Method for monitoring and treating chlorine in cement clinker production system for co-treating waste incineration fly ash and cement clinker production system thereof

A technology for waste incineration fly ash and cement clinker, applied in cement production, separation methods, chemical instruments and methods, etc., can solve the problems of low disposal efficiency, occupying large space, and high disposal costs, and achieves good and stable operation. Quality and yield, the effect of improving disposal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Example 1: Monitoring and disposal method of chlorine in cement clinker production system for co-processing waste incineration fly ash

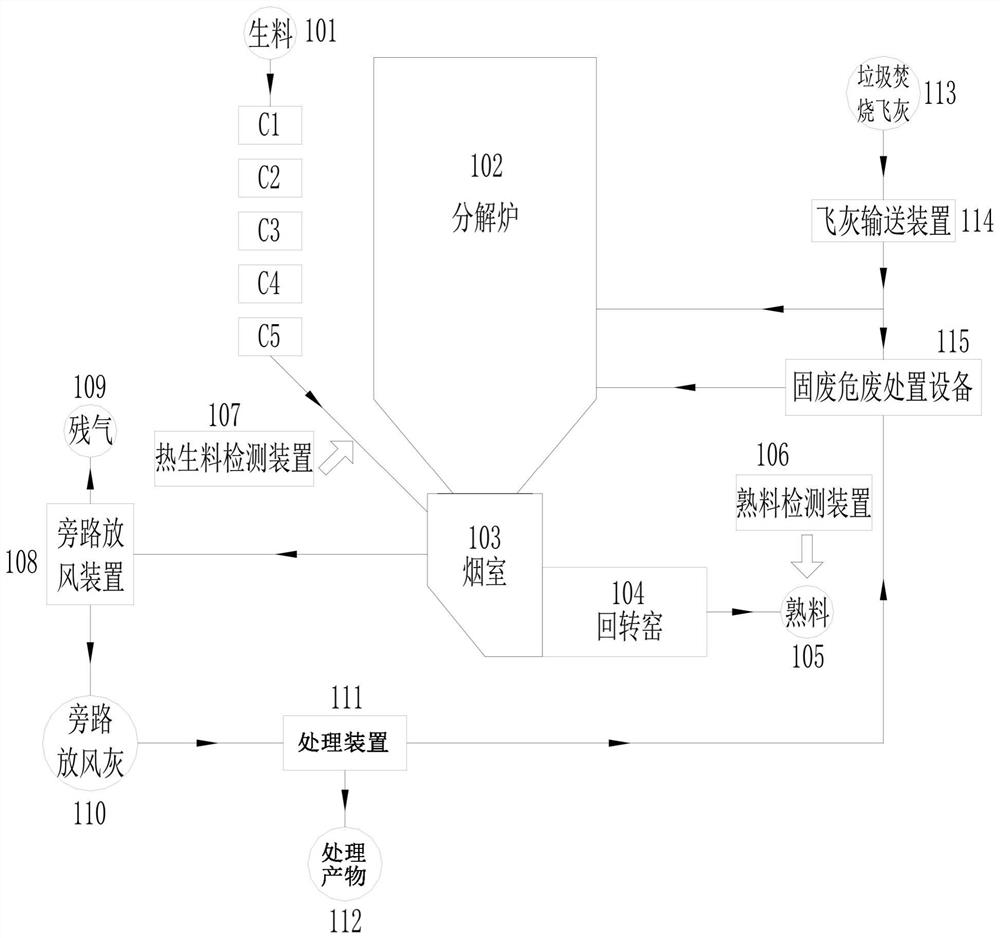

[0063] Such as figure 1 As shown, the cement clinker production system based on the method provided in this embodiment may include: a cement kiln system, an element detection device, a bypass ventilation device 108 and a fly ash conveying device 114, and may also include a solid waste and hazardous waste disposal device 115 .

[0064] The cement kiln system can be an existing dry process cement clinker production system, which includes a multi-stage preheater (this embodiment is a C1-C5 five-stage preheater), a calciner 102, a smoke chamber 103 and a rotary kiln 104, etc. , the raw materials used for cement clinker production (i.e. raw meal 101) first enter the C1 preheater, then pass through the C3 preheater, C2 preheater, C4 preheater, then enter the calciner 102, and then enter the C5 preheater Heater, and then enter the smoke chambe

Embodiment 2

[0082] Example 2: Cement clinker production system for co-processing waste incineration fly ash

[0083] Such as figure 1 As shown, it shows a schematic structural diagram of the cement clinker production system for co-processing waste incineration fly ash provided by this embodiment. On the basis of Embodiment 1, the system also includes a processing device 111 for bypassing fly ash, so as to The bypass ash 110 with high chlorine content separated by the bypass blowing device 108 is washed with water to obtain a treatment product 112 with high economic value, such as potassium chloride. The remaining residues after washing treatment can be sent to solid waste and hazardous waste disposal equipment 115 as solid waste and hazardous waste disposal for premixing treatment with waste incineration fly ash, and then enter the decomposition furnace 102 of the cement kiln system, or the Part of the residue is collected for other uses. The disposal depth of waste incineration fly ash an

Embodiment 3

[0088] Embodiment 3: Utilize the processing device to process the method for blown ash in the bypass

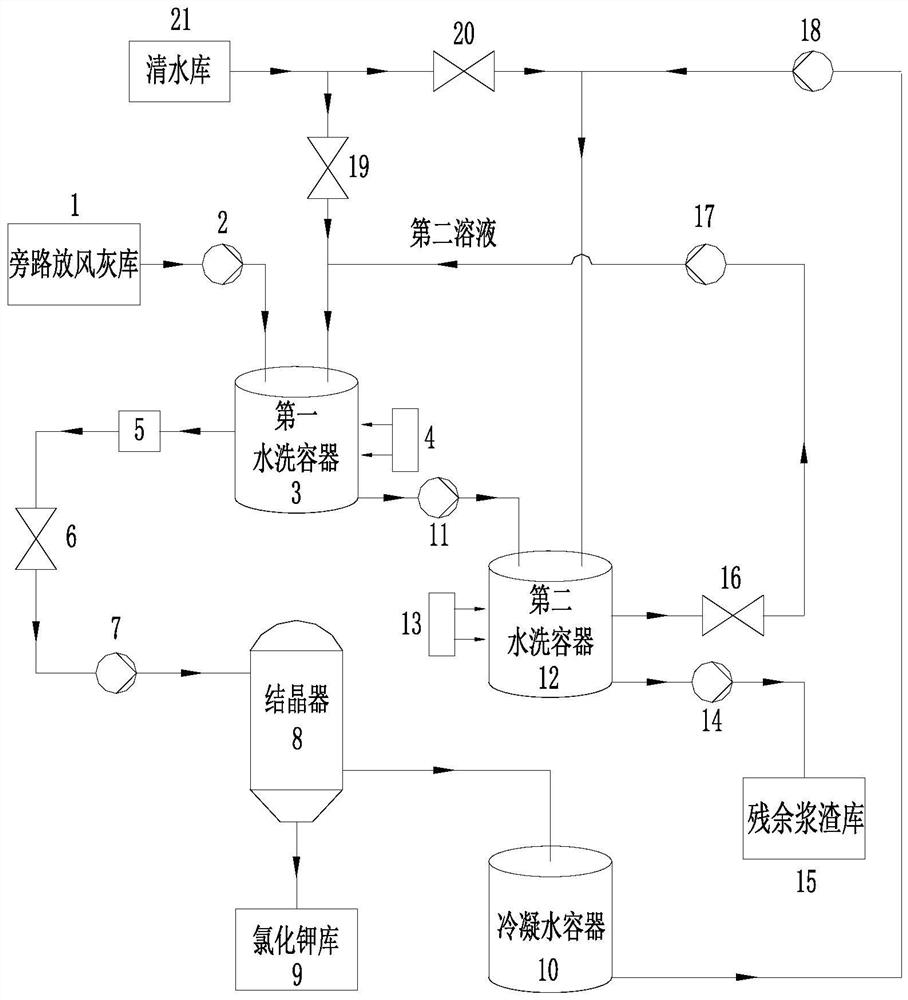

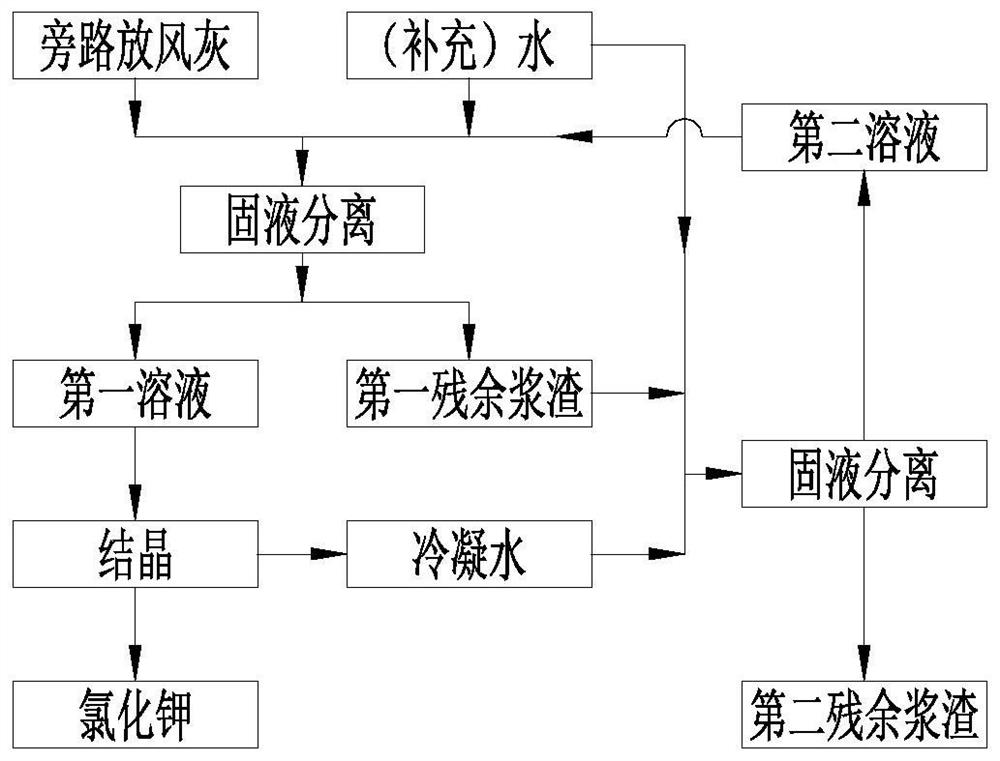

[0089] In this embodiment, the processing device 111 in the cement clinker production system provided in Example 2 is used to wash the bypass blown ash separated by the bypass blowing device 108, combined with figure 2 with image 3 As shown, it mainly includes the following steps:

[0090] T1: Open the bypass ash conveying device 2, and send an appropriate amount of bypass ash to the first water washing container 3;

[0091] T2: Open the secondary water pumping valve 16, open the secondary water pump 17, and the second upper layer solution through solid-liquid separation in the second washing container 12 (i.e. figure 2 with image 3 The second solution in the water) is sent to the first water washing container 3 by the secondary water pump 17; if the second solution is insufficient, replenish the condensed water from the condensed water container 10, if the condensed wate

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap