Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16 results about "Backflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Backflow is a term in plumbing for an unwanted flow of water in the reverse direction. It can be a serious health risk for the contamination of potable water supplies with foul water. In the most obvious case, a toilet flush cistern and its water supply must be isolated from the toilet bowl. For this reason, building codes mandate a series of measures and backflow prevention devices to prevent backflow.

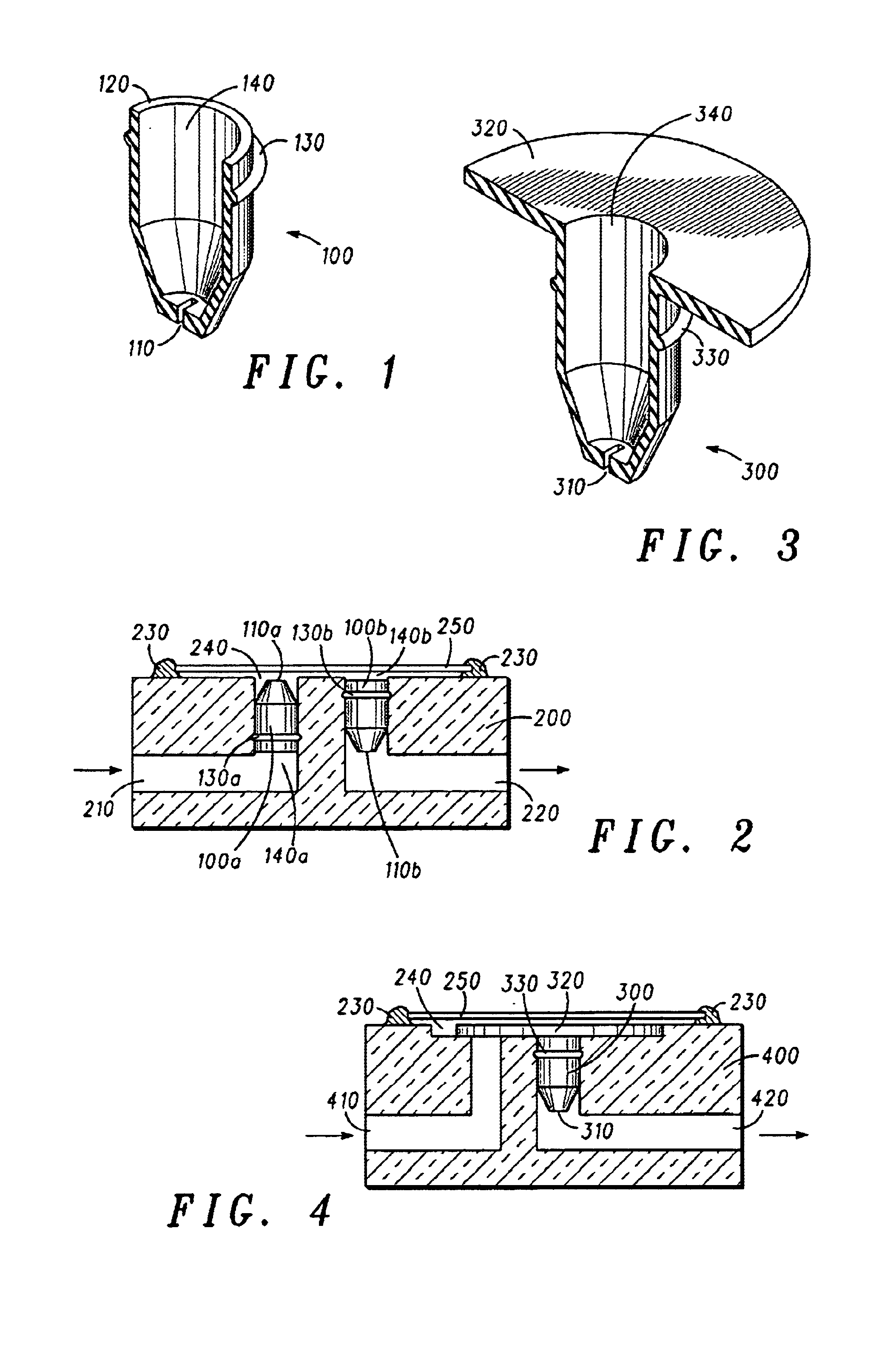

Micropumps with passive check valves

Owner:WATERS TECH CORP

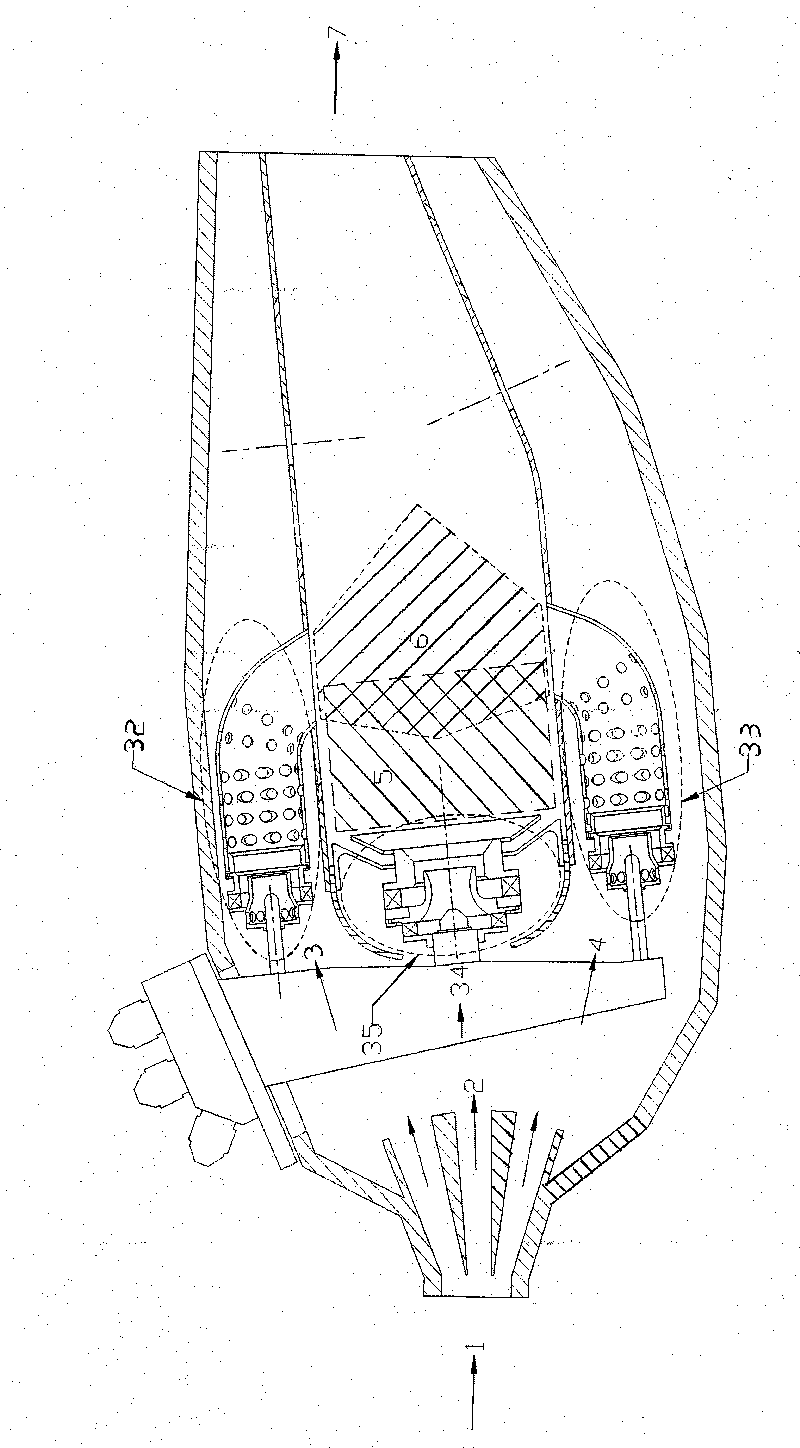

Counter-flow flame combustion chamber

Owner:BEIHANG UNIV

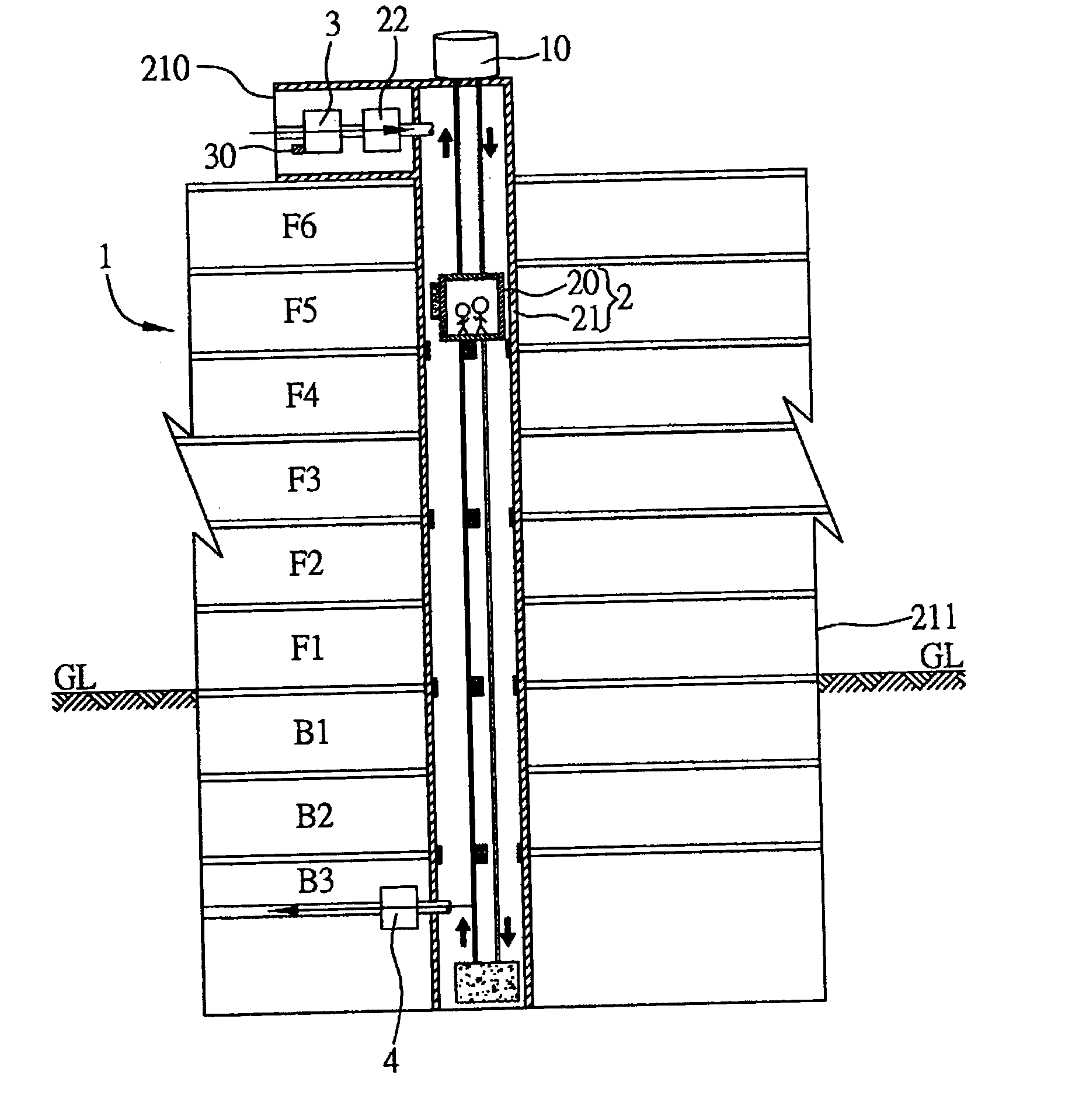

System of enhancing air quality used for buildings

InactiveUS20050000754A1Improve air qualityPrevent backflowLighting and heating apparatusElevatorsAir cycleBasement

Owner:LEE NIEN CHIN

Sewage treatment integrated equipment

ActiveCN109876599AEasy dischargeEasy to collectDispersed particle separationWater/sewage treatmentFixed frameEngineering

The invention discloses sewage treatment integrated equipment, which structurally comprises a compression tank device, a controller, a wire, a hydraulic rod, a compressor and a supporting frame. Sewage is guided onto an odor-backflow-preventing device, a floating block is pushed through buoyancy of the sewage to move upwards, and then a flow-stop block is driven to move upwards to open a sewage discharging channel to discharge the sewage; after no sewage flows into the channel, the flow-stop block and a semicircular connecting block are connected to close the channel so as to avoid backflow ofodor in the sewage; when the compressor is pressed to the compression tank device, a movable plate extrudes an airbag to guide an air flow into a pneumatic rod, thus the pneumatic rod pushes a deodorization filter net device to rotate around a return rod, and the air flow is blown onto a deodorization filter net to be deodorized; and when the compressor moves upwards, a fixing frame is provided with restoration power by arranging a return spring in the return rod, and the compressor moves upwards and makes contact with the fixing frame to provide the fixing frame restoration power.

Owner:ANHUI BAIBANG ENVIRONMENTAL ENG CO LTD

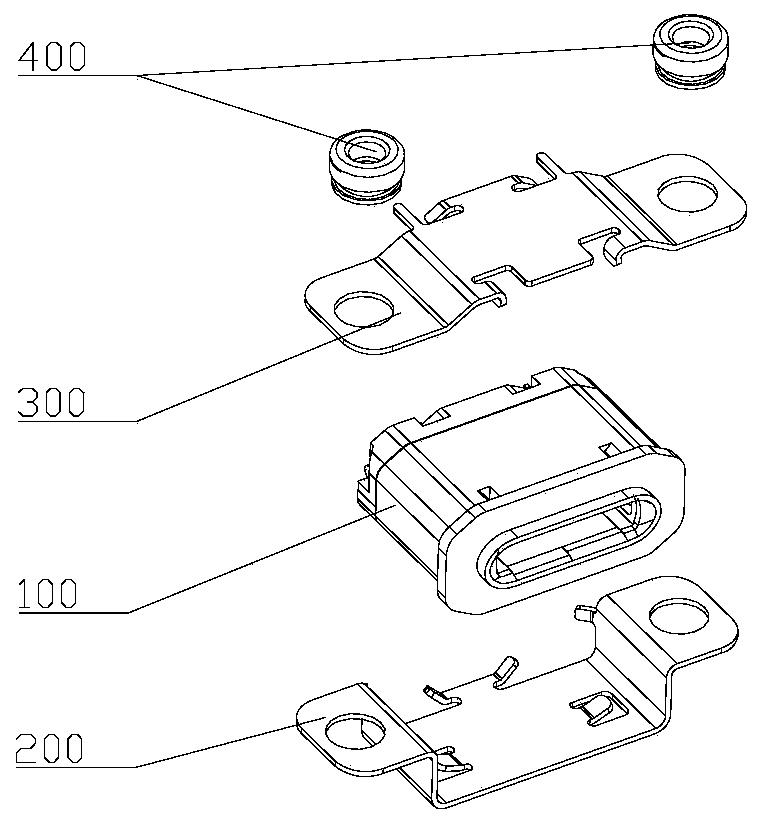

Flow Rate Safety Valve

ActiveUS20180128392A1Improve sealingImprove mobilityCheck valvesEqualizing valvesEngineeringSafety valve

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

Preparation method of silicon dioxide antireflection film

The invention discloses a preparation method of a silicon dioxide antireflection film. The preparation method comprises the following steps of preparing a clear sol by using raw materials like a silicon compound, a solvent, a suppressor, deionized water and acid catalyst under an acidic condition through a sol-gel method; stirring and adding aqueous ammonia and ethyl acetate into the clear sol, and reacting for 0.5-24 hours in a 40-100DEG C constant temperature backflow condition, so as to prepare milky white silicon dioxide sol, wherein the milky white silicon dioxide sol contains 2-10 mass percent of silicon compound, 60-90 mass percent of solvent and 1-40 mass percent of water; and applying the milky white silicon dioxide sol onto a substrate with the surface treated, so as to obtain acoating. The silicon dioxide antireflection coating prepared by the method has higher air porosity and lower refractive index, and has much better antireflection effect while maintaining the frictionresistance. The preparation method is low in production cost, slightly affects surrounding environment, and is suitable for large-scale production and application of industry.

Owner:HUNAN XINGWEI NEW MATERIAL CO LTD

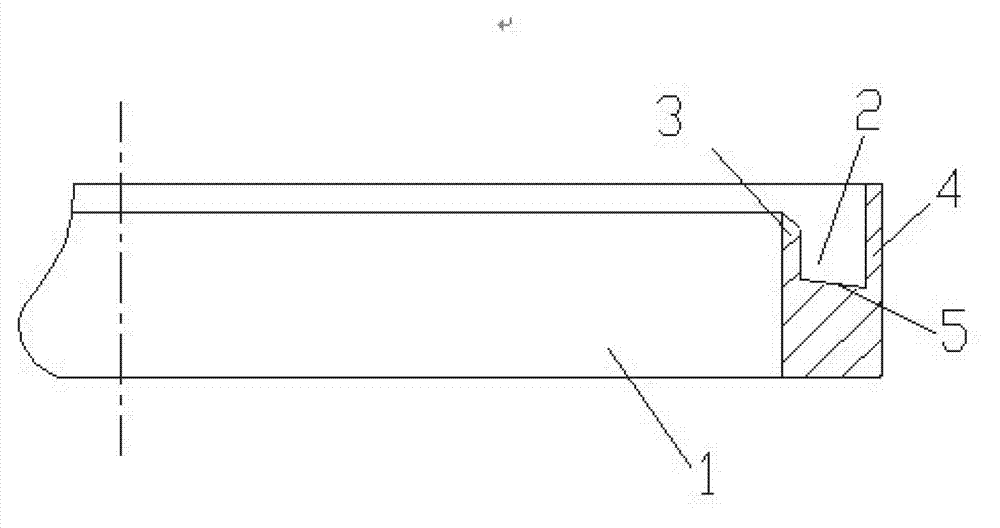

Oil scraper ring

InactiveCN102900651APrevent flying outPrevent backflowPositive displacement pump componentsPositive-displacement liquid enginesLow speedEngineering

Owner:SUZHOU WUZHONG DISTRICT DALU ELECTRIC EQUIP FACTORY

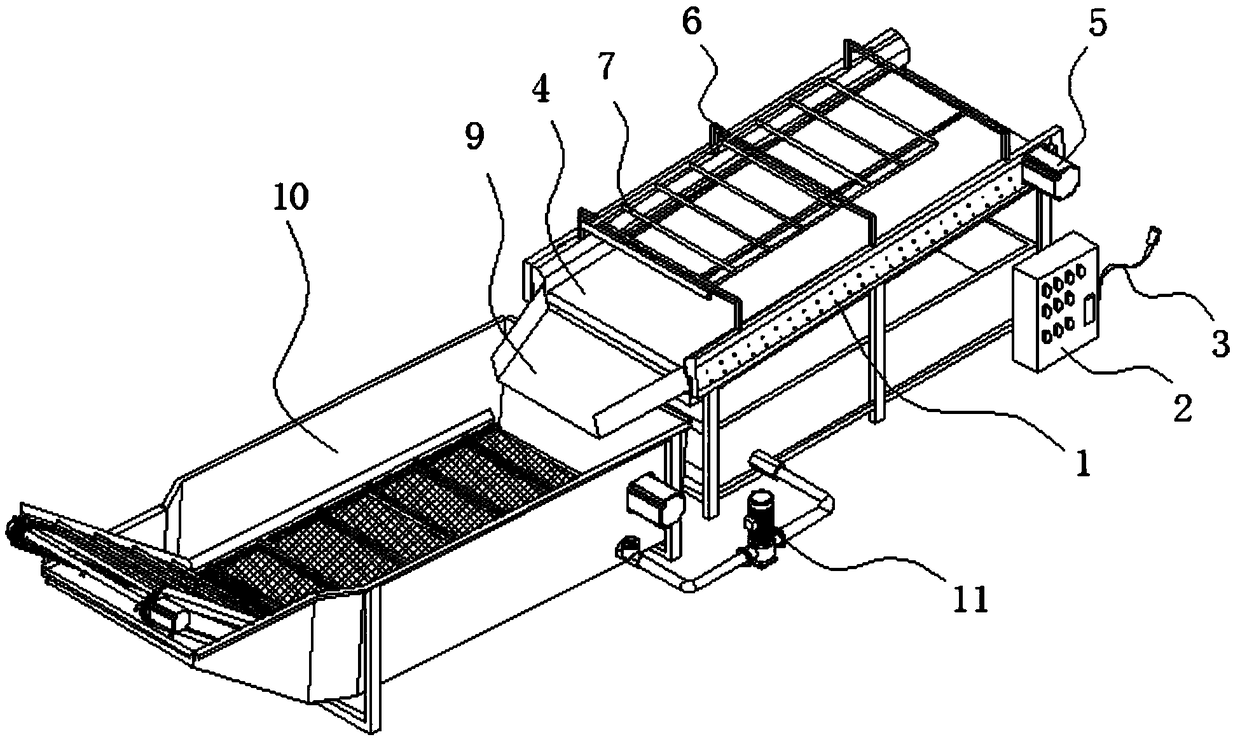

Flavored needle mushroom cleaning device

PendingCN109259271AFully cleanedQuality improvementClimate change adaptationFood treatmentMicroorganismCleaning needle

Owner:泉州市佳创工业产品设计有限公司

Waterfall type cap sorter

Owner:广州市比美高智能系统科技有限公司

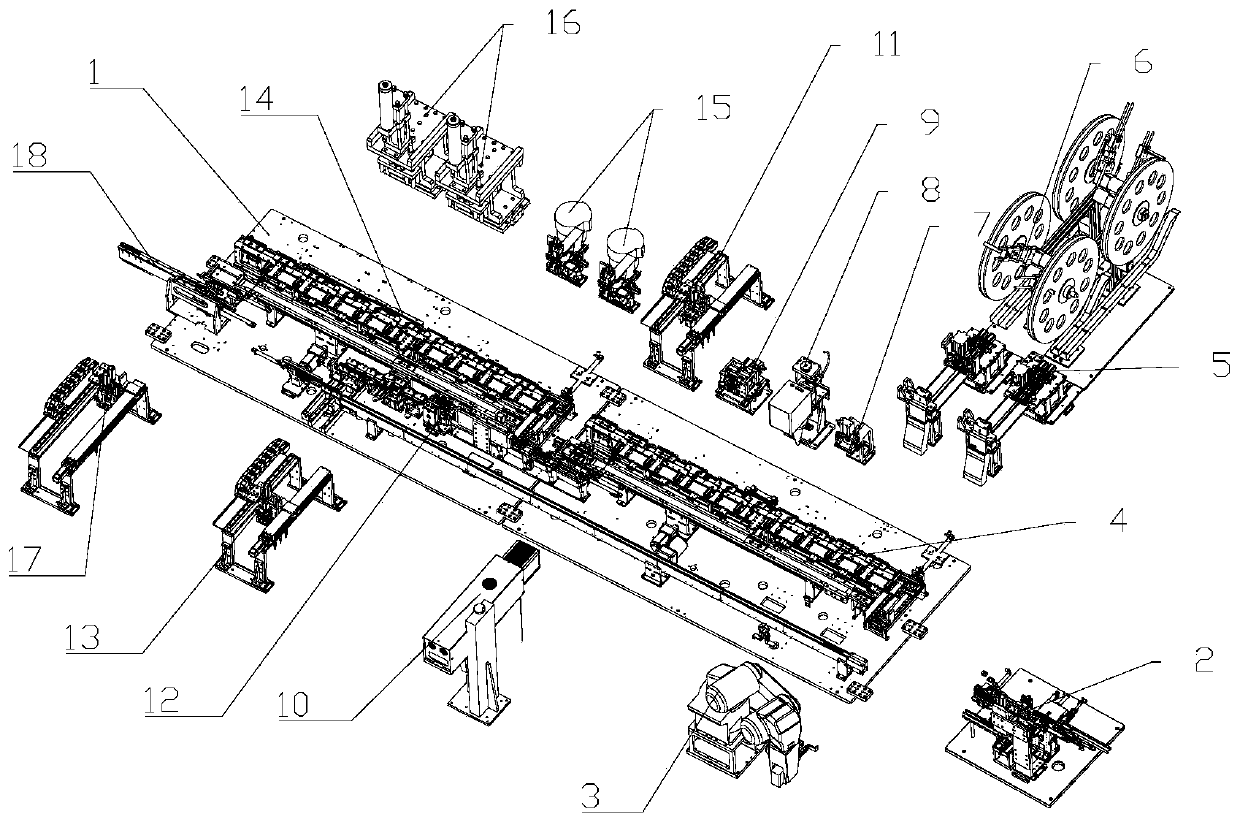

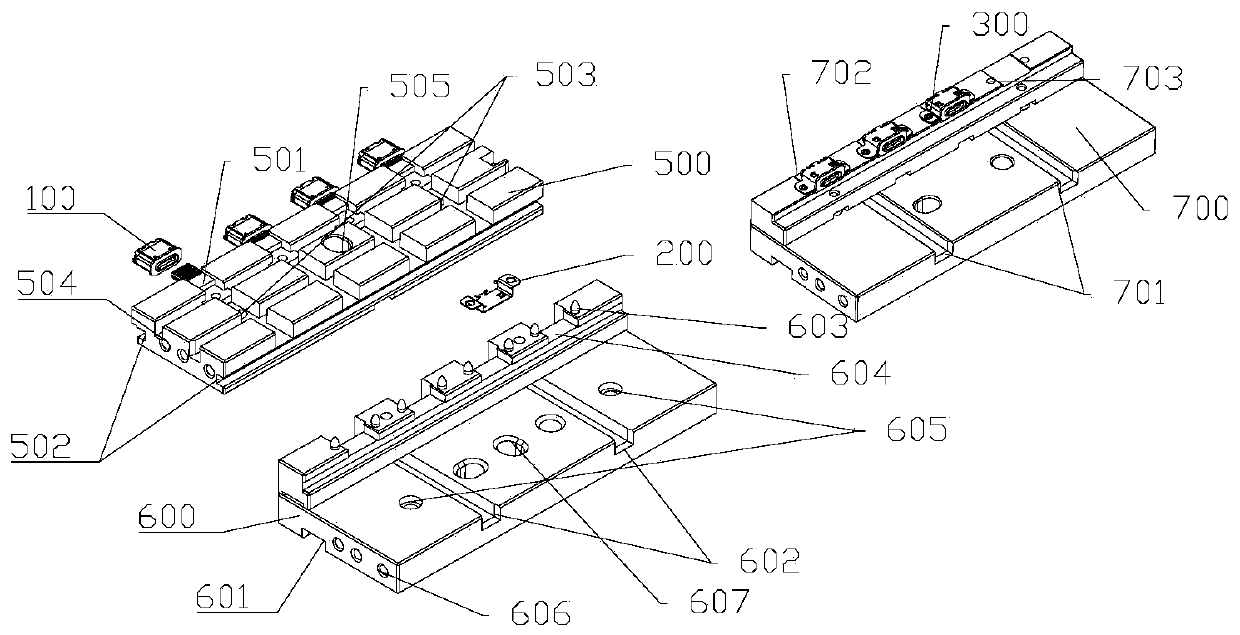

Automatic circulation device and method for charging connector shell clamping jig

InactiveCN109732343AEfficient circulationAvoid the problem of poor stiffnessAssembly machinesEngineeringMechanical engineering

Owner:李琼

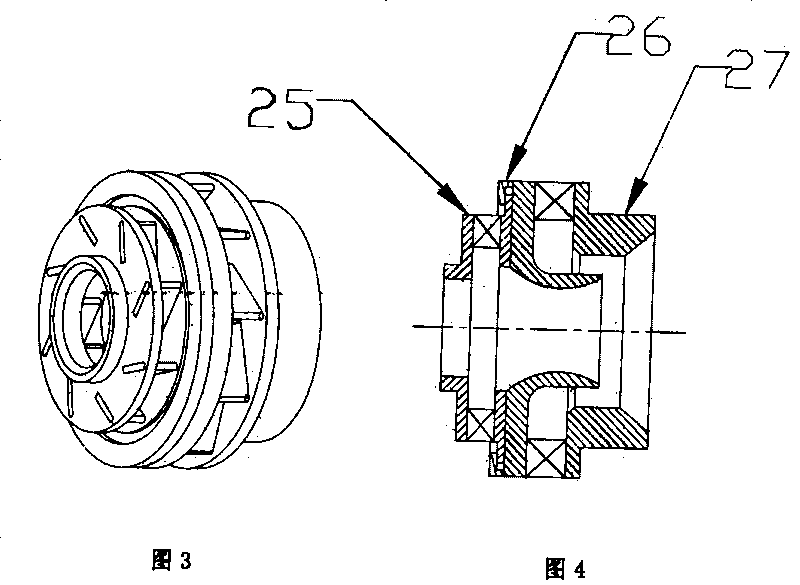

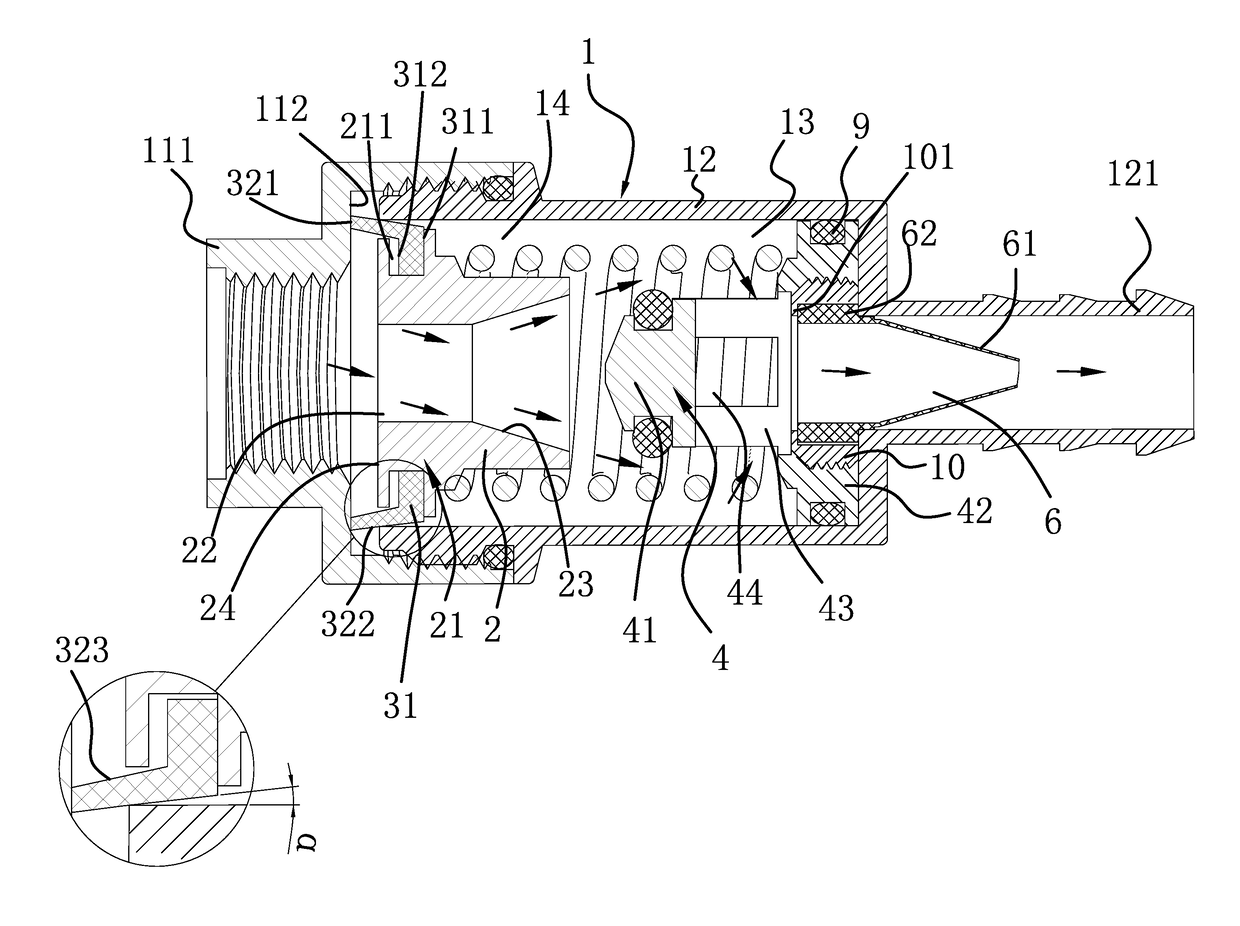

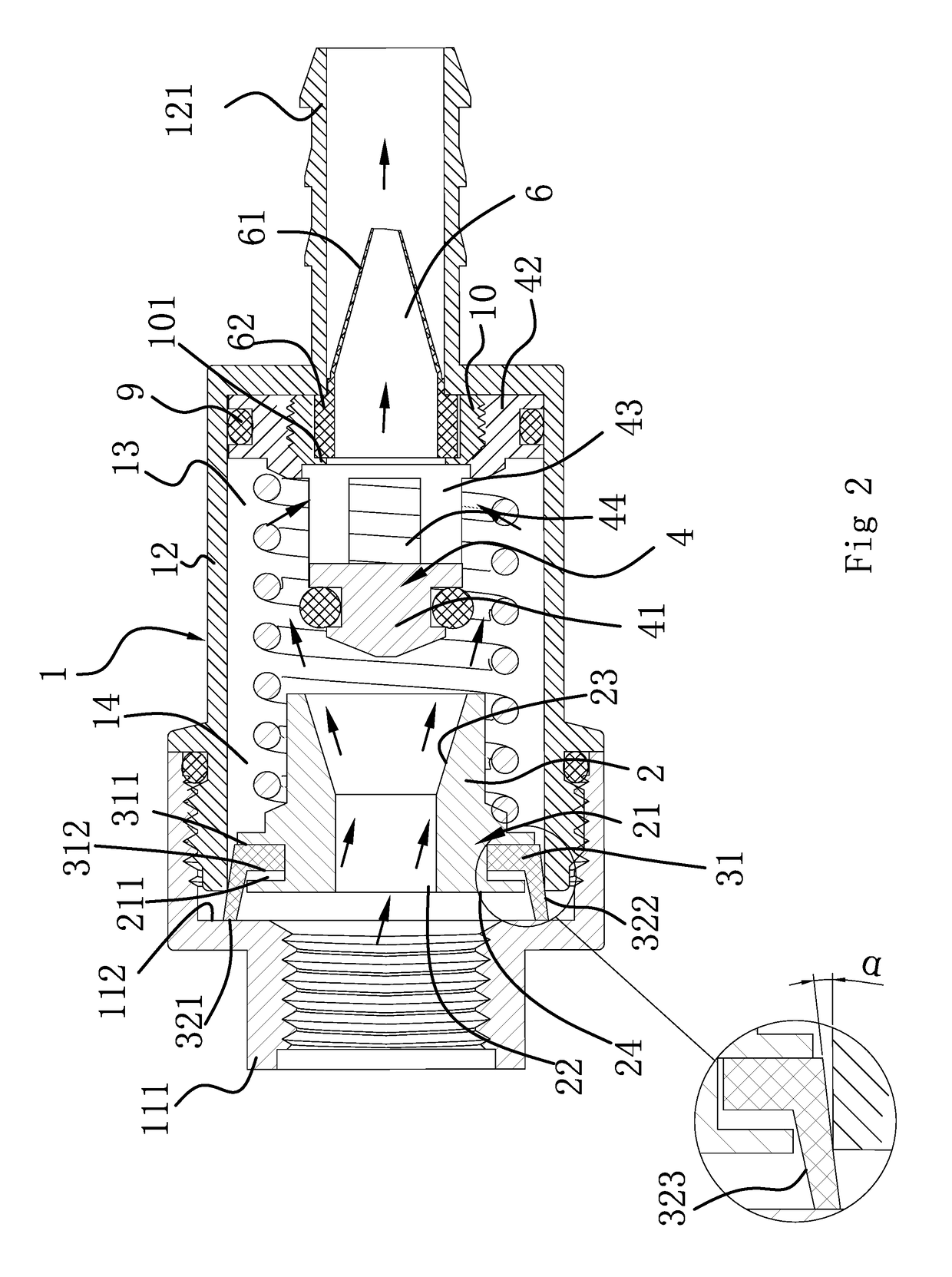

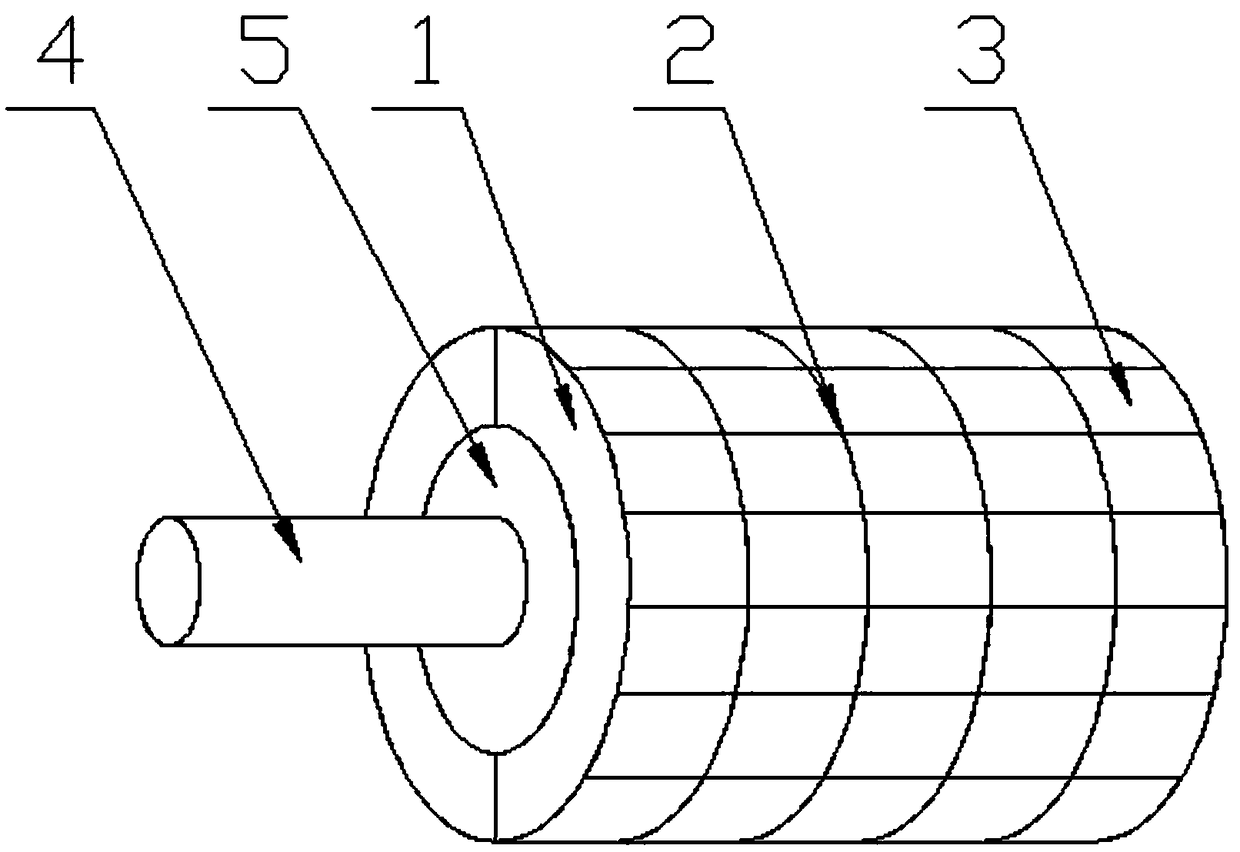

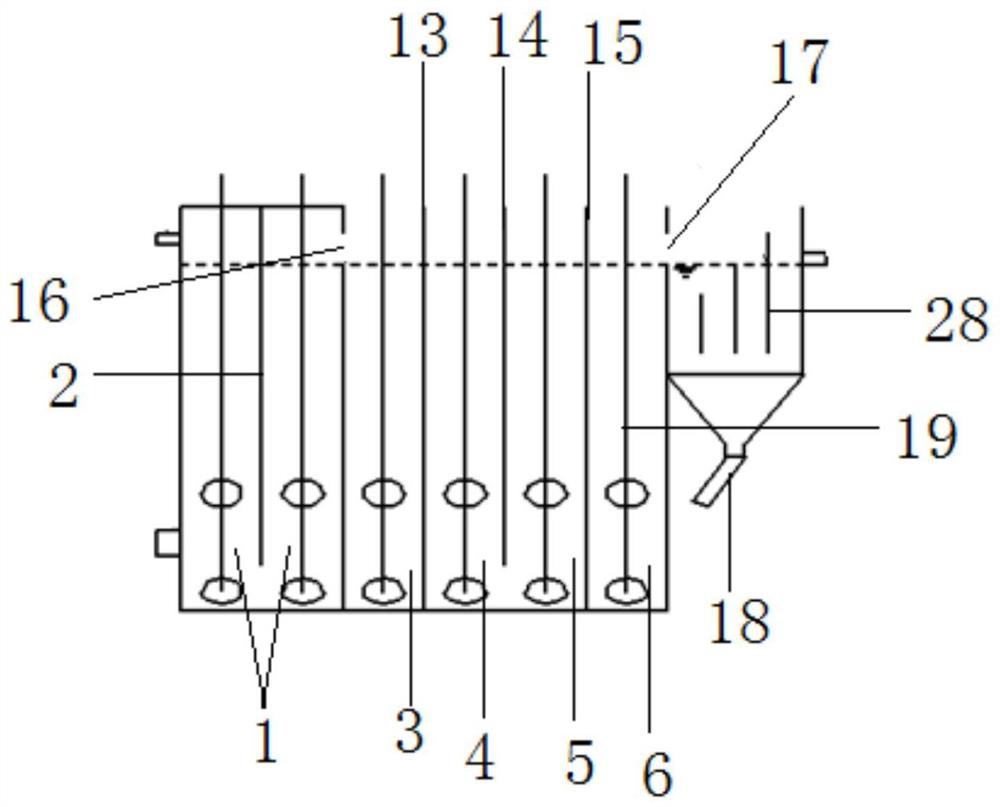

Spiral guide type submersible jet aerator

InactiveCN104843883AAvoid depositionHigh oxygenation efficiencyWater aerationSustainable biological treatmentJet flowSpiral blade

The invention relates to aerator equipment, in particular to a spiral guide type submersible jet aerator. The spiral guide type submersible jet aerator comprises a submersible motor fixed underwater through a supporting rod, wherein the front end of the submersible motor is provided with a mixer, an air inlet pipe is connected onto the mixer and the front end of the mixer is provided with a spiral guide device; the spiral guide device comprises an external guide cylinder, a spiral blade is arranged in the guide cylinder, and a center shaft for the spiral blade penetrates through the mixer and is fixedly connected with a motor rotating shaft; the spiral blade is fixedly connected with the guide cylinder; the mixer is conical and the mixer is provided with an air inlet interface; a water inlet passages is arranged between the guide cylinder and the mixer, and the inner chamber of the mixer is an air inlet passage. The spiral guide type submersible jet aerator has the advantages that the sedimentation of large particle sand can be prevented, the aerating efficiency of the aerator is improved, the used land is reduced, the power cost is decreased and the sludge backflow lifting effect is enhanced.

Owner:SHANDONG HANGAO ENVIRONMENTAL PROTECTION EQUIP CO LTD

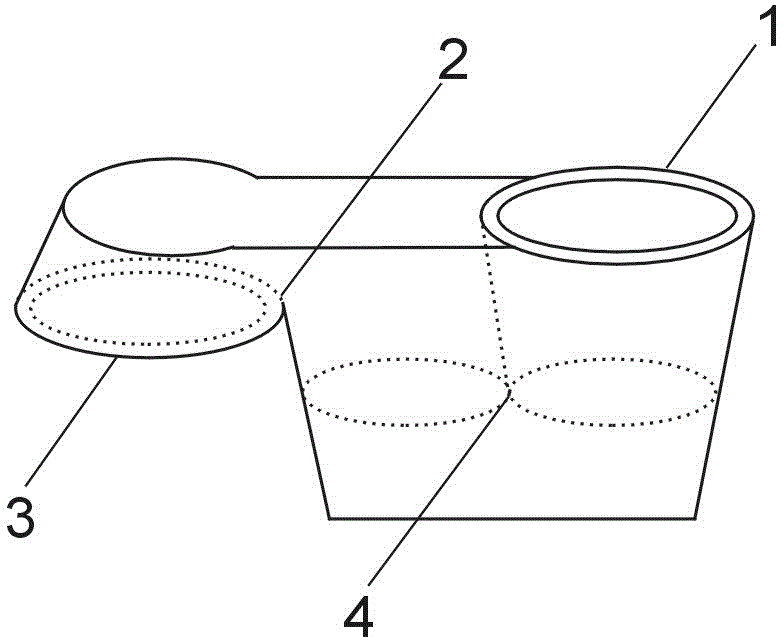

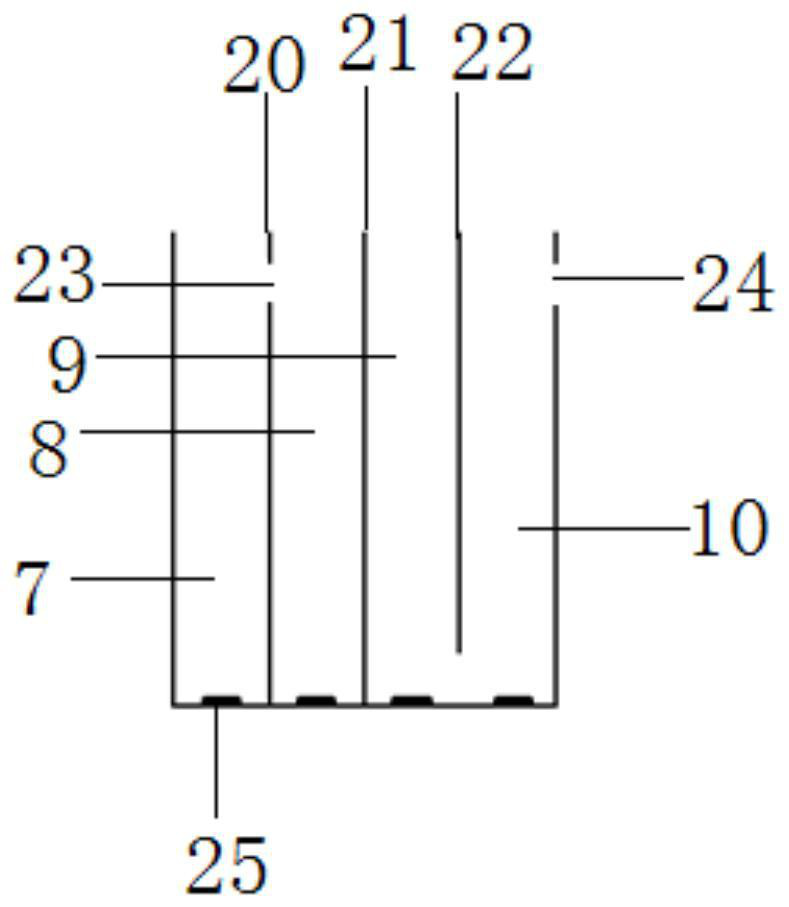

Double-large-end drain trap

InactiveCN104563260AAbility to replace without impactSolve the problem of insufficient water storage depthWater closetsWater storageEngineering

Owner:GUANGDONG HEGII SANITARY WARES CO LTD

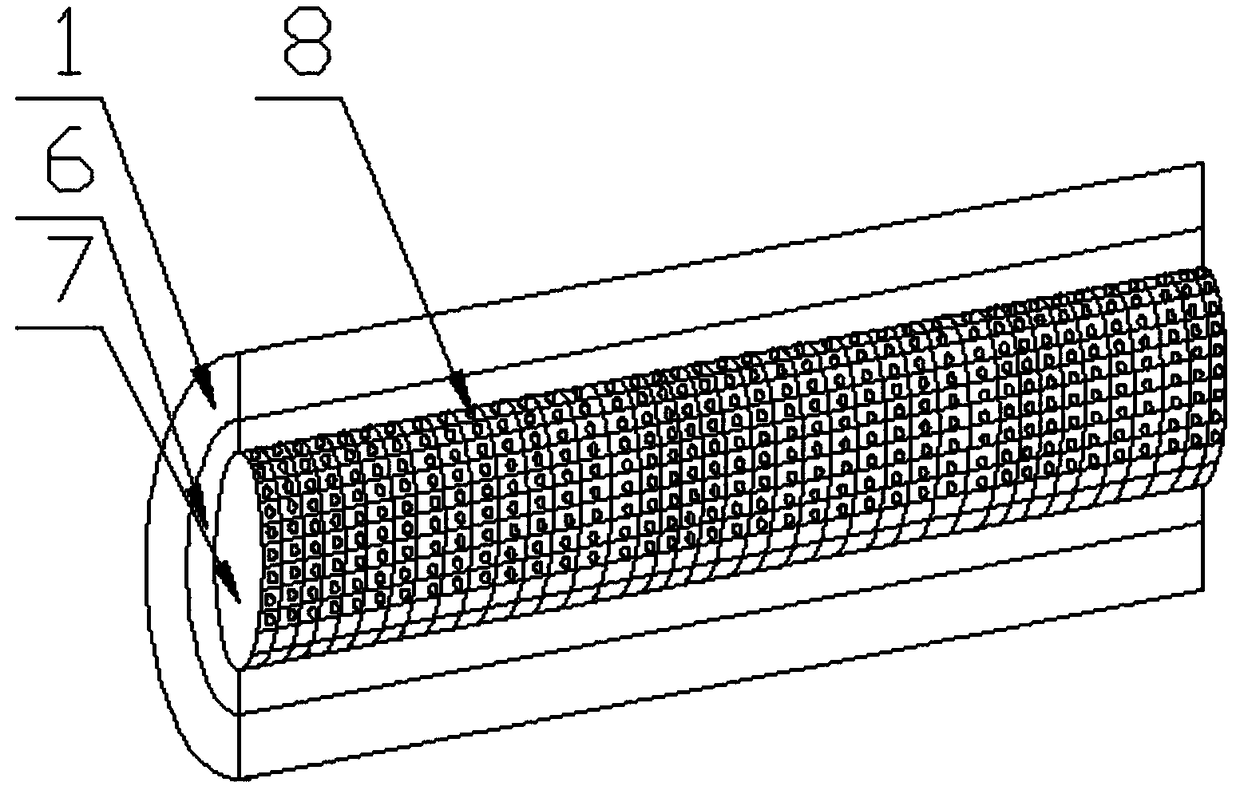

Braided cotton roll for dental operation

InactiveCN109009673AAvoid secondary infectionGood hemostatic effectDentistrySurgerySecondary InfectionsEngineering

Owner:东台市华鑫福利色织厂

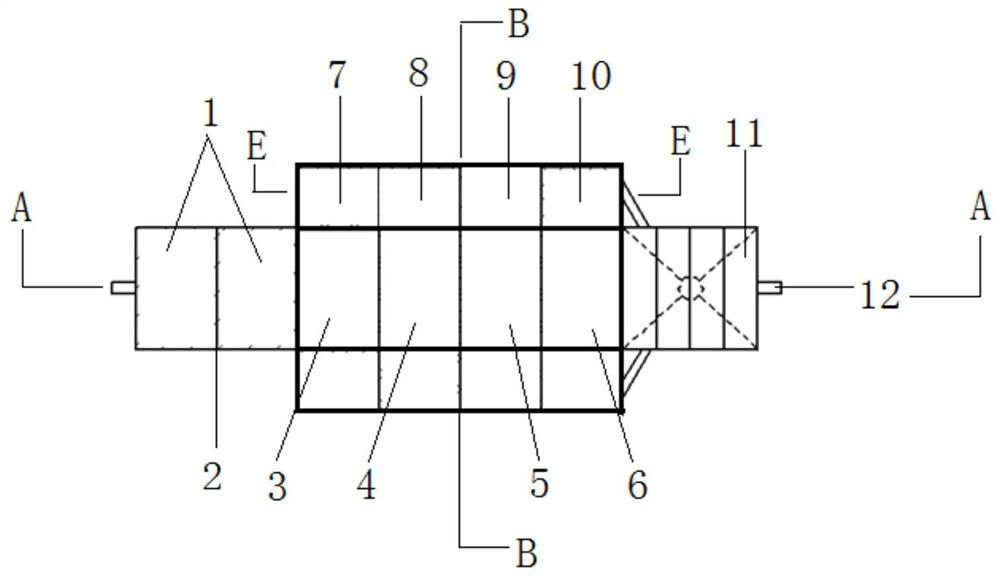

Integrated backflow-free A2O equipment based on fluidized bed

ActiveCN112777742ATreatment with aerobic and anaerobic processesSustainable biological treatmentFluidized bedBackflow

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

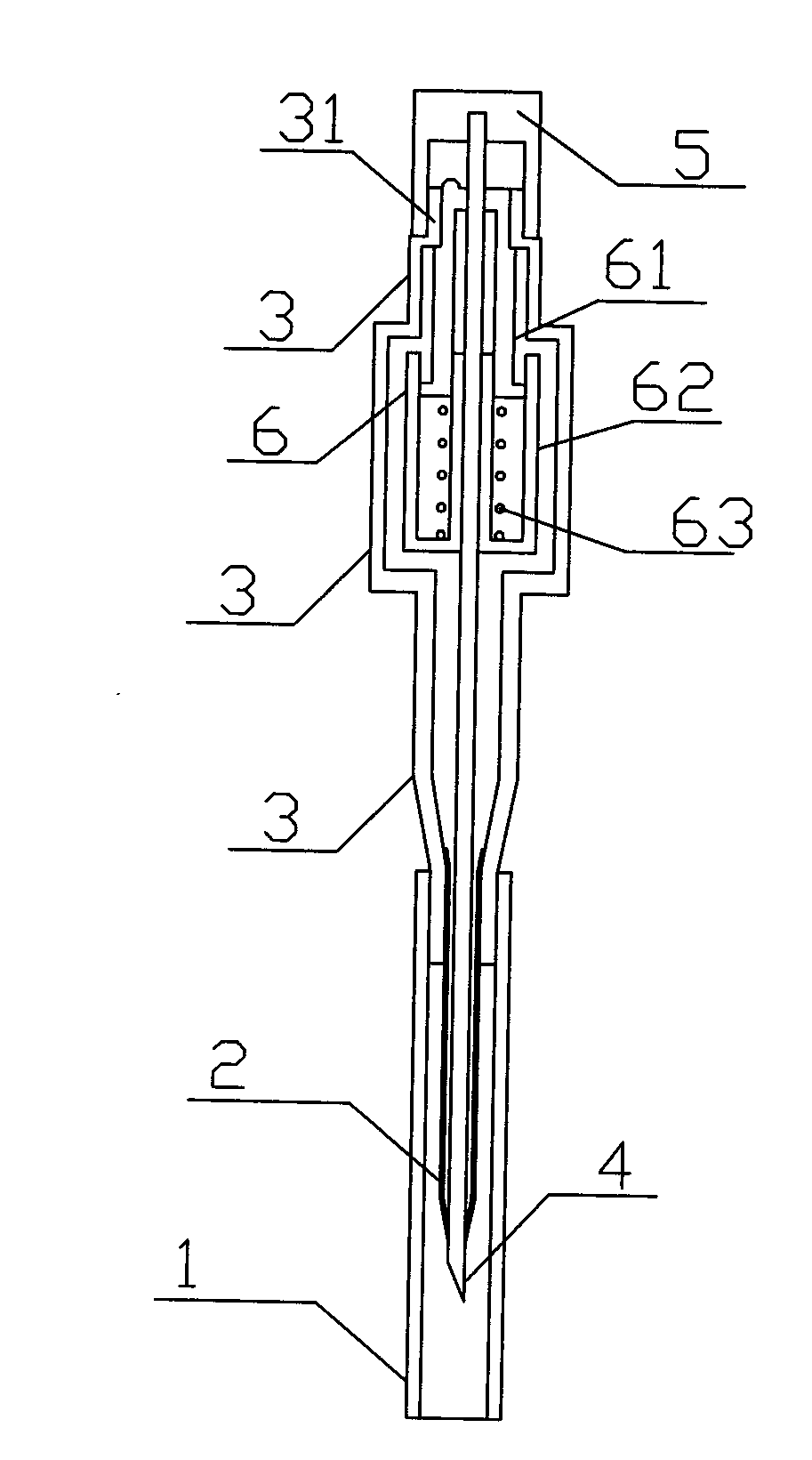

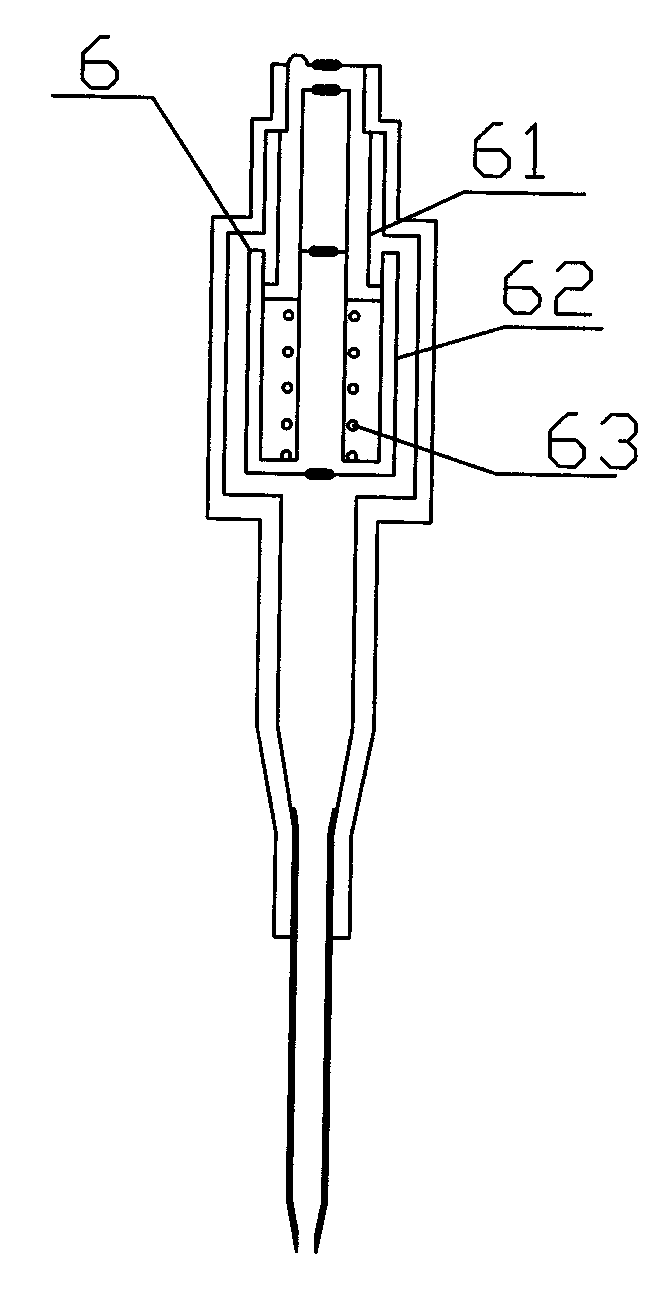

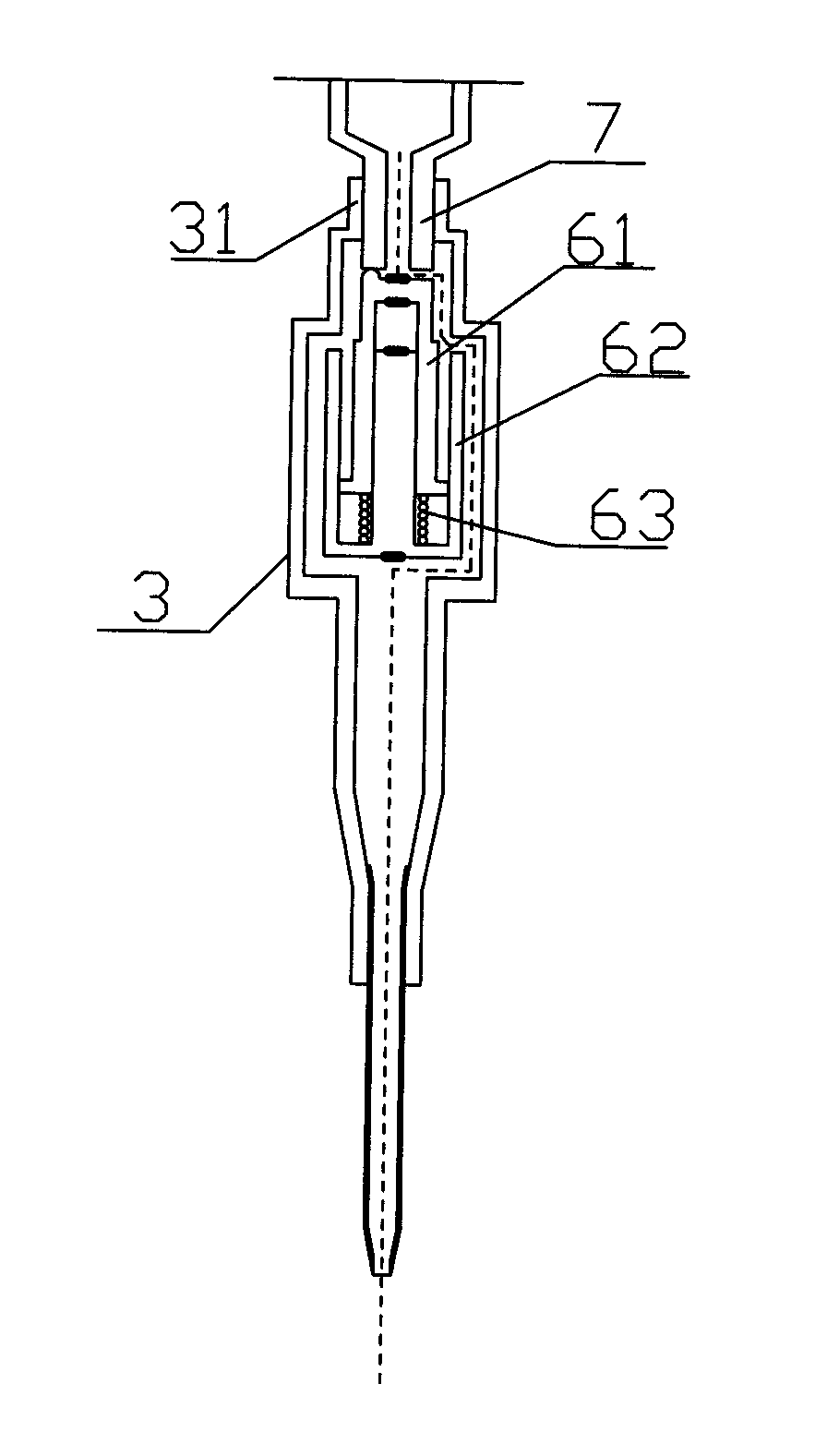

Novel pen type indwelling needle

Owner:ZHEJIANG KANGTAI MEDICAL DEVICES

Automatic closing floor drain with independent filtering barrel and independent floating body

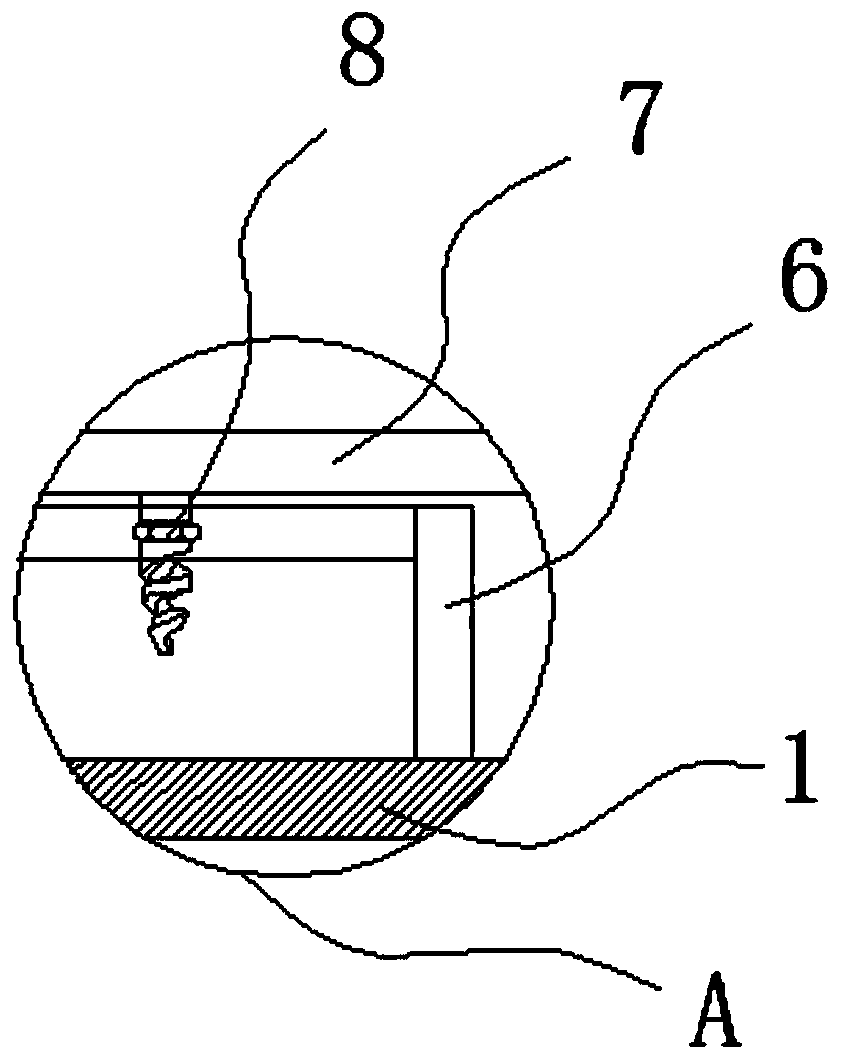

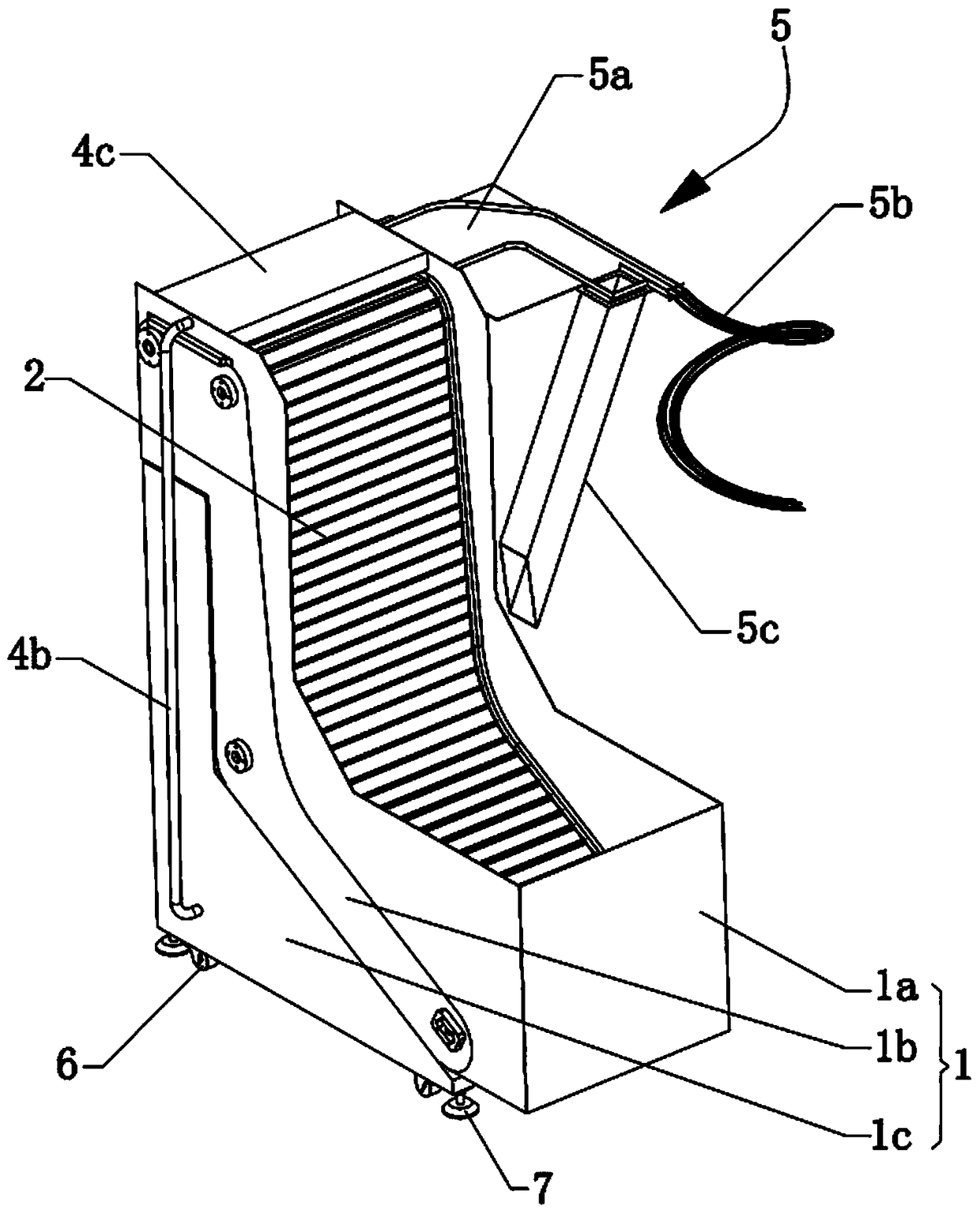

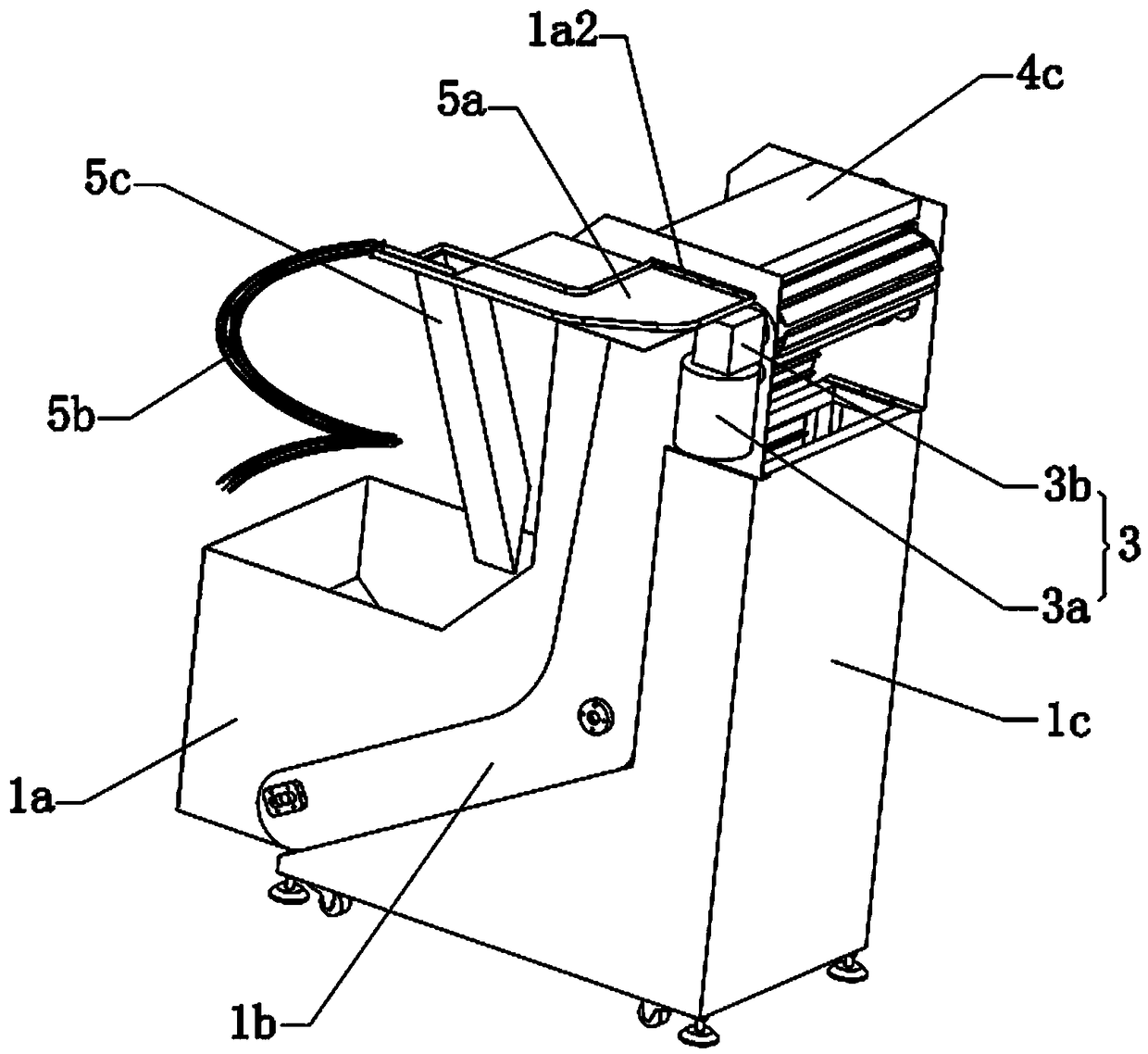

The invention discloses an automatic closing floor drain with an independent filtering barrel and an independent floating body. The automatic closing floor drain comprises a main body, the filtering barrel and the floating body; a water inlet is formed in the top of the main body, a water outlet is formed in the bottom of the main body, and a water outlet channel is formed between the water inletand the water outlet; the filtering barrel and the floating body are arranged in the water outlet channel, and the floating body is located on the lower portion of the filtering barrel; a flow guidingopening is formed in the upper portion of the water outlet, the flow guide opening is in a horn shape, and the edge with the larger opening is connected to the upper portion of the water outlet; an arc-shaped groove is formed in the lower portion of the inner wall of the main body, and the arc-shaped groove is connected with the lower portion of the flow guide opening; a through hole is formed inthe side wall of the filtering barrel; the bottom of the floating body is provided with a second horn-shaped bottom surface, and the second horn-shaped bottom surface is matched with the flow guide opening in shape; an arc-shaped outer wall is arranged at the joint of the second horn-shaped bottom surface and the side wall of the floating body. According to the floor drain, harmful gas in a sewerpipeline can be prevented from flowing out, the phenomenon of odor backflow of the sewer pipeline is avoided, and the accumulation of solid matter can be avoided.

Owner:董永茂

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap