Extinguishing Nozzle, Fire Extinguishing Installation and Fire Protection System with Energy Harvesting

a technology of energy harvesting and exhaust nozzle, which is applied in the direction of piezoelectric/electrostriction/magnetostriction machines, fire rescue, electrical equipment, etc., can solve the problems of high cost, high simple alternative solutions such as batteries, which fail to meet the needs of emergency situations, etc., to reduce installation and/or maintenance costs, the effect of reducing one or more disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

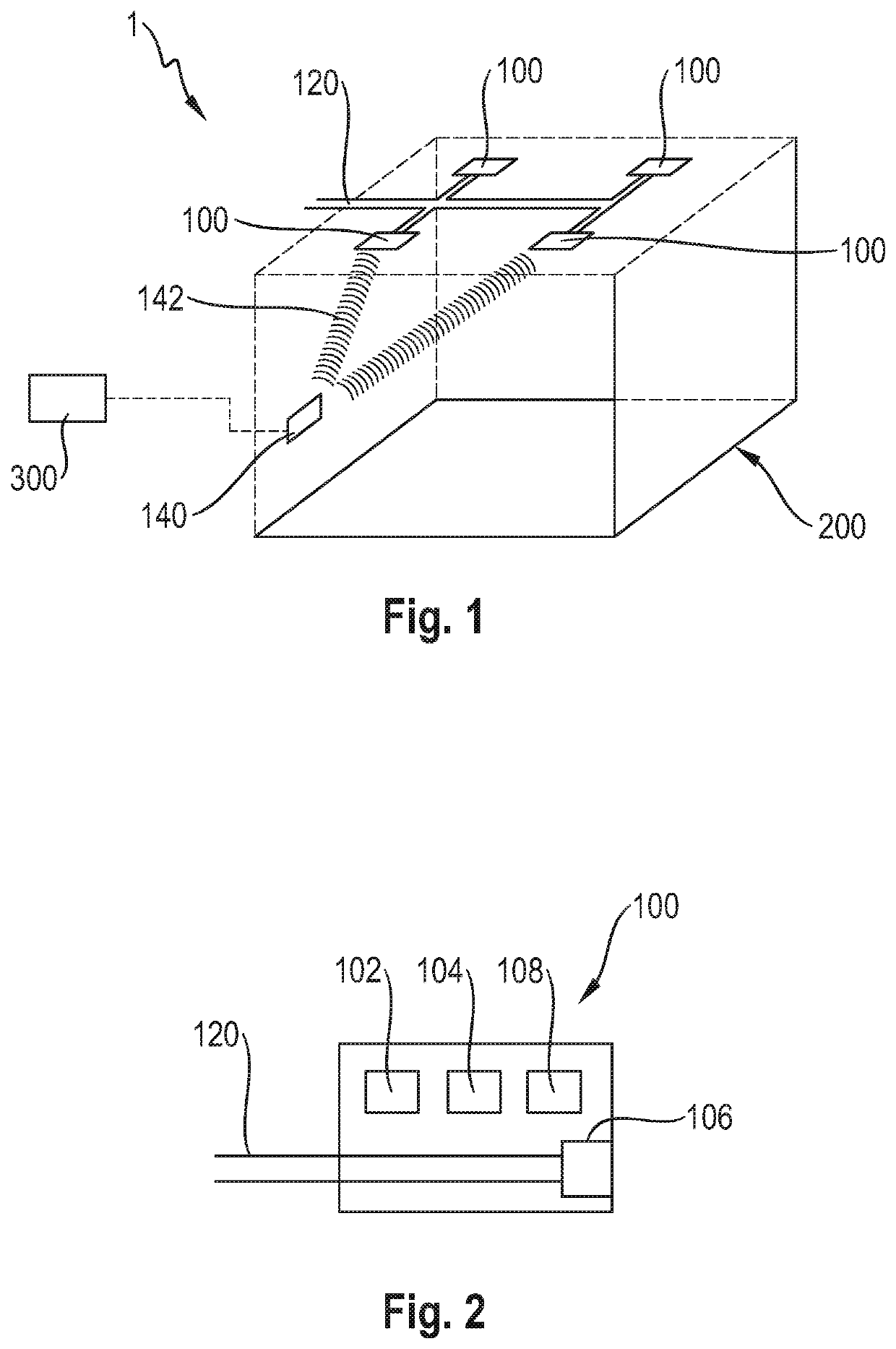

[0080]FIG. 1 shows, schematically and by way of example, a fire extinguishing installation 1 according to the invention for protecting, in particular for fighting a detected fire in, at least one protected area 200. The fire extinguishing installation 1 comprises a fluid line network with a fluid line 120 and multiple extinguishing nozzles 100 connected to the fluid line 120. In a preferred case, the fire extinguishing installation 1 also has sensor means, for example as part of the extinguishing nozzles 100, which sensor means are configured for detecting fires. The fire extinguishing installation 1 is then also designed for monitoring the one or more protected areas 200.

[0081]The extinguishing nozzle 100 is configured for receiving energy. In this exemplary embodiment, the extinguishing nozzle 100 is configured for receiving energy 142 from an energy transmitter 140. The energy transmitter 140 may for example be configured for transmitting electromagnetic energy in the form of light

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap