Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Spiral blade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

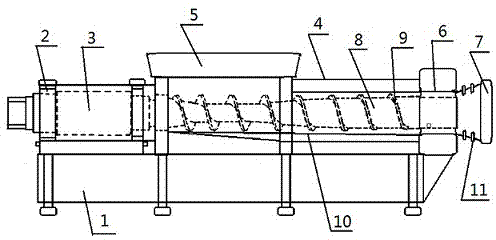

Single-screw extruder

Owner:NANNING SUGAR INDUSTRY CO LTD

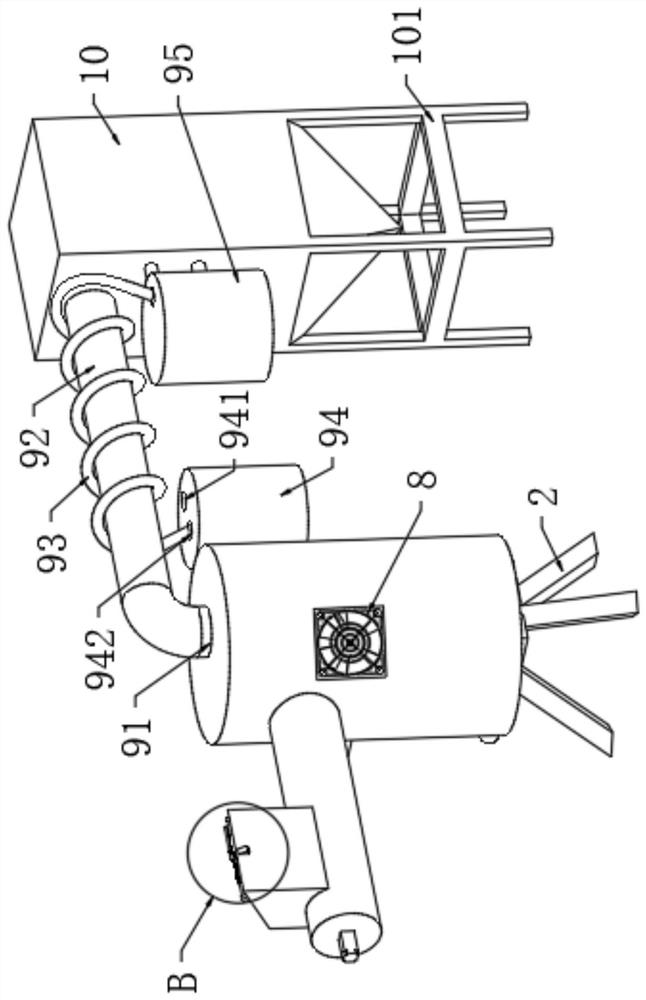

Automobile exhaust pipe with tail gas filtering function

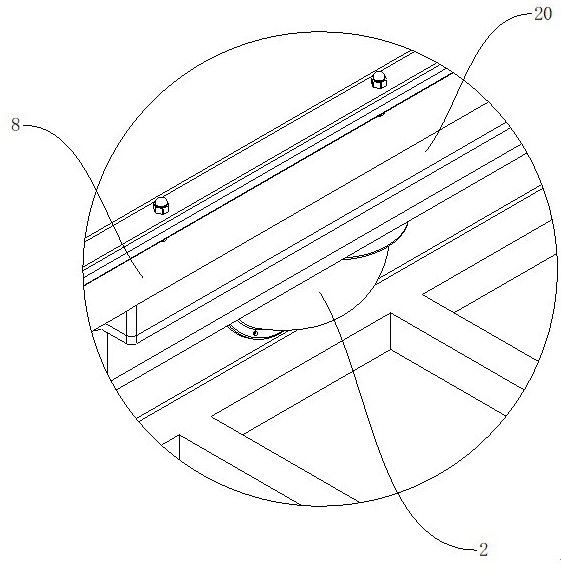

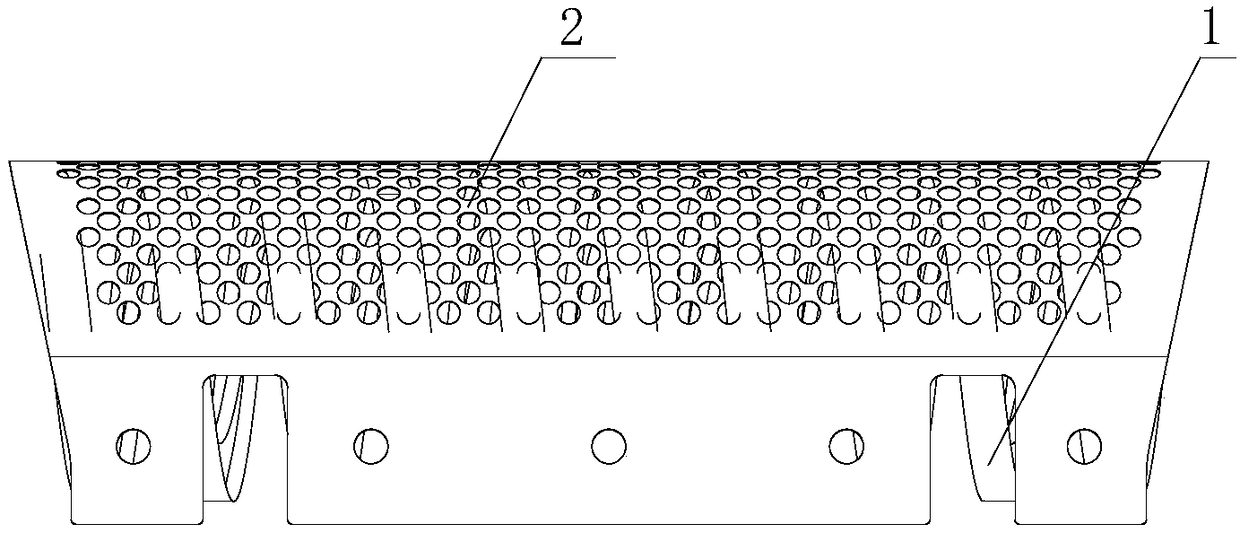

InactiveCN108561217AEvenly through theIncrease contact areaInternal combustion piston enginesExhaust apparatusCircular discSpiral blade

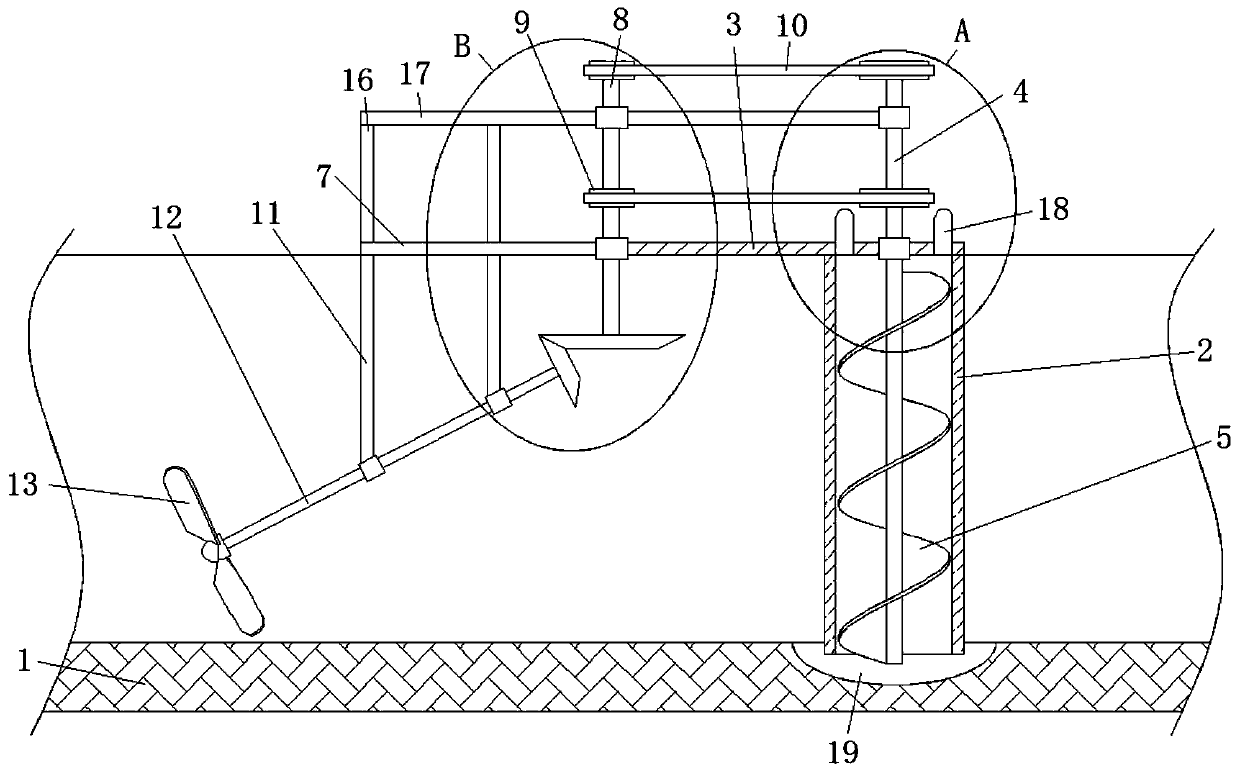

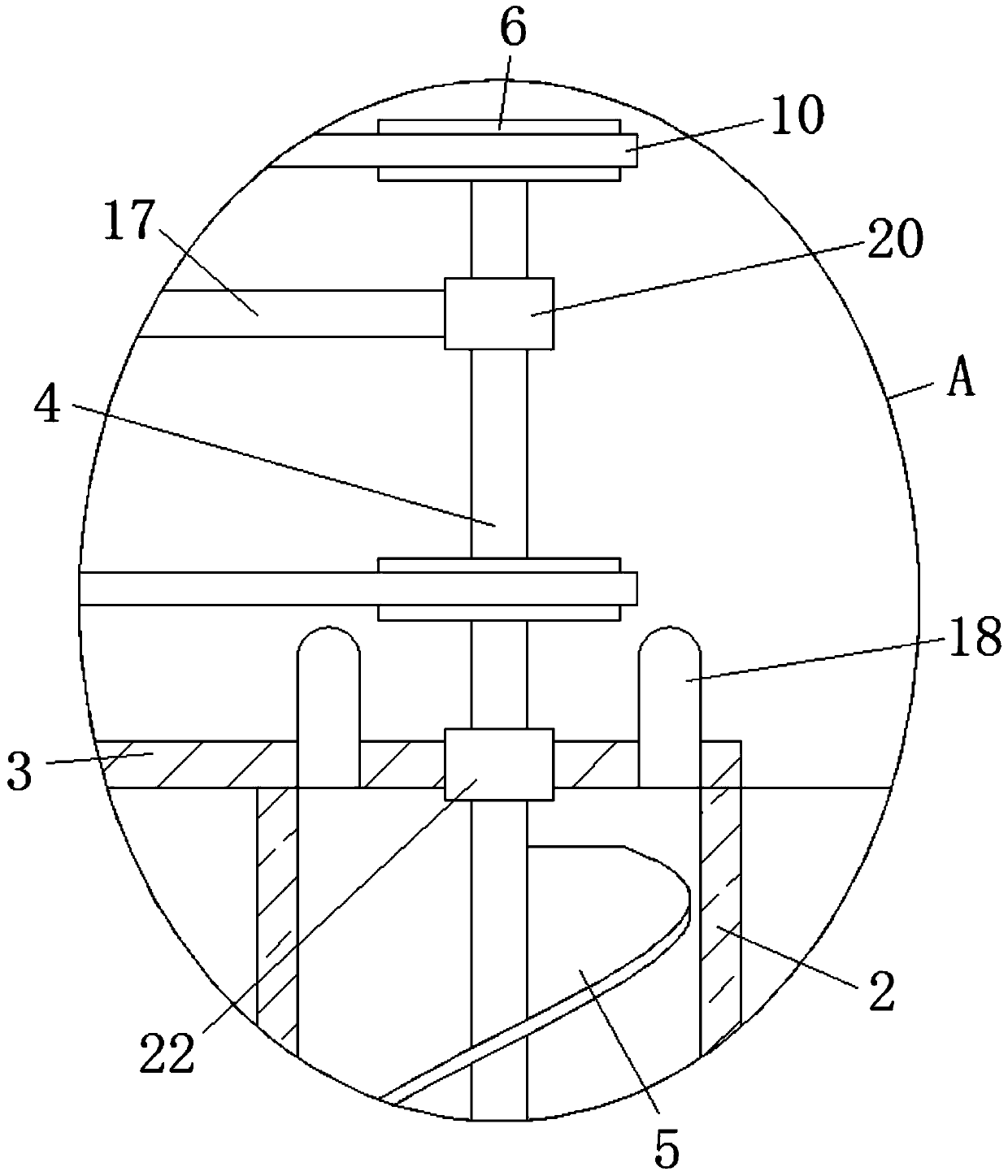

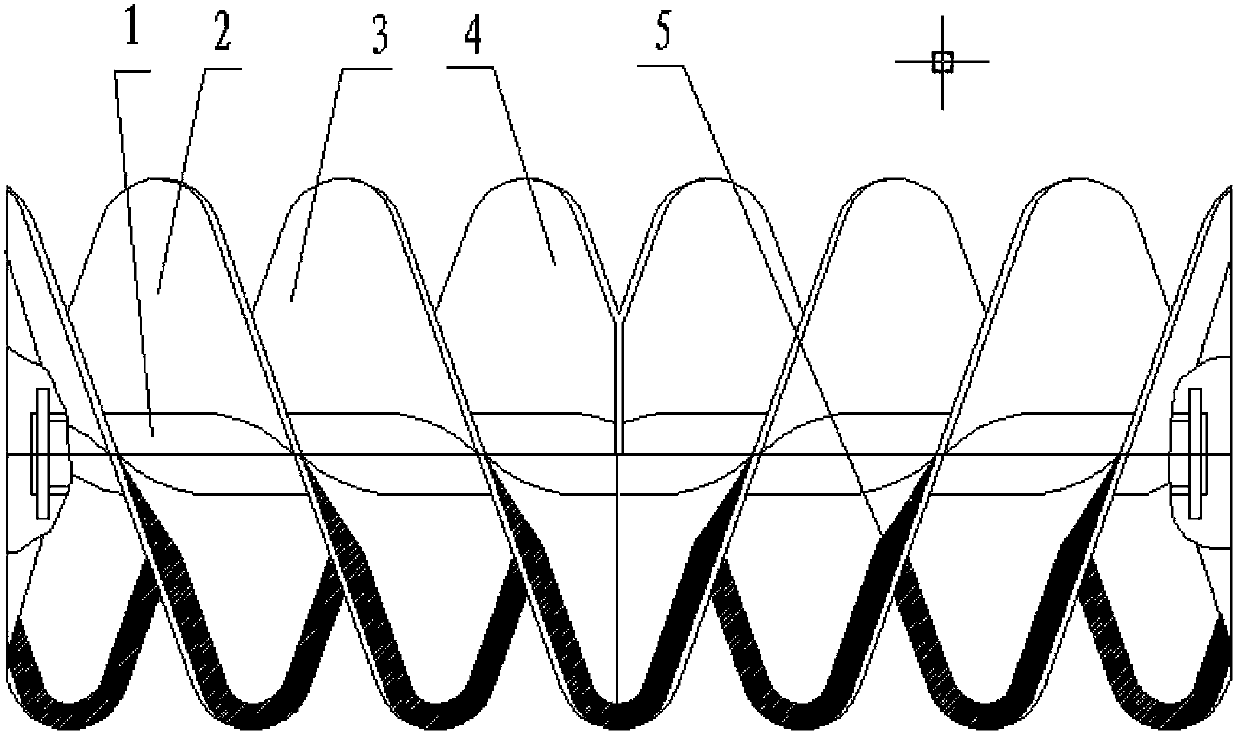

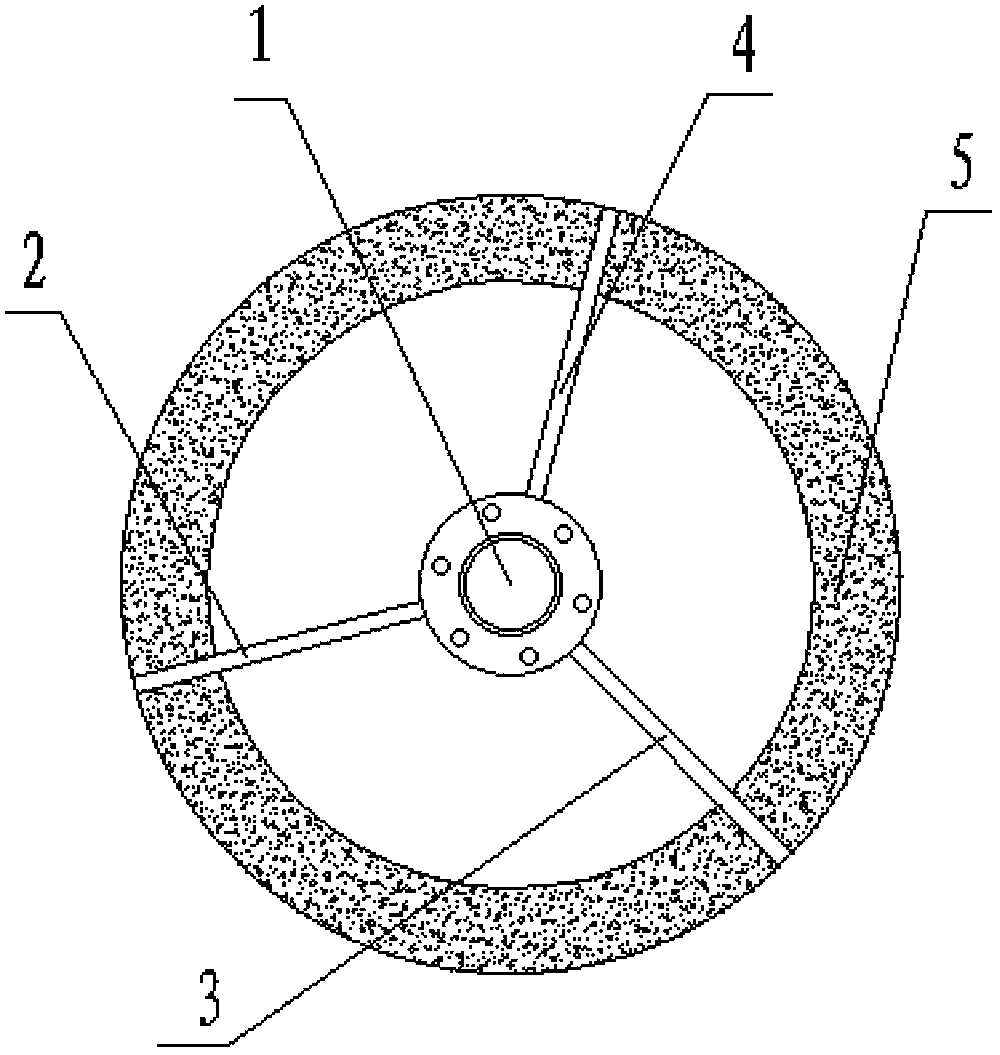

The invention discloses an automobile exhaust pipe with a tail gas filtering function. The automobile exhaust pipe comprises an exhaust pipe body and an air inlet pipe, wherein one side of the exhaustpipe body is communicated with the air inlet pipe; the other side of the exhaust pipe body is communicated with a filtering pipe through a flow guide pipe; the inner surface wall of the flow guide pipe is welded with a fixed circular disc positioned on the horizontal axial line of the flow guide pipe through flow guide plates in equal angle distribution; a rotating shaft is movably connected witha position at one side of the fixed circular disc and positioned inside the filtering pipe; a spiral blade is welded on the outer surface wall of the rotating shaft in the horizontal direction; a plurality of sound absorption convex blocks are uniformly distributed on the inner surface wall of the filtering pipe; a vacuum cavity is formed inside the casing of the filtering pipe. The automobile exhaust pipe has the advantages that the spiral blades can rotate under the tail gas circulation effect; the rotating shaft is driven to rotate; through the rotating effect of the spiral blade, the contact area between the active carbon adsorption plate and the tail gas can be effectively increased, so that the adsorption efficiency is improved; harmful gas in the tail gas can be efficiently adsorbed; the goals of filtering and environment protection are achieved.

Owner:CHENGDU YIRUIXIN TECH CO LTD

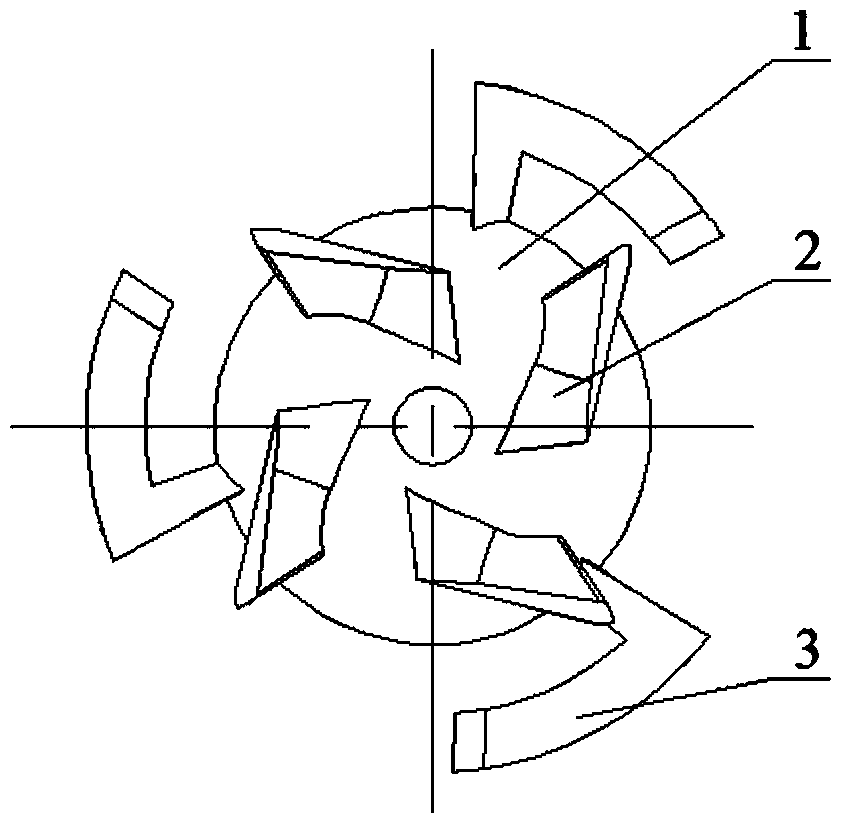

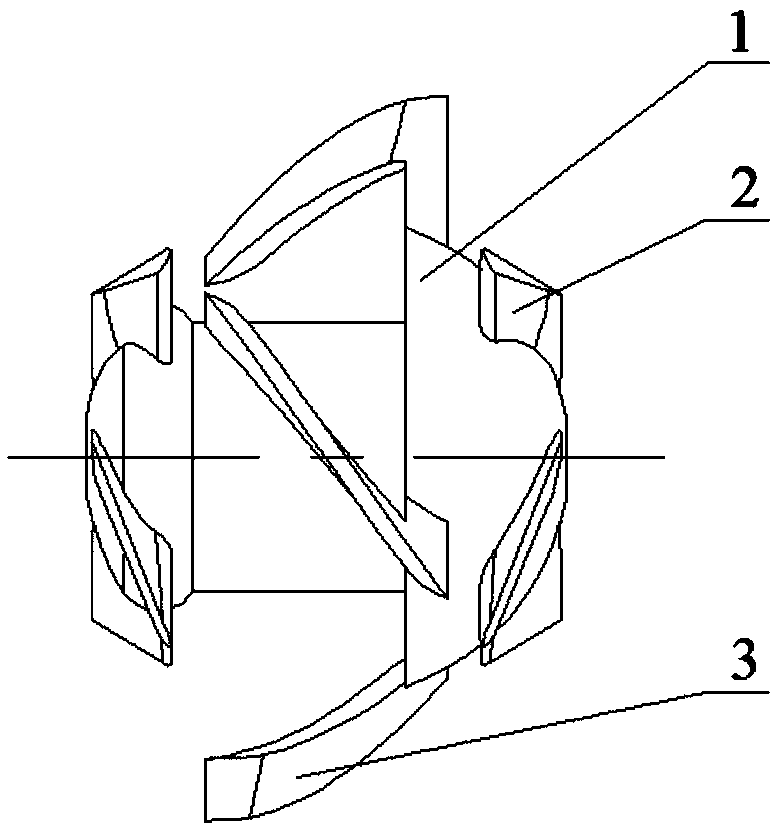

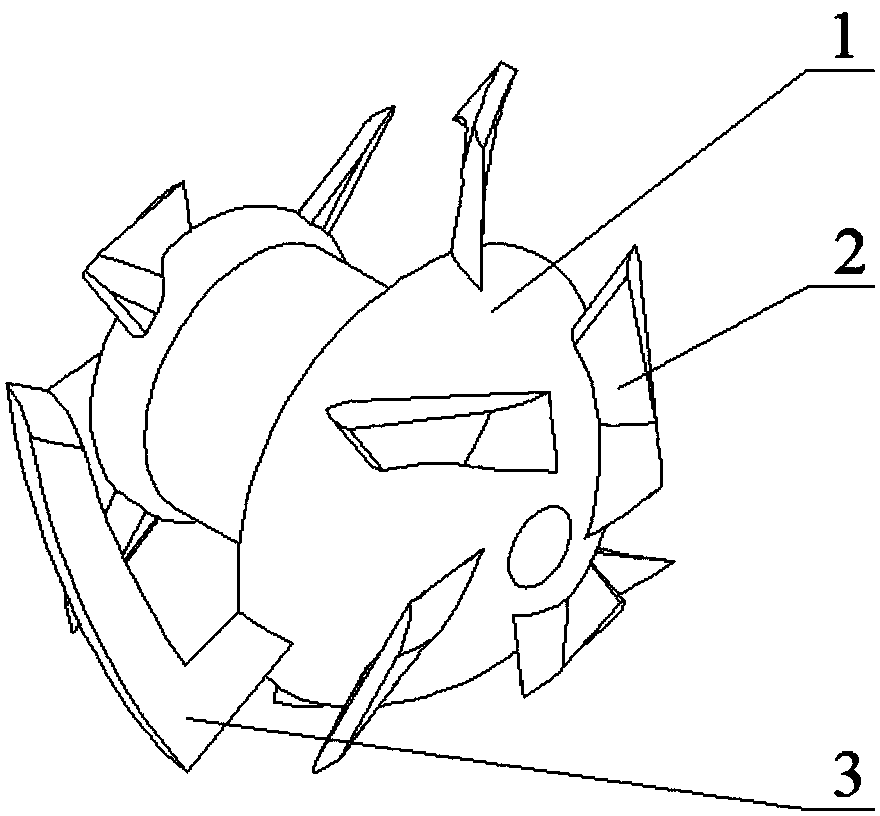

High flow disturbance sphere rotor inside heat exchange pipe

ActiveCN103411474AImprove the mixing effectIncrease tangential movementHeat transfer modificationRotary device cleaningRadial motionSpiral blade

Owner:BEIJING UNIV OF CHEM TECH

Screw rubber extruder for cable production

InactiveCN112026134AImprove practicalityAvoid the impact of product qualityDomestic articlesReciprocating motionSpiral blade

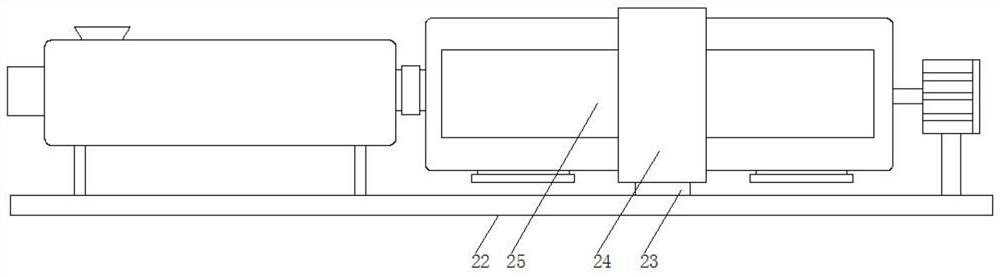

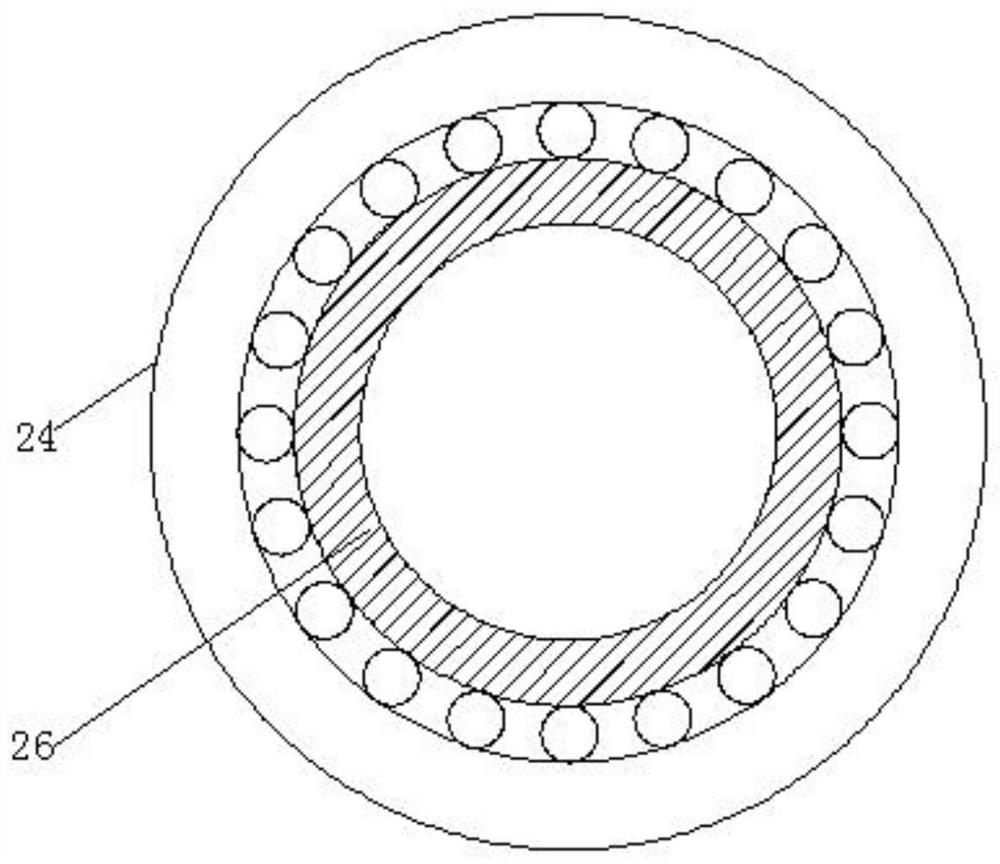

The invention relates to the technical field of cable production, and discloses a screw rubber extruder for cable production; the screw rubber extruder comprises a bottom plate; universal wheels are fixedly connected to the lower surface of the bottom plate; first brackets are fixedly connected to the left and right sides of the upper surface of the bottom plate; and conveying cylinders are fixedly connected to the inner walls of the first brackets. According to the screw rubber extruder for cable production, a heating wire, a stirring motor, a first cross rod, a second rotating shaft, a second cross rod and a third rotating shaft are arranged, so that a first gear can conveniently and effectively do reciprocating motion by taking the circle center of a first circular shaft as the center,a second gear can conveniently and effectively drive a second circular shaft and a stirring roller to do reciprocating motion to stir the material, heat is concentrated, the material is stirred to enable the material to be more uniformly and finely, the influence on the product quality due to the fact that the materials are adhered to the conveying cylinder and a spiral blade in the working process is avoided, and the practicability of the extruder is greatly improved.

Owner:HENGYANG SOUTH CHINA ELECTRIC WIRE CO LTD

Hospital wastewater treatment system

InactiveCN107032531AInto the uniformEasy to handleTreatment involving filtrationMultistage water/sewage treatmentFlocculationWater treatment system

The invention discloses a hospital sewage treatment system, which comprises a sewage feed pipe, a sedimentation tank, a flocculation tank, a treatment tank and a waste storage bin. Helical blades are welded, the bottom of the sewage feed pipe is fixed with a filter groove by bolts, the outlet end of the sewage feed pipe is connected to a treatment pool, and one side of the treatment pool is connected to a flocculation pool through a pipeline. One side of the flocculation tank is connected with a sedimentation tank through a pipeline, and one side of the sedimentation tank is connected with a disinfection tank through a pipeline. In the present invention, the inside of the sewage feed pipe is fixed with a spiral blade, which can make the sewage enter more evenly, and in the sewage feed pipe, a filter groove is arranged at the bottom of the spiral blade, and the sewage is filtered by the spiral blade. During the transportation, the impurities in the sewage can be removed in time, so that the treatment effect of the sewage in the later stage is better.

Owner:CHENGDU YIRUIXIN TECH CO LTD

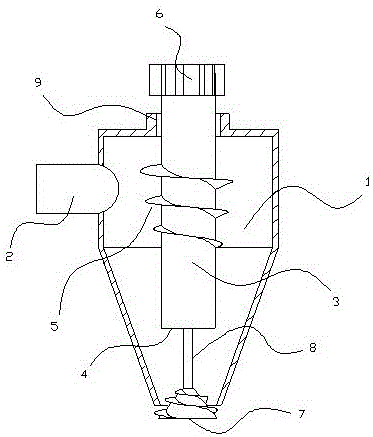

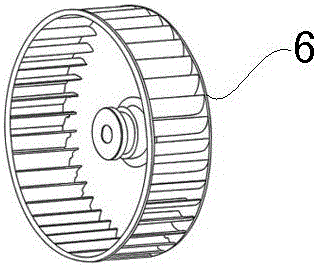

Cyclone separator

Owner:SHENTONG TECH GRP CO LTD

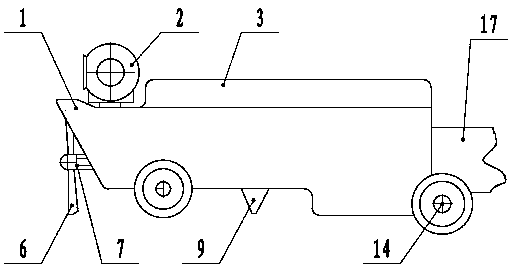

Online farmland soil remediation device

InactiveCN108856279AImprove continuityImprove work efficiencyContaminated soil reclamationSpiral bladeSoil remediation

The invention discloses an online farmland soil remediation device. The device comprises a machine body, a hollow rotating shaft and a liquid medicine box; a travelling mechanism is installed on the bottom of the machine body; the machine body is of a box-shaped structure with an opening in front side, and a shovel board is arranged on the front side of the machine body; the hollow rotating shaftis transversely arranged at a central position of a cavity of the machine body, liquid outlet holes communicated with a cavity of the hollow rotating shaft are evenly formed in a shaft body of the hollow rotating shaft, and a spiral blade is fixedly arranged on the periphery of the hollow rotating shaft; a pump is installed on the side wall of the liquid medicine box; the pump is connected with awater suction pipe and a water outlet pipe, and the other end of the water outlet pipe is connected with the hollow rotating shaft through a rotating connector. According to the online farmland soil remediation device, by adopting an online work mode, farmland soil is remediated, the work continuity is high, and the working efficiency is high; through the hollow rotating shaft, liquid medicine conveying is conducted so that a liquid medicine can be in full contact with the soil, and the remediation effect is guaranteed; meanwhile, by controlling a telescoping device, the action depth of the shovel board can be adjusted, so that use is more flexible.

Owner:SUZHOU XUNYU NEW MATERIAL TECH CO LTD

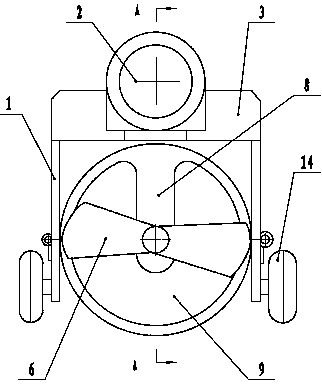

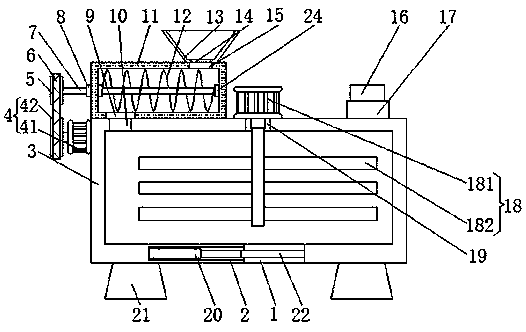

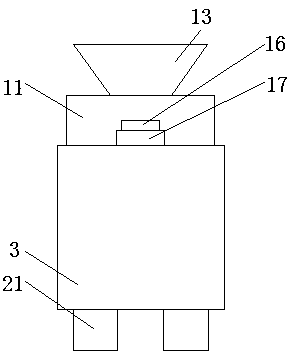

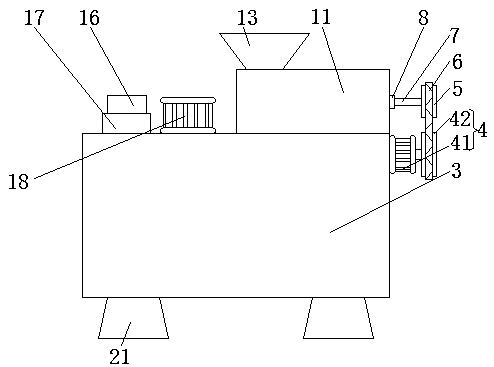

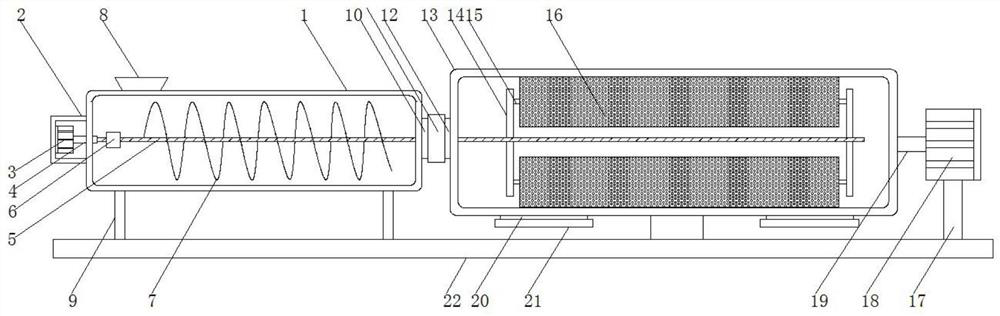

Plant essential oil extraction device, and using method thereof

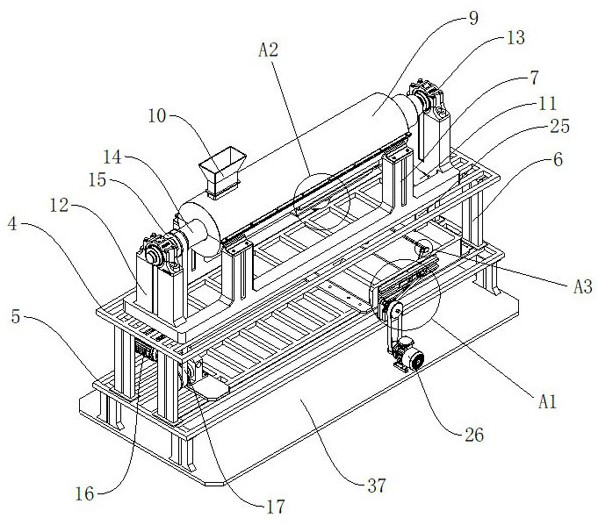

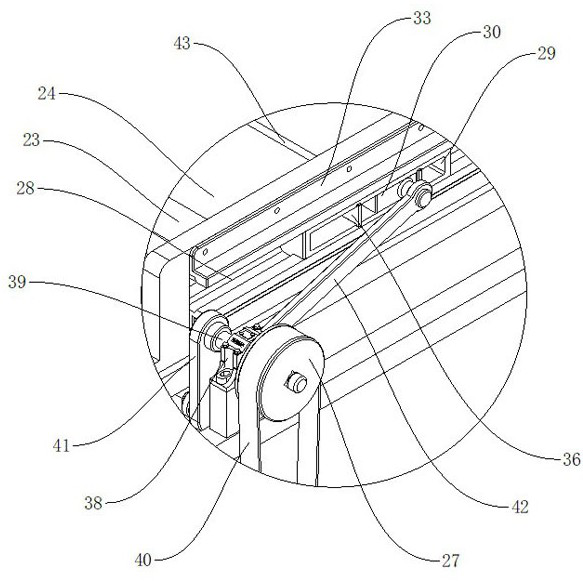

ActiveCN108998249AFully contactedGuaranteed Extraction EffectEssential-oils/perfumesDrive shaftSpiral blade

The invention discloses a plant essential oil extraction device, and a using method thereof. The plant essential oil extraction device comprises a sealed tank; a conveying cylinder is arranged in thesealed tank; one end of the conveying cylinder is designed to penetrate the sealed tank; the external end of the conveying cylinder is provided with a driving motor; the external side of the conveyingcylinder is provided with a material guide pipe; the upper end of the material guide pipe is provided with a material injection hopper; the external side of the conveying cylinder is penetrated by gas guide holes; the gas guide holes are arranged in the sealed tank; a transmission shaft is arranged in the conveying cylinder through bearings; the external terminal part of the transmission shaft isprovided with a steam injection pipe using a sealing bearing; a material conveying spiral blade, a stirring blade, and a deslagging spiral blade are arranged on the external side of the transmissionshaft successively; the surface of the stirring blade is penetrated by a gas outlet. The beneficial effects are that: steam is introduced into the conveying cylinder through the steam injection pipe,at the same time, the stirring blade is used for stirring plant residue, so that full contact of steam with plant residue is realized, and essential oil extraction effect and extraction efficiency areensured.

Owner:LINYI UNIVERSITY

Ecological drainage channel

InactiveCN111560925AMeet the needs of useAvoid cloggingMechanical machines/dredgersSoil drainageSludgeSpiral blade

Owner:陈文娟

Three-head abrasion-resistant spiral device

InactiveCN103863773ATroubleshoot scrappingEffective Process MeasuresPackagingLoading/unloadingLeft directionButt joint

Owner:HARBIN HONGTAI ELECTRIC POWER EQUIP

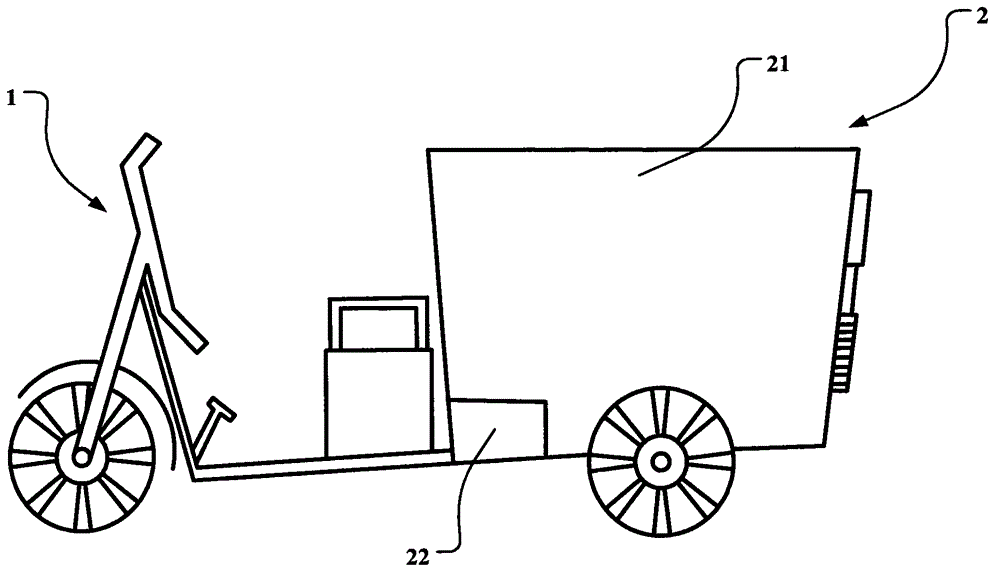

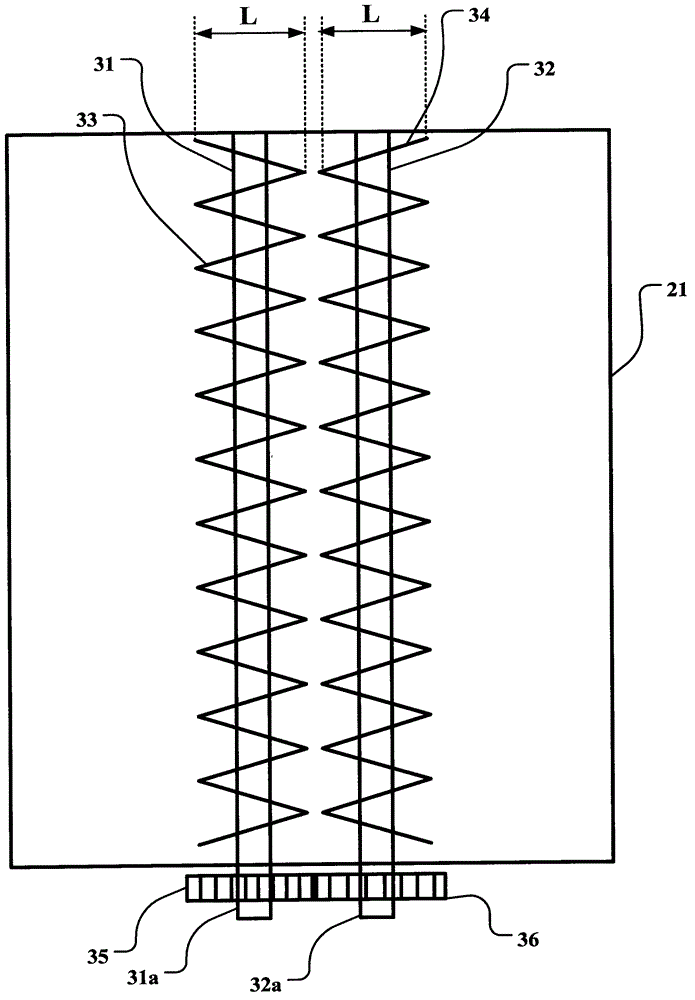

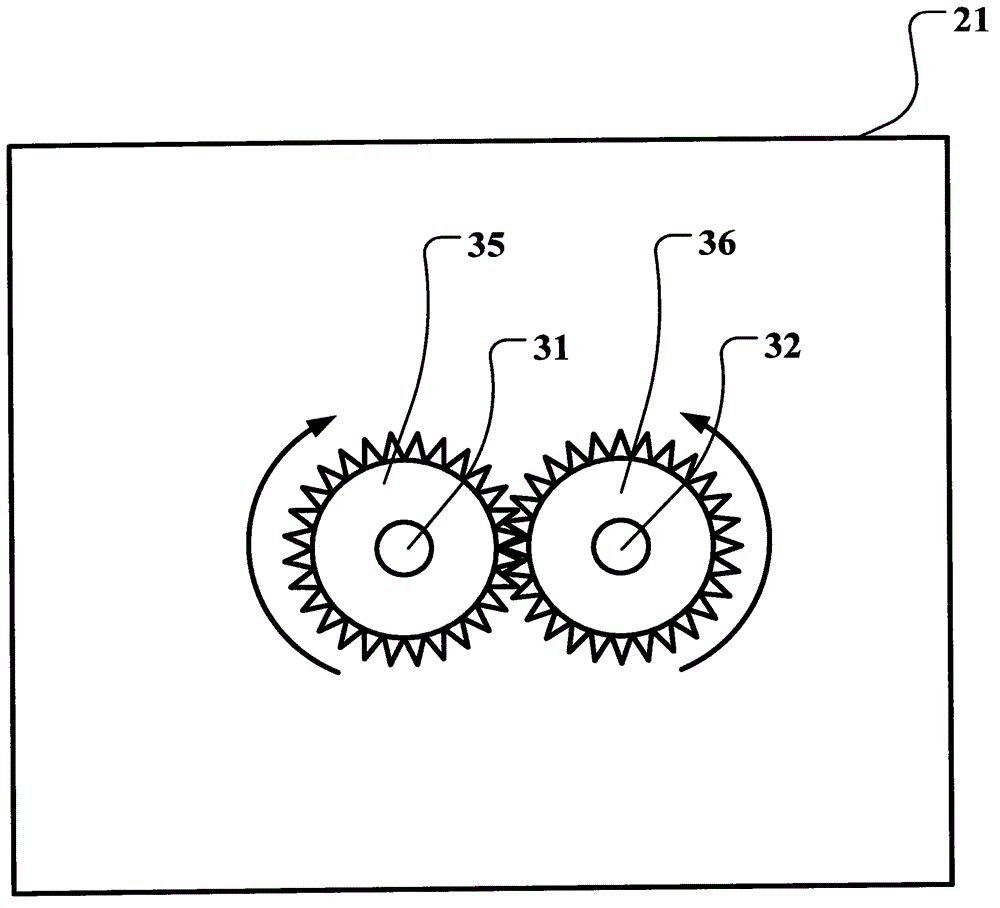

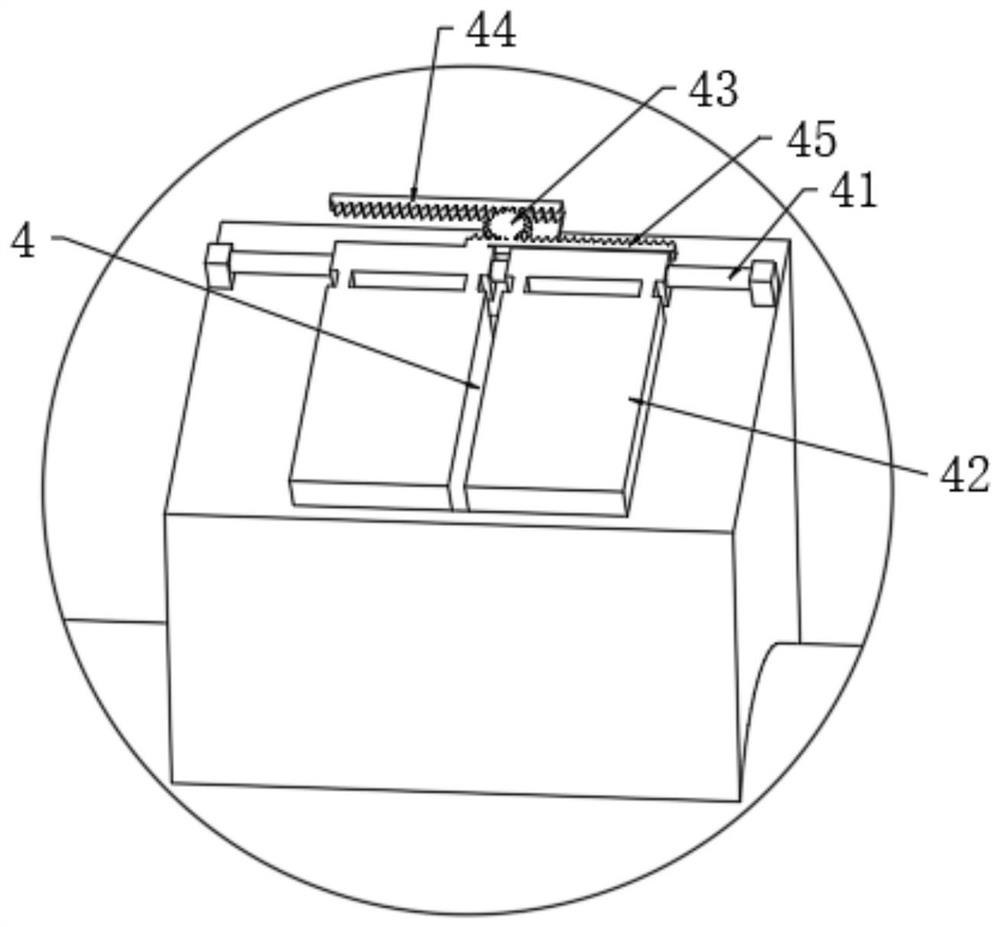

Material conveying control device of battery car with feeding machine

Owner:MENGYANG PROVENANCE SCI & TECH

Solid waste incineration method

Owner:重庆知翔科技有限公司

Ground sewer detecting and clearing robot

PendingCN109868893ASimple structureReduce artificial downhole serious poisoning accidentsSewer systemsSpiral bladeSludge

Owner:ZIGONG MODERN AUTUMN HARVEST MACHINERY CO LTD

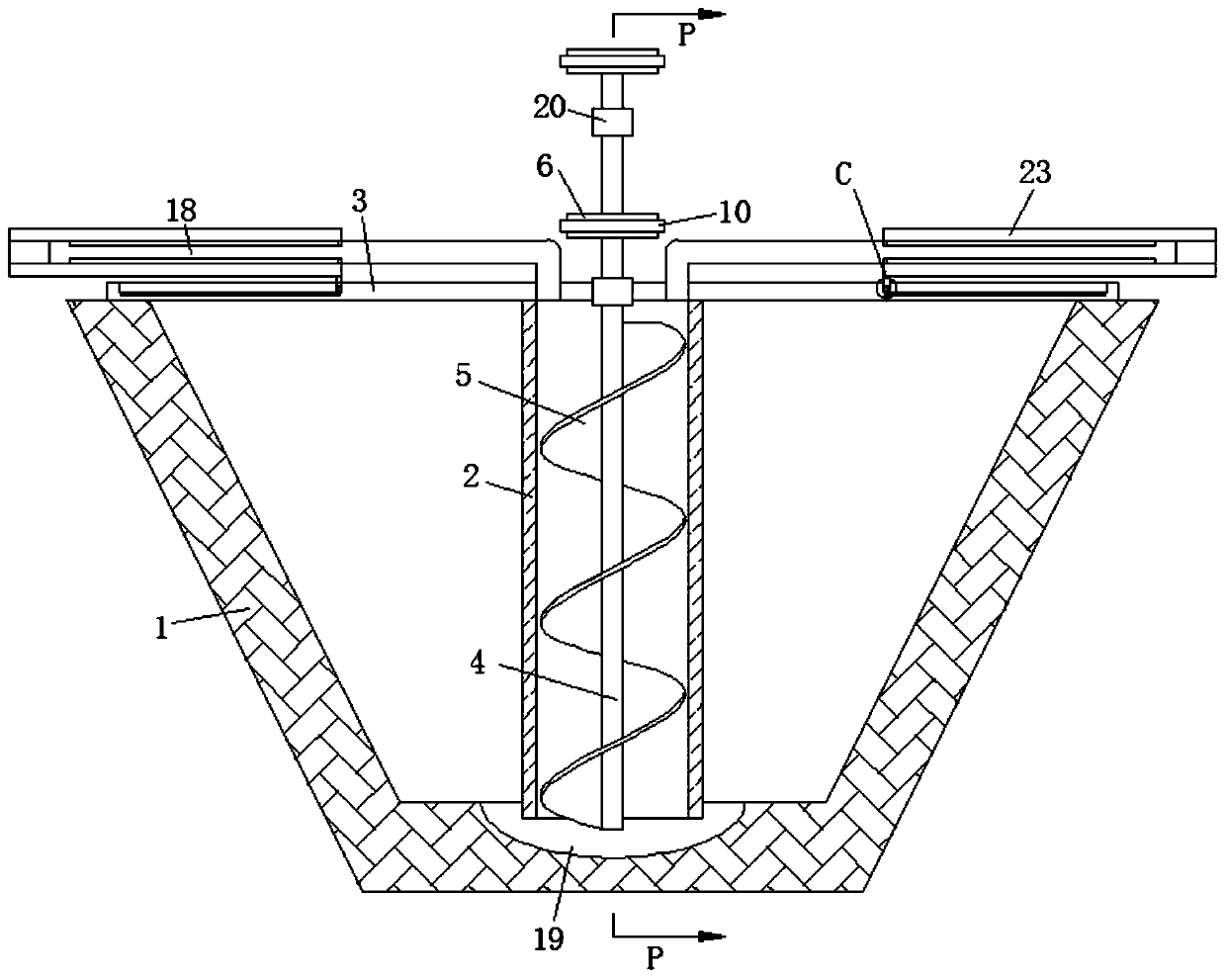

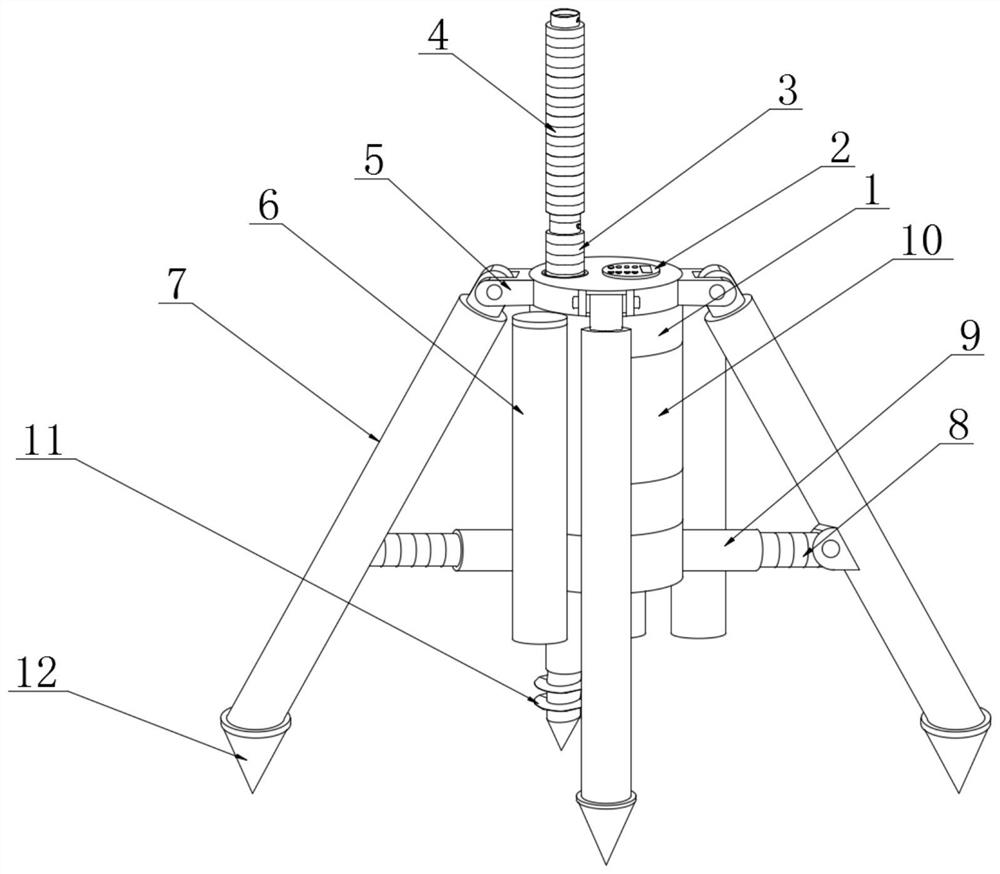

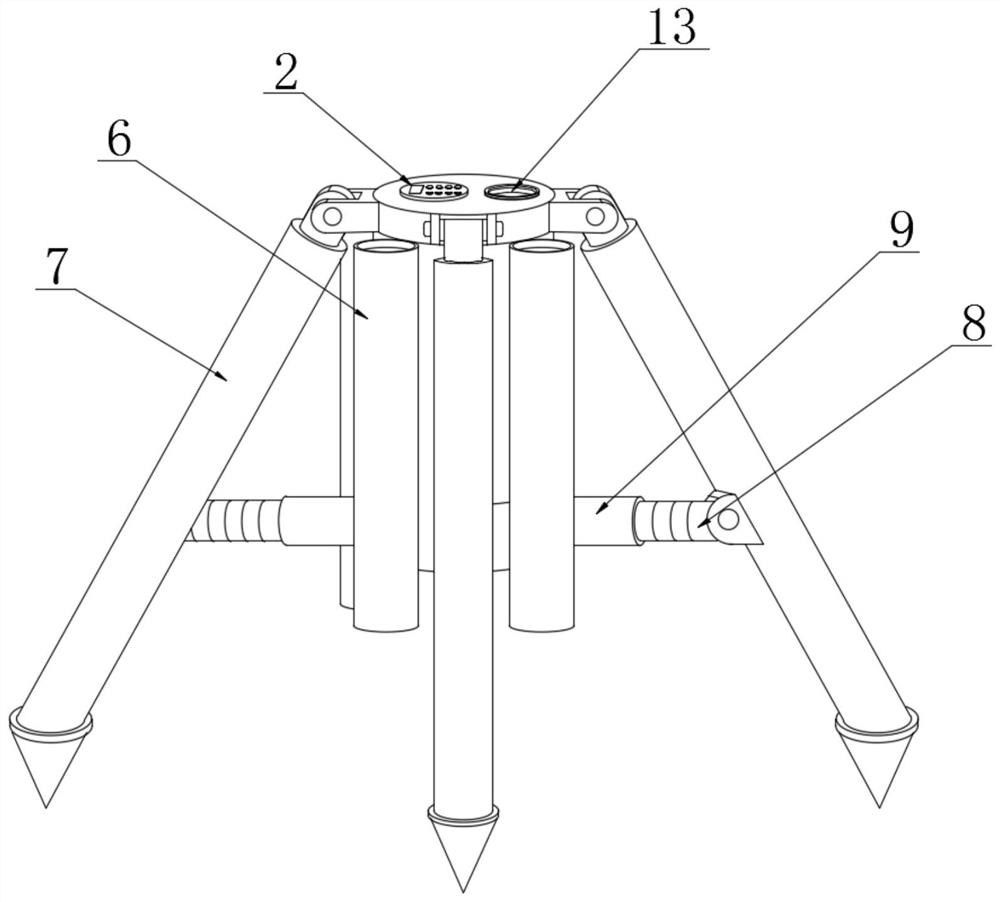

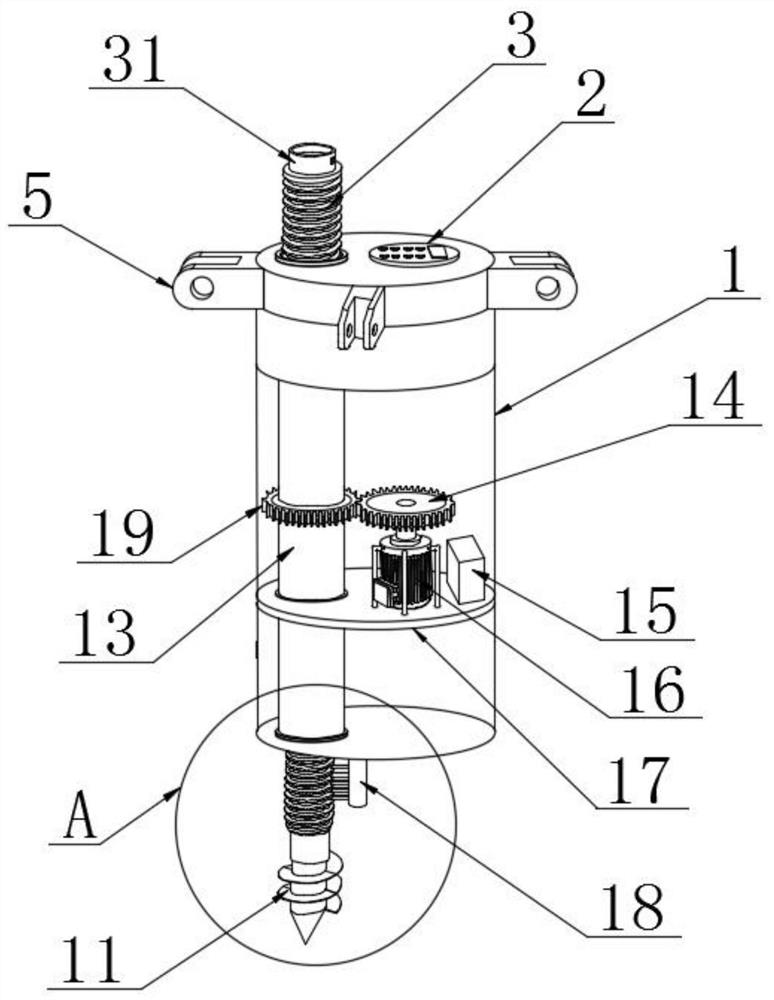

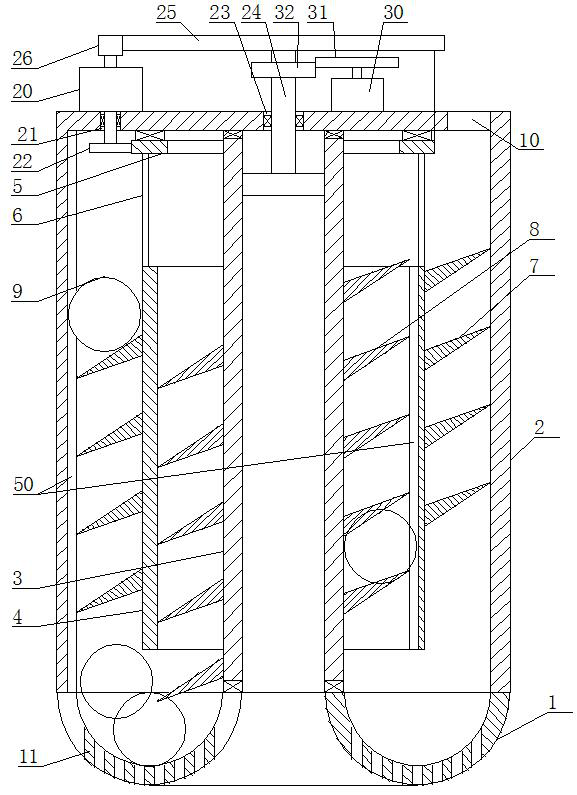

Hydrogeological exploration device and method

PendingCN112610163AStrong firmnessSmall footprintEarth drilling toolsDerricks/mastsHydrometryGear wheel

Owner:晏传山

Catalyst extrusion molding machine convenient to maintain

Owner:ZIBO QIMAO CATALYST

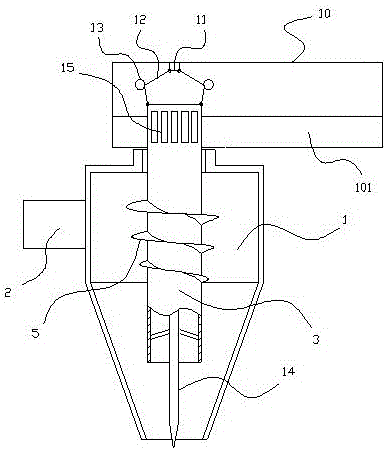

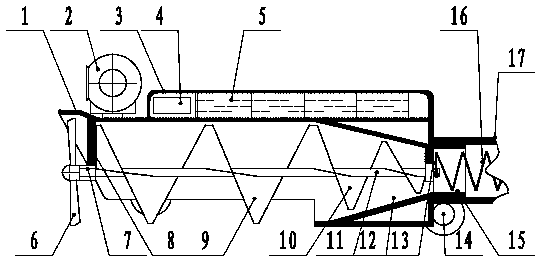

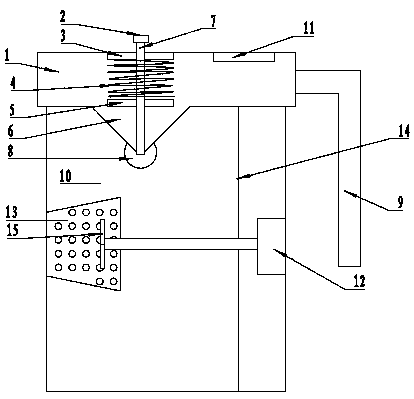

Spiral guide type submersible jet aerator

InactiveCN104843883AAvoid depositionHigh oxygenation efficiencyWater aerationSustainable biological treatmentJet flowSpiral blade

The invention relates to aerator equipment, in particular to a spiral guide type submersible jet aerator. The spiral guide type submersible jet aerator comprises a submersible motor fixed underwater through a supporting rod, wherein the front end of the submersible motor is provided with a mixer, an air inlet pipe is connected onto the mixer and the front end of the mixer is provided with a spiral guide device; the spiral guide device comprises an external guide cylinder, a spiral blade is arranged in the guide cylinder, and a center shaft for the spiral blade penetrates through the mixer and is fixedly connected with a motor rotating shaft; the spiral blade is fixedly connected with the guide cylinder; the mixer is conical and the mixer is provided with an air inlet interface; a water inlet passages is arranged between the guide cylinder and the mixer, and the inner chamber of the mixer is an air inlet passage. The spiral guide type submersible jet aerator has the advantages that the sedimentation of large particle sand can be prevented, the aerating efficiency of the aerator is improved, the used land is reduced, the power cost is decreased and the sludge backflow lifting effect is enhanced.

Owner:SHANDONG HANGAO ENVIRONMENTAL PROTECTION EQUIP CO LTD

Top-grade stone grinding device facilitating feeding and discharging

InactiveCN108435399AEasy loading and unloadingShorten the timeGrain treatmentsDrive wheelMotor drive

Owner:JIANGSU KERUIXIN MACHINERY

Energy-saving preparation device of lead tetroxide

InactiveCN112278915AShorten heating timeImprove uniformityLoading/unloadingHeating timeElectric machine

Owner:张家港市翔林机械有限公司

Dehydration device for pea starch production

ActiveCN114801289ATroubleshoot blocky appearanceImprove dehydration efficiencyGrain treatmentsPressesWater filterSpiral blade

Owner:优承生物科技(烟台)有限公司

Spiral blade and shaver comprising same

PendingCN109202968AEasy to processReduce processing costsMetal working apparatusSpiral bladePulp and paper industry

Owner:浙江海顺电工有限公司

Improved titanium equipment reactor

InactiveCN108927098AEnsure safetyFully mixed reactionChemical/physical/physico-chemical stationary reactorsFeed devicesSpiral bladeTitanium

Owner:SUZHOU ZHUOCHENG TITANIUM EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap