Grains airing koji-adding device

A technology for grain grains and a spreader is applied in the field of liquor brewing, which can solve the problems of high labor intensity, uneven addition of koji, low heat dissipation efficiency, etc., and achieve the effects of realizing mechanical automation, reducing production costs and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

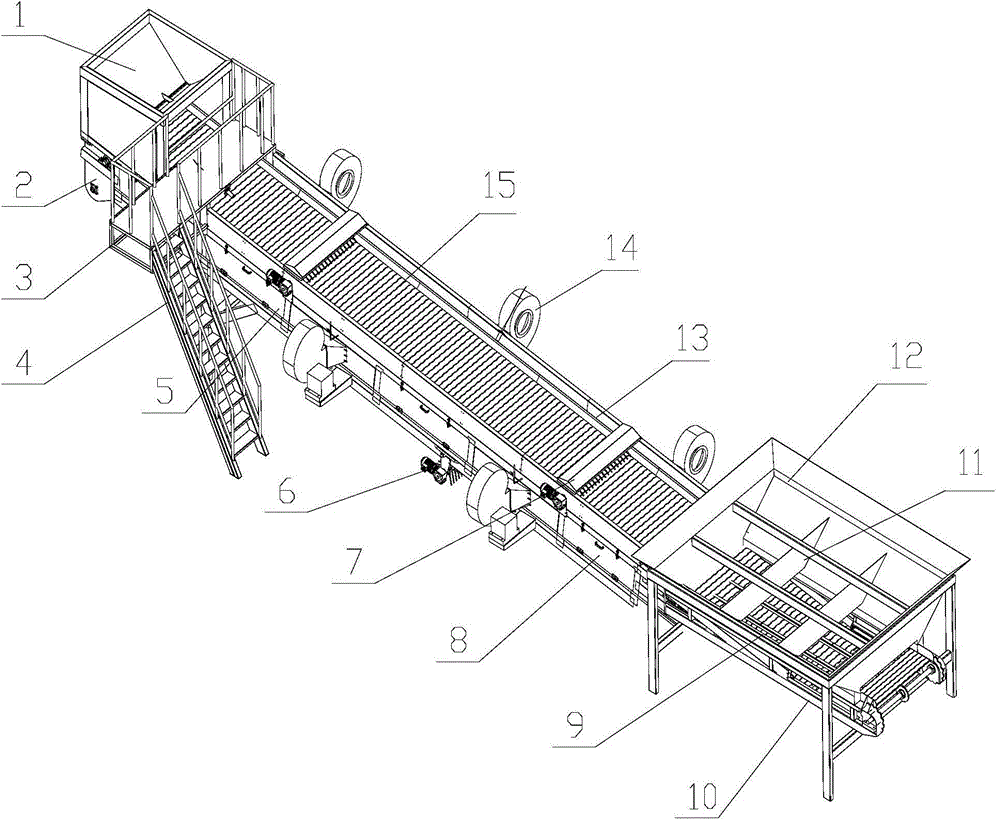

[0028] Such as figure 1 Shown, a kind of grain dregs is aired and added song device, comprises controller and feeder frame 10, is provided with feeder hopper 12 between described feeder frame 10, and described feeder frame 10 bottoms The position corresponding to the feeder hopper 12 is provided with a feeder chain plate 9 driven by a driving device, and a vertical feeder partition 11 is arranged between the feeder hopper 12 and the feeder chain plate 9 , wherein one end of the feeder chain plate 9 is connected with the airing machine chain plate 15 arranged on the airing machine frame 5, and the airing machine chain plate 15 has several round holes, and the airing machine Both sides of the chain plate 15 are provided with a drier guard plate 13, and an air chamber 8 is formed between the drier guard plate 13, the drier frame 5 and the drier chain plate 15, and the side of the air chamber 8 is provided with There is a centrifugal blower 14 communicating with the inside thereof,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap