Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11 results about "Incineration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Incineration is a waste treatment process that involves the combustion of organic substances contained in waste materials. Incineration and other high-temperature waste treatment systems are described as "thermal treatment". Incineration of waste materials converts the waste into ash, flue gas and heat. The ash is mostly formed by the inorganic constituents of the waste and may take the form of solid lumps or particulates carried by the flue gas. The flue gases must be cleaned of gaseous and particulate pollutants before they are dispersed into the atmosphere. In some cases, the heat generated by incineration can be used to generate electric power.

Device technology configuration method for treating house refuses by using rotary cement kiln

The invention provides a device technology configuration method for treating house refuses by using a rotary cement kiln, comprising a pre-treatment device technology configuration method and an incineration device technology configuration method, wherein the whole process of the crushing treatment of the house refuses is implemented by using the pre-treatment device technology configuration method, and a whole incineration process is carried out on the crushed house refuses by using the incineration device technology configuration method; the incineration device technology configuration comprises a double-layer power-driven flap valve, an L-shaped incinerator, a double-layer heavy punch flap valve, a vibrating conveyor and a bucket elevator; and partial tertiary air captured from a tertiary air tube of a rotary kiln enters into the L-shaped incinerator through an air intake tube and high temperature incineration is carried out on the house refuses in the incinerator, smoke generated when incineration passes through an air discharging tube and then is converged with the tertiary air tube, a loop formed by the air intake tube and the air discharging tube of the L-shaped incinerator is provided with a second high-temperature electric butterfly valve and a third high-temperature electric butterfly valve, and a first high-temperature electric butterfly valve is arranged on the tertiary air tube. Harmful gases such as dioxin can be inhibited by high-temperature environment which is generated by using the rotary cement kiln.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Industrial castoff fusing and solidifying device

InactiveCN101086334AFlammability ControlGood effectIndirect carbon-dioxide mitigationIncinerator apparatusCombustorPesticide residue

There is provided an industrial waste melting / solidifying apparatus comprising: melting furnace; an oxygen generating device for supplying oxygen-enriched air to the melting furnace; and a burner provided so as to face the inside of the melting furnace, wherein industrial wastes, such as asbestos, pesticide residues and incineration ashes, are thrown into the melting furnace, and combustible materials within the industrial wastes and fuel from the burner are combusted at high temperature by using the oxygen- enriched air, whereby a melting process is performed on the industrial wastes. An entrance slot formed on the melting furnace is provided with a water-cooling jacket via a throw-in gate. The water-cooling jacket is provided with a throw-in door for throwing the industrial wastes. The water-cooling jacket is further provided with a pusher for pushing the thrown industrial wastes out toward the entrance slot to control throwing speed and combustion speed.

Owner:高桥 贤三

Household garbage incineration fly ash source reduction treatment system and method

InactiveCN111905535AReduce productionReduce landfill volumeCombination devicesGas treatmentBottom ashFlue gas

The invention discloses a household garbage incineration fly ash source reduction treatment system and method, and the treatment system comprises a deacidification reaction tower, a classifier and a chelating agent atomization reactor which are sequentially communicated, the bottom of the deacidification reaction tower is connected with a circulating fan, and household garbage incineration flue gas enters the deacidification reaction tower for deacidification treatment; the bottom ash of the deacidification reaction tower enters the deacidification reaction tower again under the action of thecirculating fan to be circulated, the flue gas subjected to deacidification treatment is classified into fine-particle fly ash and coarse-particle fly ash through the classifier, and the fine-particlefly ash enters the chelating agent atomization reactor to be subjected to chelating stabilization treatment for the first time; and the treated fine-particle fly ash and the treated coarse-particle fly ash are converged and subjected to dust removal treatment and secondary chelating stabilization treatment in sequence. According to the method, the consumption of consumables in the flue gas purification process is reduced, the action efficiency of desulfurization and heavy metal fixing agents is improved, the fly ash yield and harmless treatment cost are reduced, and fly ash reduction and efficient stabilization treatment of heavy metals are realized.

Owner:BEIJING CAPITAL ENVIRONMENT TECH CO LTD

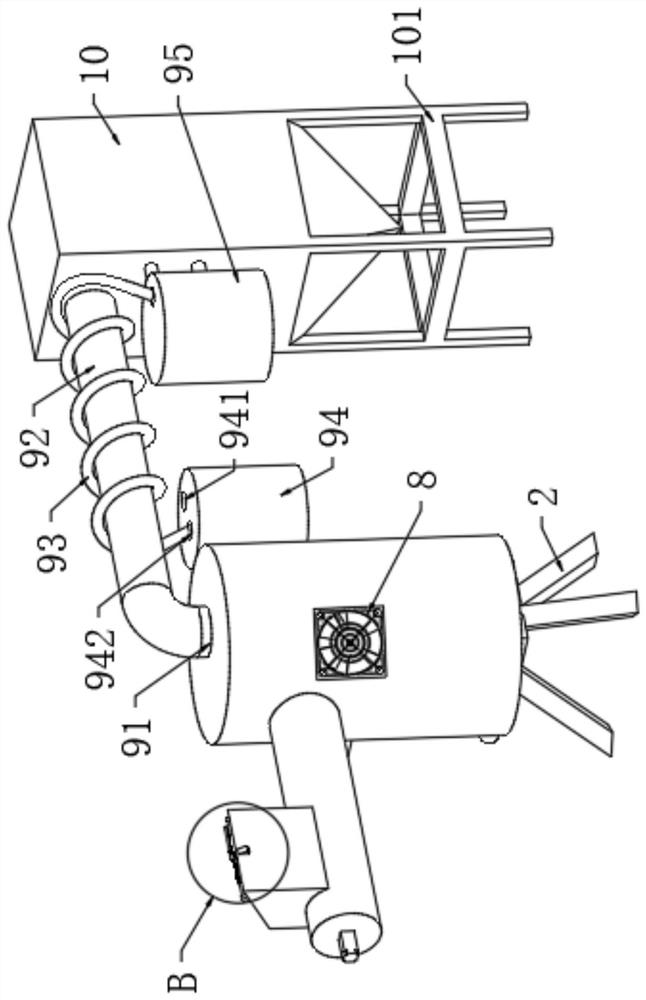

Incineration waste gas treatment device based on planetary gear transmission principle

InactiveCN111408252AGuaranteed one-way flowPrevent backflowGas treatmentDispersed particle separationGear wheelEnvironmental engineering

The invention relates to the technical field of environmental protection. The invention further discloses an incineration waste gas treatment device based on the planetary gear transmission principle.The device comprises a treatment tank, and an air inlet is fixedly connected to the outer part of the treatment tank; the interior of the air inlet is movably connected with a rotating ring; a fan plate is movably connected to the interior of the rotating ring; reset springs are movably connected to the outer part of the fan plate; a convex block is movably connected to the outer part of the fanplate; a rotating block is movably connected to the interior of the treatment tank; an air cavity is formed in the rotating block; a net plate is movably connected to the outer part of the rotating block; a spiral plate is movably connected to the upper part of the net plate; through cooperative use of the air inlet, the rotating ring, the fan plate, the reset spring and a protruding block, it isguaranteed that waste gas at the air inlet is adsorbed, one-way flowing of the waste gas is guaranteed through rotation of the fan plate, waste gas backflow is effectively prevented, air pollution caused by waste gas backflow leakage is avoided, and the waste gas treatment efficiency is effectively improved.

Owner:陈秀凤

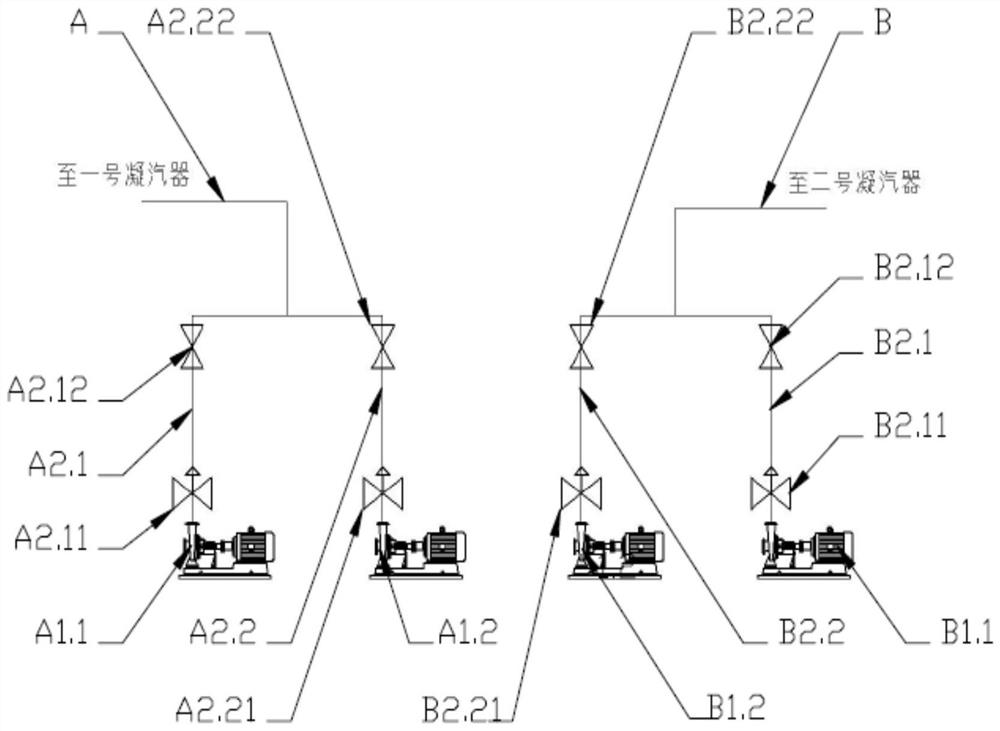

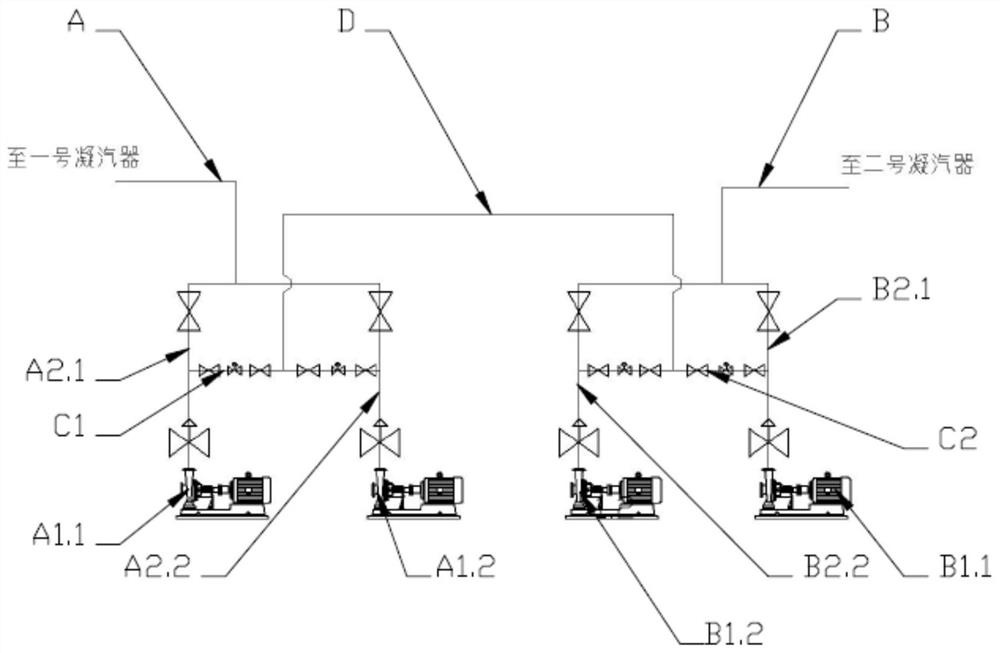

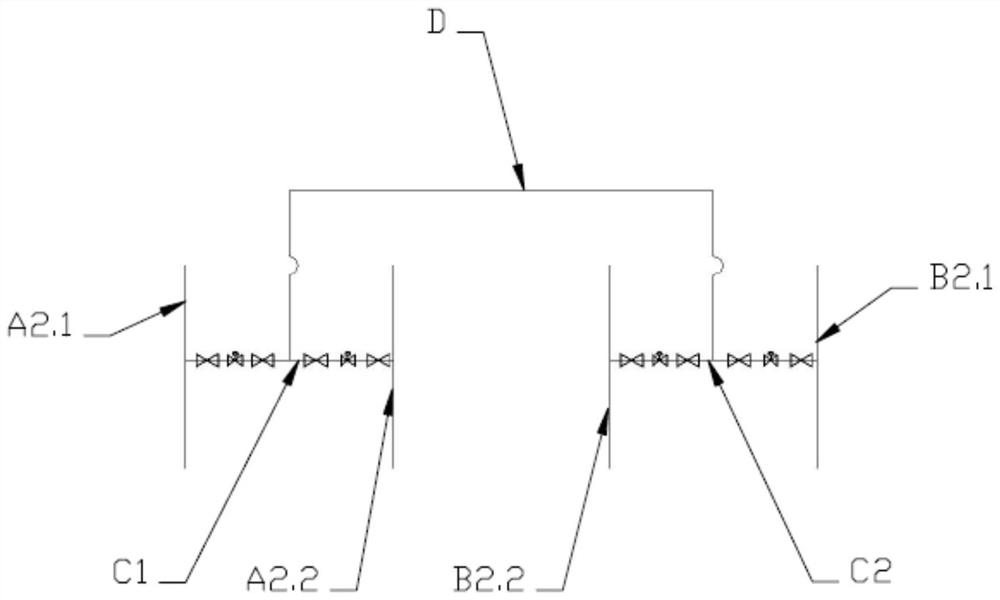

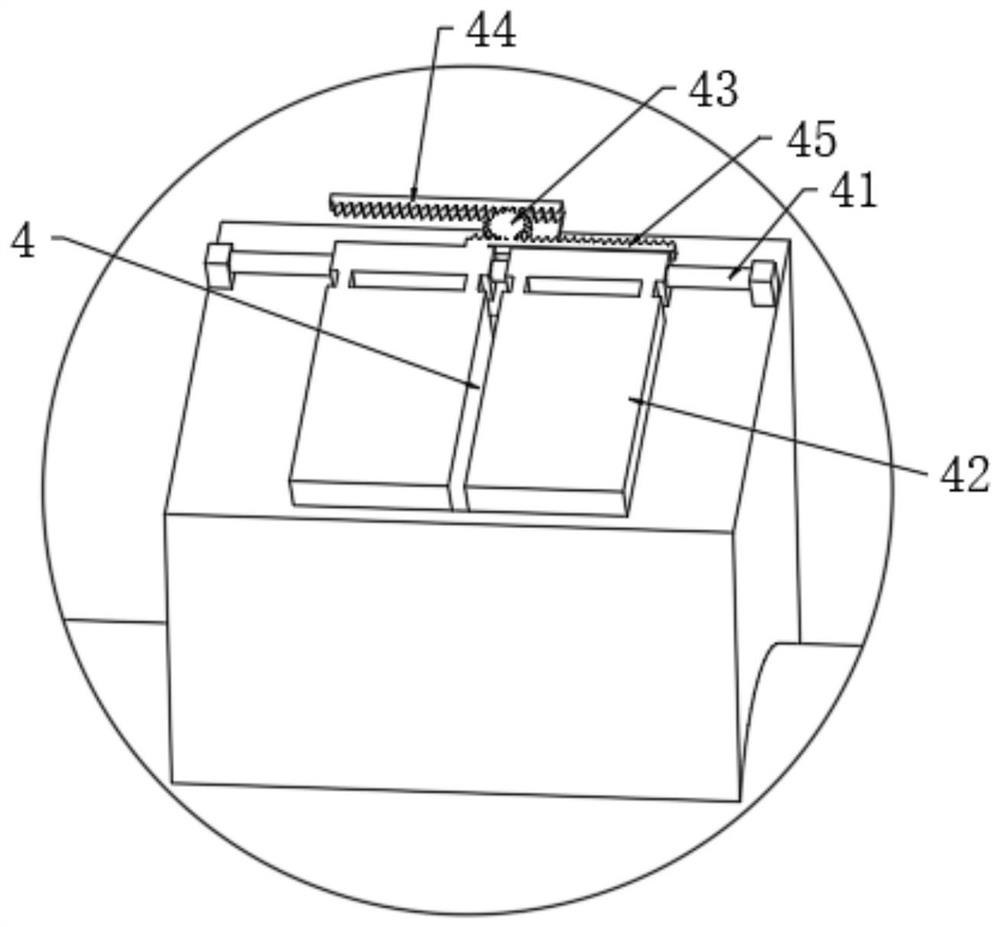

Pipeline system of vacuum pump unit of waste incineration power plant

PendingCN113833630AReduce downtime incidentsMake sure the connection works securelyPositive displacement pump componentsPump installationsPower stationProcess engineering

Owner:CHAOZHOU SHENZHEN ENERGY ENVIRONMENT CO LTD +5

Solid waste incineration method

Owner:重庆知翔科技有限公司

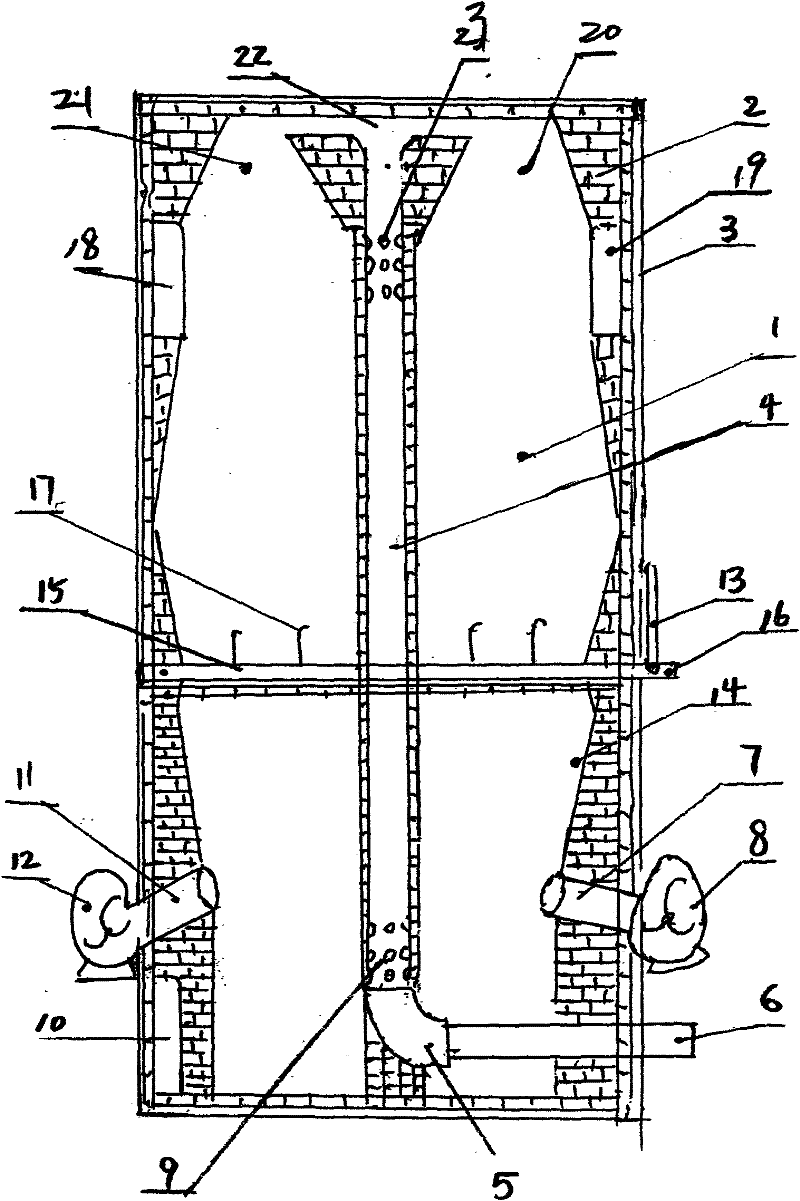

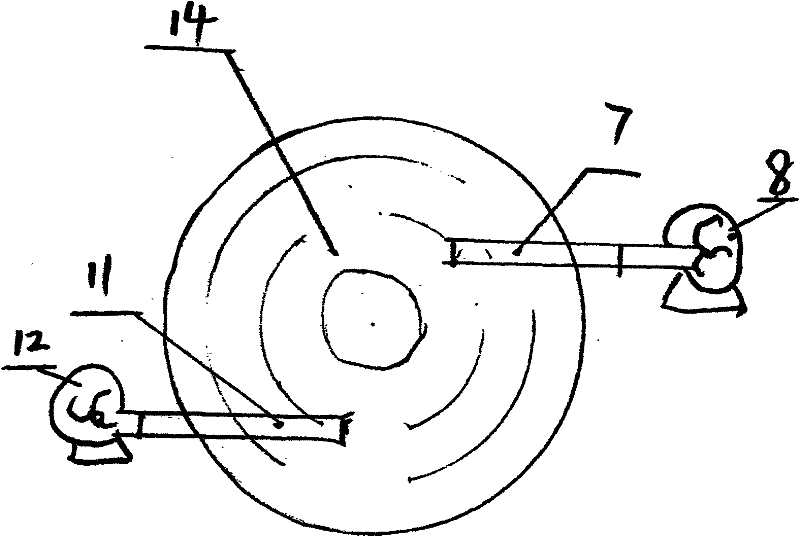

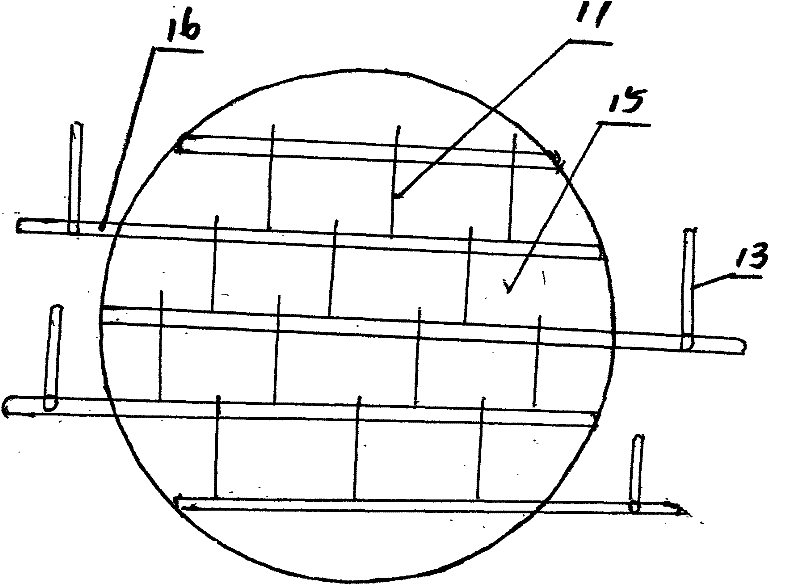

Chemical waste incinerator

InactiveCN111928250ABurn fullyReduce the likelihood of an explosionIncinerator apparatusCombined combustion mitigationCombustorExhaust fumes

The invention discloses a chemical waste incinerator. The chemical waste incinerator comprises a furnace body, wherein a feed hopper is arranged on one side of the furnace body, a feed inlet is formedin the upper end of the feed hopper, a baffle plate is arranged in the position, corresponding to the feed hopper, of the interior of the furnace body, a rotating roller is arranged in the feed hopper, a guide blade is arranged on the rotating roller, a burner is arranged in the furnace body, an ash discharge hopper is arranged below the furnace body, an air supplement opening is arranged on oneside of the furnace body, a waste heat recovery device is arranged at the upper end of the furnace body, an air outlet is arranged at the top end of the furnace body, a water tank is arranged on one side of the furnace body, an air outlet pipe is arranged at the air outlet, an air exhaust opening is arranged on the water tank, and a spraying device is arranged in the furnace body. A user directlydumps chemical engineering garbage into the feed hopper, materials are conveyed through the inner guide blade, the baffle plate is pushed away under the action of gravity, the materials enter the furnace body for combustion, oxygenation work is regularly carried out through an air supplement opening, the interior of the furnace body is fully combusted, and then generated hot waste gas is subjectedto heat exchange work through the waste heat recovery device at the top.

Owner:HUNAN DELI SAFETY & ENVIRONMENTAL PROTECTION TECH CO LTD

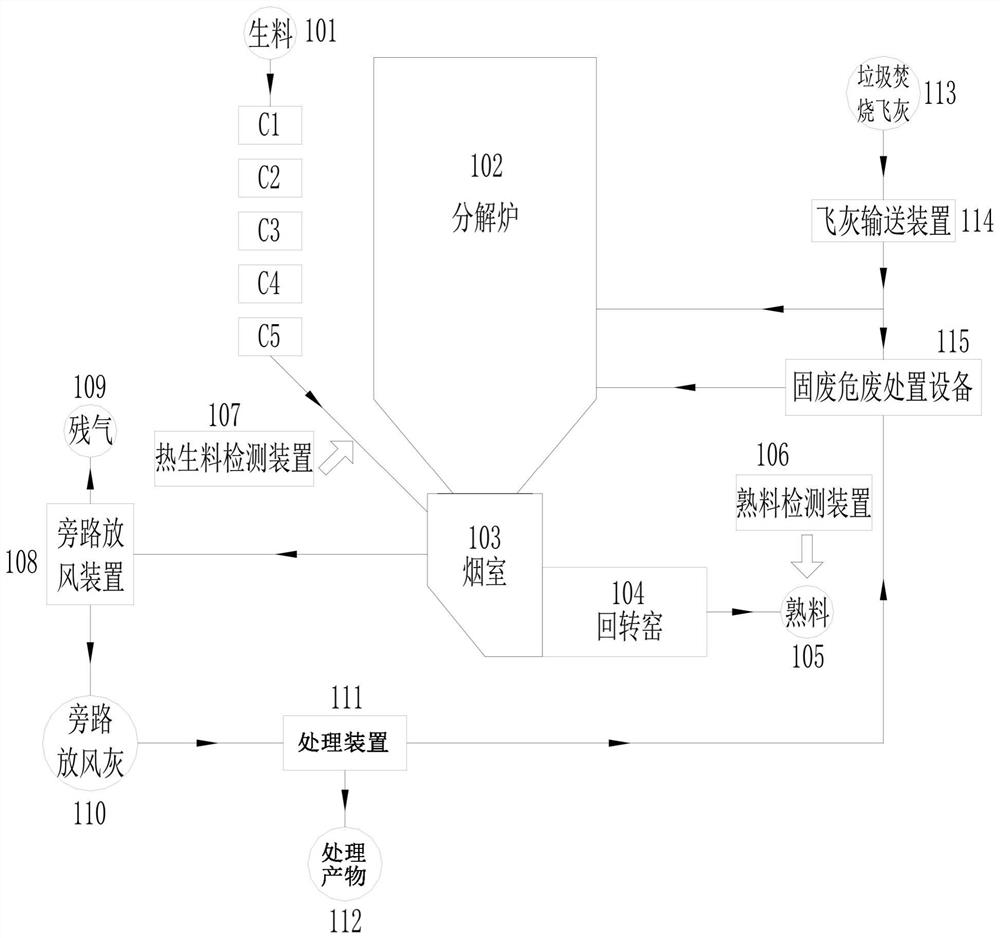

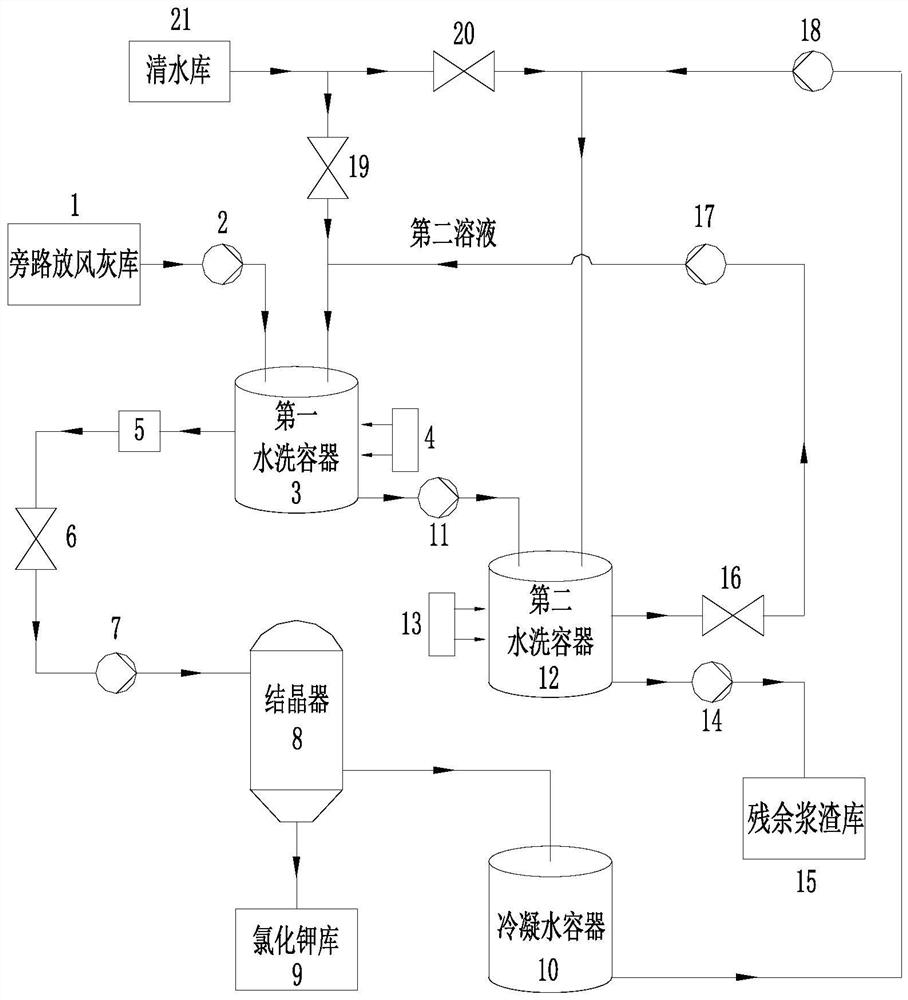

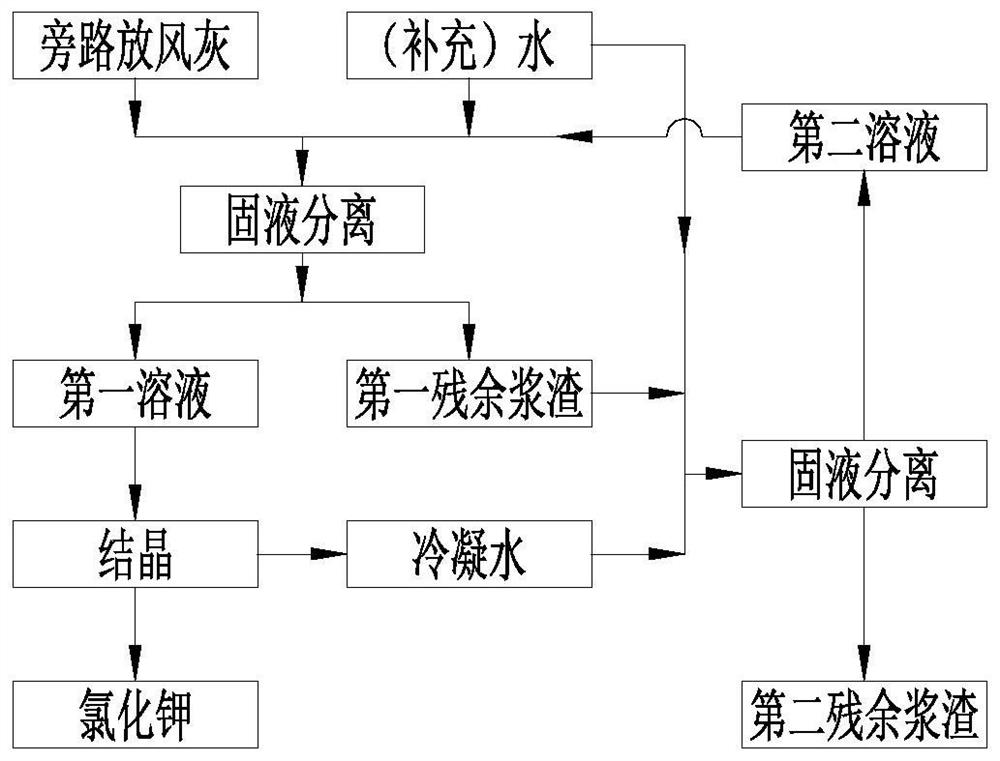

Method for monitoring and treating chlorine in cement clinker production system for co-treating waste incineration fly ash and cement clinker production system thereof

PendingCN114368922AReduce disposal costsReduce shipping costsMaterial analysis using wave/particle radiationUsing liquid separation agentClinker (waste)Process engineering

Owner:北京优巨源环保工程技术有限公司

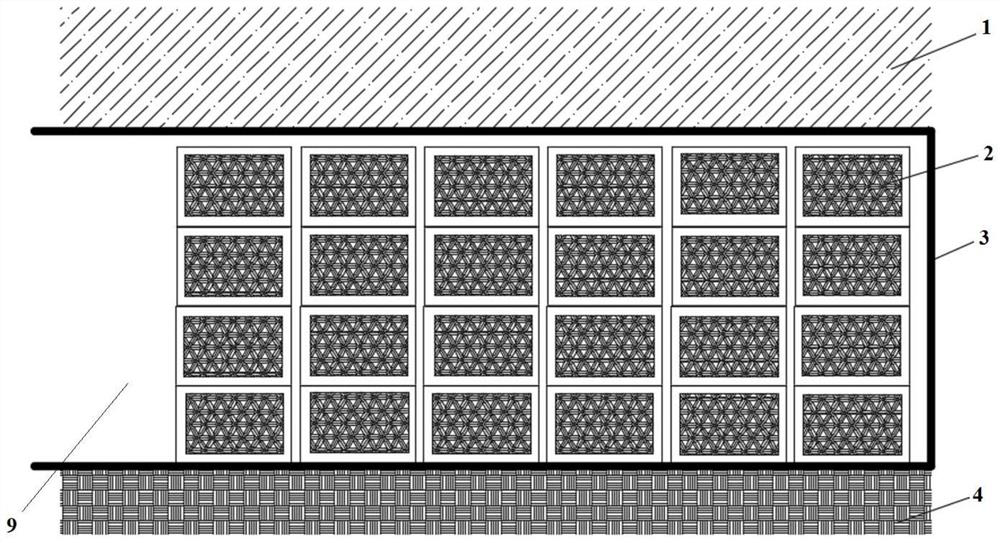

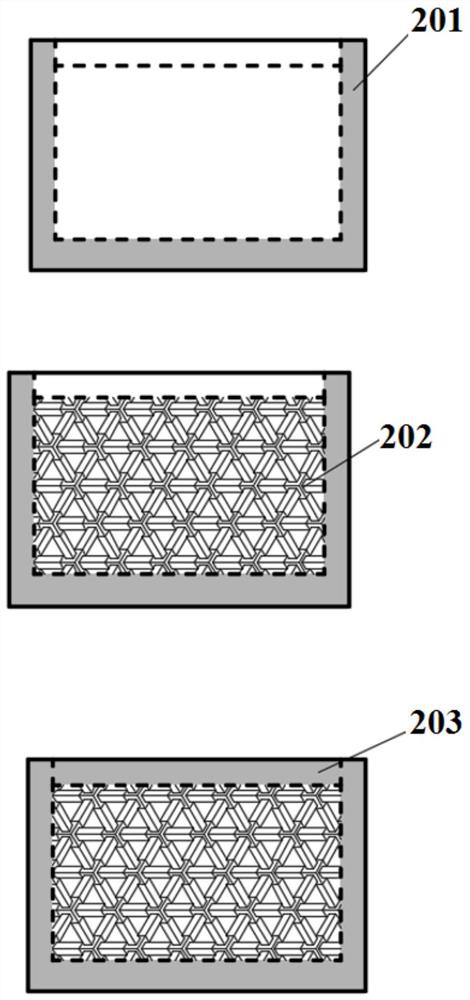

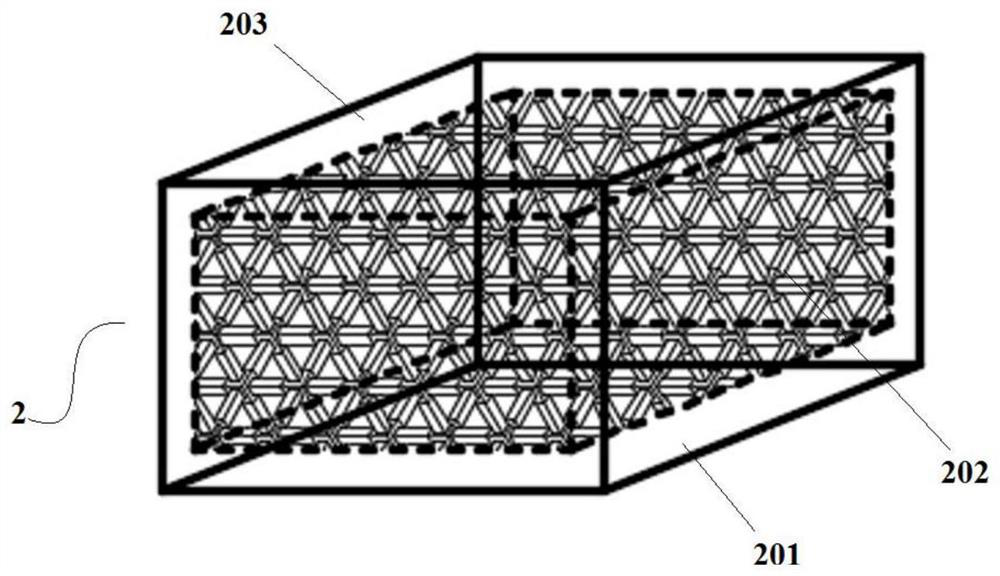

Method and structure for co-processing waste incineration fly ash underground in mine

ActiveCN114160542AAlleviate resource constraintsAlleviating the Nowhere to Dispose ProblemSolid waste disposalTransportation and packagingEnvironmental engineeringCement mortar

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Method for preparing Cr6+ collecting agent with high selectivity

The invention belongs to the field of environmental engineering, and discloses a method for preparing a Cr6+ collecting agent with high selectivity. The collecting agent is prepared by a series of means of coordination, cross linking and the like according to the structure and the property of polyacrylamide. The collecting agent has stable chemical performance, can selectively collect wastewater and sludge containing heavy metal Cr6+, garbage burnt fly ash and the like, and does not produce secondary pollution.

Owner:刘转年 +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap