Speed reducer

A technology of reducer and deceleration transmission, which is applied in the direction of door/window accessories, wing leaf parts, gear transmission devices, etc. It can solve the problems of unstable output torque, laborious trouble, and affecting the life of the transmission accuracy of the transmission pair, so as to reduce the applied force. The space occupied by the force and the axial direction is small, and the effect of meeting the transmission requirements of the large reduction ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

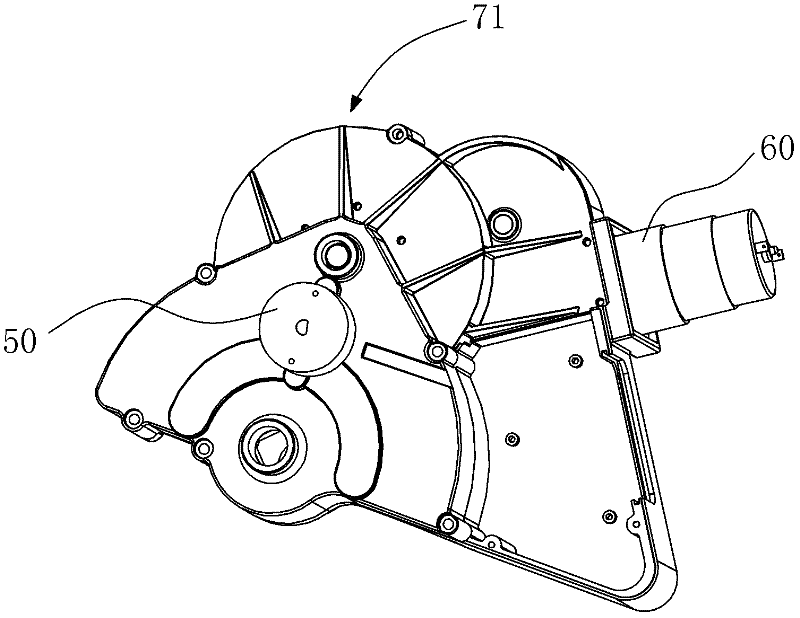

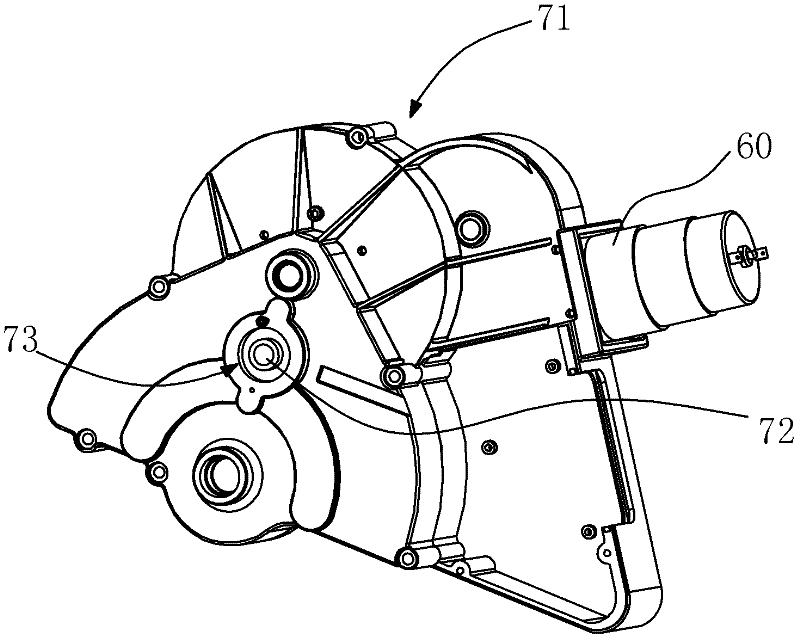

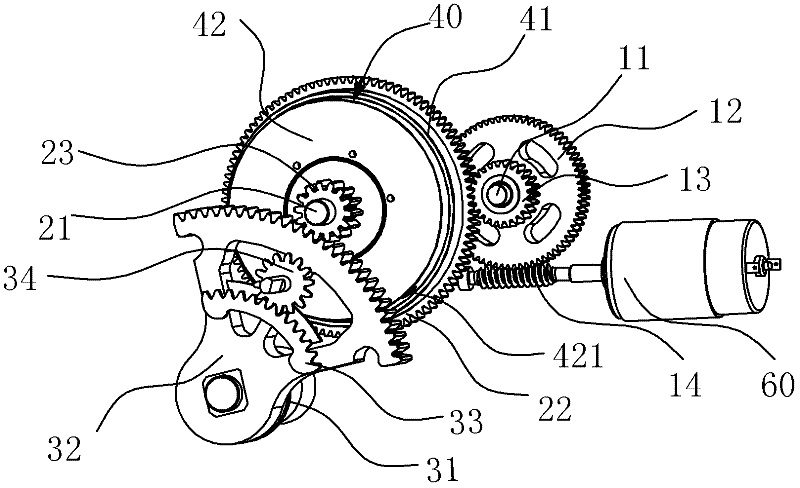

[0014] Such as figure 1 , figure 2 , image 3 As shown, the speed reducer includes a housing 71, and the airtight cavity in the housing 71 is provided with a three-stage reduction transmission mechanism, and the reduction transmission mechanisms of each stage are gear meshing transmissions, which are connected with the output end of the motor 60 and serve as a The worm 14 of the first-stage main transmission meshes with the first-stage driven gear 12 to form the first-stage reduction transmission pair, and the second-stage driving gear 13, which is coaxially fixed with the first-stage driven gear 12, meshes with the second-stage driven gear teeth 22 to form the second stage. The three-stage driving gear 23 coaxially arranged with the two-stage driven gear 22 and the three-stage output gear 32 constitute the third-stage reduction transmission pair, and the three-stage d

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap