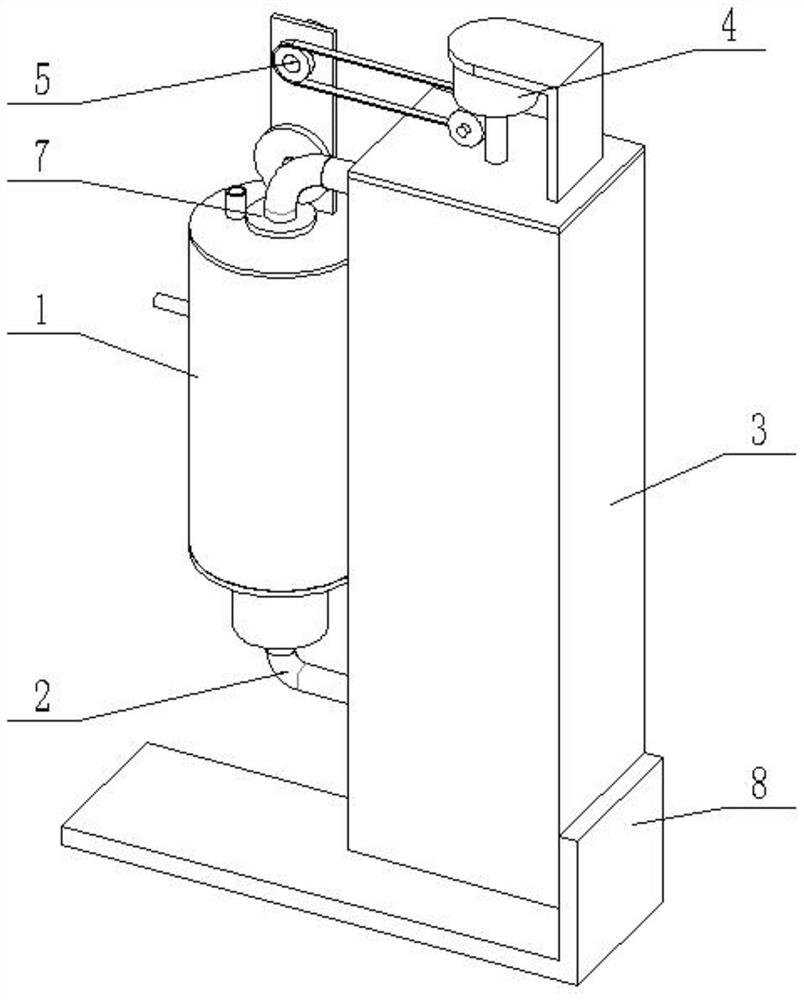

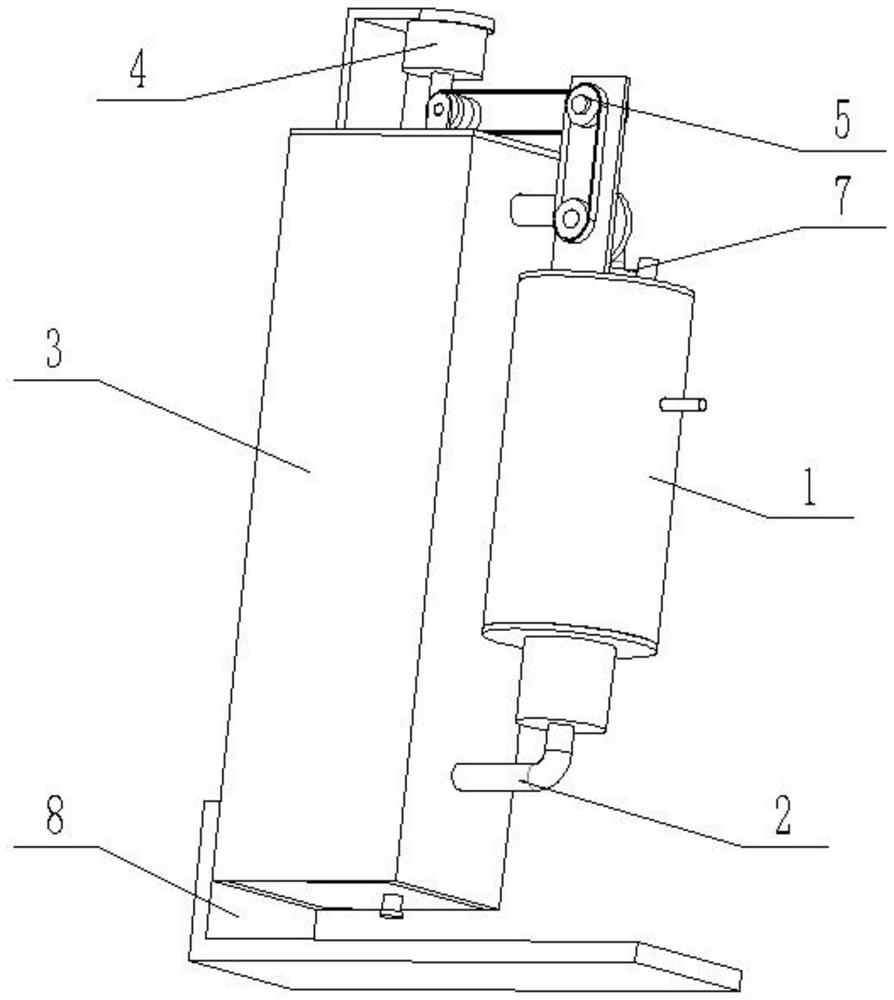

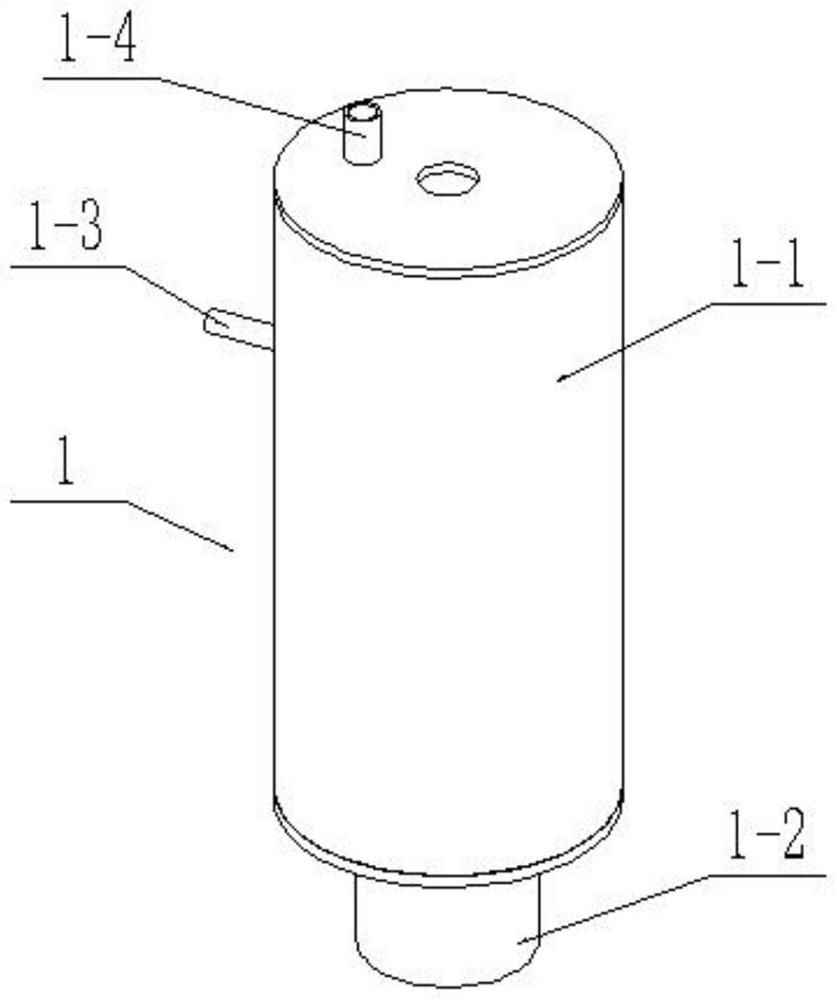

Industrial castoff fusing and solidifying device

InactiveCN101086334AFlammability ControlGood effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustorPesticide residue

There is provided an industrial waste melting / solidifying apparatus comprising: melting furnace; an oxygen generating device for supplying oxygen-enriched air to the melting furnace; and a burner provided so as to face the inside of the melting furnace, wherein industrial wastes, such as asbestos, pesticide residues and incineration ashes, are thrown into the melting furnace, and combustible materials within the industrial wastes and fuel from the burner are combusted at high temperature by using the oxygen- enriched air, whereby a melting process is performed on the industrial wastes. An entrance slot formed on the melting furnace is provided with a water-cooling jacket via a throw-in gate. The water-cooling jacket is provided with a throw-in door for throwing the industrial wastes. The water-cooling jacket is further provided with a pusher for pushing the thrown industrial wastes out toward the entrance slot to control throwing speed and combustion speed.

Owner:高桥 贤三

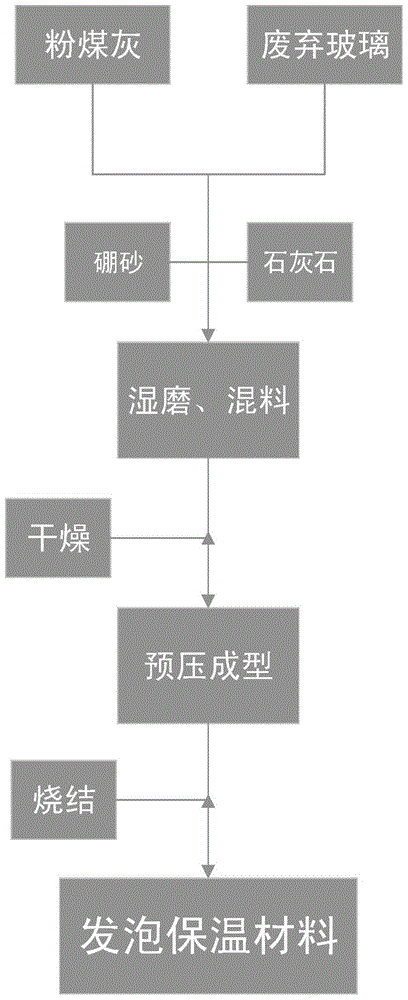

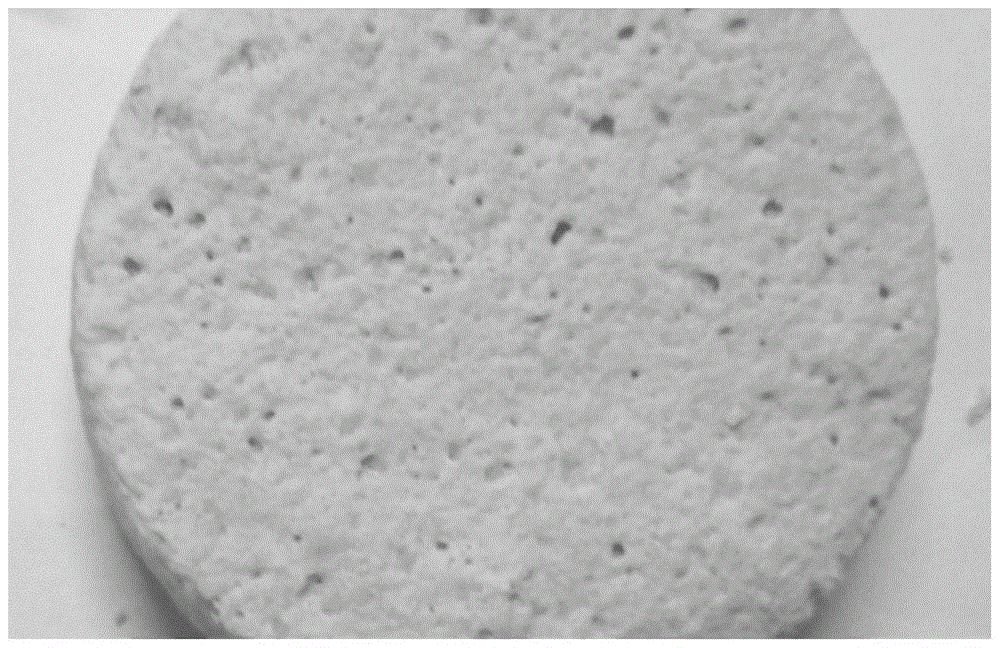

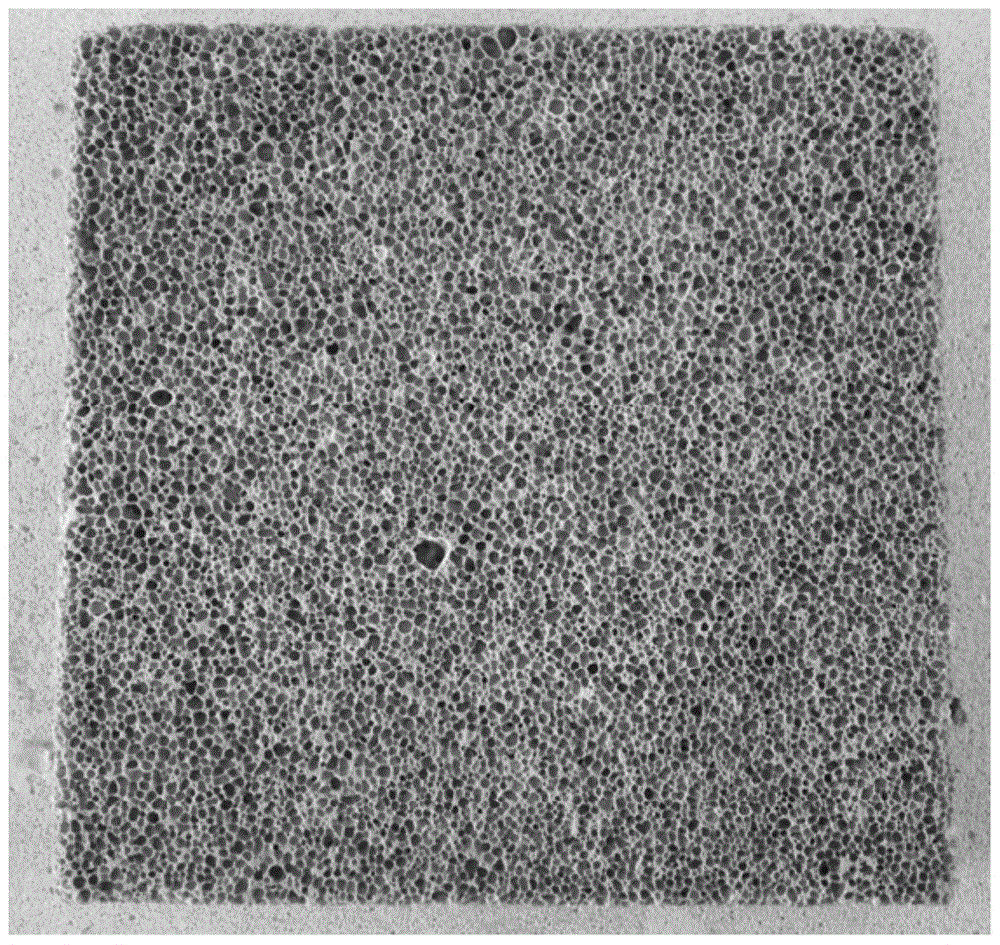

Foamed heat insulation material and preparation method thereof

InactiveCN105800945AIndustrial wasteWet grinding

Owner:PEKING UNIV

Mixed molten salt type heat transfer and storage working medium and application thereof

InactiveCN105199678ALow cost of ingredientsSimple preparation processHeat-exchange elementsAdditive ingredientCoal

Owner:百吉瑞(天津)新能源有限公司

Method for catalytic synthesis of dichloropropanol by hydrogen chloride-containing industrial waste gas and glycerol

InactiveCN102234224ATake advantage ofAchieving the goals required by green chemistryPreparation by halogen introductionReaction temperatureGlycerol

Owner:JIANGSU LEE & MAN CHEM

Fluid extraction of metals of metalloids

InactiveCN1265160AEfficient extractionEfficient separationSolid waste disposalSeparation devicesSolventPhosphine

Owner:IDAHO RESARCH FOUNDATION INC

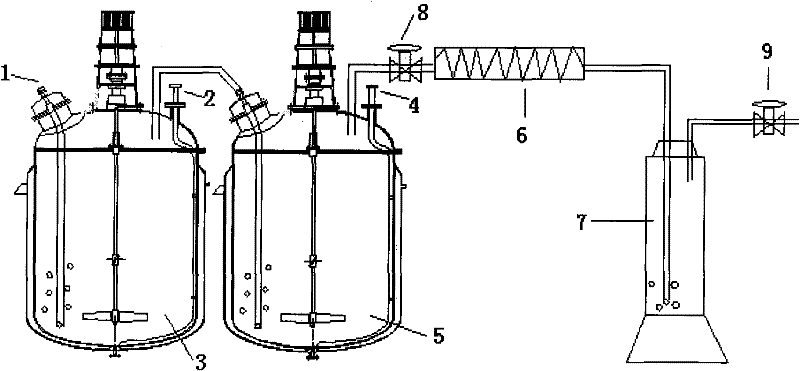

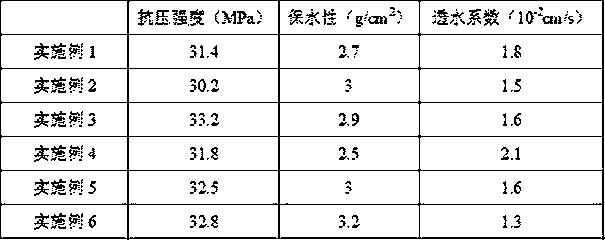

Highly water-retaining water-permeable brick prepared from building recycled material and preparation method thereof

Owner:广东怡兴食品有限公司

Processing method for preparing modified plastic rubber through utilizing waste plastic and waste rubber

Owner:SUZHOU XIANGYUAN SPEICAL FINE CHEM

Glass fiber composite cement and preparation method thereof

InactiveCN110698096ACement productionIndustrial wasteCement Material

Owner:衡阳县海华水泥有限责任公司

Method for preparing polyaluminum ferric chloride by adopting wastes

InactiveCN108275725AImprove responseThe reaction process is green and environmentally friendlyIron compoundsWater/sewage treatment by flocculation/precipitationIndustrial wasteChemistry

The invention relates to a method for preparing polyaluminum ferric chloride by adopting wastes, and belongs to the technical field of waste treatment. The method comprises the steps of dissolving a waste aluminum profile to obtain an aluminum solution, compounding with pulverized fuel ash, and reacting with waste gas hydrochloric acid to obtain the polyaluminum ferric chloride. According to the method provided by the invention, the adopted raw materials are industrial wastes, on the basis that a final product has an industrial practical application value, the industrial wastes are greatly treated, and the reaction process is simple and environmentally friendly.

Owner:无锡日月水处理有限公司

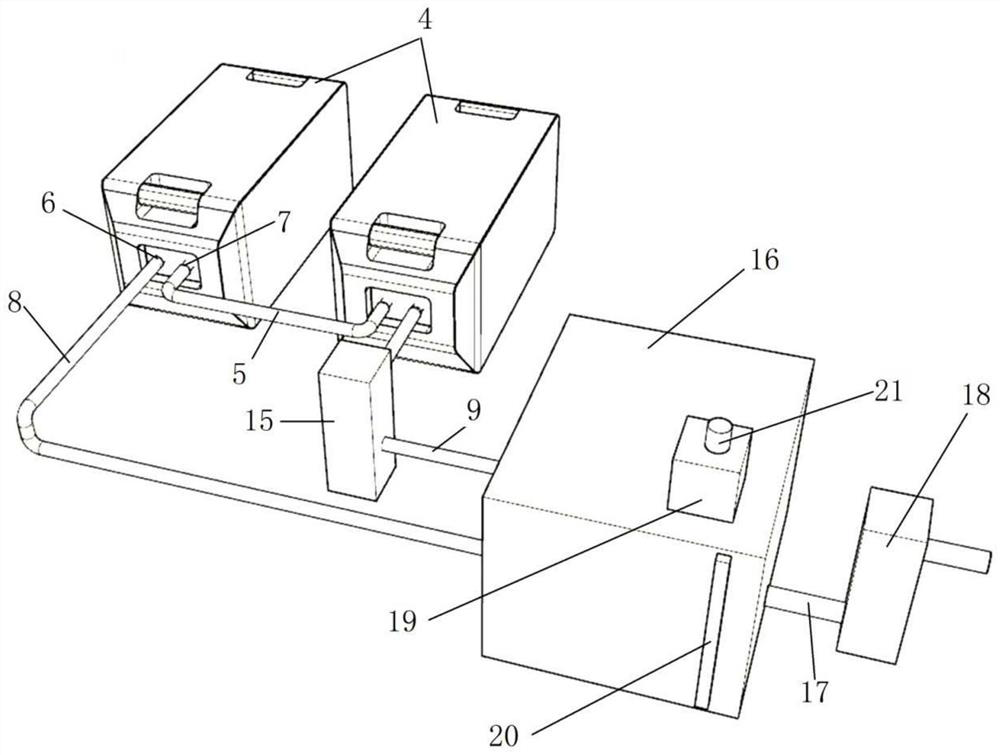

Industrial waste gas treatment device

InactiveCN109092027AQuality improvementImprove processing qualityDispersed particle separationEnvironmental engineeringDrive motor

The invention discloses an industrial waste gas treatment device. The device comprises a connecting pipeline part and a waste gas treatment part, wherein a gas inlet and a gas outlet are arranged at the connecting pipeline part, a main pipeline is arranged on the right side of the gas inlet, a plurality of branch pipelines are arranged below the main pipeline, switching valves are arranged on thebranch pipelines, a first waste gas treatment chamber, a second waste gas treatment chamber and a third waste gas treatment chamber are sequentially arranged on the right side of the branch pipelines,drive motors are arranged in the first waste gas treatment chamber, the second waste gas treatment chamber and the third waste gas treatment chamber, rotating rods are arranged below the drive motors, rotating paddles are arranged below the rotating rods, and heating layers are arranged at bottoms of the first waste gas treatment chamber, the second waste gas treatment chamber and the third wastegas treatment chamber. By the aid of structures such as the switching valves, the rotating paddles and the heating layers, the waste gas treatment quality is improved in multiple ways such as changeof the treatment process, heating and stirring, and use in production is facilitated.

Owner:JIANGYIN CITY CHECKING FIXTURE CO LTD

Resource utilization method of fructus momordicae industrial waste

Owner:广西壮族自治区科学技术情报研究所

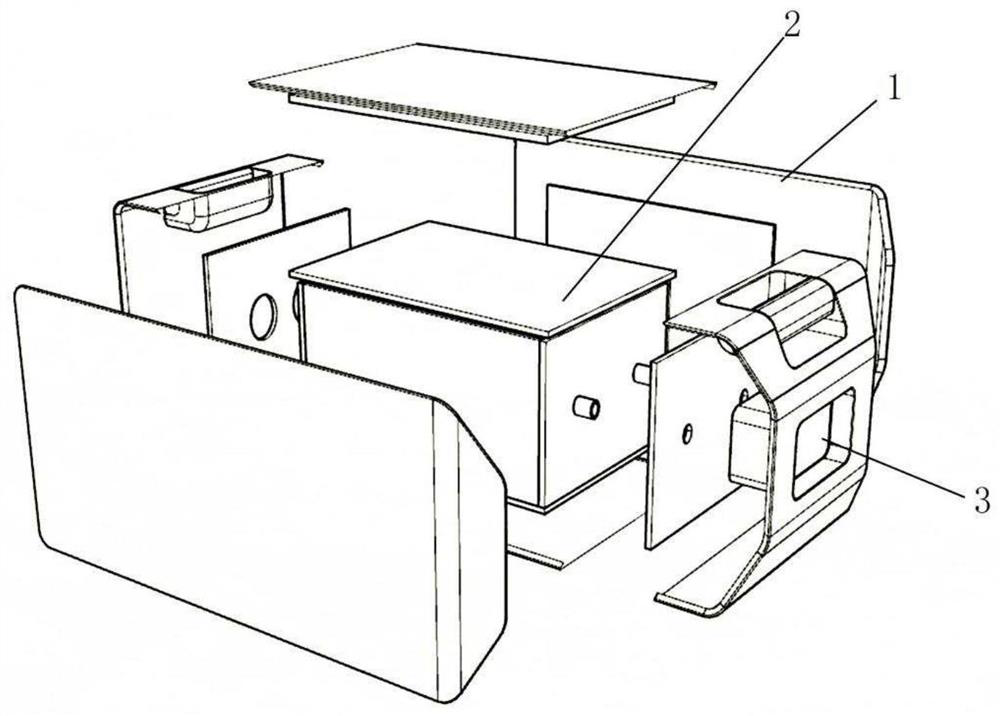

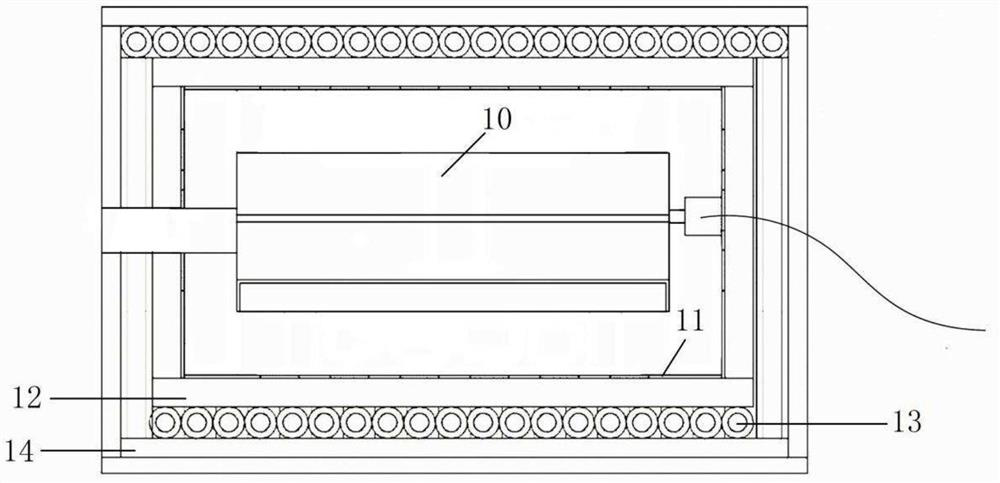

Modular heat storage device

PendingCN112728981ANeutralizes uneven heat conduction issuesCan control and speed up heat conductionFluid heatersHeat storage plantsThermodynamicsWater storage tank

Owner:星金俫瑞(天津)能源科技有限公司

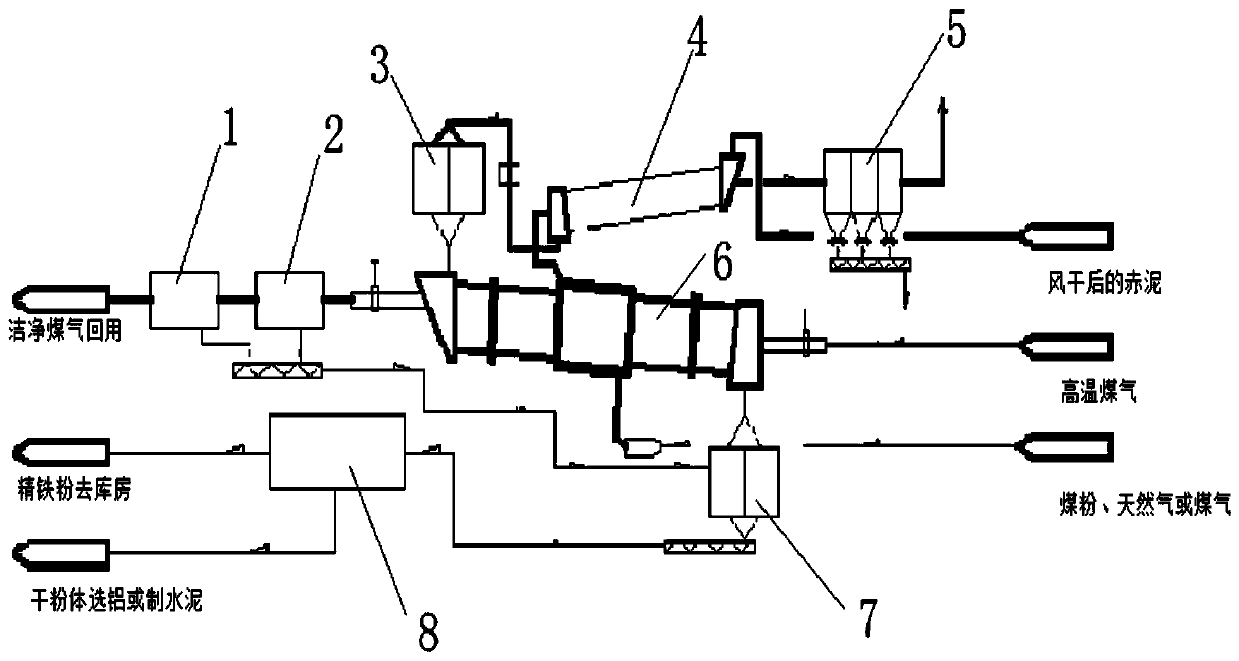

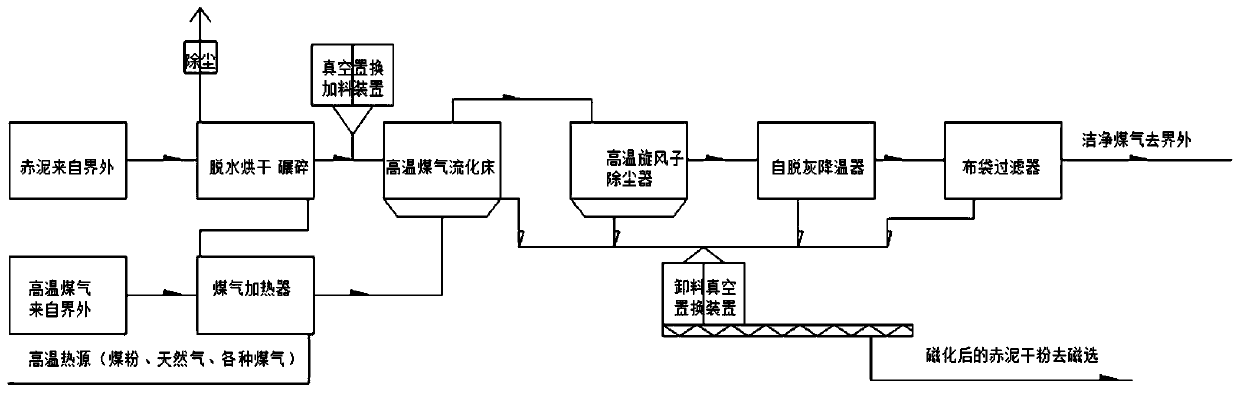

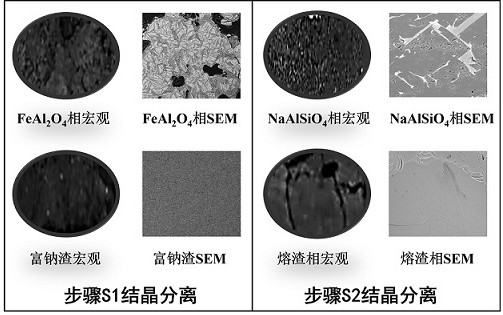

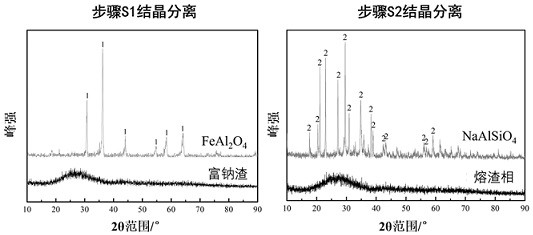

Method and equipment for eliminating high alkalinity of red mud through supergravity

ActiveCN114833166AEliminate high alkalinityEliminate fractional crystallization separationSolid waste disposalProcess efficiency improvementSlagRed mud

Owner:UNIV OF SCI & TECH BEIJING

Exhaust system for industrial waste gas purification equipment

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

Fluxing medium production method based on waste salt resource utilization

Owner:OCEAN UNIV OF CHINA

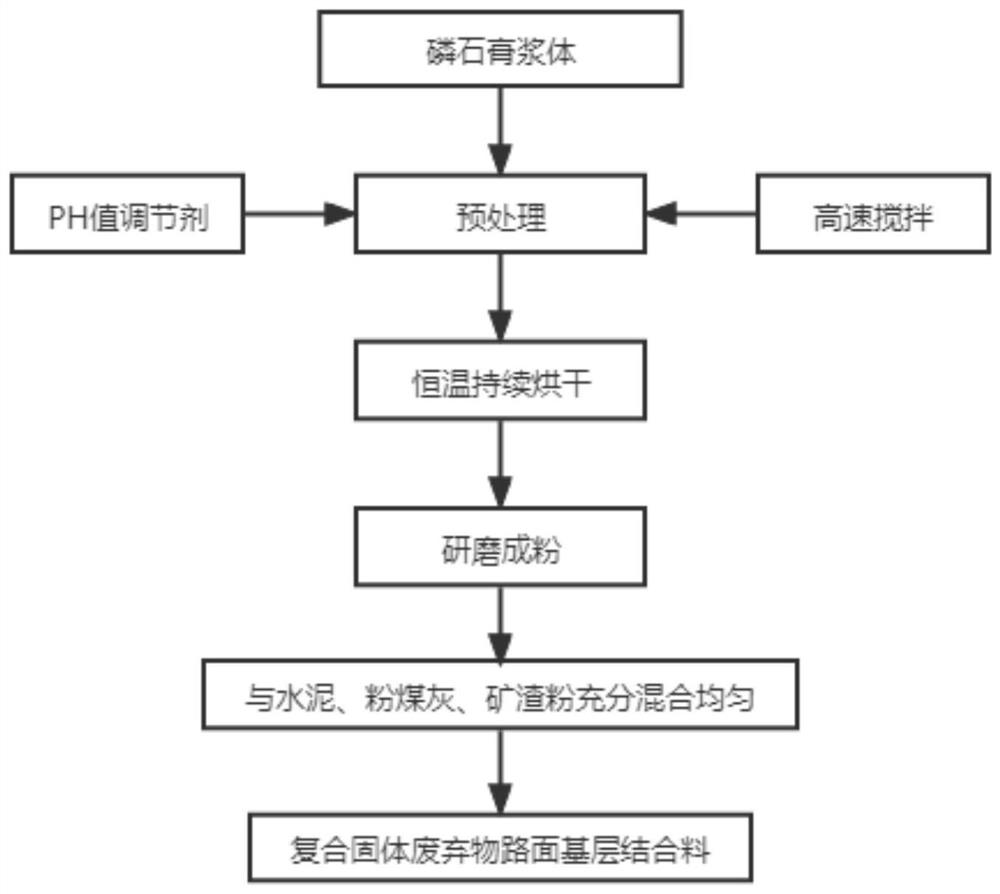

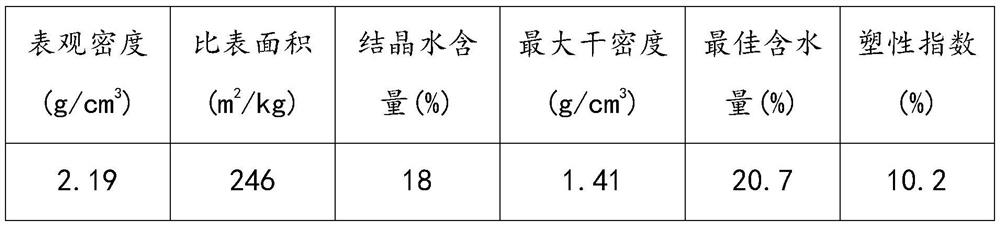

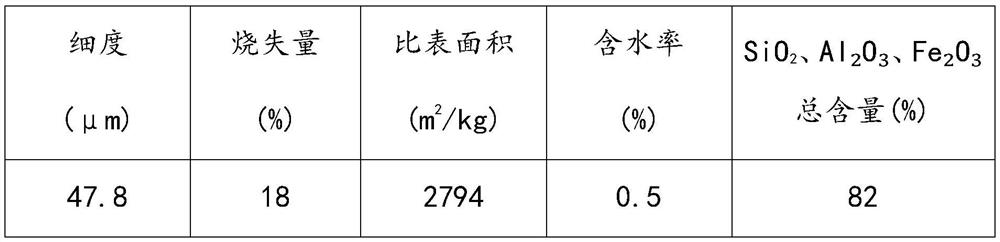

Composite solid waste pavement base binder and preparation method thereof

PendingCN114804773AAchieve recyclingAchieve environmental protectionShrinkage crackingRoad engineering

Owner:中路高科交通检测检验认证有限公司

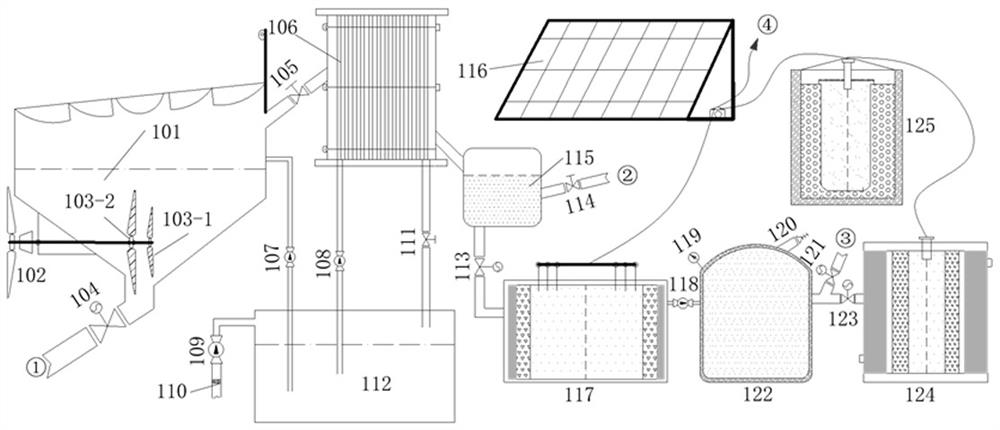

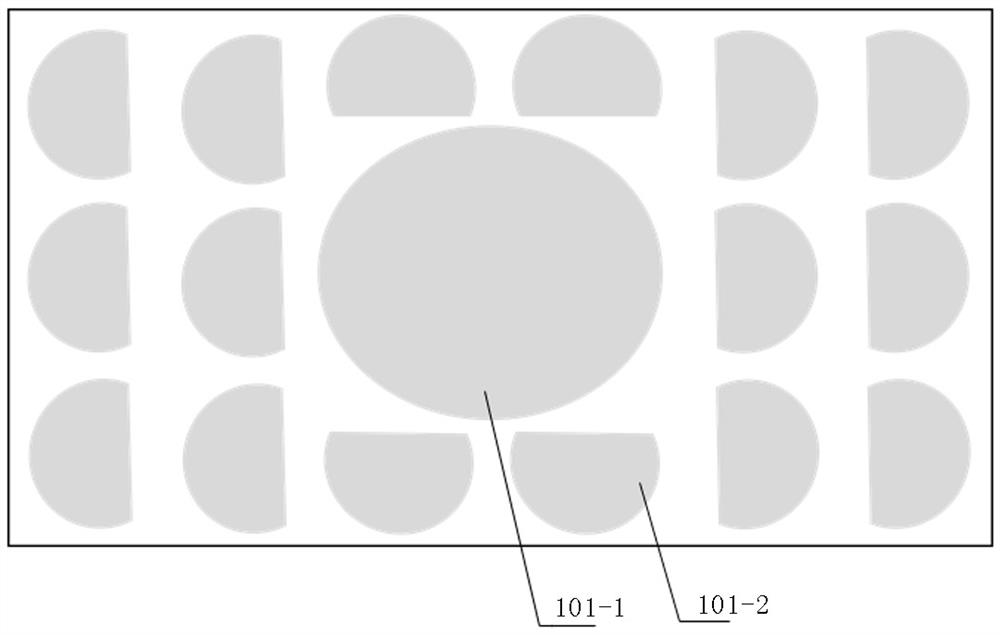

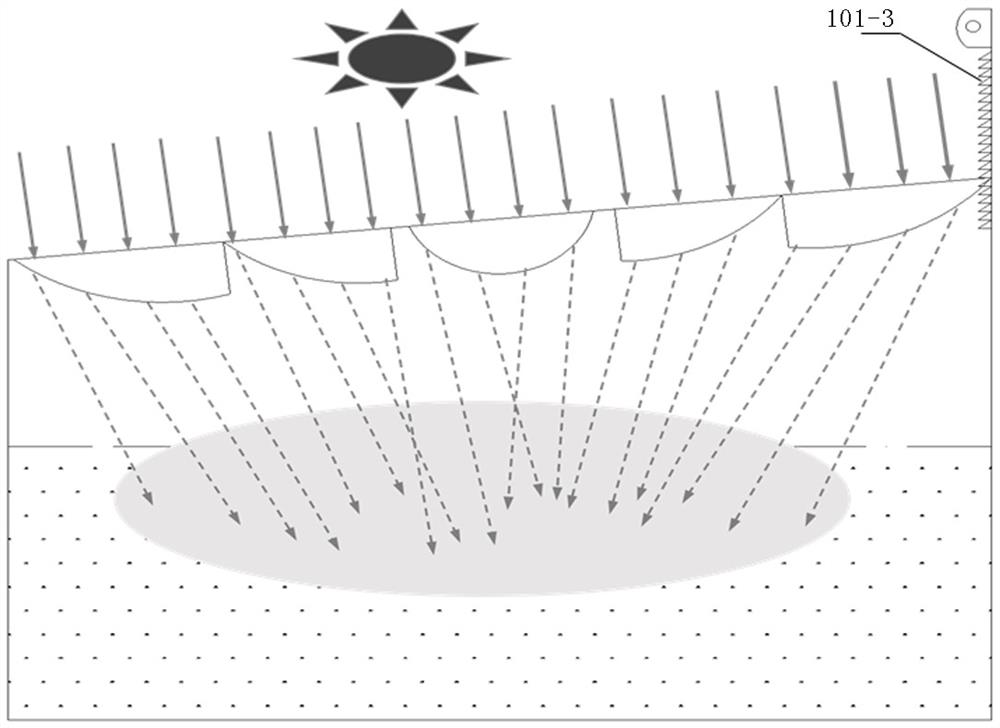

Unattended industrial waste liquid treatment and water-hydrogen-electricity co-production system and method

PendingCN114031143ARealize process conversionRealize external water-hydrogen co-productionCellsBatteries circuit arrangementsSteam condensationHydrogen fuel cell

Owner:HENAN UNIV OF SCI & TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap