Closed-cycle recycling method for solvent in PVC foaming board production

A closed-loop, foamed board technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve problems such as pollution, and achieve the effects of significant economic benefits, high recovery efficiency, and quick results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

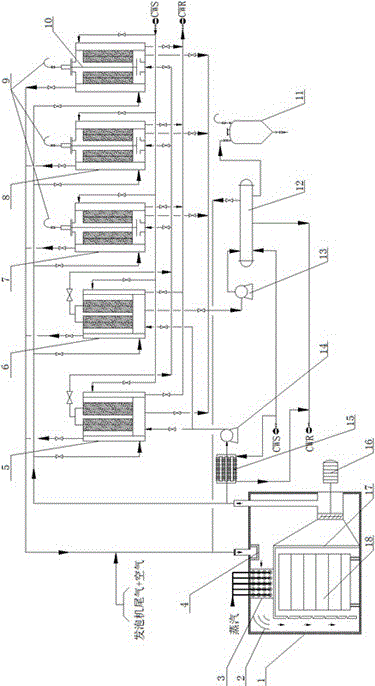

[0017] Refer to attached figure 1 , a method for solvent closed-circuit recycling in the production of PVC foam boards, comprising sequentially connected hot air circulation oven 1, surface condenser 15, centrifugal fan 14, preprocessor I5, preprocessor II6, adsorber A7, adsorption B8, adsorber C10, compressor 13, condenser 12, recovery solvent storage tank 11, a filter 4 is installed at the entrance of the hot air circulation oven 1, and a heater 3, deflector 2, and damper 17 are arranged inside the hot air circulation oven , automatic conveying trolley 18, main blower 16; the exhaust gas from the top of the foaming machine enters the hot air circulation oven together with the air under the drive of the main blower, and is filtered through the filter in turn, heated by the heater, deflected by the deflector, and enters Air door, and heat up the foamed sheet on the automatic conveying car, evaporate the organic solvent in the sheet and send it out of the hot air circulation oven

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap