Industrial robot operation and demonstration system based on augmented reality technology

An industrial robot and augmented reality technology, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems of parts damage, splash, accidents, low efficiency, etc., to improve work efficiency and reduce trial and error costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0085] 1. Robot operation training

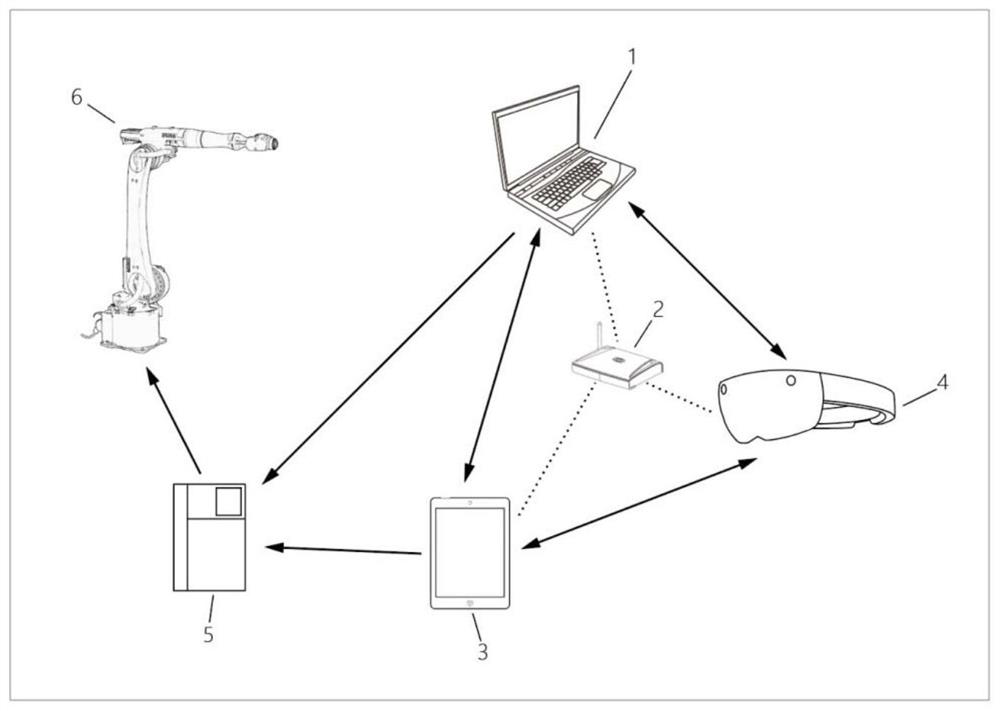

[0086] In one-to-one teaching, a router 2 is equipped in the field, a mobile device 3 and a virtual imaging device 4 can be equipped for the students, and a computer 1 is prepared for the teacher. Students practice by manipulating and viewing virtual projections on mobile devices. The content of the teaching pendant and the virtual projection will be simultaneously displayed on the teacher's computer, and the teacher can remotely control the teaching pendant through the computer or mark on the teaching pendant and the virtual image to guide the students.

[0087] In collective teaching, a router 2 can be equipped in the field, and each student can be equipped with a mobile device 3 and a virtual imaging device 4 , and practice by operating on the mobile device 3 and watching the stereoscopic images in the virtual imaging device 4 . The teacher can use the computer 1 to connect to each control terminal through the local area network, and us...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap