Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Chemical waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical waste is a waste that is made from harmful chemicals (mostly produced by large factories). Chemical waste may fall under regulations such as COSHH in the United Kingdom, or the Clean Water Act and Resource Conservation and Recovery Act in the United States. In the U.S., the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA), as well as state and local regulations also regulate chemical use and disposal. Chemical waste may or may not be classed as hazardous waste. A chemical hazardous waste is a solid, liquid, or gaseous material that displays either a “Hazardous Characteristic” or is specifically “listed” by name as a hazardous waste. There are four characteristics chemical wastes may have to be considered as hazardous. These are Ignitability, Corrosivity, Reactivity, and Toxicity. This type of hazardous waste must be categorized as to its identity, constituents, and hazards so that it may be safely handled and managed. Chemical waste is a broad term and encompasses many types of materials. Consult the Material Safety Data Sheet (MSDS), Product Data Sheet or Label for a list of constituents. These sources should state whether this chemical waste is a waste that needs special disposal.

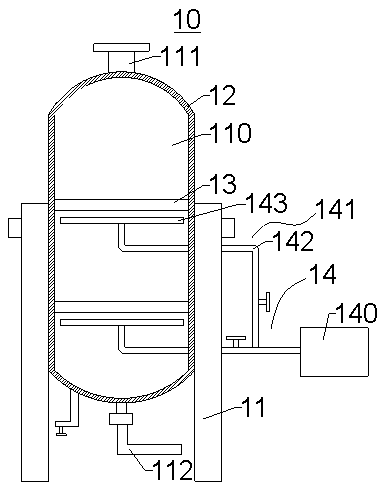

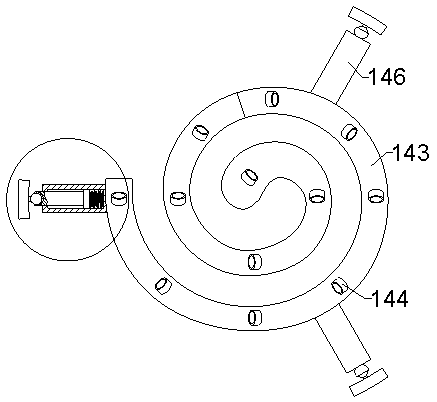

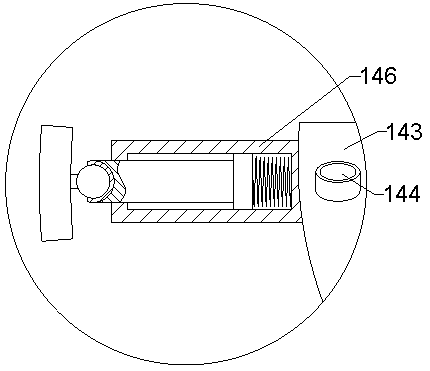

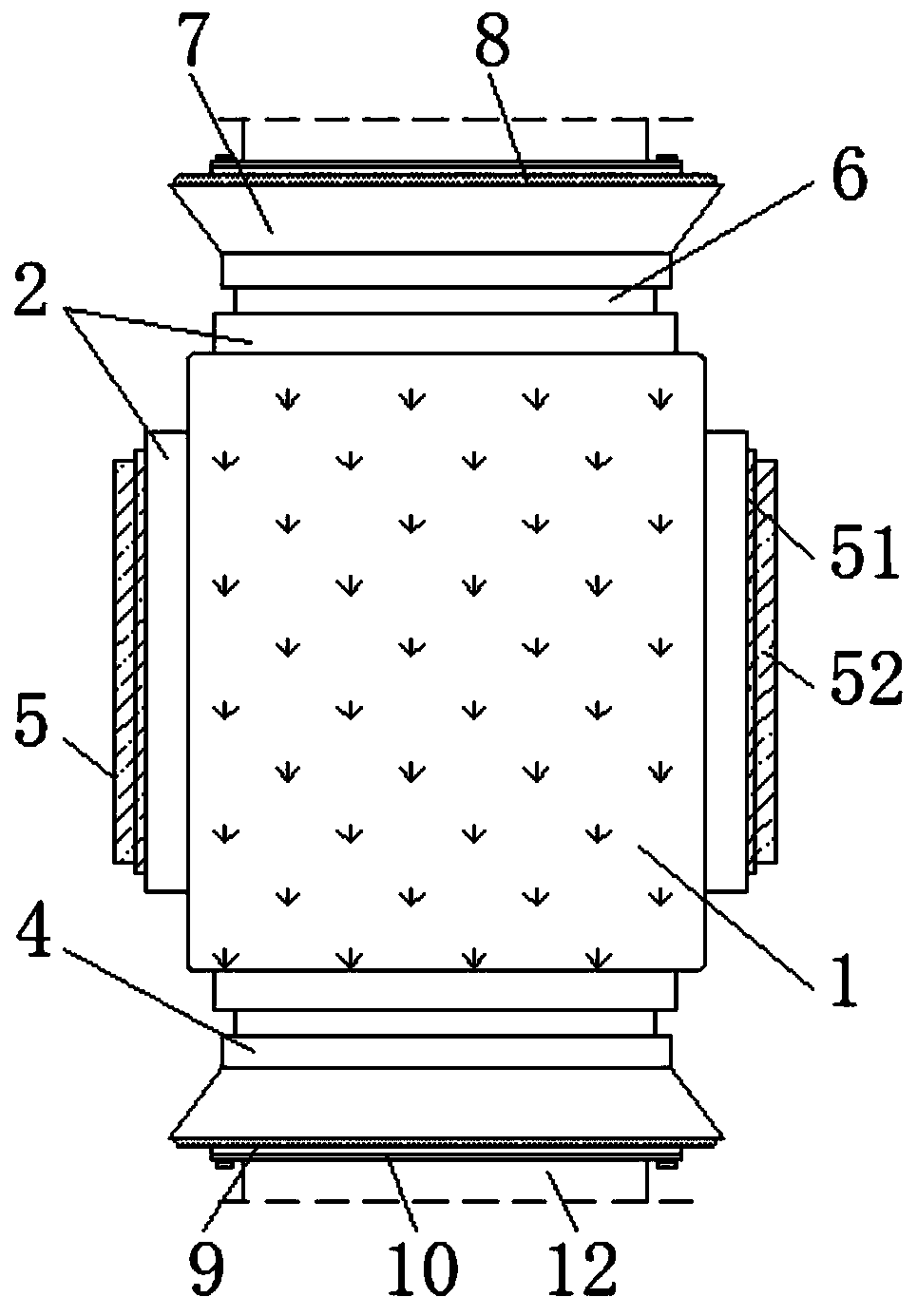

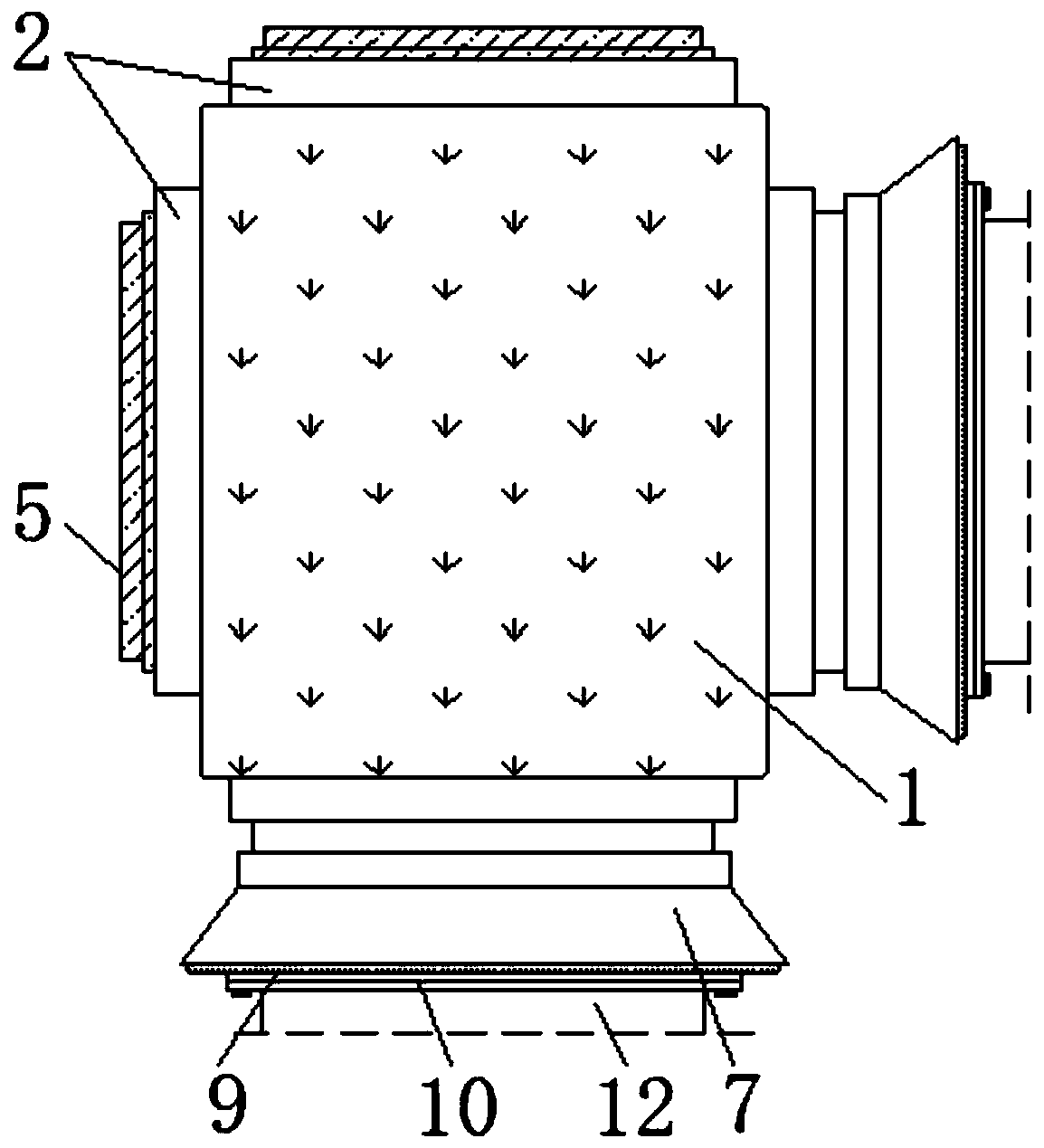

Filtering device for chemical water treatment

InactiveCN107551634AAvoid cloggingImprove filtration efficiencyStationary filtering element filtersChemical treatmentCause blockage

Owner:张莲莲

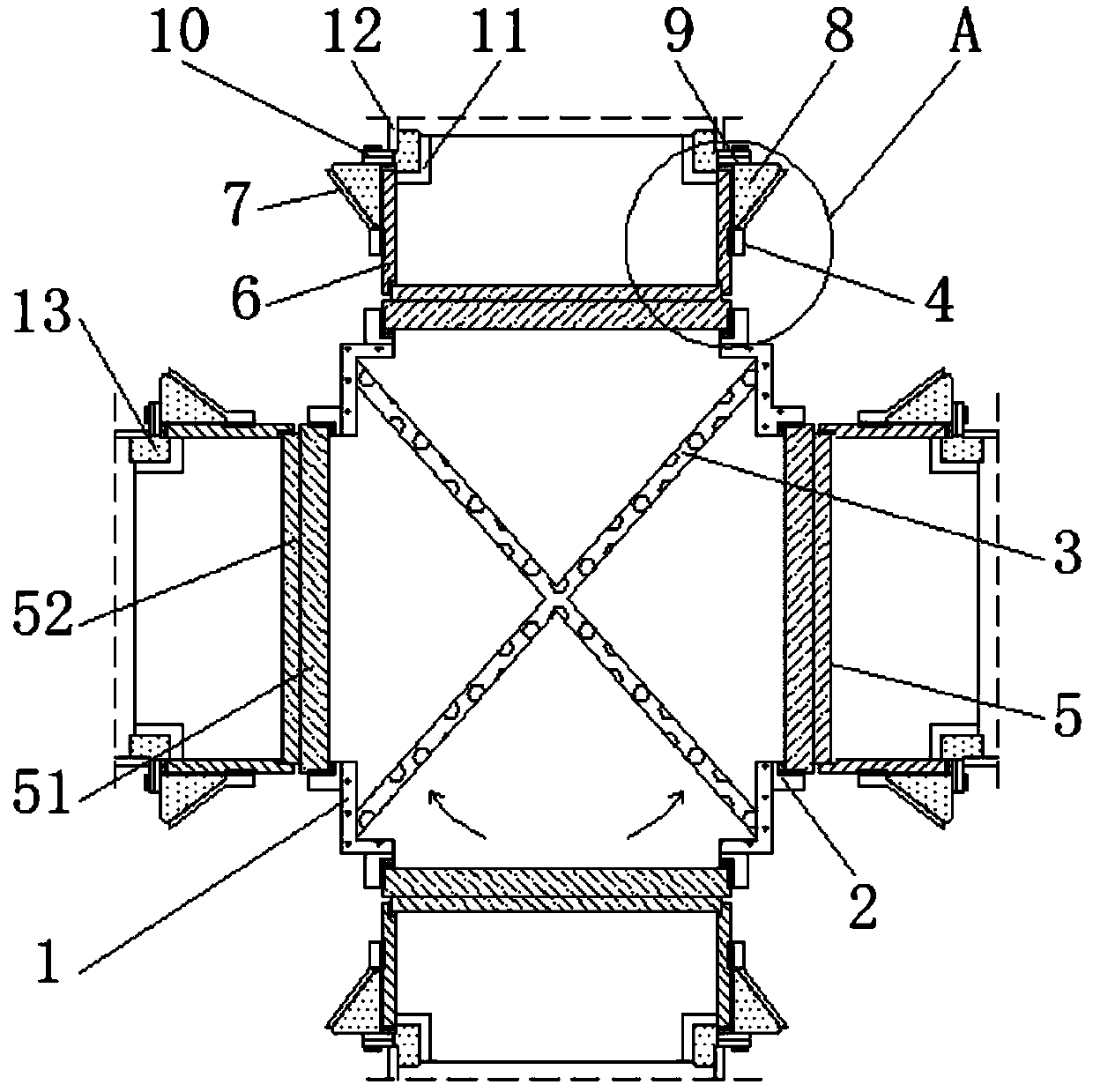

Chemical waste incinerator

InactiveCN111928250ABurn fullyReduce the likelihood of an explosionIncinerator apparatusCombined combustion mitigationCombustorExhaust fumes

The invention discloses a chemical waste incinerator. The chemical waste incinerator comprises a furnace body, wherein a feed hopper is arranged on one side of the furnace body, a feed inlet is formedin the upper end of the feed hopper, a baffle plate is arranged in the position, corresponding to the feed hopper, of the interior of the furnace body, a rotating roller is arranged in the feed hopper, a guide blade is arranged on the rotating roller, a burner is arranged in the furnace body, an ash discharge hopper is arranged below the furnace body, an air supplement opening is arranged on oneside of the furnace body, a waste heat recovery device is arranged at the upper end of the furnace body, an air outlet is arranged at the top end of the furnace body, a water tank is arranged on one side of the furnace body, an air outlet pipe is arranged at the air outlet, an air exhaust opening is arranged on the water tank, and a spraying device is arranged in the furnace body. A user directlydumps chemical engineering garbage into the feed hopper, materials are conveyed through the inner guide blade, the baffle plate is pushed away under the action of gravity, the materials enter the furnace body for combustion, oxygenation work is regularly carried out through an air supplement opening, the interior of the furnace body is fully combusted, and then generated hot waste gas is subjectedto heat exchange work through the waste heat recovery device at the top.

Owner:HUNAN DELI SAFETY & ENVIRONMENTAL PROTECTION TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap