Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Cathode material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode materials are comprised of cobalt, nickel and manganese in the crystal structure forming a multi-metal oxide material to which lithium is added.

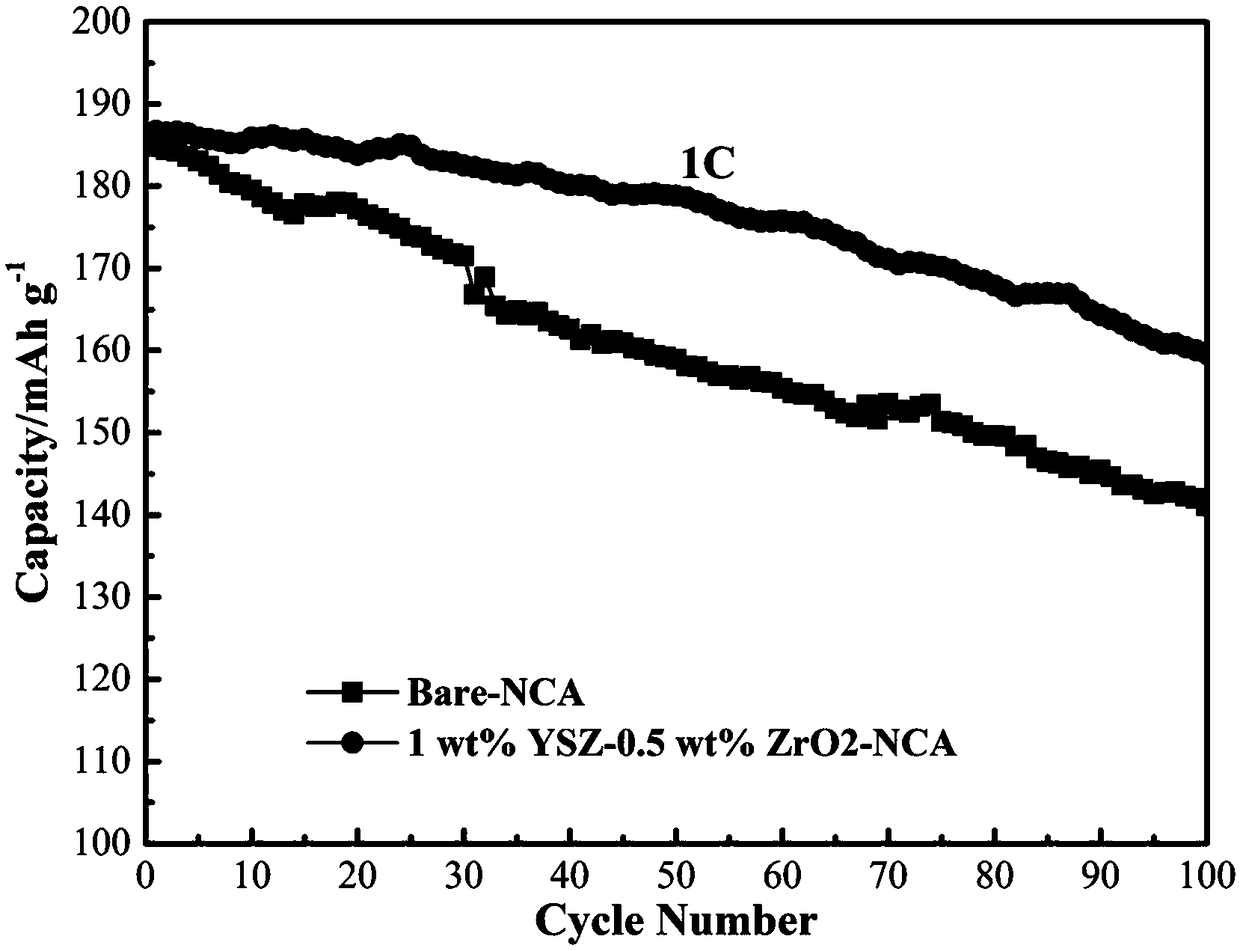

Surface coating modified lithium ion battery cathode material and preparation method thereof

InactiveCN104577093AImprove securityNo significant reduction in specific capacityCell electrodesLithium iron phosphatePhysical chemistry

Owner:ZHEJIANG MEIDARUI NEW MATERIAL TECH CO LTD

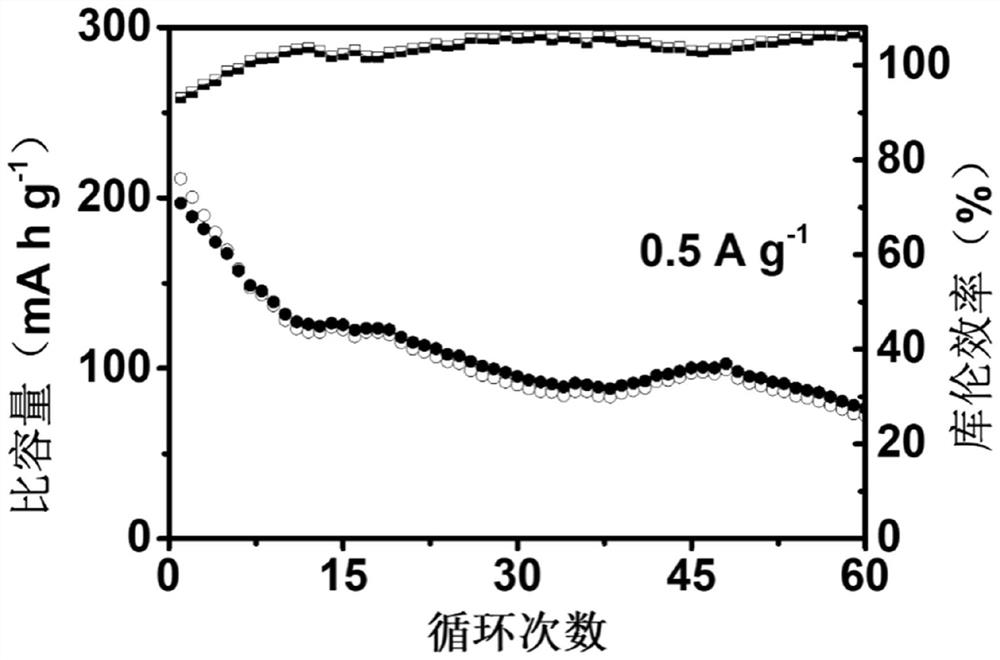

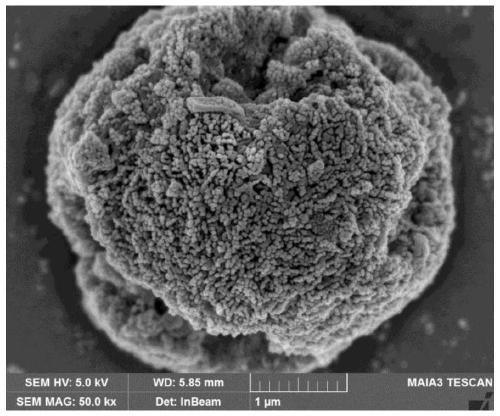

Preparation method of submicron CuS (copper sulphide) classification ball

The invention discloses a preparation method of submicron CuS (copper sulphide) classification balls. The method comprises the following steps: adding polymer into a good solvent to dissolve and remove big gel particles; adding copper source solution to the good solvent and stirring; adding sulfur source solution and then stirring; reacting the reaction liquid under 100-1,000 KPa at 100-200 DEG C; naturally cooling to the room temperature to obtain black precipitate; and washing and drying the precipitate to obtain the classification balls. The classification balls has the advantages of cheap and readily available templates, environmental friendliness, safety without toxicity, renewability and high water solubility, the contents of raw materials are abundant in nature and the operation of the reaction system is simple; the size and structure of the prepared classification ball are adjustable: the diameter can be controlled by adjusting the molar weight of the added precursor, the template concentration, the reaction temperature and time and the like; the operation is simple; and the prepared classification balls have wide application value in the fields of catalyst, catalyst carrier, optical equipment, sensor, lithium-ion rechargeable battery cathode material, superconductor and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

Electrolyte for ternary cathode material lithium ion battery and ternary cathode material lithium ion battery

InactiveCN106356562ASuppress generationPrevent agingSecondary cellsOrganic electrolytesOrganic solventInternal resistance

Owner:ZHANGJIAGANG GUOTAI HUARONG NEW CHEM MATERIALS CO LTD

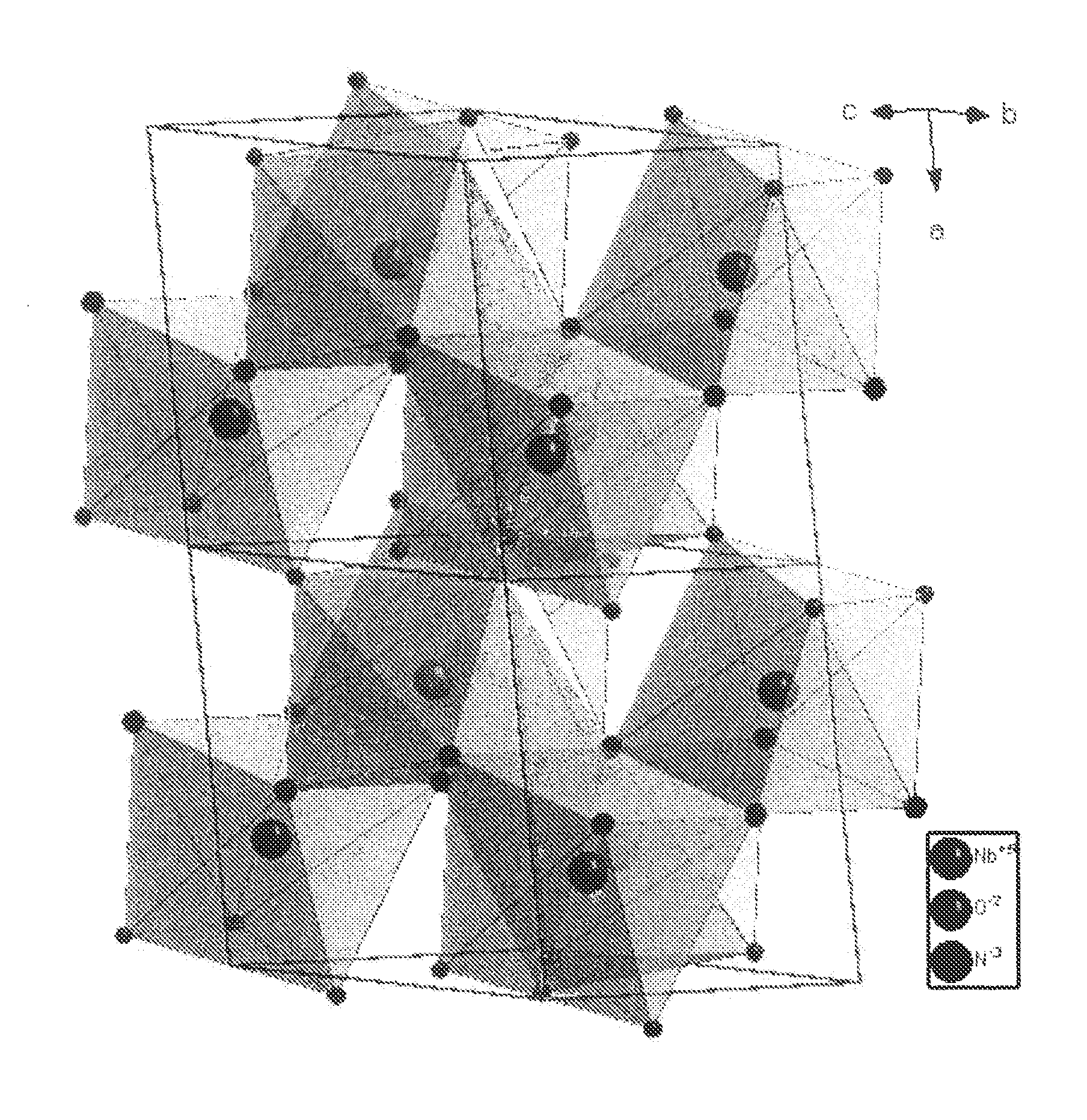

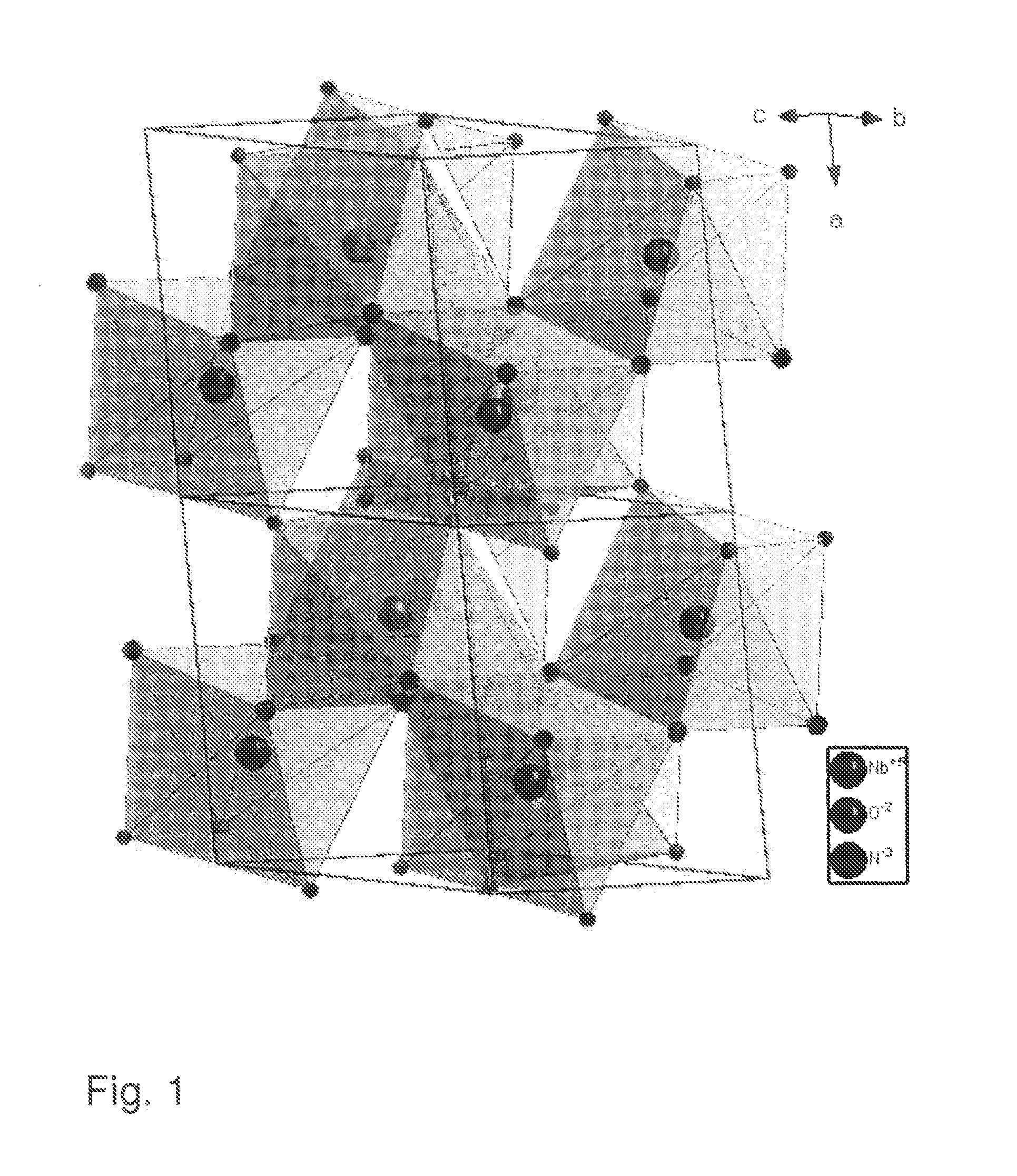

Transition metal oxidenitrides

ActiveUS20110305949A1Weight increaseImprove electrical performanceMaterial nanotechnologyNitrogen compoundsElectrical conductorNanoparticle

Owner:BELENOS CLEAN POWER HLDG

Auto-thermal evaporative liquid-phase synthesis method for cathode material for battery

InactiveUS20140239235A1Simple processReduce energy consumptionNon-metal conductorsPhosphatesInternal resistanceSynthesis methods

Owner:SHENZHEN DYNANONIC

Modified lithium-rich manganese-based cathode material for lithium ion battery

ActiveCN103682290AImprove the first Coulombic efficiencyImprove cycle performanceCell electrodesManganeseStrontium

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for preparing positive pole material for ferrous phosphate lithium battery from low-valence oxygen-containing acid of phosphorus

InactiveCN101332984ALow costWide variety of sourcesCell electrodesPhosphorus compoundsPhosphateFerrous salts

Owner:FUJIAN NORMAL UNIV

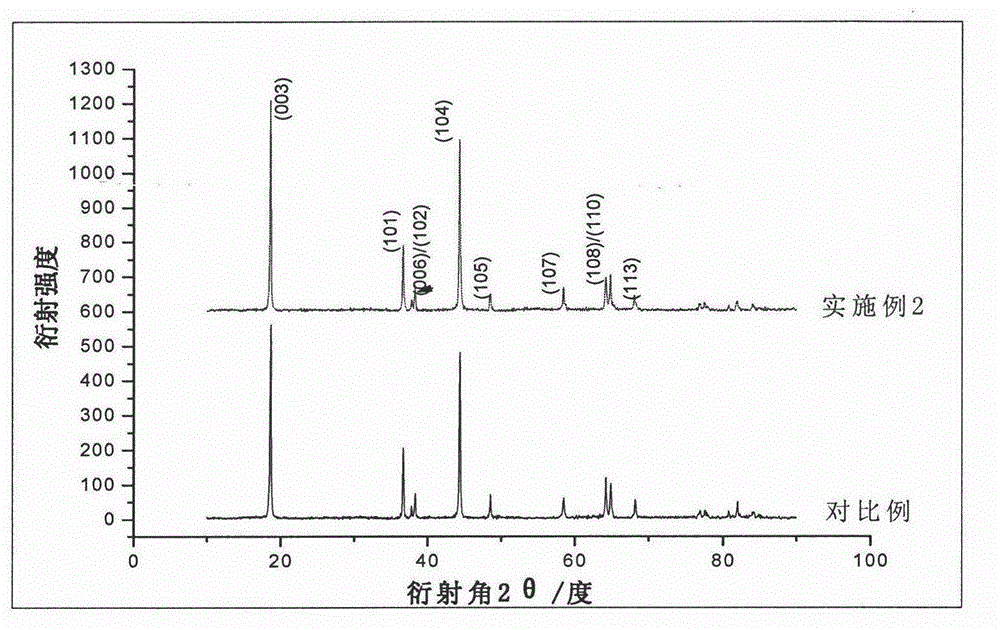

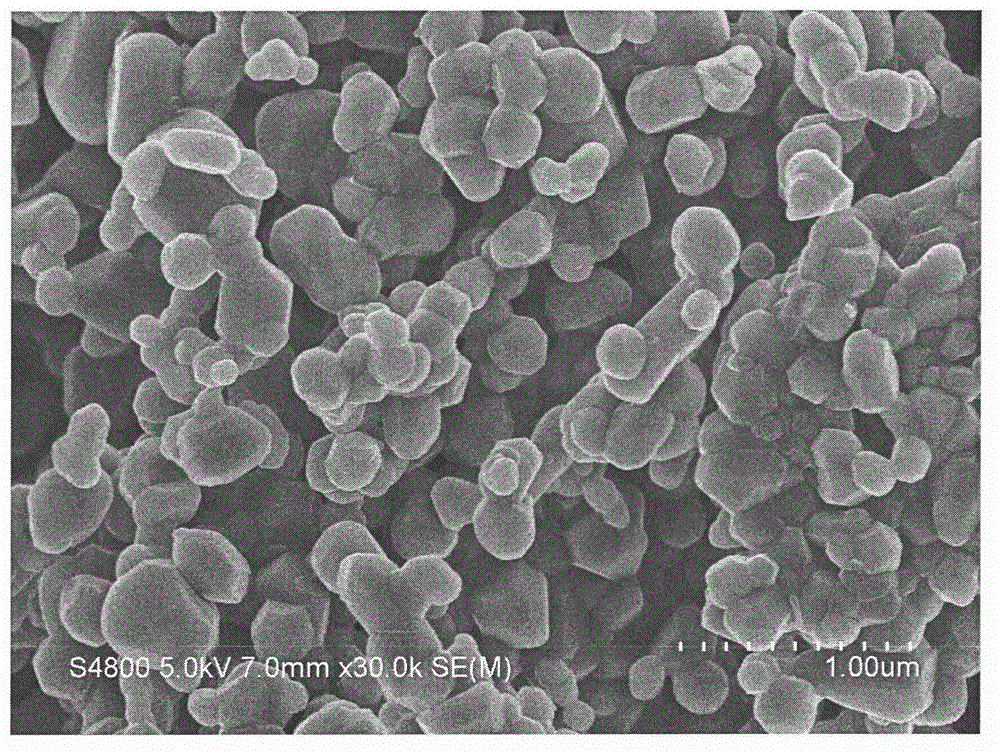

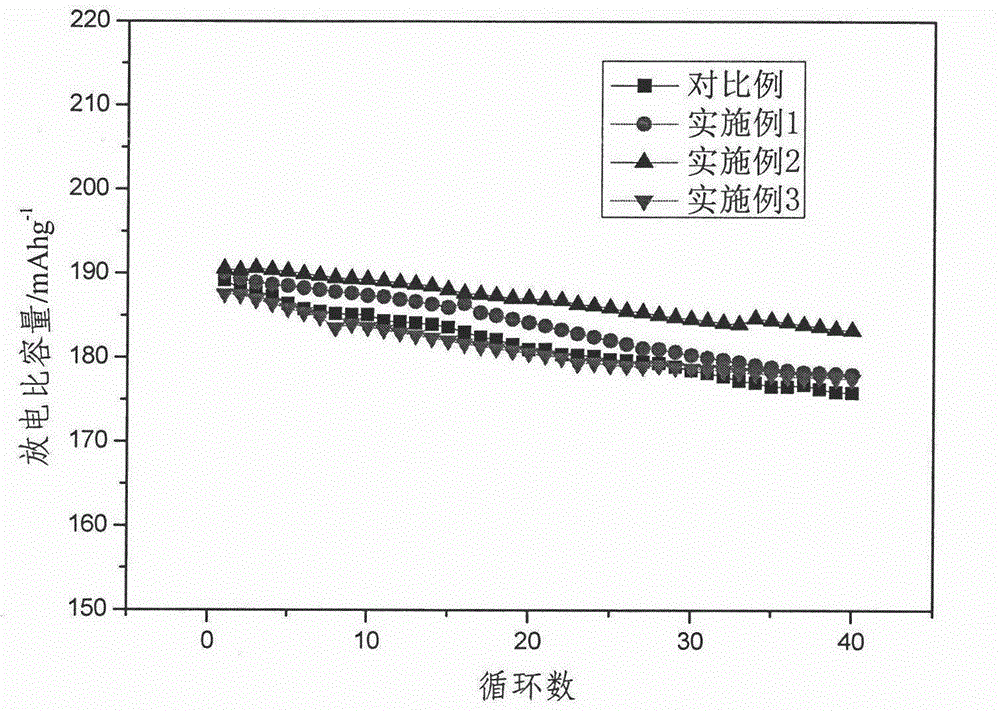

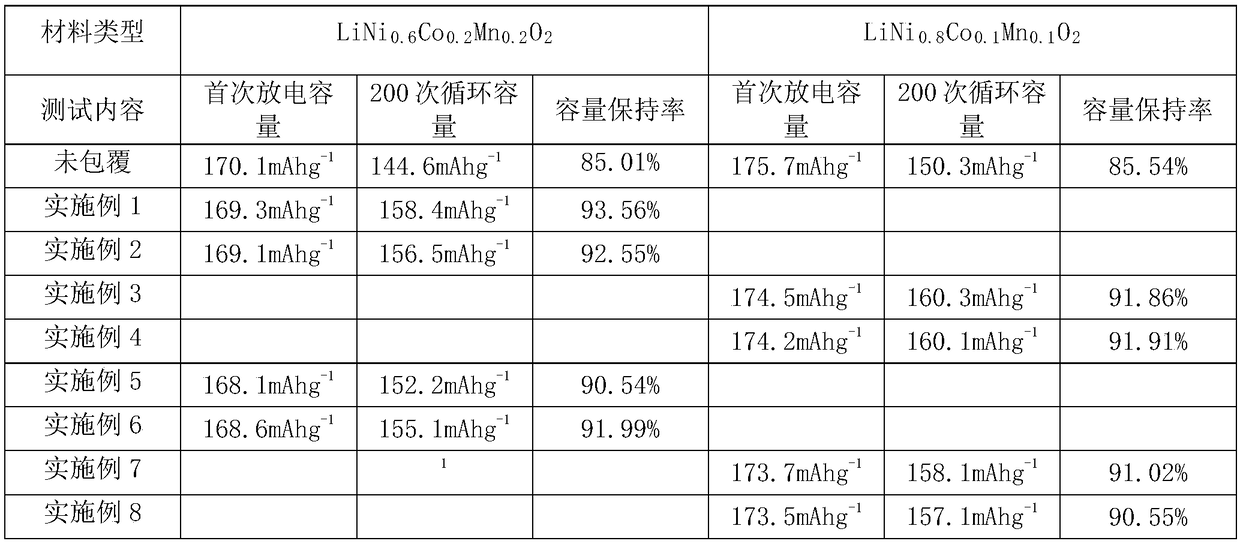

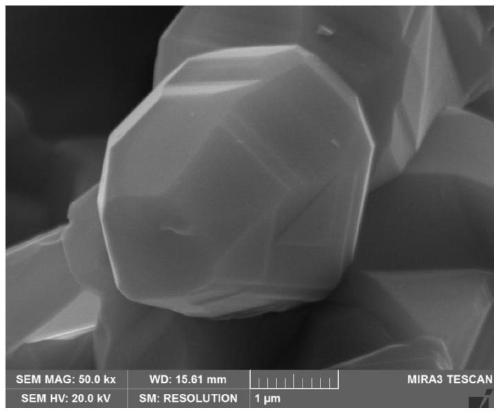

Anion doped modified lithium ion battery (4:4:2) type ternary cathode material and preparing method thereof

InactiveCN103943841AUniform particle size distributionHigh crystallinityCell electrodesSecondary cellsLithium electrodeCathode material

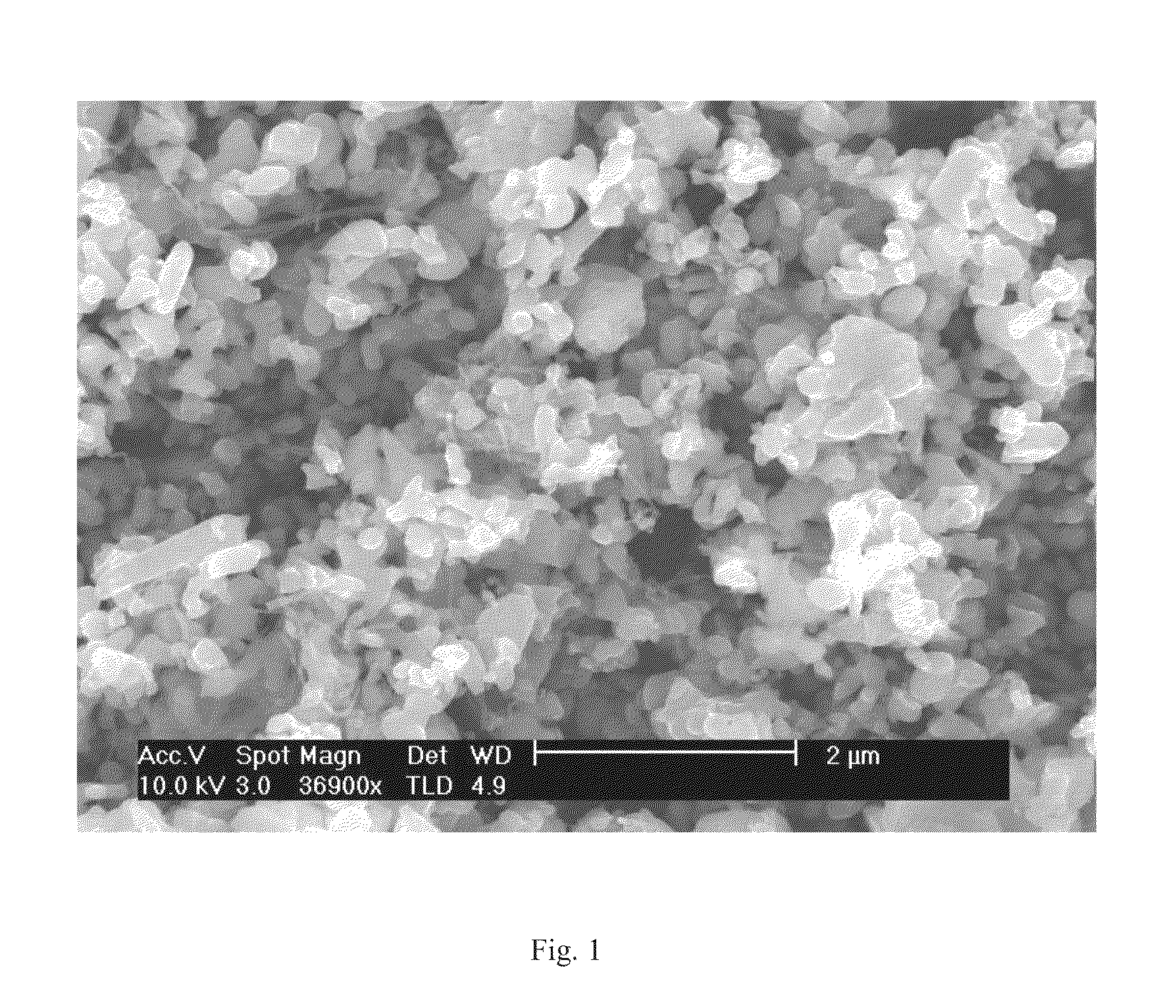

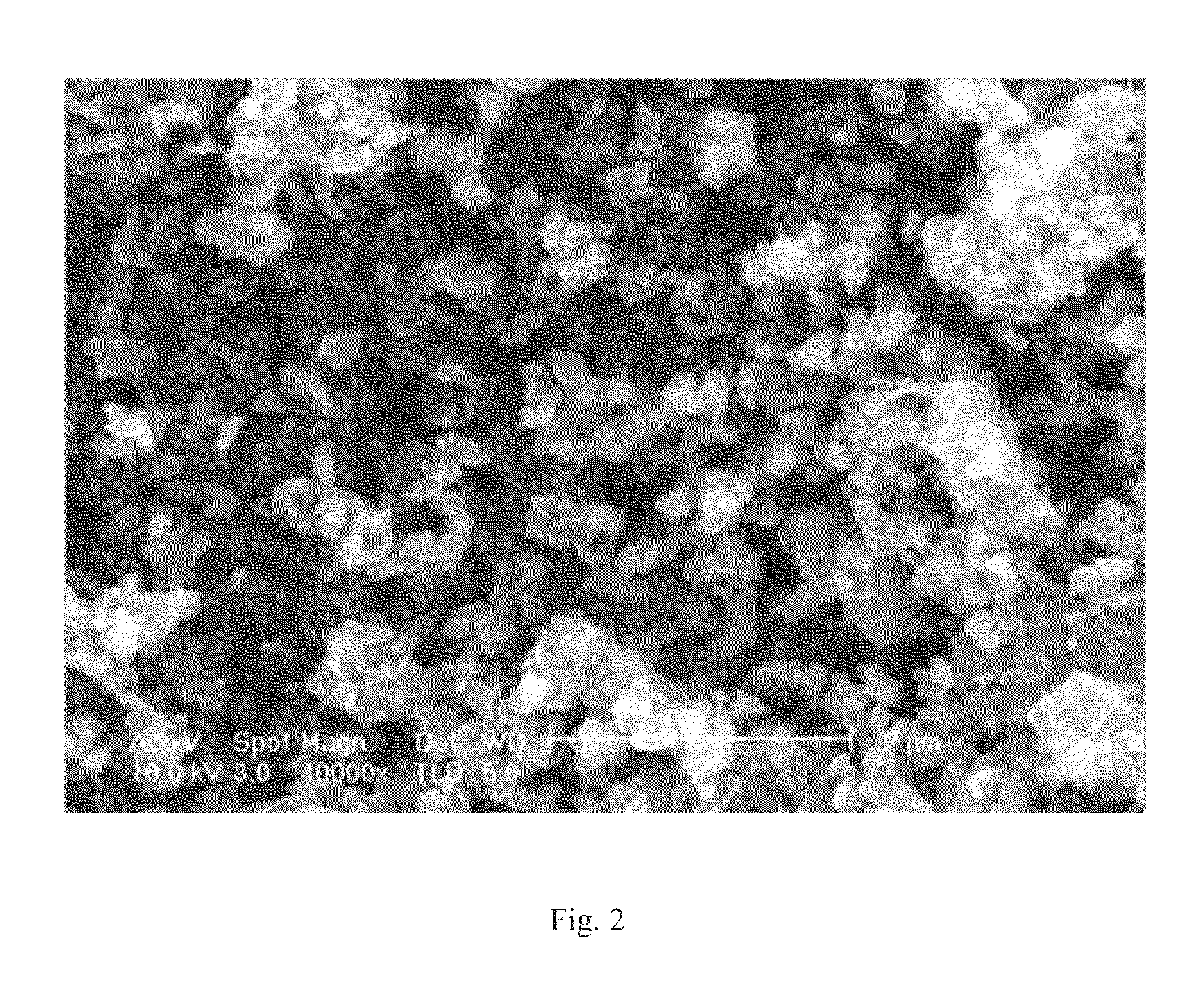

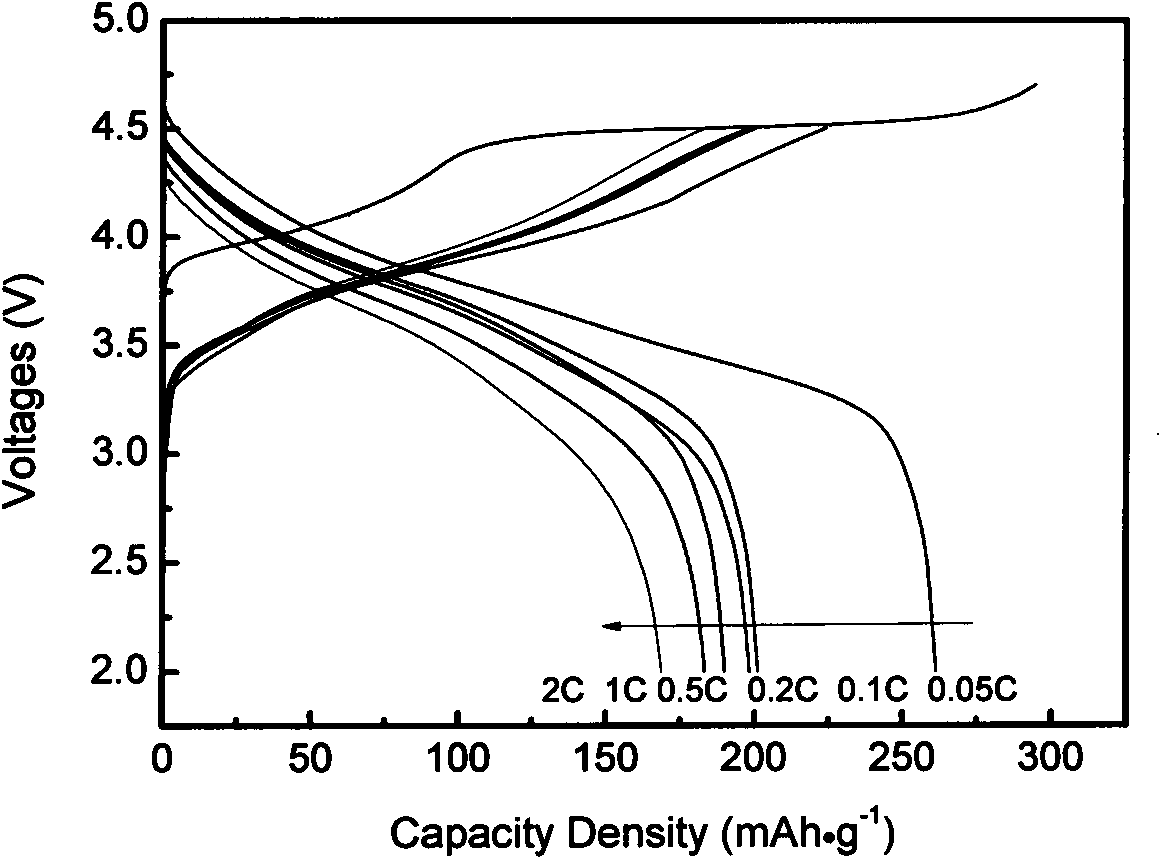

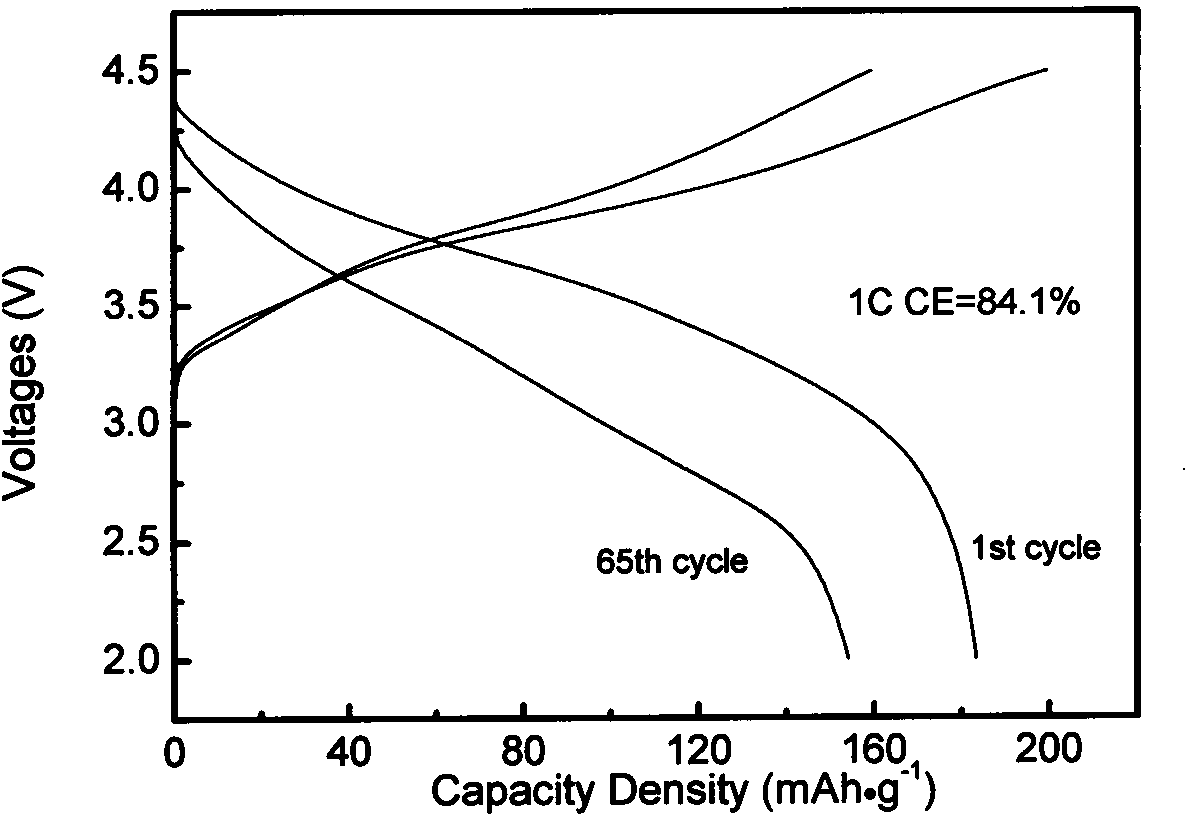

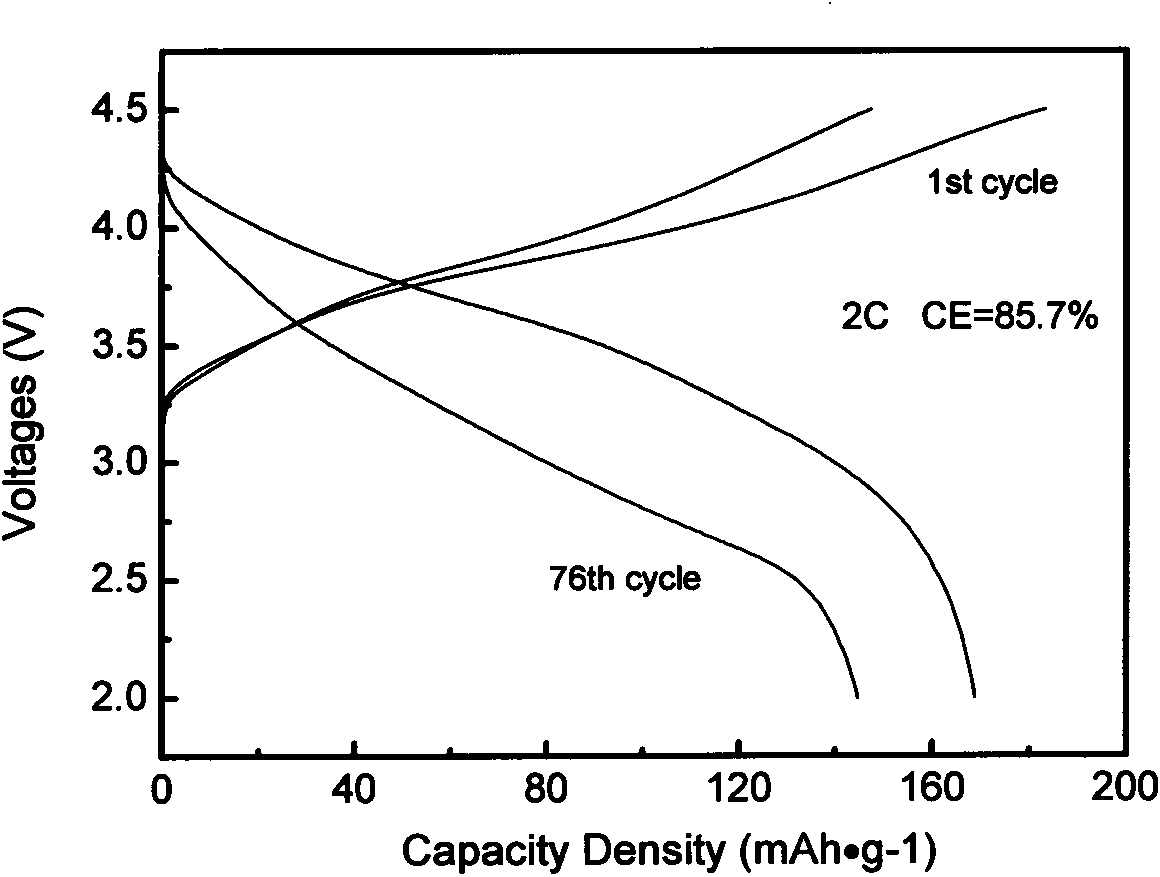

The invention relates to an anion doped modified lithium ion battery (4:4:2) type ternary cathode material and a preparing method thereof, and belongs to the field of lithium ion batteries. The general chemical formula of the cathode material is LiNi<0.4>Co<0.2>Mn<0.4>O<2-z>Xz, wherein the X is F, Cl or Br; and the Z is more than 0 and not more than 0.15. The method includes steps of: weighing a soluble lithium salt, a nickel salt, a manganese slat, a cobalt salt and an X salt according to a molar ratio, dissolving the weighed compounds separately with deionized water, adding a citric acid solution and mixing and stirring uniformly, adjusting the pH value by utilization of concentrated ammonia liquor, heating and evaporating to obtain gel, heating and drying the gel, and performing two times of firing and grinding to obtain the anion doped modified lithium ion battery (4:4:2) type ternary cathode material. Particles of the lithium ion battery cathode material are fine and uniform and reach the nanometer level, so that the cathode material has characteristics of high discharge capacity, excellent cyclic stability and rate capacity, capability of maintaining the properties at high or low temperature conditions, convenience for large-scale industrial production, and high practical degree.

Owner:JIANGNAN UNIV

Lithium ion battery cathode and its preparation method and battery

InactiveCN102487136AOmit mixingOmit coatingElectrode carriers/collectorsSecondary cellsElectrical batteryAlloy

Owner:BYD CO LTD

Sagger with high-yield for lithium battery cathode material and manufacturing method thereof

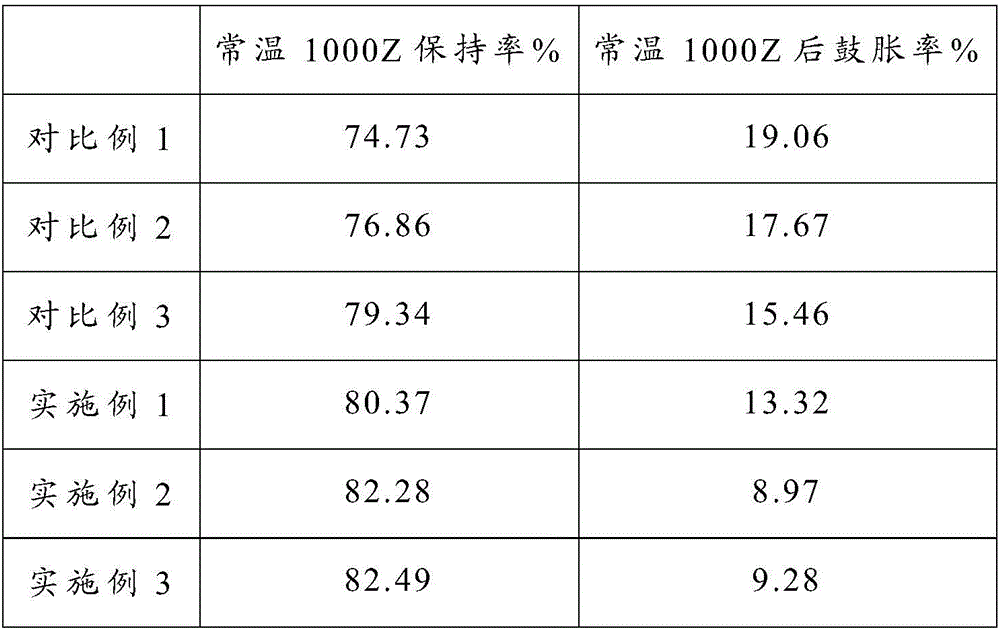

The invention discloses a sagger with high-yield for a lithium battery cathode material. The sagger comprises a sagger body and a protective coating, wherein the sagger body comprises: 50-70% of mullite, 10-30% of alpha-alumina, 5-15% of an organic metal salt, and 1-5% of a binder; and the protective coating comprises: 30-40% of silicon carbide coarse powder, 30-40% of silicon carbide fine powder,10-20% of polyacrylate, 1-10% of methanol, and 0.1-0.5% of attapulgite. A manufacturing method of the sagger comprises the following steps: weighing the raw materials constituting the sagger body, and adding water to form a slurry; placing the slurry in a mold, and performing press-forming to obtain a blank material; performing demoulding on the blank material after curing to obtain a blank body,and oven-drying the blank body after demoulding and then performing firing to obtain the sagger body; weighing the raw materials of the protective coating, and adding water to form a coating; covering the coating on the inner surface of the sagger body, and performing natural drying; and performing firing. The disclosed sagger for the lithium battery cathode material has high yield, high servicelife and corrosion resistance.

Owner:HUNAN TAIZI NEW MATERIAL TECH CO LTD

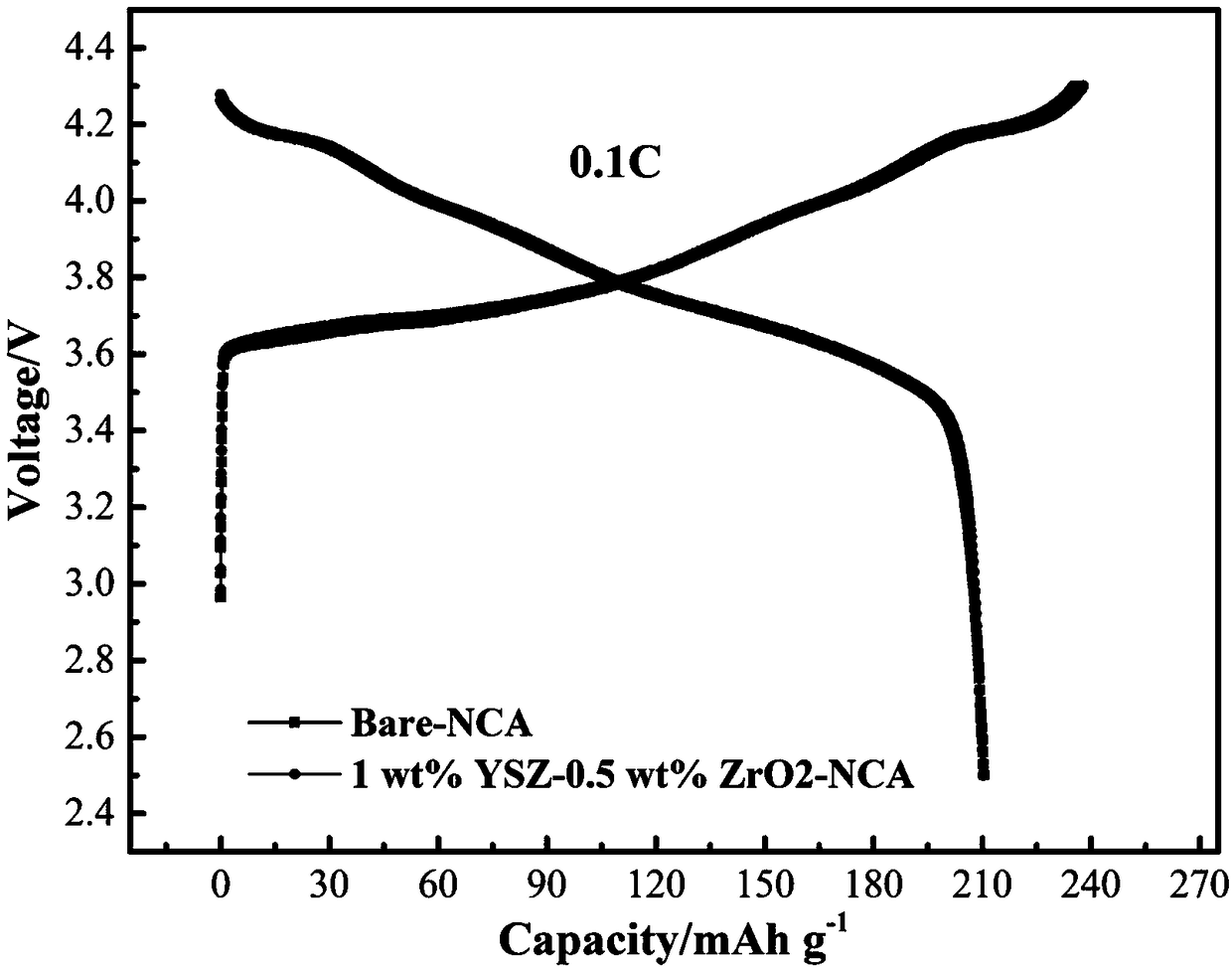

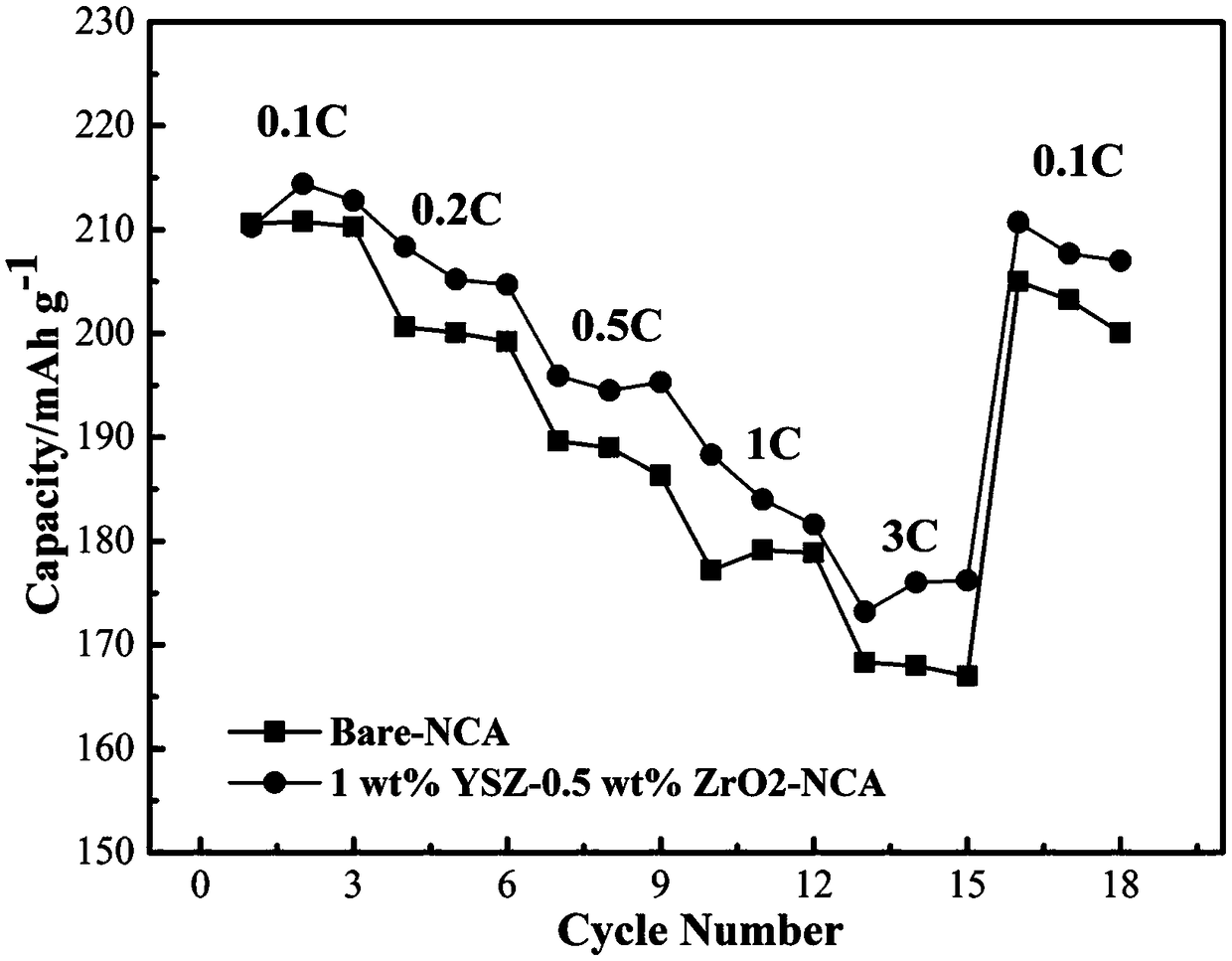

A surface modify ternary cathode material, a preparation method thereof, and a battery made of that surface modified ternary cathode material

ActiveCN109065858APromote migrationFast migration rateCell electrodesSecondary cellsOxygen vacancyMagnification

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

Preparation method of silicon-coated modified ternary cathode material

Owner:浙江德升新能源科技有限公司

Preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor

The invention discloses a preparation method of battery cathode material lithium nickel cobalt aluminum oxide precursor and relates to the technical field of batteries. The preparation method comprises the steps of (1) preparing nickel-cobalt solution; (2) preparing precipitate; (3) purifying the precipitate; (4) preparing a premix; (5) roasting an end product. The lithium nickel cobalt aluminum oxide precursor is prepared by means of aluminum nitrate roasting; the difficulty in forming large particulate precipitate due to high precipitating speed of trivalent aluminum ions is avoided; the lithium nickel cobalt aluminum oxide precursor that is roasted has high true density. In addition, roasting allows fewer acid radicals to be left in the precipitate, and the purity of the lithium nickelcobalt aluminum oxide precursor is further improved accordingly.

Owner:HEFEI CHENGDIAN TECH CO LTD

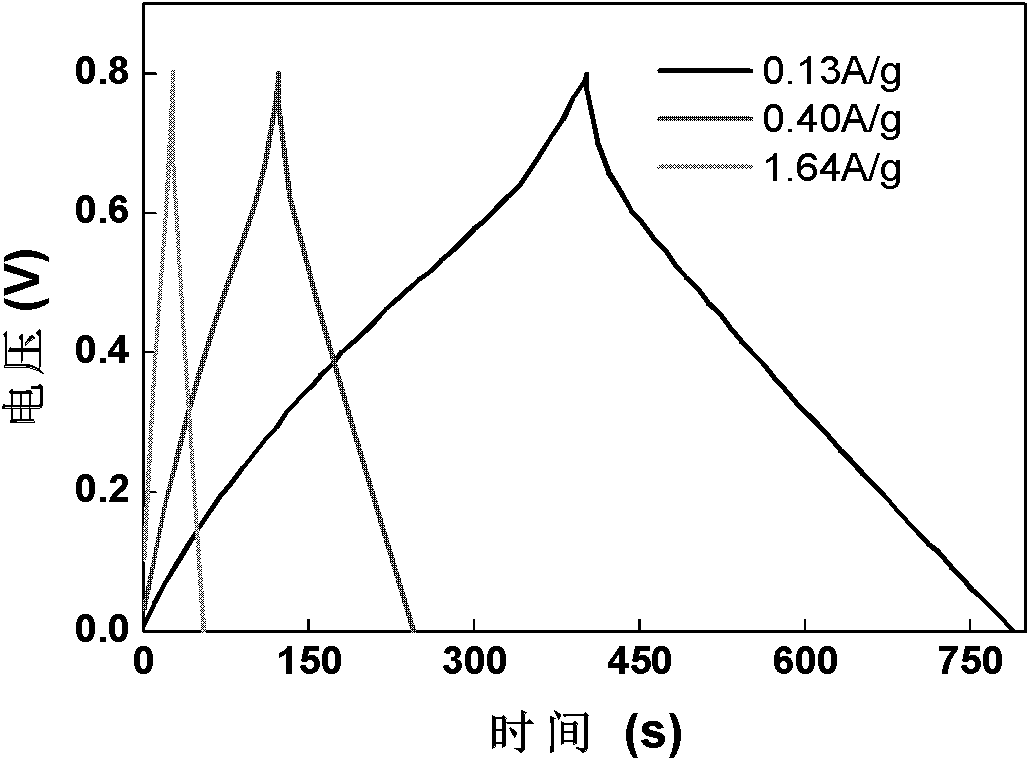

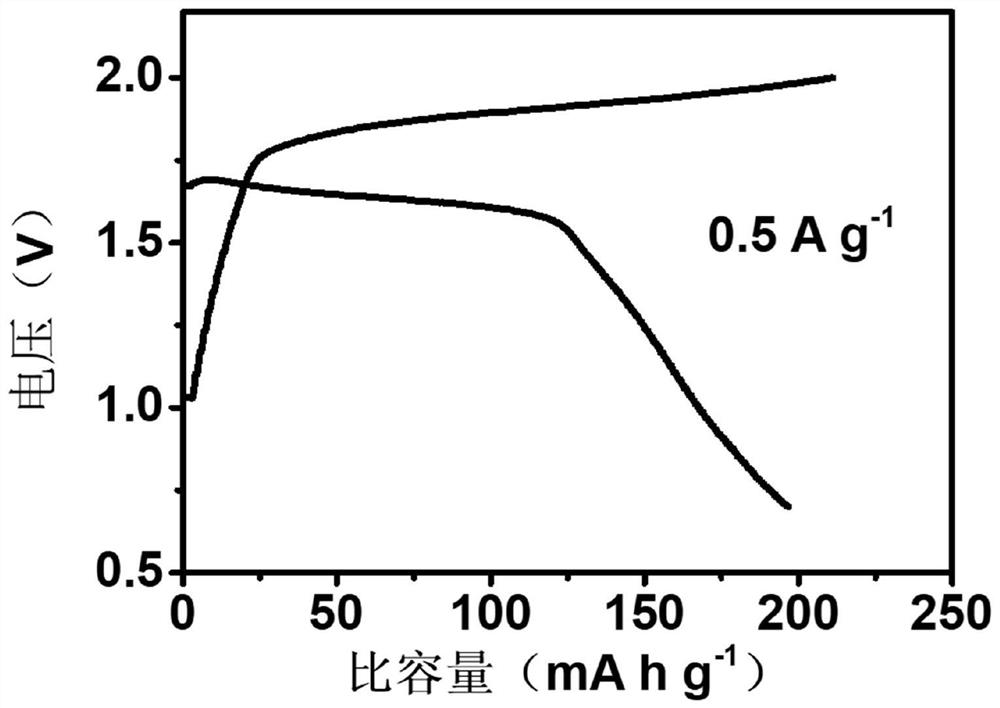

Stable lithium ion battery with high capacitance

InactiveCN103606666AImproved high-magnification performanceImprove power densityCell electrodesSecondary cellsCapacitanceManganese

The invention discloses a stable lithium ion battery with high capacitance. Two poles are respectively prepared from a composite carbon cathode material and a ternary composite anode material. By adopting the stable lithium ion battery, the high magnification performance and the power density of the lithium ion battery can be effectively improved. The stable lithium ion battery has high-magnification charge and discharge properties. Three transition metals such as nickel, manganese and cobalt are evenly mixed, so that a layered structure of the material is stabilized by synergistic effects of the nickel, manganese and cobalt, and the charge and discharge capacities, the cycle performance and the overcharging tolerance of the material are improved.

Owner:JIANGSU TENPOWER LITHIUM

Secondary battery anode material

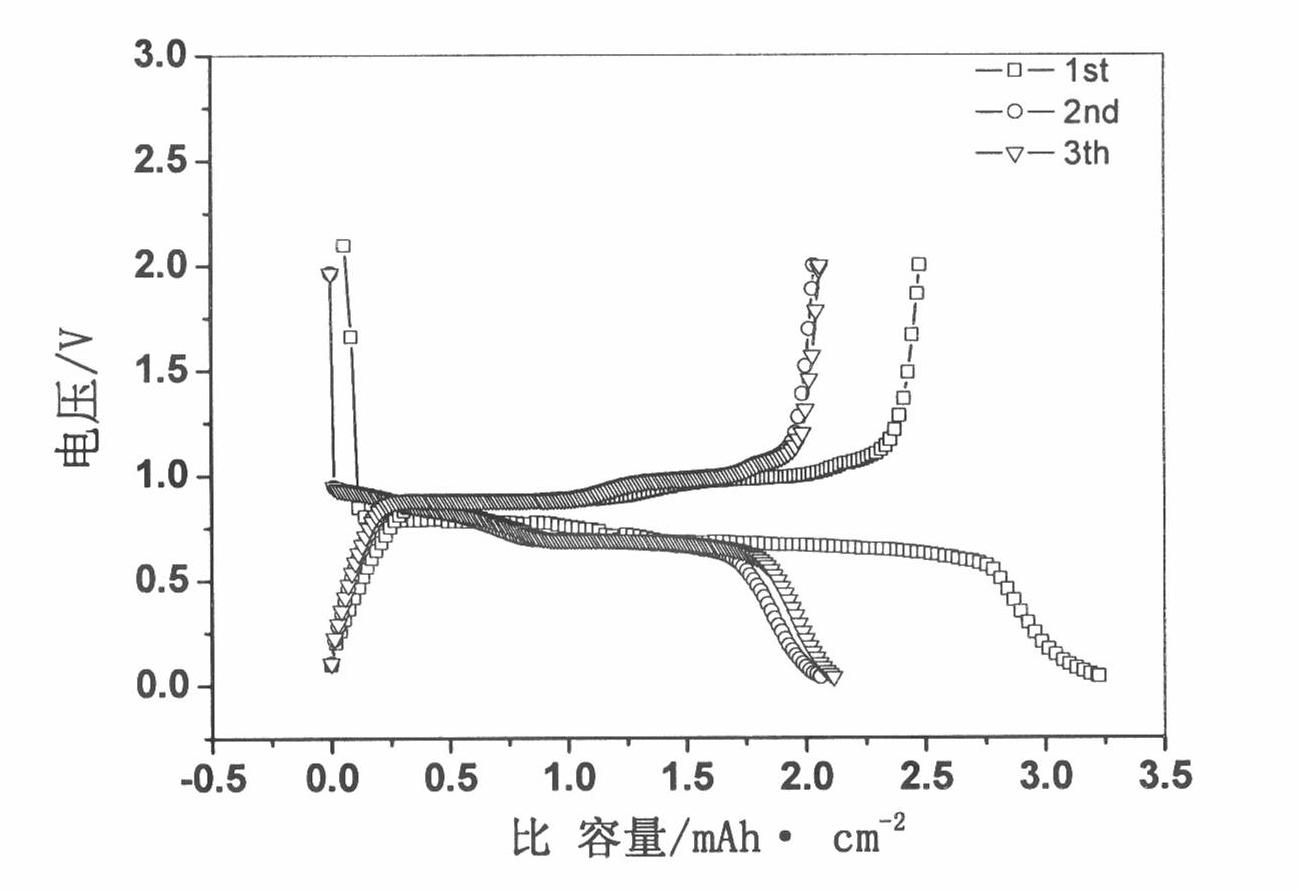

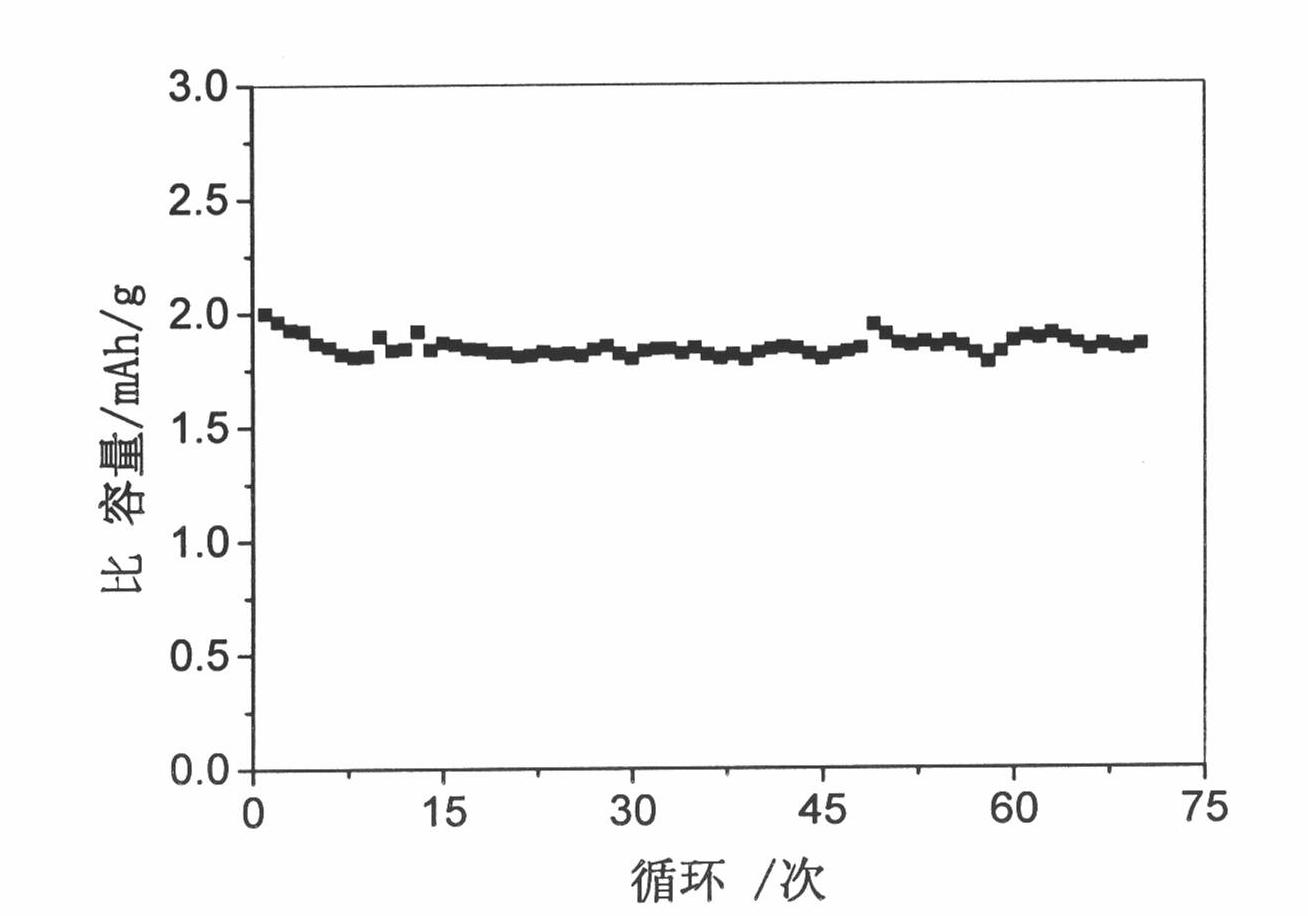

InactiveCN106299370ASolving intractable dendrite problemsCell electrodesElectrochemical responseElectron

The invention discloses a secondary battery anode material. The material comprises a framework, chelating / adsorption groups and active substances. The framework does not participate in electrochemical reaction and just provides carriers for the chelating / adsorption groups; the chelating / adsorption groups outer layer electrons of contained atoms such as N, S, P and O which have lone pair electrons and can form chelating or chemisoptive bonds (represented by iminodiacetic acid chelating groups in the drawing) along with divalent or multivalent metals; the active substances are divalent or multivalent metal ions which can be reduced into a lower-valence state. During charging, the metal ions used as the active substances are reduced into a lower-valence state or metal elementary substance state, and during discharging, metal ions can be reversibly produced and can form ionic bonds or coordination bonds along with the chelating / adsorption groups. The anode material can be matched with many cathode materials to form a battery. The battery anode disclosed by the invention is novel in principle and structure, and is very expected to be applied to electric automobiles and large-size energy storage projects due to low cost and high reliability.

Owner:颜竞

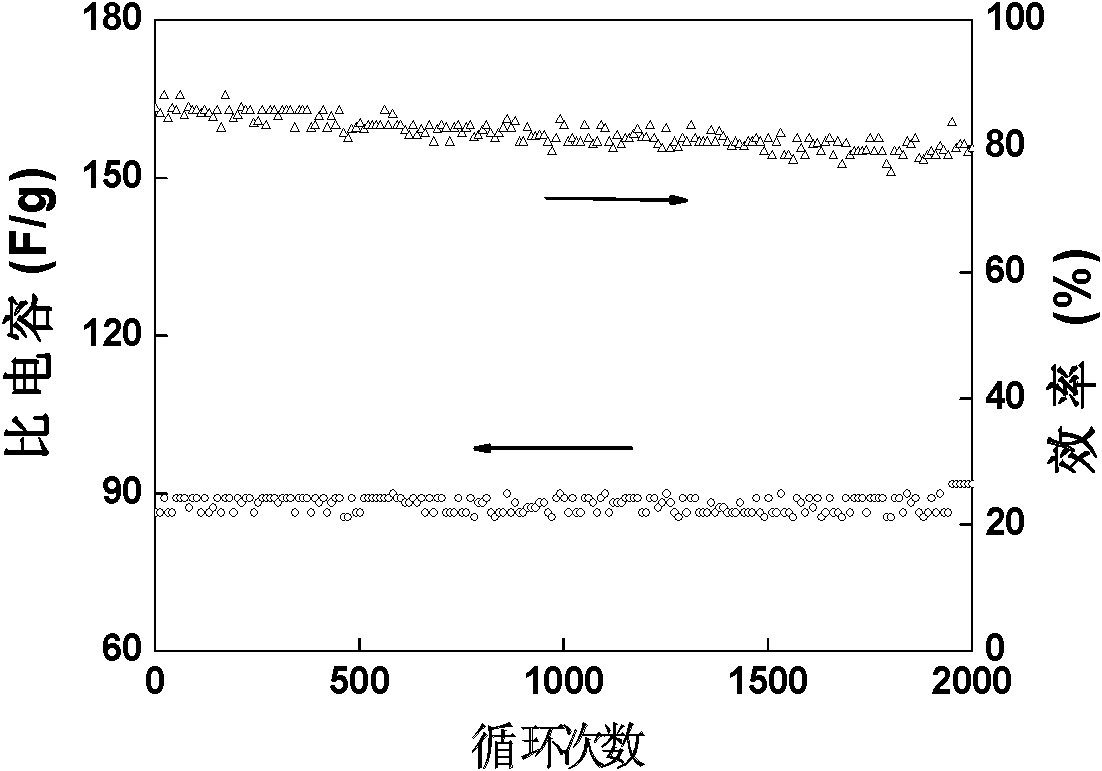

A preparation method of nanometer metatitanic acid doped polyaniline composite electrode material for supercapacitor

ActiveCN102280265AIncrease capacitance densityIncrease energy densityElectrolytic capacitorsCyclic processCapacitance

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Coating method of lithium ion battery cathode material

ActiveCN108767232AFull and effective contactUniform particle size distributionCell electrodesSecondary cellsImpellerEngineering

The invention discloses a coating method of a lithium ion battery cathode material. According to the method, disk-nest grinding equipment is utilized to continuously input a lithium ion battery cathode material to be covered into a disk-nest grinder in a form of solid powder, solid powder is dispersed by an impeller and a disk which rotate at a high speed in a cavity of the disk-nest grinder, multiple nest type rotational flows are formed between the disk and a special lining plate, and air flow impact force between the disk and the special lining plate can fully disperse the solid powder; meanwhile, the rotation speed can be controlled to make a powder material keep morphology or be smashed; furthermore, a coating material can enter the disk-nest grinder in a form of solution or slurry ina mist spray mode and can evenly contact certain-temperature solid powder particles to be covered to finish coating. By means of the lithium ion battery cathode material coating method, a traditionalcoating technology for an existing lithium ion battery cathode material is greatly simplified, productivity is remarkably improved, a product coating effect is greatly improved, and cost is obviouslyreduced.

Owner:CENT SOUTH UNIV

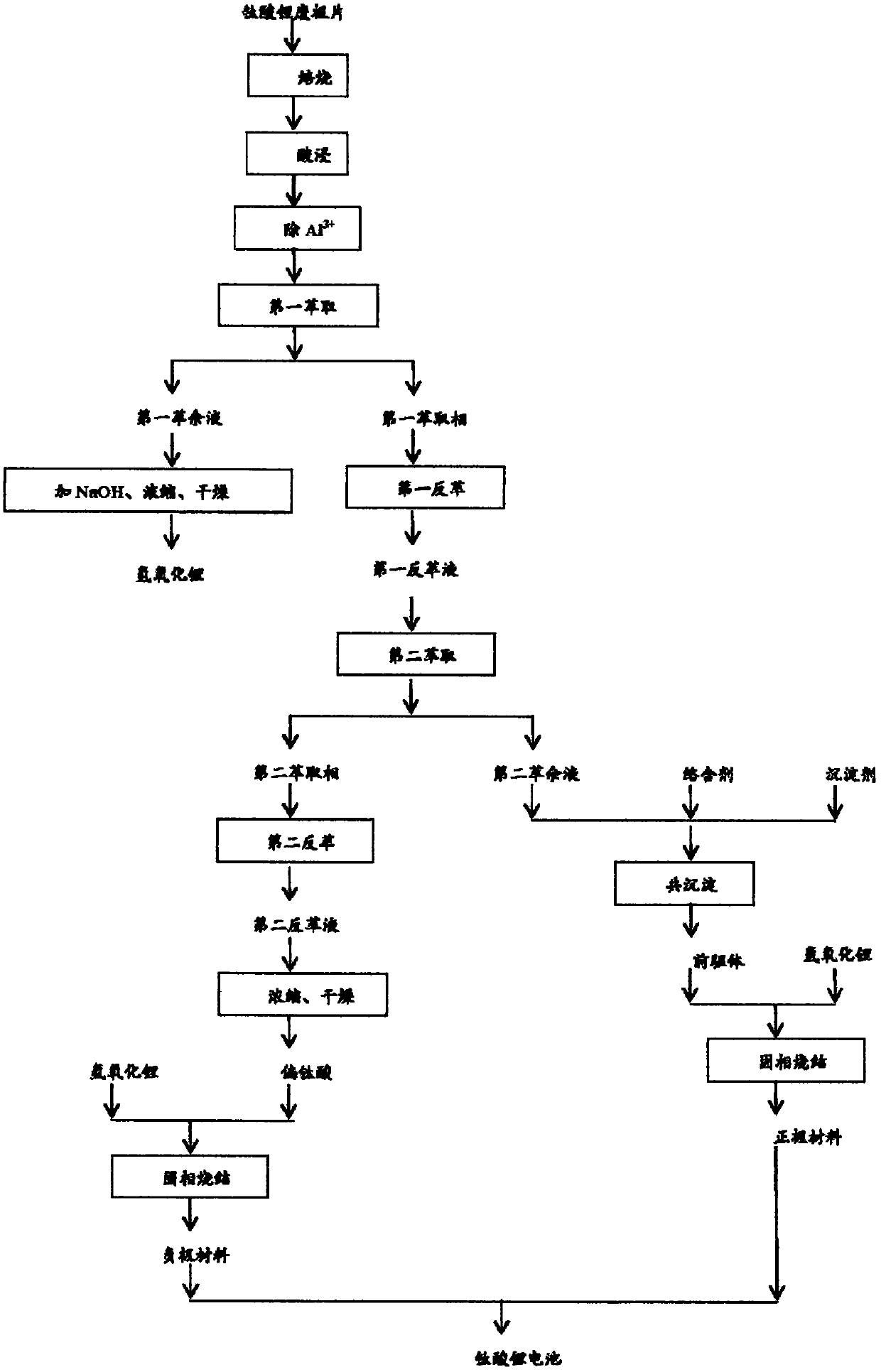

Method of recycling electrode metal material from waste lithium titanate battery

ActiveCN110735038AAvoid pollutionRealize recyclingWaste accumulators reclaimingProcess efficiency improvementMetallic materialsEnvironmental engineering

Owner:浙江遨优动力系统有限公司

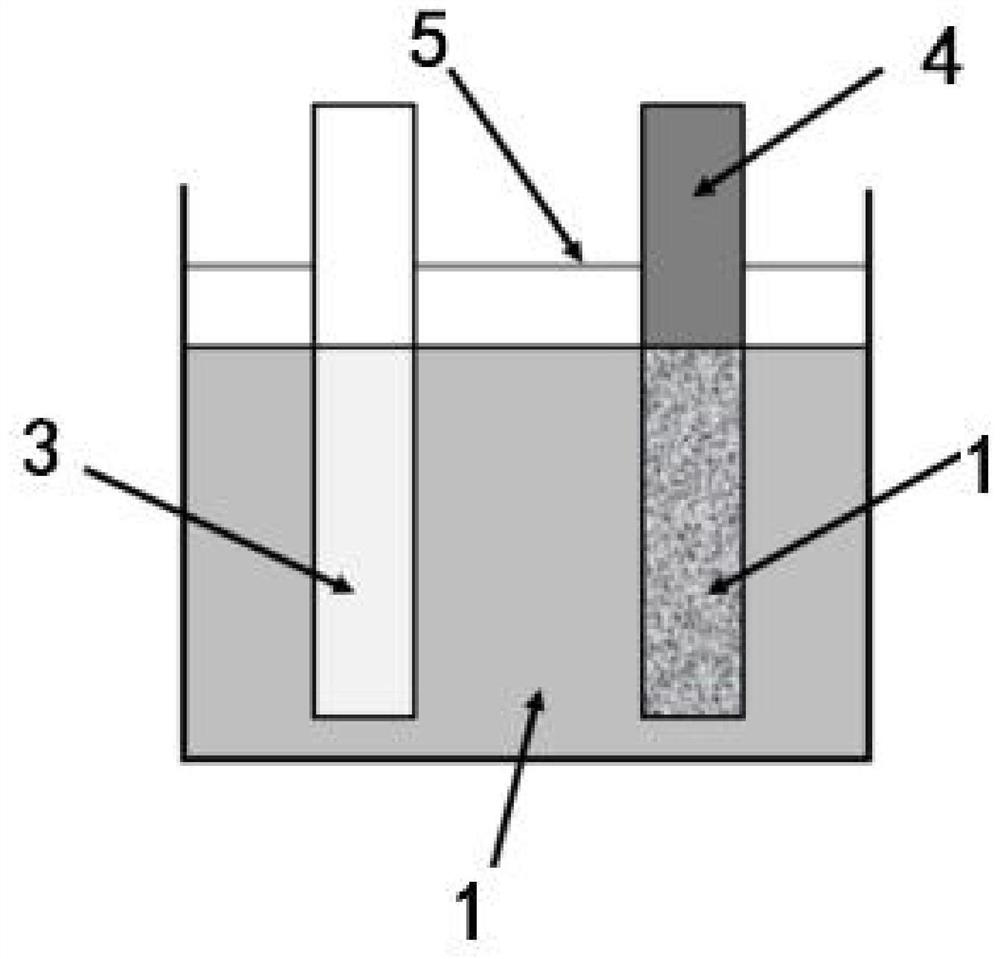

Novel aqueous magnesium metal secondary battery and preparation method thereof

PendingCN113363598AImprove scene adaptabilityAchieve reversible electrochemical deposition dissolutionCell electrodesFinal product manufactureElectrolytic agentMg alloys

Owner:SONGSHAN LAKE MATERIALS LAB

Preparation method of special-morphology micro nano structural lithium-rich manganese-based cathode material

ActiveCN110143619AAchieving controllable equipmentRealize controllable preparation of special morphologyMaterial nanotechnologyPositive electrodesNickel saltHigh energy

Owner:JISHOU UNIVERSITY

Carbon-coated lithium ion battery cathode slurry and preparation method thereof

InactiveCN108539176AEfficient Control of ConsistencyControl consistencySecondary cellsPositive electrodesSlurryLithium-ion battery

The invention relates to a lithium ion battery, and particularly discloses carbon-coated lithium ion battery cathode slurry and a preparation method thereof. The battery cathode slurry which serves asa main composition of a lithium ion battery has high discharge capacity and good cycle performance, in a preparation process, long-time roasting under the condition of carbon source coating is not required, consistency of materials is controlled effectively, preparation raw materials are easily obtained, the preparation method is simple, and the promotion and application value is high. The process of roasting for a long time under the condition that a carbon source exists is adopted to obtain a carbon-coated cathode material in the prior art is omitted, and the shortcomings that transition metal ions are partially reduced due to overtime roasting and thus the consistency of the materials is not easy to control are overcome.

Owner:WUHU ZHEXIN NEW ENERGY

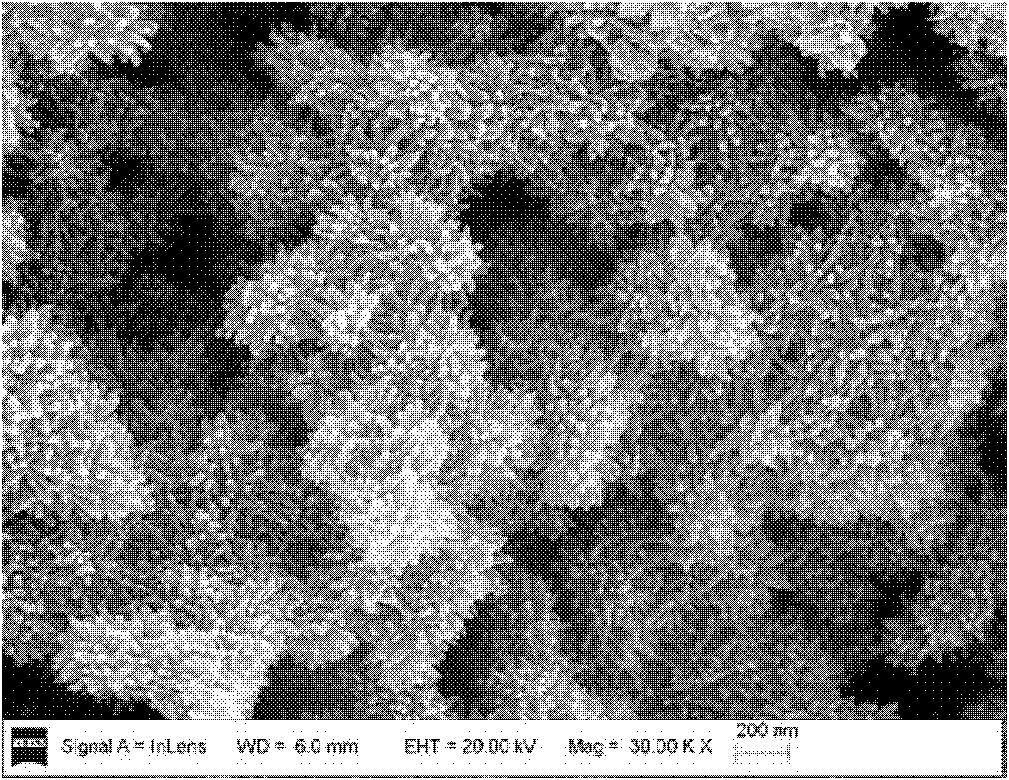

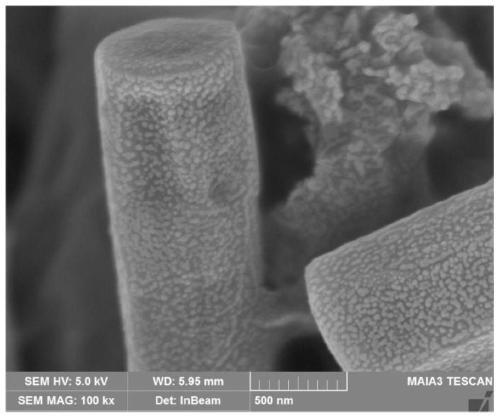

Preparation method of double-layer porous carbon nanofibers for lithium-sulfur batteries and method for preparing positive electrode materials using the same

ActiveCN106848314BAlleviate huge volume changesImprove stabilityCell electrodesNanotechnologyFiberAir atmosphere

The invention discloses a method for preparing dual-layer porous carbon nano-fibers for a lithium-sulfur battery and a method for preparing a cathode material by utilizing the dual-layer porous carbon nano-fibers. The method for preparing the dual-layer porous carbon nano-fibers comprises the following steps: (1) extruding core spinning liquid and cortex spinning liquid at the same time from a coaxial static spinning needle to a receiving net under the effects of high-speed airflow and electrostatic voltage by utilizing airflow coaxial electrospinning so as to obtain nascent fibers; and (2) insulating the nascent fibers at an air atmosphere for 8-12 hours at 200-400 DEG C, and insulating at an inert gas atmosphere for 8-12 hours at 800-1200 DEG C to obtain the dual-layer porous carbon nano-fibers. The method for preparing a cathode material by utilizing the dual-layer porous carbon nano-fibers comprises the steps of acidifying the dual-layer porous carbon nano-fibers with nitric acid, drying, uniformly mixing with nano-sulfur, conducting agent and adhesive, and performing pump filtering and drying to obtain the cathode material of a lithium-sulfur battery. The cathode material has high storage capacity, and can effectively inhibit the shuttle effect.

Owner:TIANJIN POLYTECHNIC UNIV

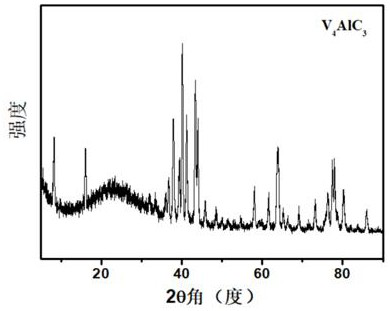

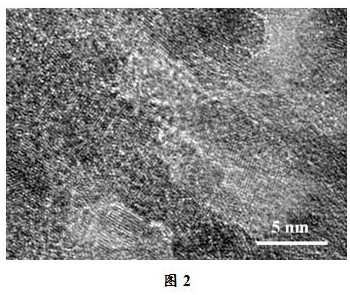

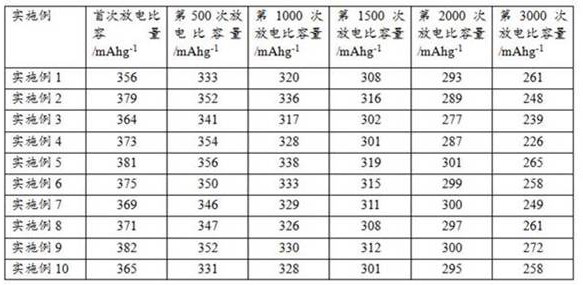

A kind of preparation method and application of vacancy vanadium base max

ActiveCN111943204BAchieve long-term stabilityThe number of vacancies can be controlled and adjustedCarbon compoundsCell electrodesElectrical batteryPhysical chemistry

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap