Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Rotational flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotational flow. [rō′tā·shən·əl ′flō] (fluid mechanics) Flow of a fluid in which the curl of the fluid velocity is not zero, so that each minute particle of fluid rotates about its own axis. Also known as rotational motion.

Coating method of lithium ion battery cathode material

ActiveCN108767232AFull and effective contactUniform particle size distributionCell electrodesSecondary cellsImpellerEngineering

The invention discloses a coating method of a lithium ion battery cathode material. According to the method, disk-nest grinding equipment is utilized to continuously input a lithium ion battery cathode material to be covered into a disk-nest grinder in a form of solid powder, solid powder is dispersed by an impeller and a disk which rotate at a high speed in a cavity of the disk-nest grinder, multiple nest type rotational flows are formed between the disk and a special lining plate, and air flow impact force between the disk and the special lining plate can fully disperse the solid powder; meanwhile, the rotation speed can be controlled to make a powder material keep morphology or be smashed; furthermore, a coating material can enter the disk-nest grinder in a form of solution or slurry ina mist spray mode and can evenly contact certain-temperature solid powder particles to be covered to finish coating. By means of the lithium ion battery cathode material coating method, a traditionalcoating technology for an existing lithium ion battery cathode material is greatly simplified, productivity is remarkably improved, a product coating effect is greatly improved, and cost is obviouslyreduced.

Owner:CENT SOUTH UNIV

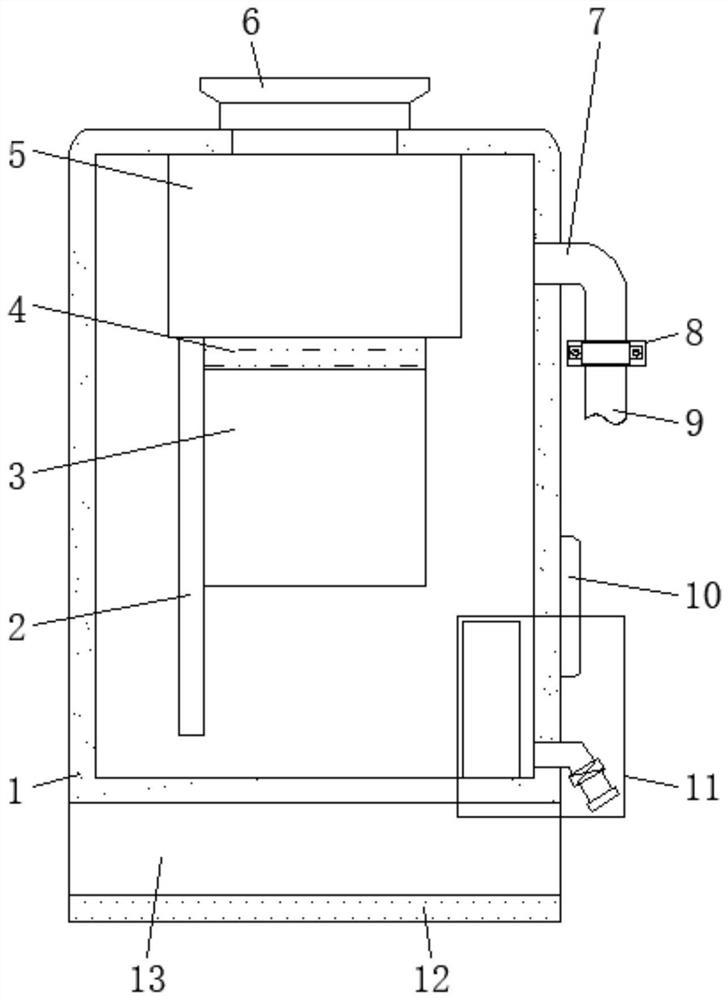

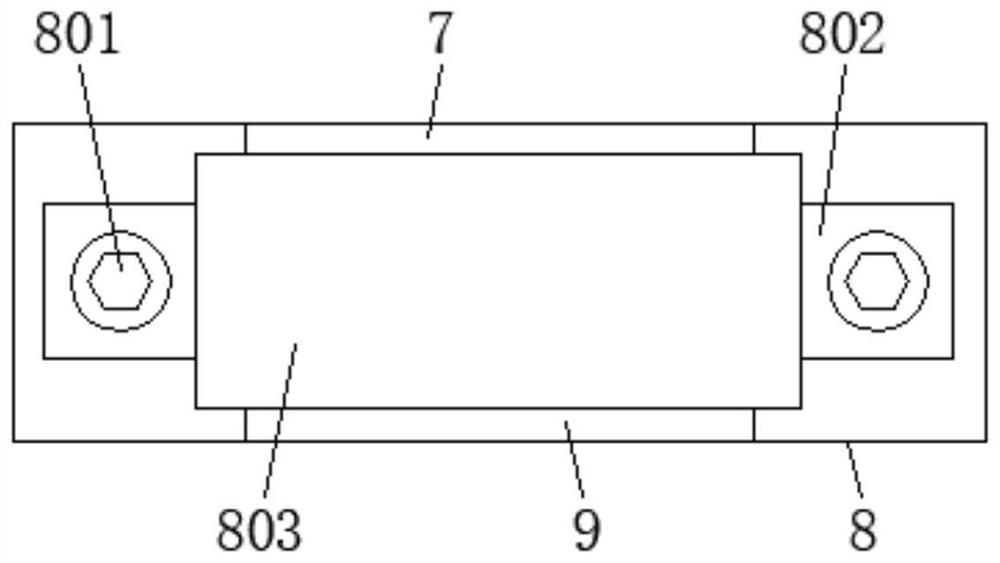

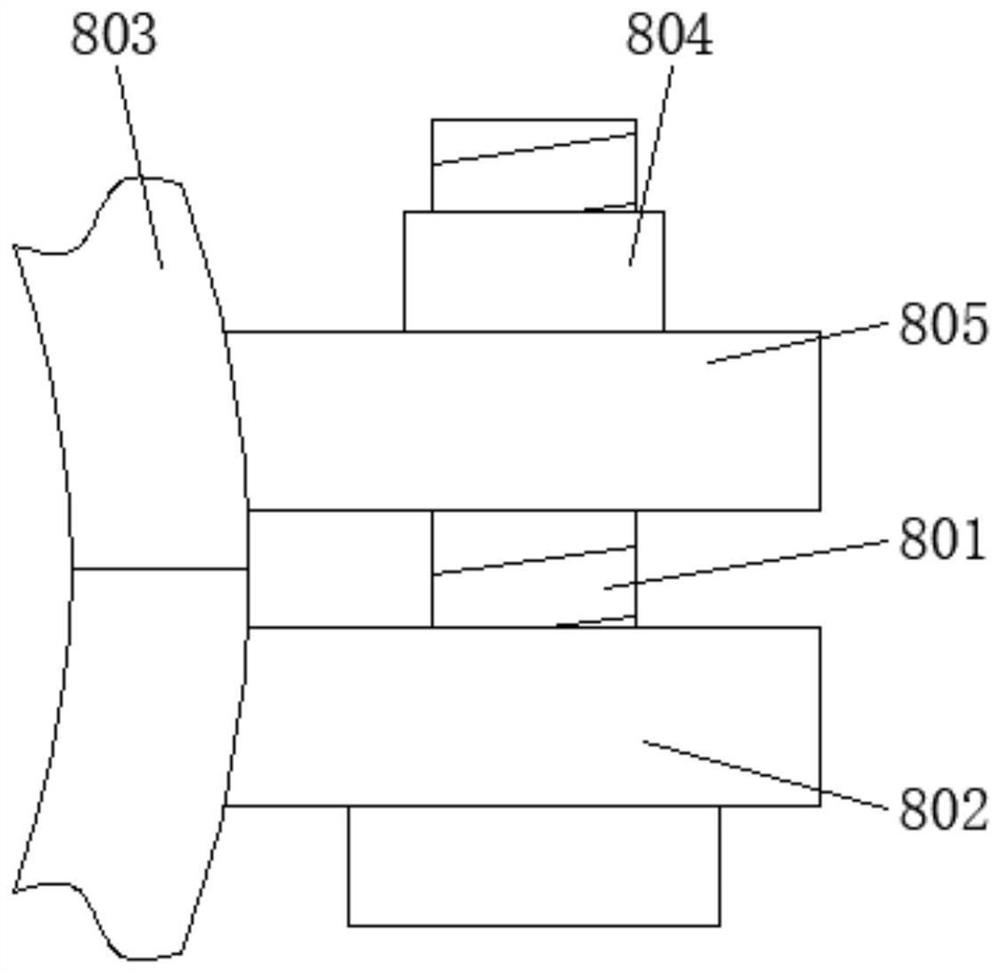

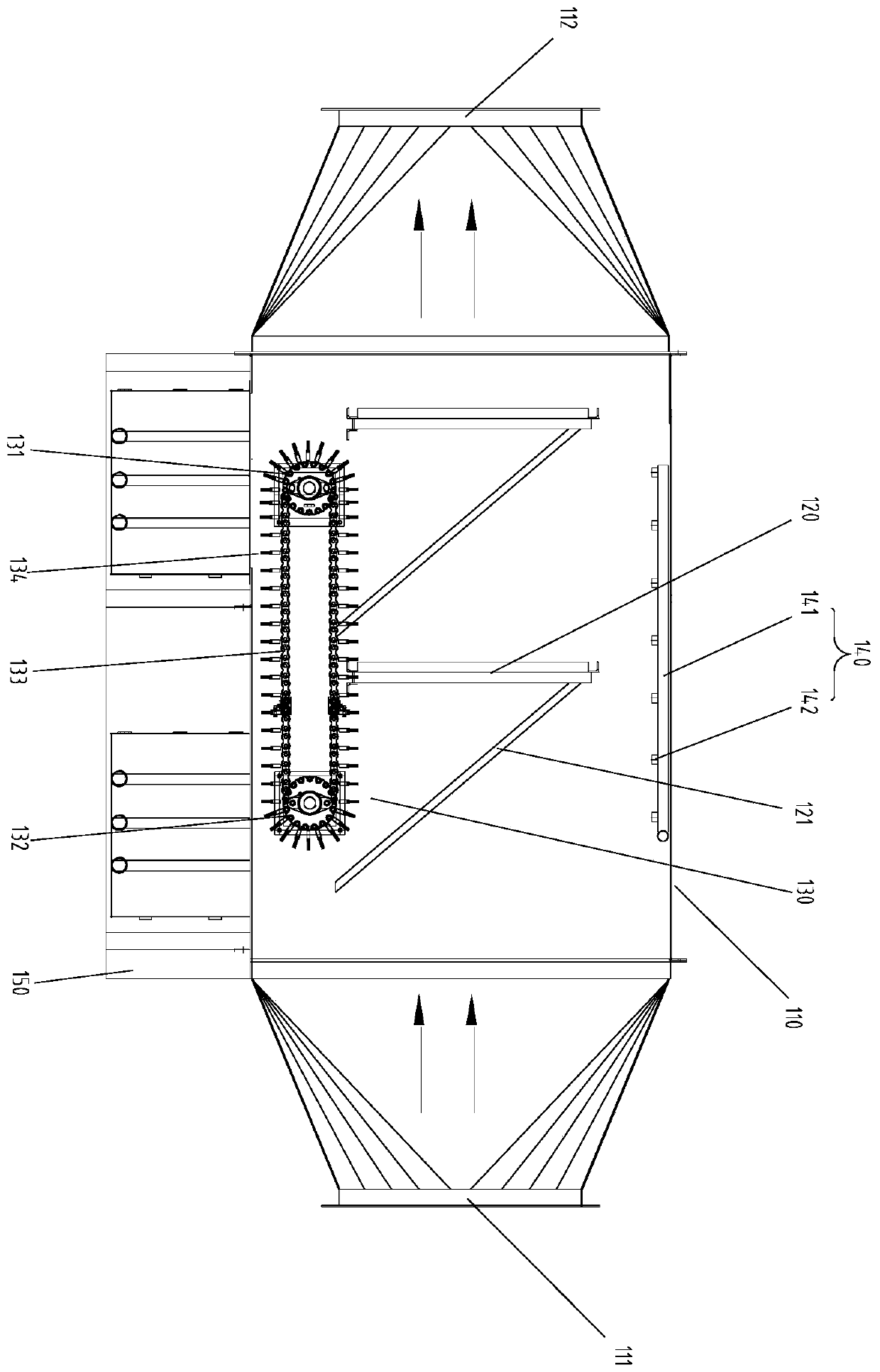

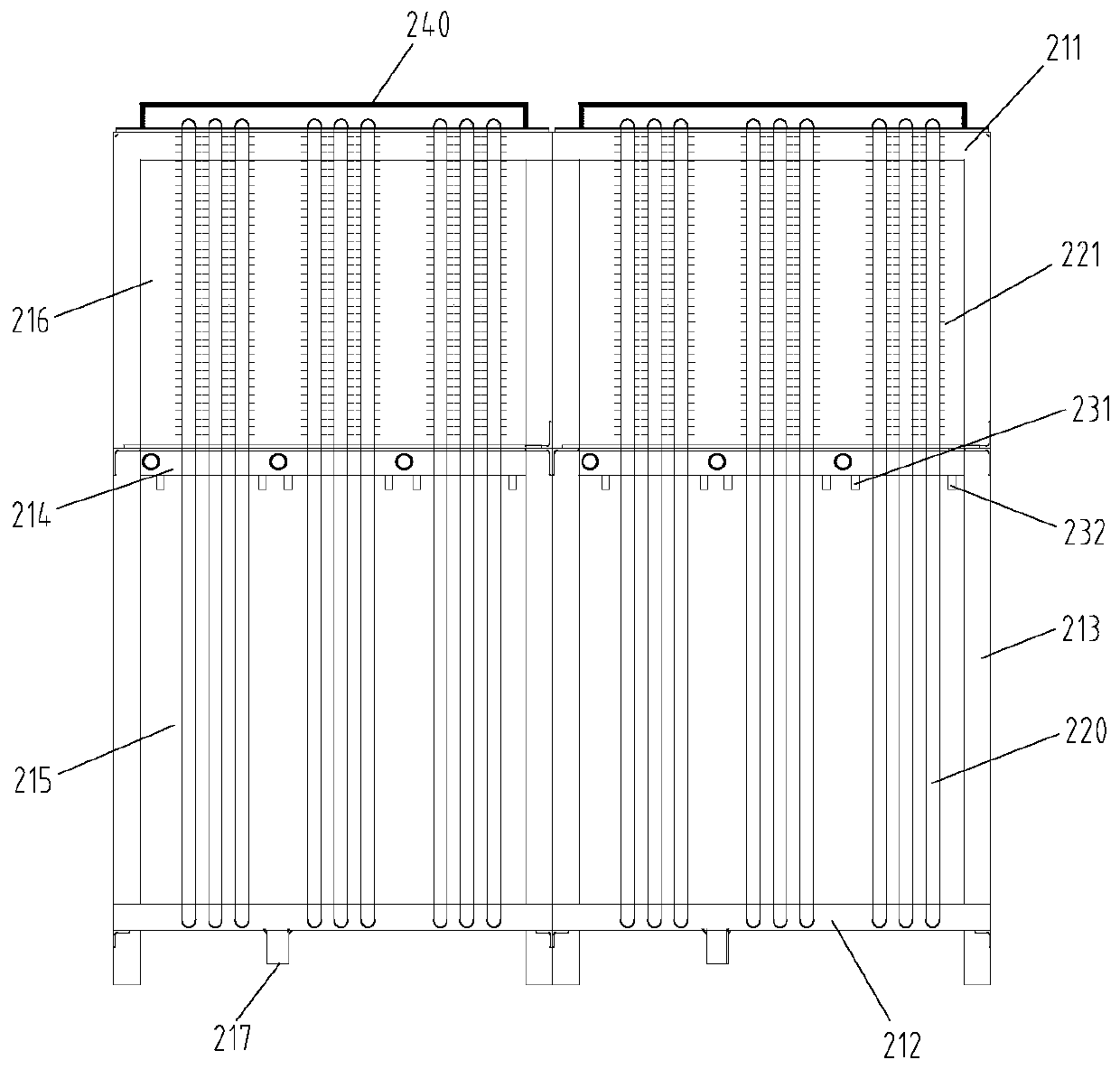

Coal gas purification system adopting rotational flow plate gas-liquid separator

InactiveCN112521984AReduce leakageImprove convenienceCombustible gas purificationThermodynamicsVapor–liquid separator

Owner:中琉科技有限公司

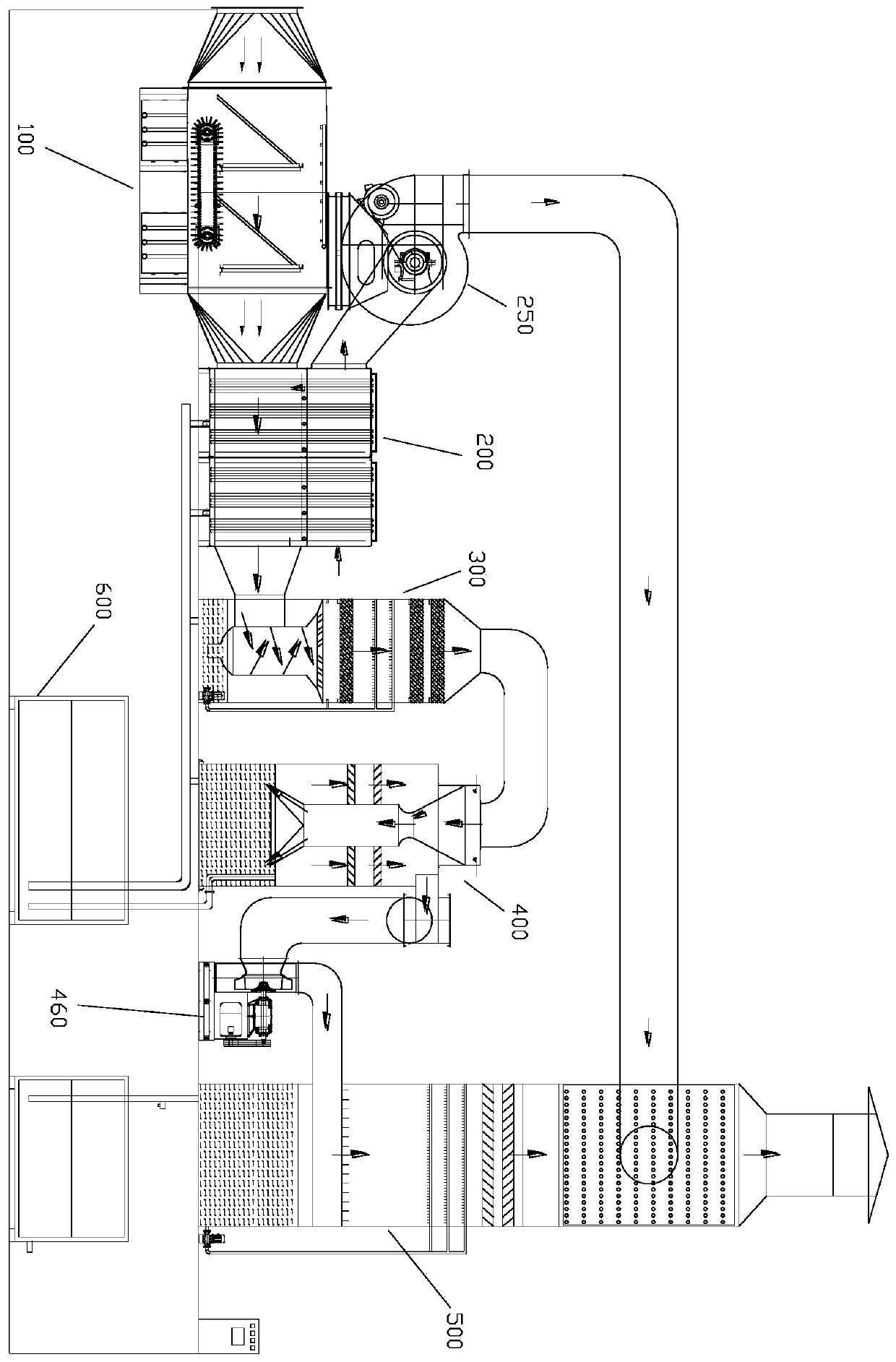

High-temperature printing and dyeing waste gas treatment equipment

PendingCN110270217AEmissions invisibleNo smellCombination devicesUsing liquid separation agentParticulatesMicrobubbles

Owner:SUZHOU BANGTIKE INTELLIGENT TECH CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap