Improved titanium equipment reactor

A technology of reaction vessel and equipment, applied in the field of improved titanium equipment reaction vessel, can solve the problems of unfavorable technical personnel safety, simple structure of reaction pool, etc., and achieve the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

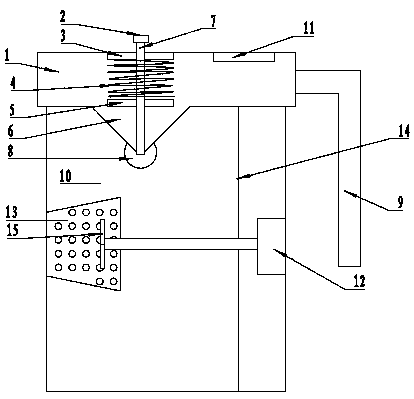

[0014] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0015] An improved reaction vessel for titanium equipment, comprising an upper cover 1, a frame body 10 and a feeding mechanism, the frame body 10 is an opening on the surface to match the upper cover 1, and the upper cover 1 is closed on the On the frame body 10, a feeding port 11 is provided on the upper cover 1, and an accommodating groove for accommodating the feeding mechanism is provided inside the upper cover 1, and the feeding mechanism is installed in the accommodating groove; The plate 14 divides the frame body 10 into a large chamber and a small chamber, the motor 12 is located in the small chamber, and the output shaft of the motor 12 extends into the large chamber through the small cha

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap