High-efficiency zero-energy-consumption AOA sewage treatment device and method

A sewage treatment device, zero energy consumption technology, applied in the direction of biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of limited use of left and right, and achieve a scientific oxygenation device , Strong practicability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

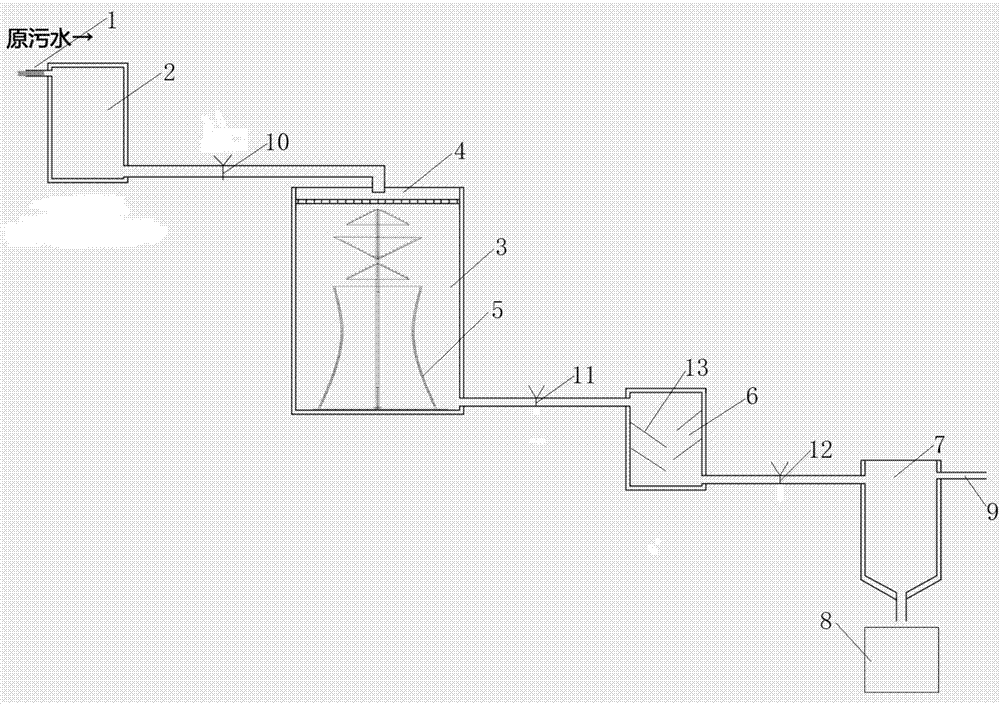

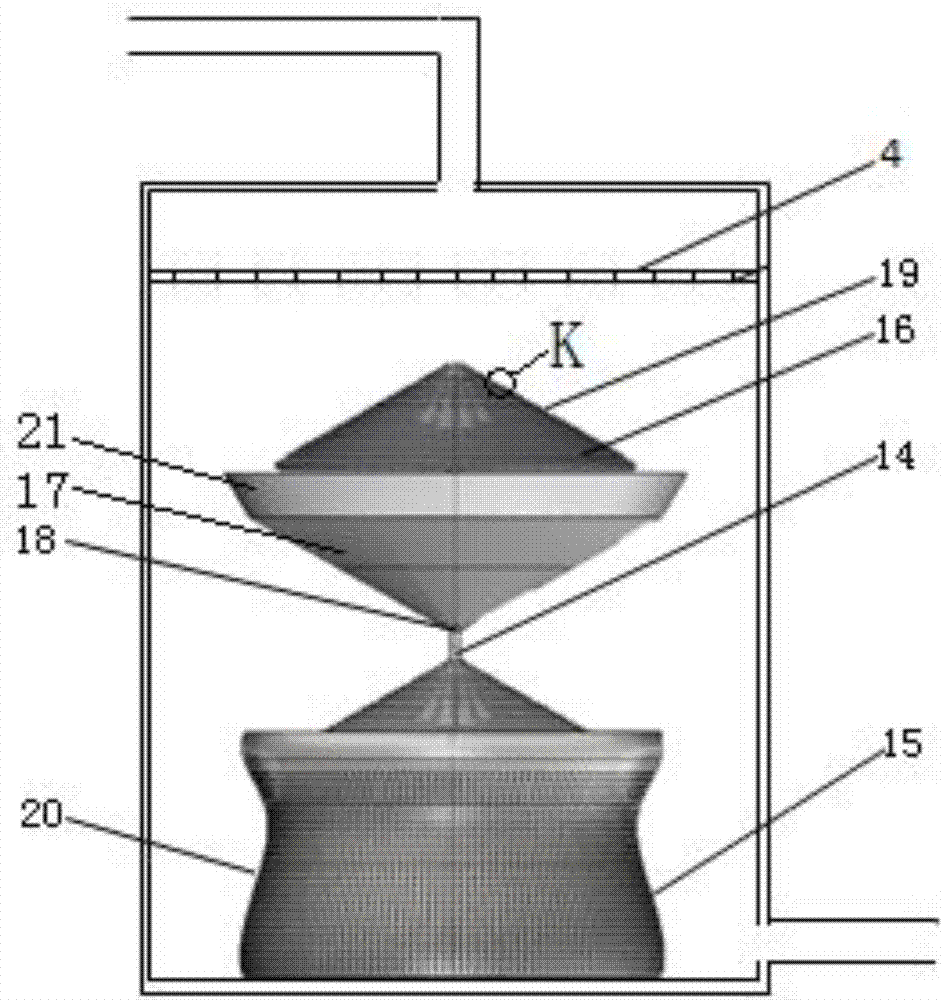

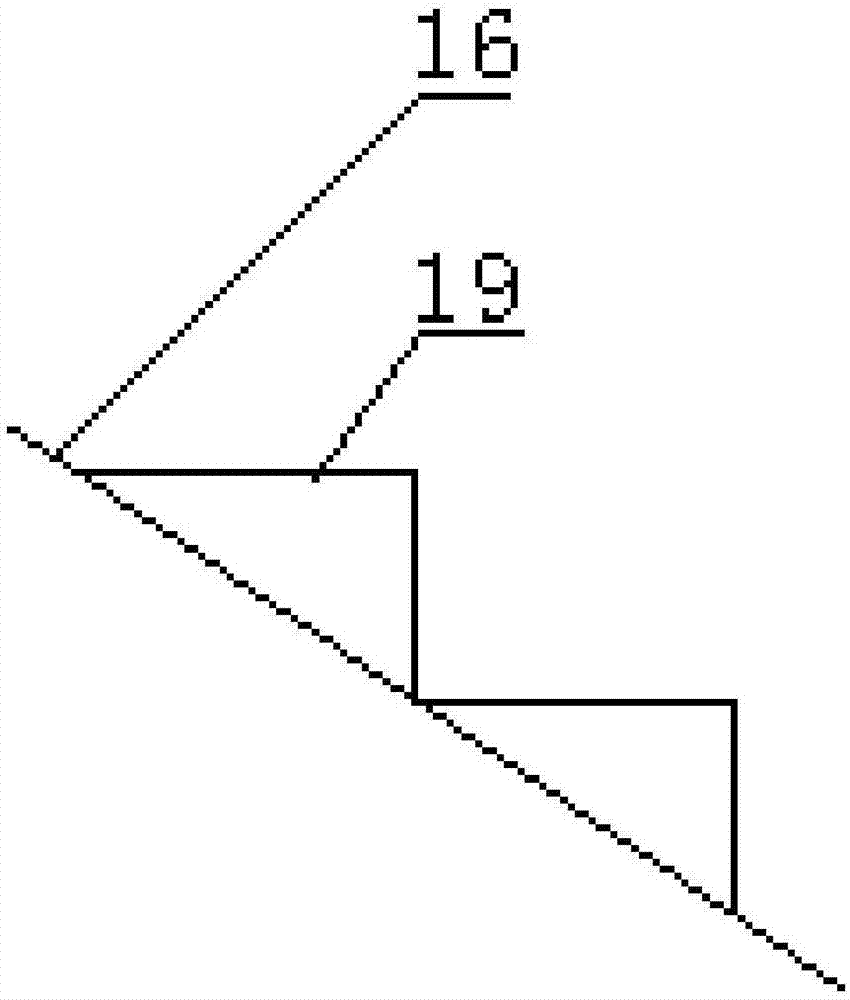

[0069] Example 1

[0070] Take a 30L high water sample. After the raw water is treated in the primary sedimentation tank for 1 to 2 hours, it enters the anaerobic tank 2 through the inlet pipe 1, and is added with denitrifying phosphorus removal bacteria to form a muddy water mixture. After 2 hours of treatment in the anaerobic tank 2, the organic matter Hydrolysis, acidification, and methanation occur, and then the first valve 10 is opened. The mud-water mixture flows from the anaerobic tank 2 to the aerobic tank 3 through the connecting pipe by gravity, and is dispersed into droplets through the sieve plate 4, and be beaten vertically. The unpowered oxygenation device 5 flows into the inner side of the hole surface after passing through four groups of positive and negative water cones, and contacts the outside air through the cavity. The water flows out through the hole 20 along the inner and outer sides of the hole surface under the action of gravity, and the wall of the hole 20

Example Embodiment

[0071] Example 2

[0072] Take a 30L medium water sample. After the raw water is treated in the primary sedimentation tank for 1 to 2 hours, it enters the anaerobic tank 2 through the water inlet pipe 1, and is added with denitrifying phosphorus removal bacteria to form a muddy water mixture. After being treated in the anaerobic tank 2 for 2 hours, The organic matter is hydrolyzed, acidified and methanated, and then the first valve 10 is opened. The mud-water mixture flows from the anaerobic tank 2 to the aerobic tank 3 through the connecting pipe by gravity, and is dispersed into droplets through the sieve plate 4, beating vertically Enter the unpowered oxygenation device 5, flow into the inner side of the hole surface after passing through the four groups of positive and negative water cones, and contact the outside air through the cavity. The water flows out through the holes 20 along the inner and outer sides of the hole surface under the action of gravity. The holes 20 The wall

Example Embodiment

[0073] Example 3

[0074] Take a 30L low-degree water sample, the raw water will enter the anaerobic tank 2 through the inlet pipe 1 after being treated by the primary sedimentation tank for 1 to 2 hours, and add denitrifying phosphorus removal bacteria to form a muddy water mixture. After 2 hours of treatment in the anaerobic tank 2, make The organic matter is hydrolyzed, acidified and methanated, and then the first valve 10 is opened. The mud-water mixture flows from the anaerobic tank 2 to the aerobic tank 3 through the connecting pipe by gravity, and is dispersed into droplets through the sieve plate 4, beating vertically Enter the unpowered oxygenation device 5, flow into the inner side of the hole surface after passing through the four groups of positive and negative water cones, and contact the outside air through the cavity. The water flows out through the hole along the inner and outer sides of the hole surface under the action of gravity, and the hole wall breaks The water

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap