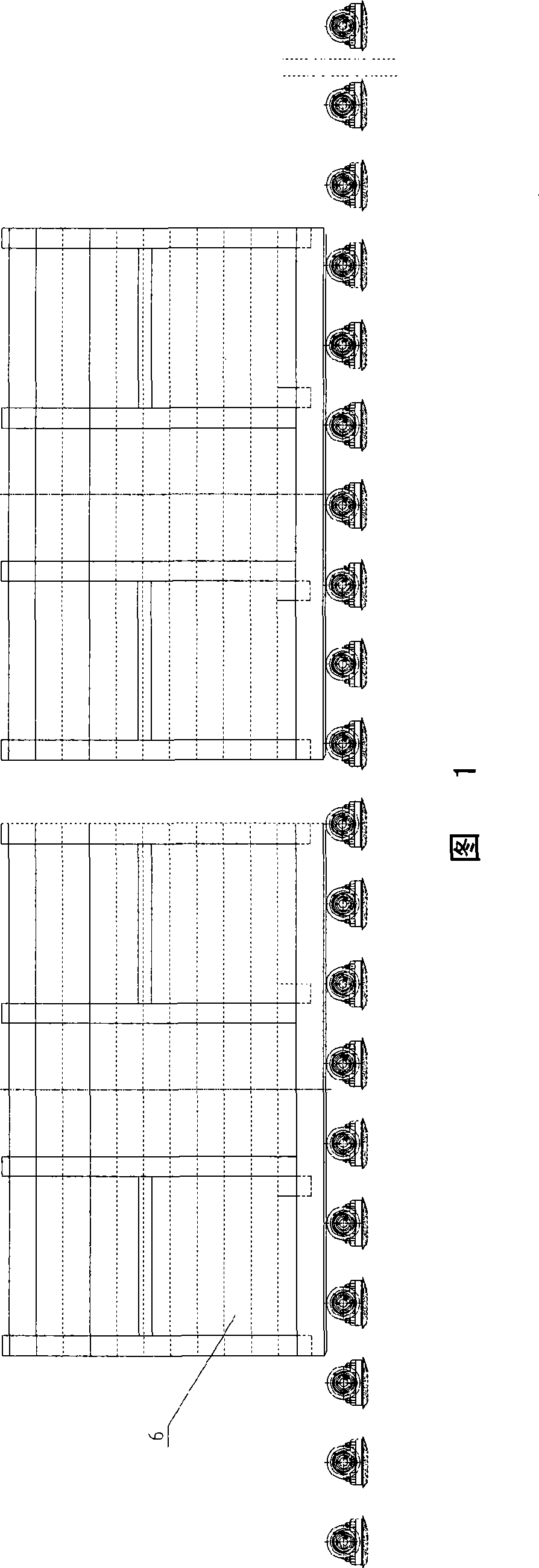

Roller way conveying buffer segment

A buffer section, roller table technology, applied in the direction of roller table, transportation and packaging, can solve the problems of sliding friction, bumping and scratching items, affecting the conveying volume and productivity, etc., to reduce sliding friction and improve service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

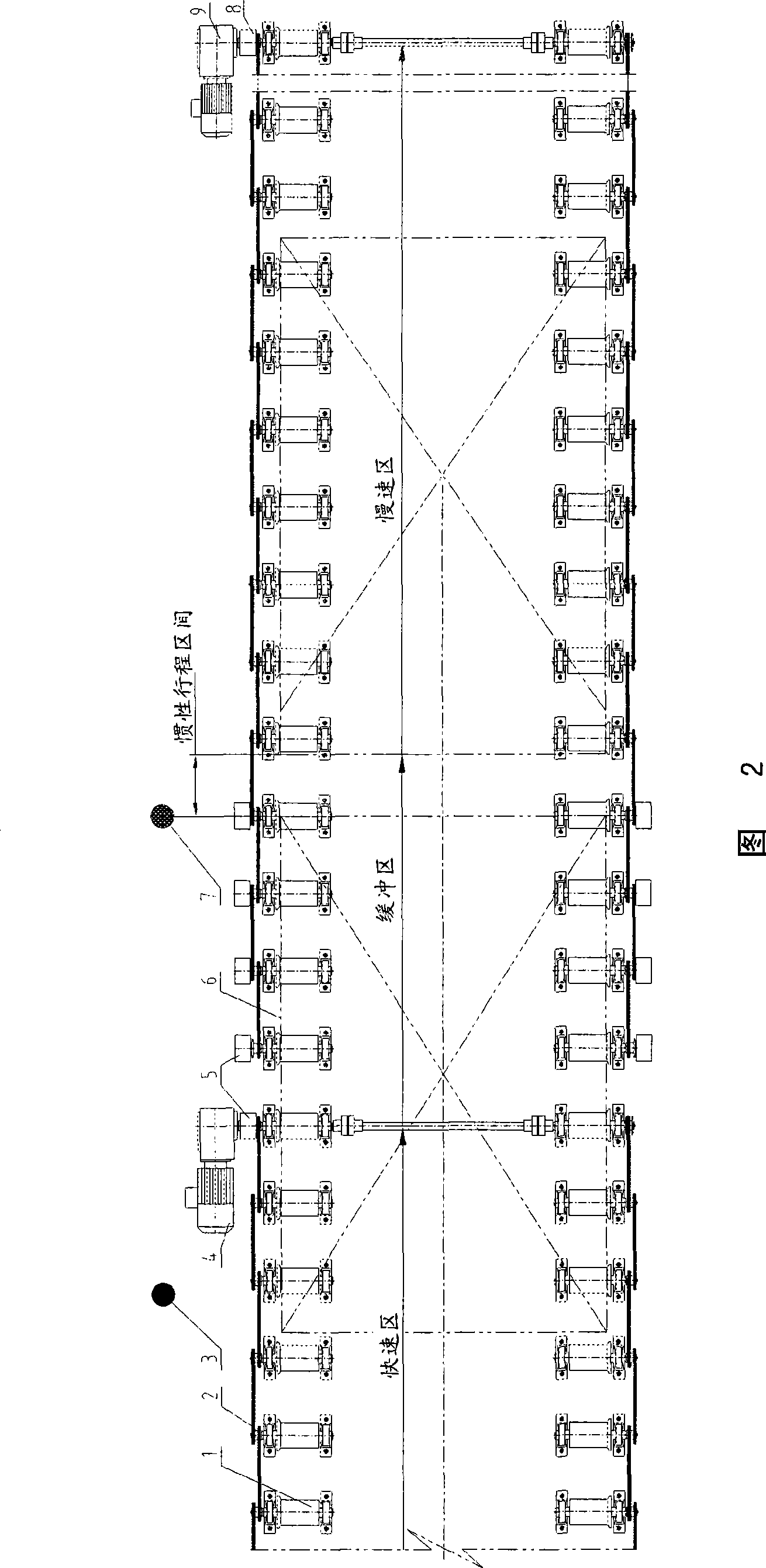

[0014] The present invention will be described in detail below with reference to the accompanying drawings.

[0015] The buffer section of the present invention is divided into a fast zone, a buffer zone and a slow zone, mainly including: idler roller 1, sprocket, chain 2, position sensor 3 for controlling departure time, motor reducer 4 in fast zone, overrunning clutch 5 and 8 , the position sensor 7 that sends out the fast and slow speed conversion signal, and the motor reducer 9 in the slow speed zone. In the present invention, the position sensor can be a photoelectric sensor or other sensors.

[0016] The working principle of the present invention will be briefly described below, and the specific structures of components known in the prior art will not be described in detail here. The article 6 runs fast on the roller table, and still advances at a fast speed when entering the buffer zone from the fast zone. The motor reducer 9 in the slow zone does not need to change the s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap