Crawler-type wind fire extinguishing robot with adjustable wind outlet speed

A fire-fighting robot and crawler-type technology, applied in fire rescue, climate change adaptation and other directions, can solve the problems of high safety, high fire-fighting cost, high labor intensity, etc., and achieve the effect of adjustable fire-extinguishing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

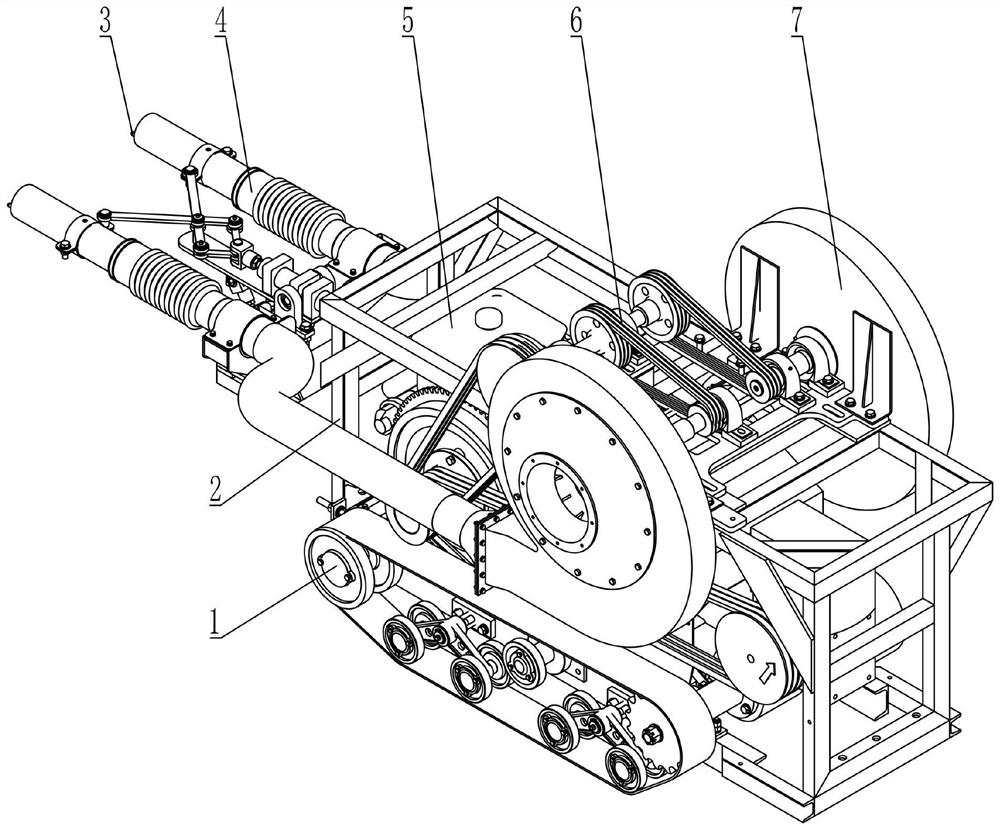

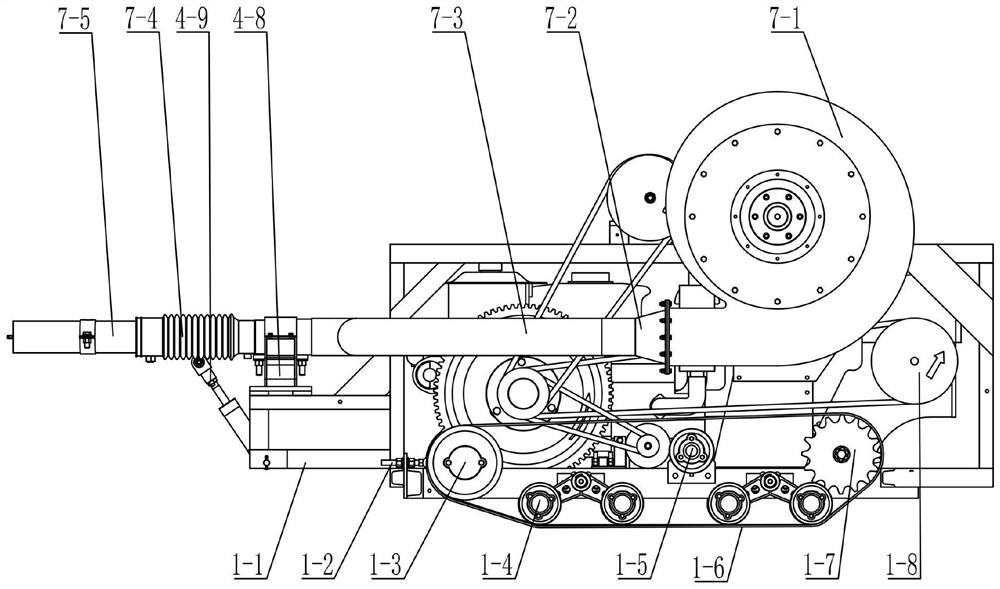

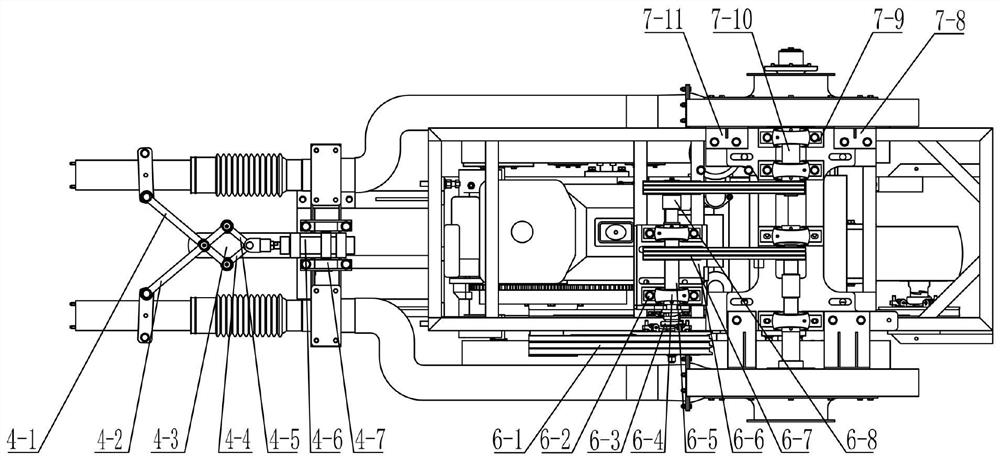

[0045] In a further embodiment of the present invention, a crawler-type wind-powered fire-fighting robot that can adjust the wind speed includes: a crawler running mechanism 1, a crawler chassis frame 2, a wind speed regulating mechanism 3, a double air duct regulating mechanism 4, a power System 5, intermediate transmission mechanism 6, double fan system 7; crawler chassis assembly includes chassis frame 1-1, tensioning mechanism 1-2, guide wheel 1-3, supporting wheel 1-4, drag wheel 1-5 , metal track 1-6, drive wheel 1-7, gearbox 1-8, gear operation box 1-9; Connecting plate 3-3, baffle plate 3-4, chute plate 3-5, cardan shaft 3-6 are formed; Double air pipe adjustment mechanism 4 is made up of right long rod 4-1, left long rod 4-2, the first Mounting plate 4-3, left short rod 4-4, right short rod 4-5, hinge head hydraulic cylinder 4-6, bearing with seat 4-7, gantry frame 4-8, vertical hydraulic cylinder 4-9, etc. ; The intermediate transmission mechanism 6 is mainly composed

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap