Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Centrifugal fan" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A centrifugal fan is a mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. Centrifugal fans often contain a ducted housing to direct outgoing air in a specific direction or across a heat sink; such a fan is also called a blower fan, biscuit blower, or squirrel-cage fan (because it looks like a hamster wheel). These fans increase the speed and volume of an air stream with the rotating impellers.

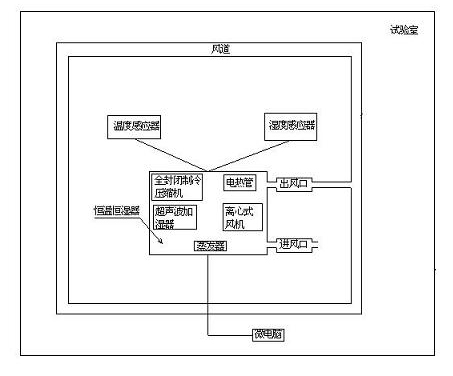

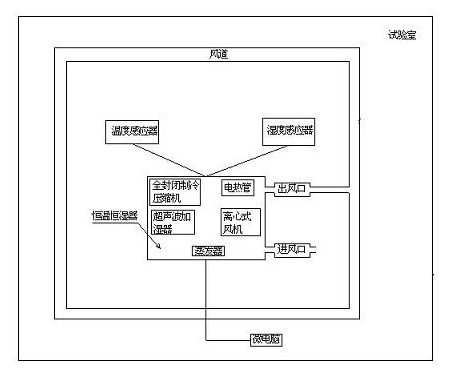

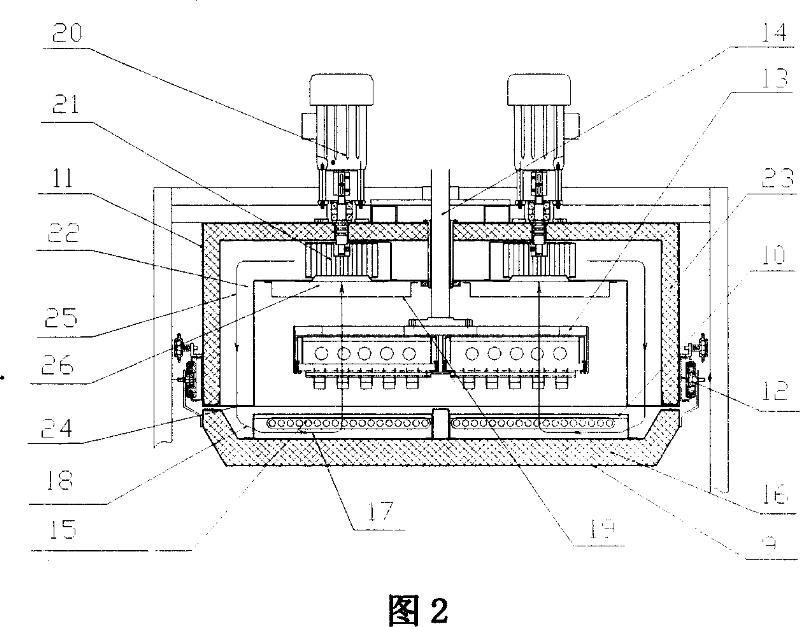

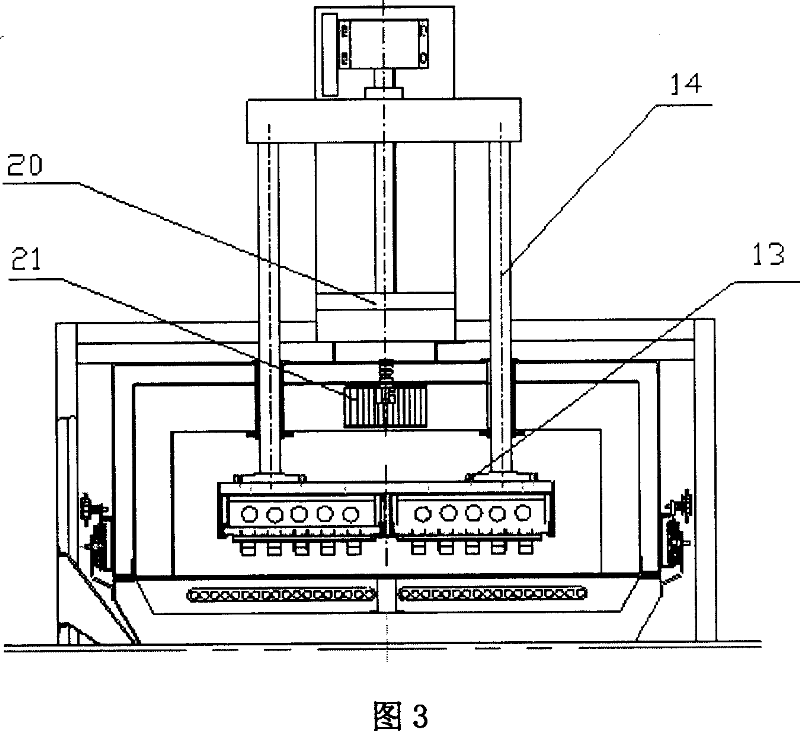

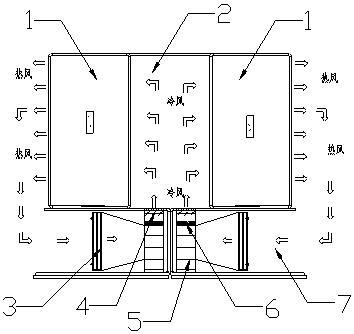

Concrete sample curing room

ActiveCN101947810AUniform temperatureUniform humidityCeramic shaping apparatusMicrocomputerThermodynamics

Owner:JSTI GRP INSPECTION & CERTIFICATION CO LTD

Industrial gas purification dust removal equipment

InactiveCN106731372ASimple structureEasy to useHuman health protectionCombination devicesParticulatesHEPA

The invention discloses industrial gas purification dust removal equipment, which comprises an air inlet pipeline, a cyclone separation tower, an electrostatic dust removal tower, a spraying tower, an activated carbon adsorption device and an air outlet pipeline, wherein the air inlet pipeline is arranged on an air inlet of the cyclone separation tower; a first centrifugal fan is arranged on the air inlet pipeline; an air outlet of the cyclone separation tower is connected with the air inlet of the cyclone separation tower; the air outlet of the cyclone separation tower communicates with an air inlet of the electrostatic dust removal tower; an HEPA (high efficiency particulate air) filtering net is arranged inside a pipeline for connecting the cyclone separation tower and the electrostatic dust removal tower; an air outlet of the electrostatic dust removal tower communicates with an air inlet of the spraying tower. The industrial gas purification dust removal equipment has the advantages that the structure is simple; the use is convenient; effective purification and dust removal can be performed on industrial waste gas; the purification effect is good; in addition, the environment pollution can be reduced; a protection effect is achieved on environment; meanwhile, industrial dust can be removed, so that the work environment of workers is more comfortable and healthy.

Owner:HEFEI QIFEI INFORMATION TECH CO LTD

Powder packaging device of electronic element based on the heating structure with controllable wind direction and speed

InactiveCN101032715ABreak through the technical problem of uneven thermal claddingLiquid surface applicatorsCoatingsHeat flowFluidized bed

Owner:XI AN JIAOTONG UNIV

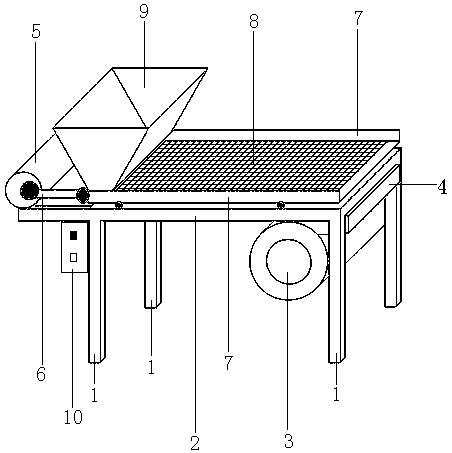

Grains airing koji-adding device

Owner:LUZHOU GUOZHIRONGYAO LIQUOR IND CO LTD +1

Air conditioner

InactiveCN104807109AIncrease the use of spaceCompact internal structureDucting arrangementsLighting and heating apparatusEngineeringCentrifugal fan

The invention provides an air conditioner. The air conditioner comprises a bottom shell, a first centrifugal fan, a second centrifugal fan and an electrical box mounting part, wherein an upper side and a lower side are arranged on the bottom shell and are oppositely arranged; a first air duct and a second air duct are arranged on the bottom shell and extend from the upper side to the lower side; a first upper air outlet and a first lower air outlet are formed in the first air duct; a second upper air outlet and a second lower air outlet are formed in the second air duct; a first upper volute tongue is arranged on the first upper air outlet; a first lower volute tongue is arranged on the first lower air outlet; a second upper volute tongue is arranged on the second upper air outlet; a second lower volute tongue is arranged on the second lower air outlet; the first upper volute tongue and the second upper volute tongue are respectively protruded toward a mutually departing direction, and the first lower volute tongue and the second lower volute tongue are respectively protruded toward a mutually closing direction; the first centrifugal fan is arranged in the first air duct; the second centrifugal fan is arranged in the second air duct; the electrical box mounting part is arranged between the first upper volute tongue and the second upper volute tongue. The air conditioner has the advantages that the wiring is simple, and the reliability is high.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

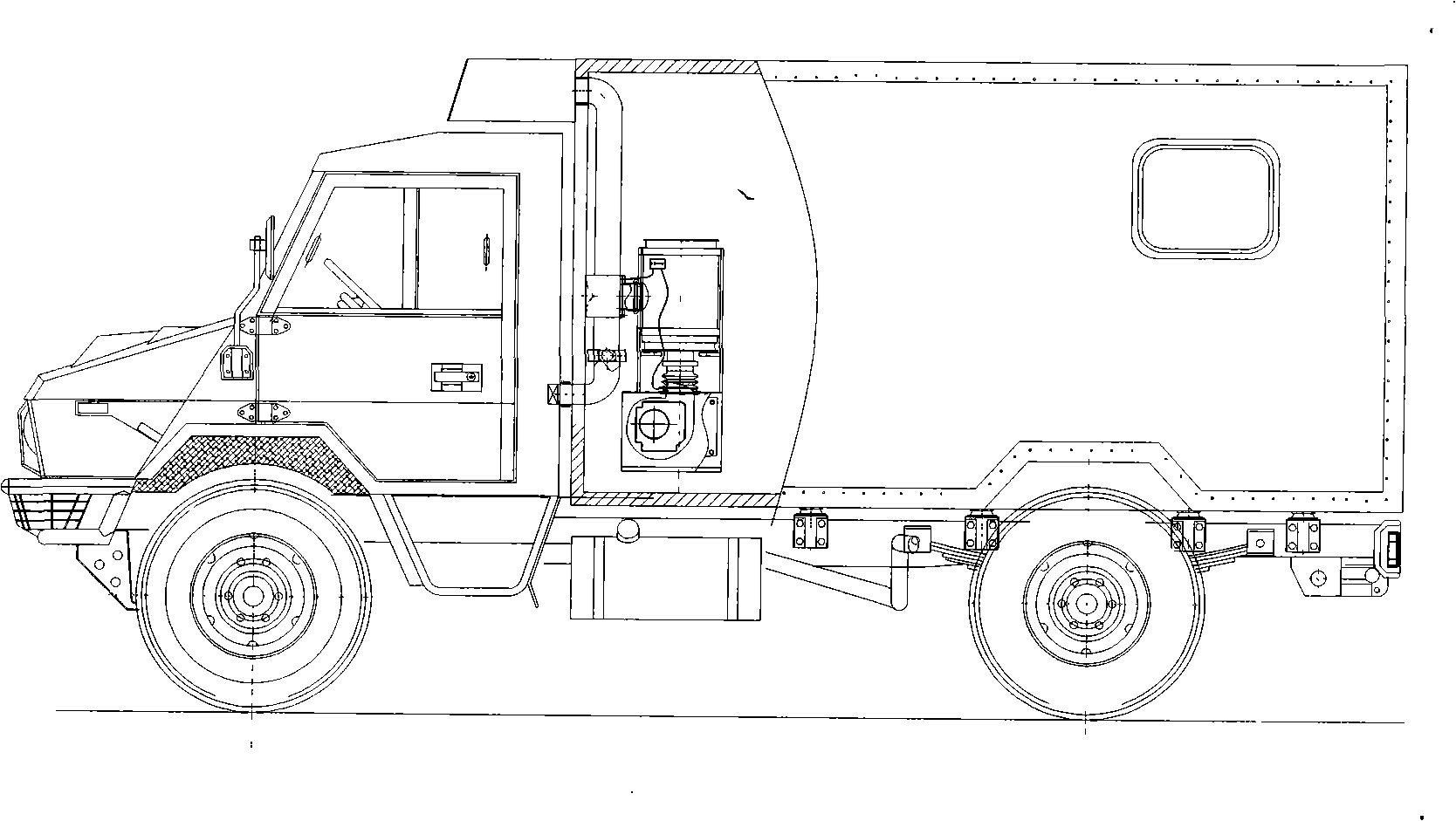

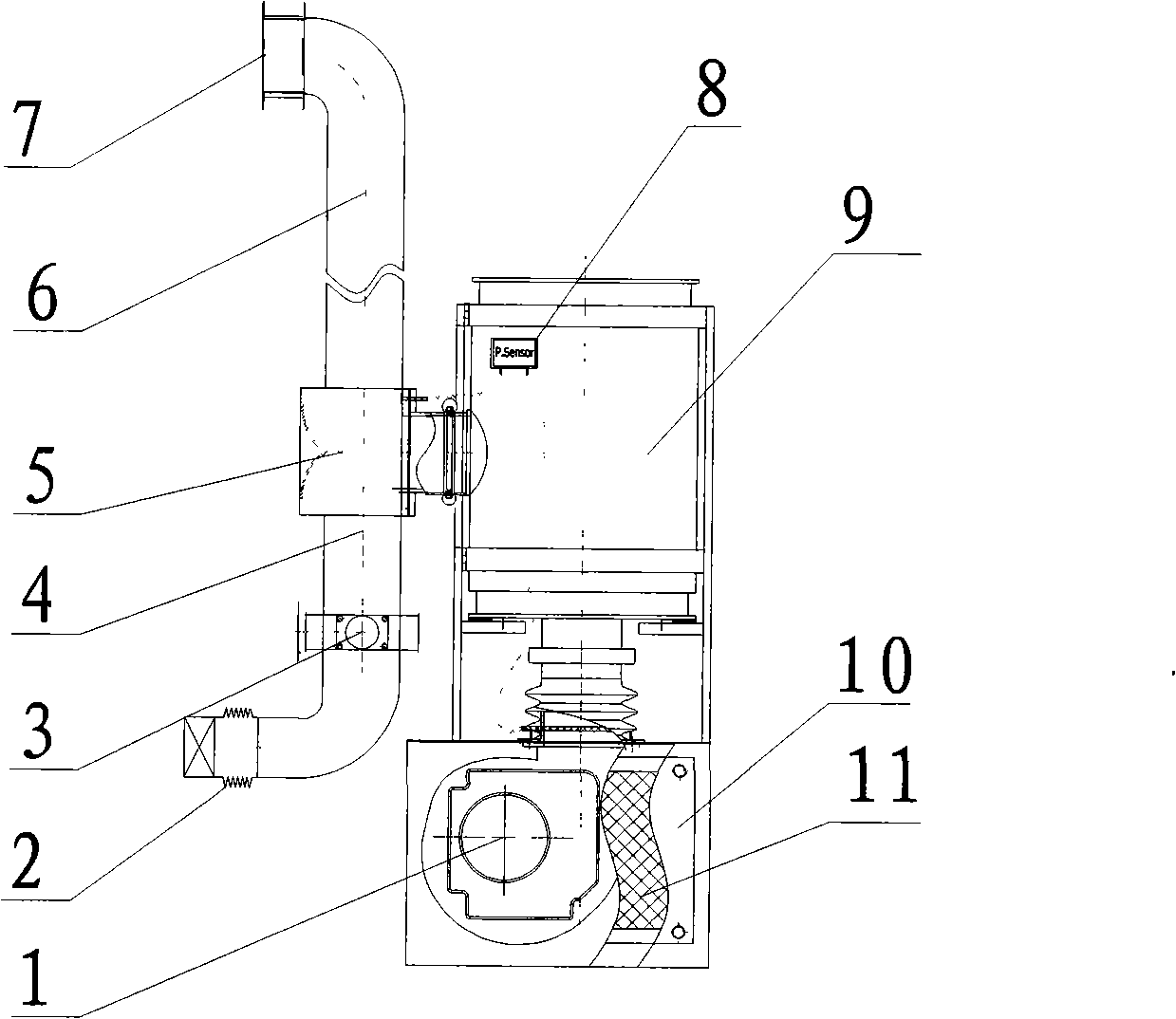

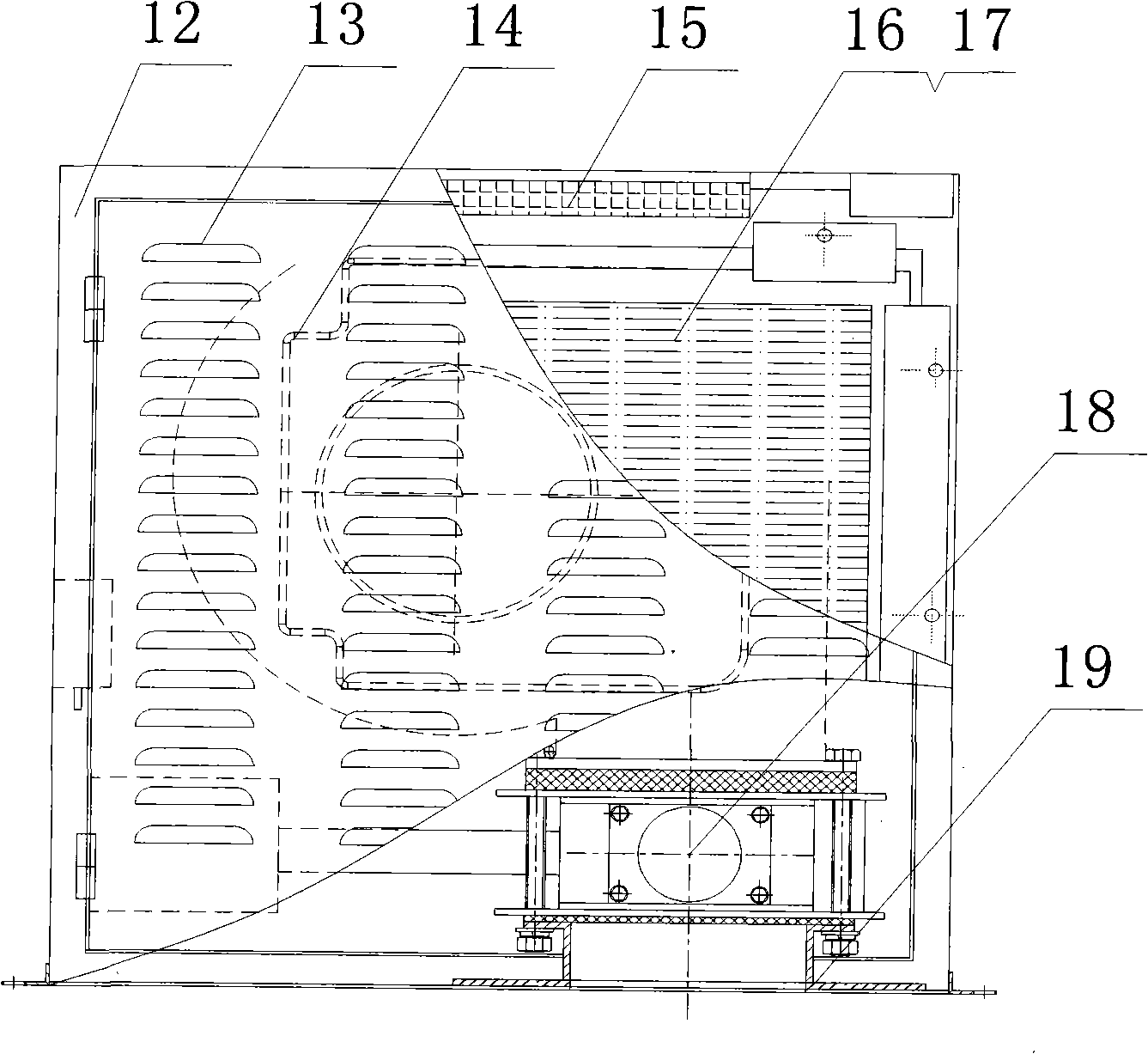

Filtration purification overpressure and negative pressure integrated protection system for vehicle

ActiveCN101264726AIncrease air pressureReduce air pressureAir-treating devicesVehicle heating/cooling devicesAir volumeFiltration

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

Multi-combined heat pipe cooling system with bottom type microchannel heat exchangers

InactiveCN109587998AReduce inhalationImprove efficiencyModifications for standard racks/cabinetsCold airEngineering

Owner:江苏天源太阳能发电有限公司

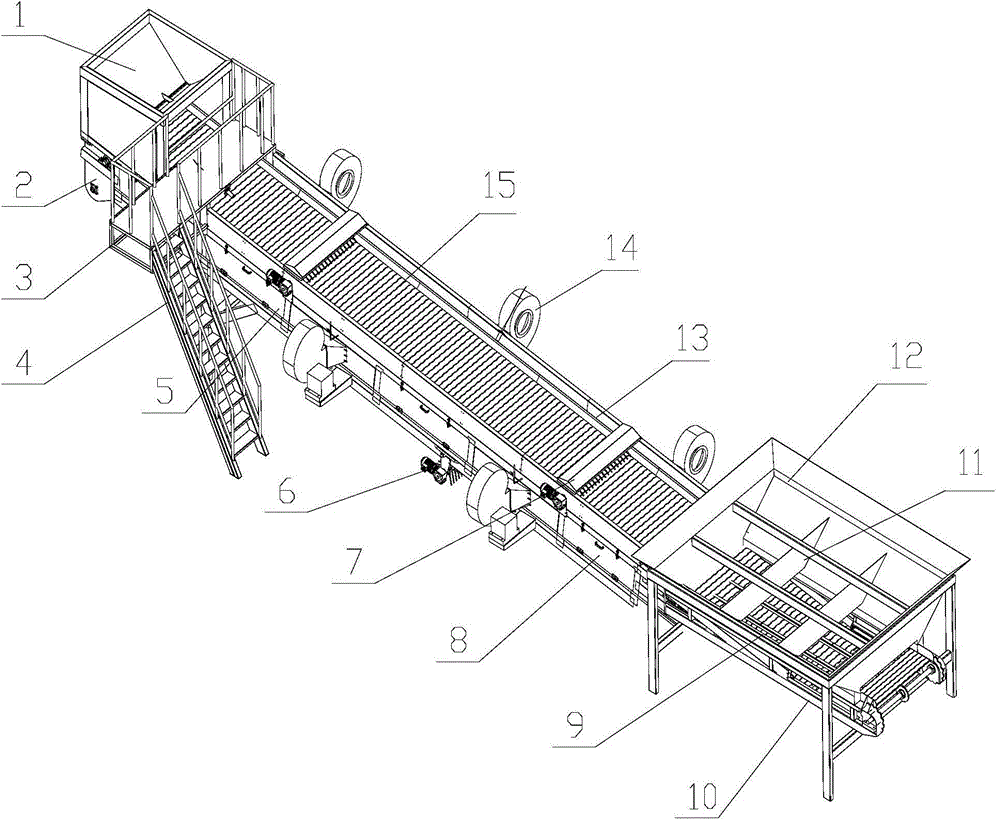

Medicinal material sorting machine

Owner:FANGXIAN COUNTY ZHONGYI EQUIP

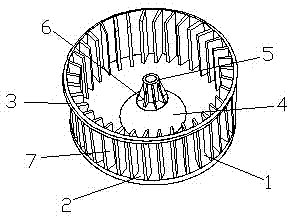

Volute-free centrifugal fan

InactiveCN104100546AReasonable structureCompactPump installationsNon-positive displacement fluid enginesElectric machineEngineering

The invention relates to the technical field of an axial flow fan, in particular to a volute-free centrifugal fan. The volute-free centrifugal fan is characterized by being provided with a motor, an impeller, a mounting disc, a motor bracket, a motor mounting frame and an air cylinder, wherein one end of the motor is fixedly connected with the motor mounting frame through a fastening bolt; an output shaft at the other end of the motor penetrates through the center of the impeller through a bolt to be fixedly connected with the impeller, so that an air outlet of the impeller corresponds to a motor rotor, and the effect of automatic cooling is achieved; the air cylinder sleeves the motor and is horn-shaped; the small-diameter end of the air cylinder is connected with an air inlet of the impeller in a sleeving way and the large-diameter end of the air cylinder is fixedly connected with the mounting disc; the motor mounting frame is fixedly connected with the mounting disc through the motor bracket, so that the effect of supporting the motor is achieved. Due to the adoption of the structure, the volute-free centrifugal fan has the advantages of reasonable structure, compact appearance, convenience in assembly and disassembly, capability of automatically cooling and the like.

Owner:WEIHAI CREDITFAN VENTILATOR

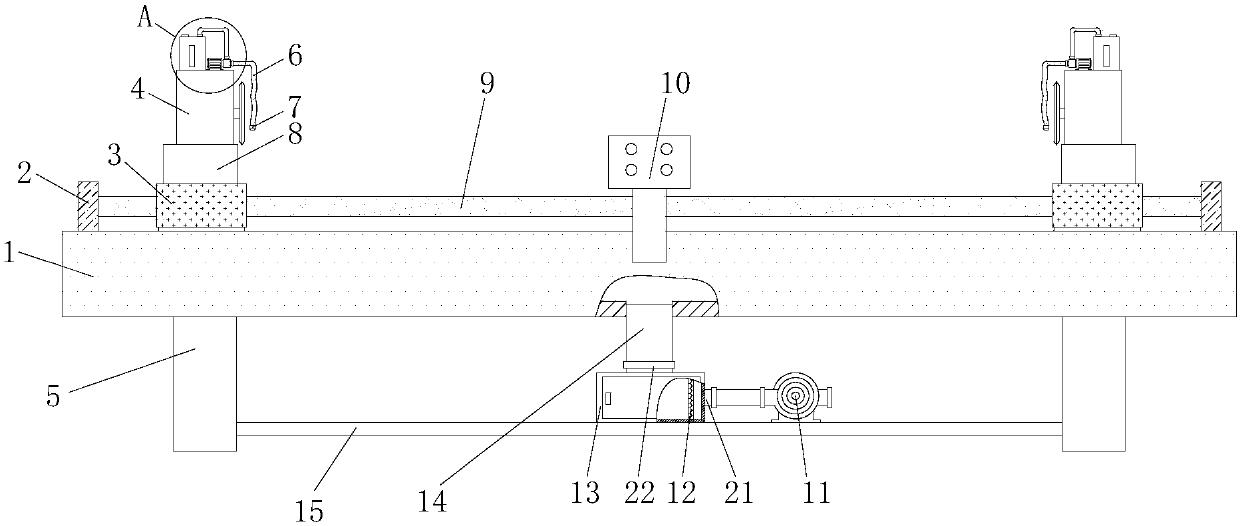

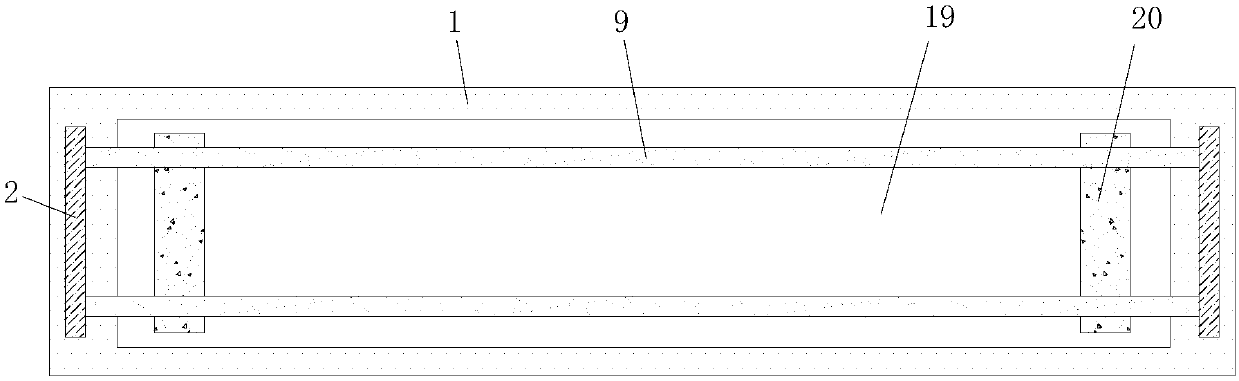

Double-end cutting saw for aluminum alloy profile machining

PendingCN109551046AQuality assuranceReduce generationMetal sawing devicesMetal sawing accessoriesCentrifugal fanMetal

Owner:重庆犇腾铝业有限公司

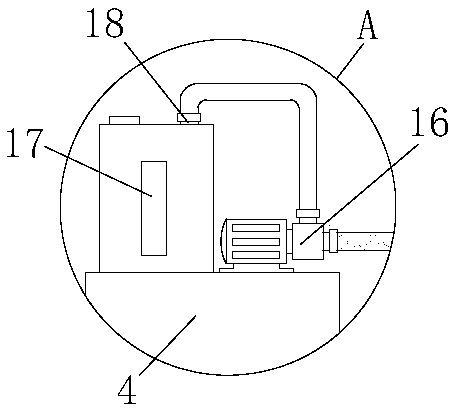

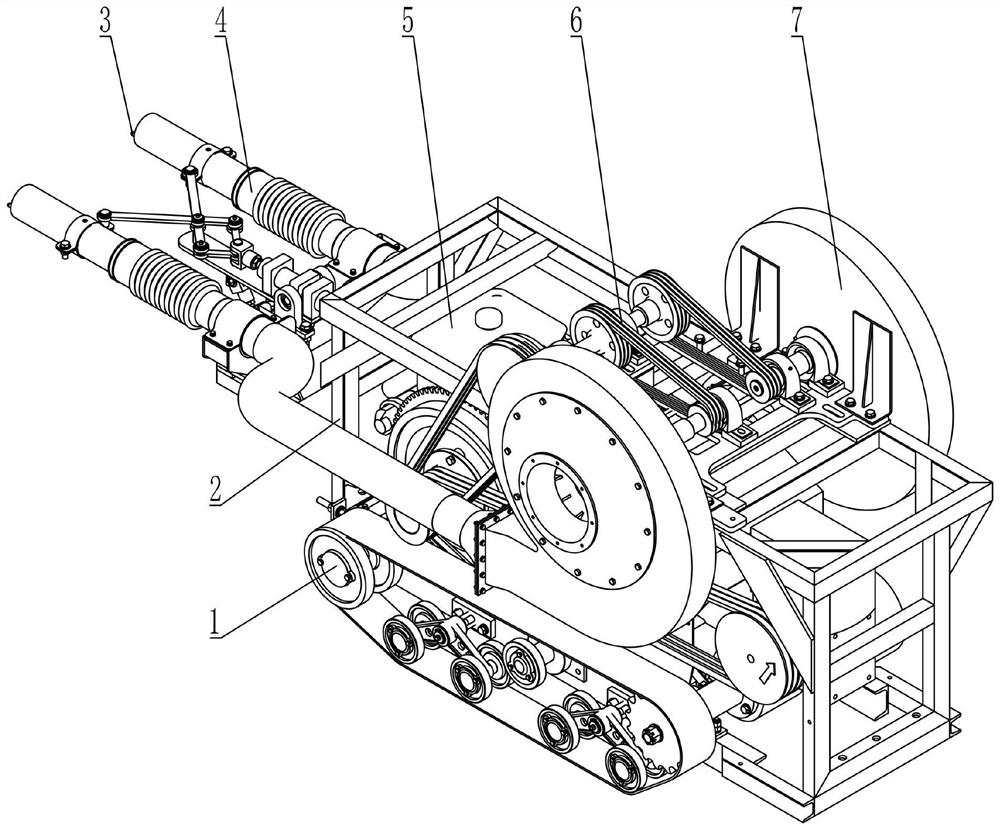

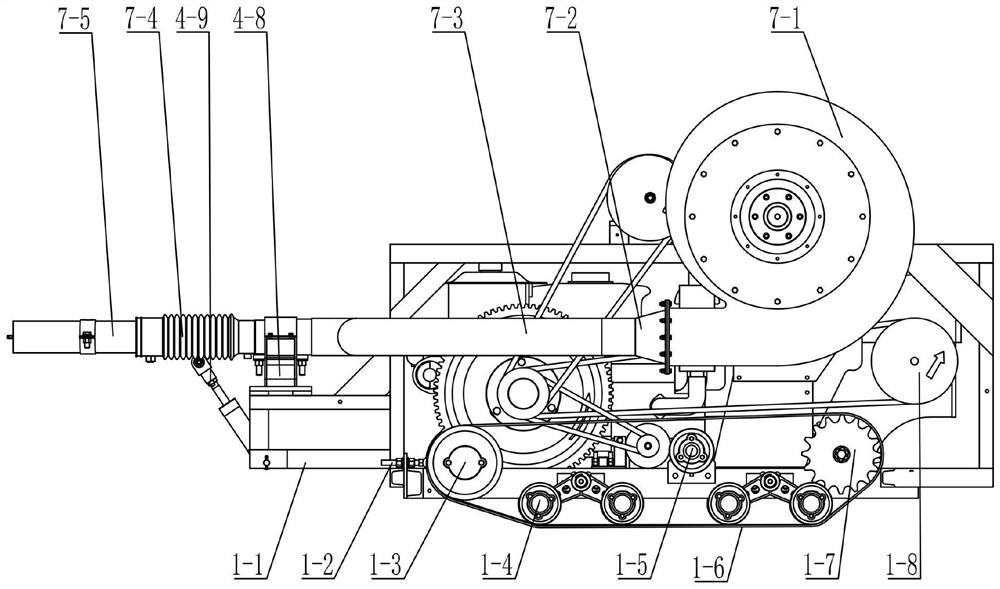

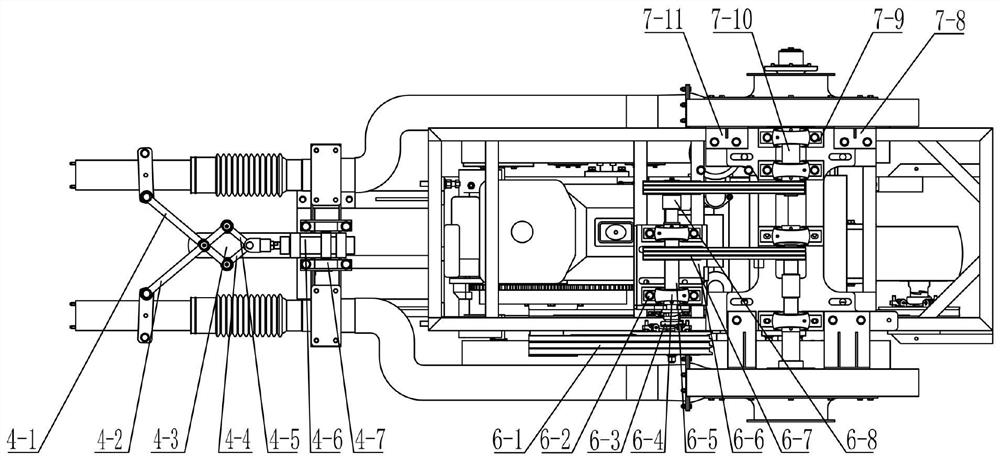

Crawler-type wind fire extinguishing robot with adjustable wind outlet speed

Owner:NORTHEAST FORESTRY UNIVERSITY

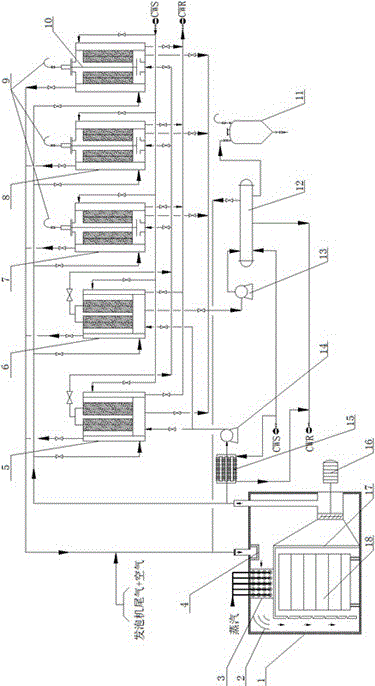

Closed-cycle recycling method for solvent in PVC foaming board production

InactiveCN105617810ASolve problems such as pollutionGuaranteed fire resistanceGas treatmentDispersed particle separationOrganic solventEngineering

Owner:TIANWEI CHEM +1

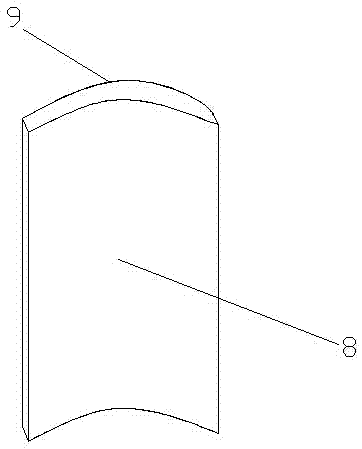

Centrifugal fan blade

InactiveCN105443428AWith sound absorptionWith heat and moisture resistancePump componentsPumpsFire protectionPolyethylene terephthalate

Owner:CHONGQING SHENGJIN AUTOMOBILE

Centrifugal fan

InactiveCN112343861APrevent intrusionAssociation with control/drive circuitsPump componentsEngineeringCentrifugal fan

The invention provides a centrifugal fan capable of visually inspecting the brazing state of the back side of a circuit substrate. The second housing (130) is provided with: a connector housing (190)having an opening (191) on the side thereof; and a connector pin (192) embedded inside, one end of the connector pin (192) protruding into the connector housing (190), the other end of the connector pin (192) passing through the circuit board (135) and being brazed to the circuit board (135), and weld legs (195a, 195b) being formed at corners formed by the connector pin (192) and the front and rear surfaces of the circuit board (135). A gap (139) is provided between the second case (130) and a portion of the circuit board (135) through which the connector pin (192) passes, and a through-hole (193) for visual confirmation is provided in the bottom wall portion of the second case (130), one opening (193d) of the through-hole for visual confirmation approaching the weld leg (195b) of the connector pin (192) and being transparent from the other opening (193e).

Owner:MINEBEAMITSUMI INC +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap