Centrifugal fan blade

A technology of centrifugal fan blades and fan blades, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc. It can solve problems such as complex design and unsuitable use by staff. Achieve stable performance, help ventilation, strong wind effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

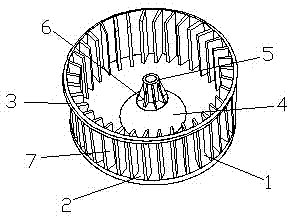

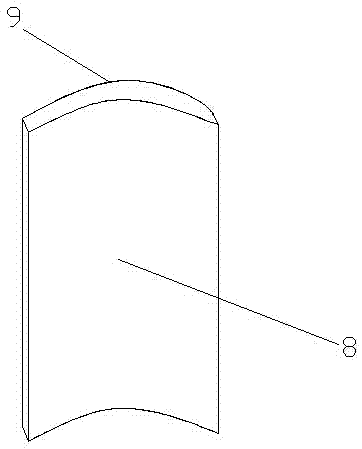

[0017] Example: see Figure 1-2 , a centrifugal fan blade according to the present invention, comprising a centrifugal fan blade body 1, said centrifugal fan blade body 1 including a guide ring 2, an annular blade bottom plate 3, a hub 4 and fan blades 7, said fan blades 7 being arranged on the guide Between the flow ring 2 and the circular leaf base plate 3, a hub 4 is arranged inside the guide ring 2, and a cylindrical plastic shaft hole sleeve 5 is arranged on the hub 4, and around the cylindrical plastic shaft hole sleeve 5 A shaft hole sleeve support member 6 is provided, and the fan blade 7 includes an inner arc surface 8 and an outer arc surface 9 .

[0018] The manufacturing material of the centrifugal fan body 1 is a noise-reducing plastic material, and its main components are renewable polypropylene and polyethylene terephthalate, so as to ensure that the centrifugal fan body 1 has sound absorption, heat and moisture resistance, Stable performance, flame retardant and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap