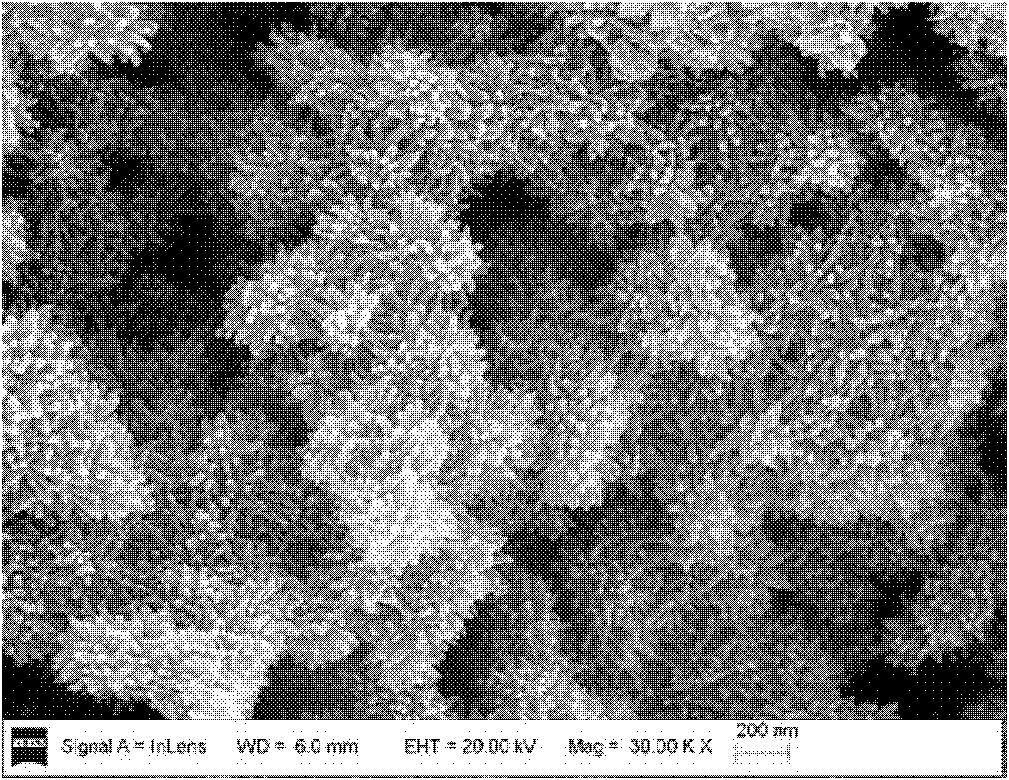

A preparation method of nanometer metatitanic acid doped polyaniline composite electrode material for supercapacitor

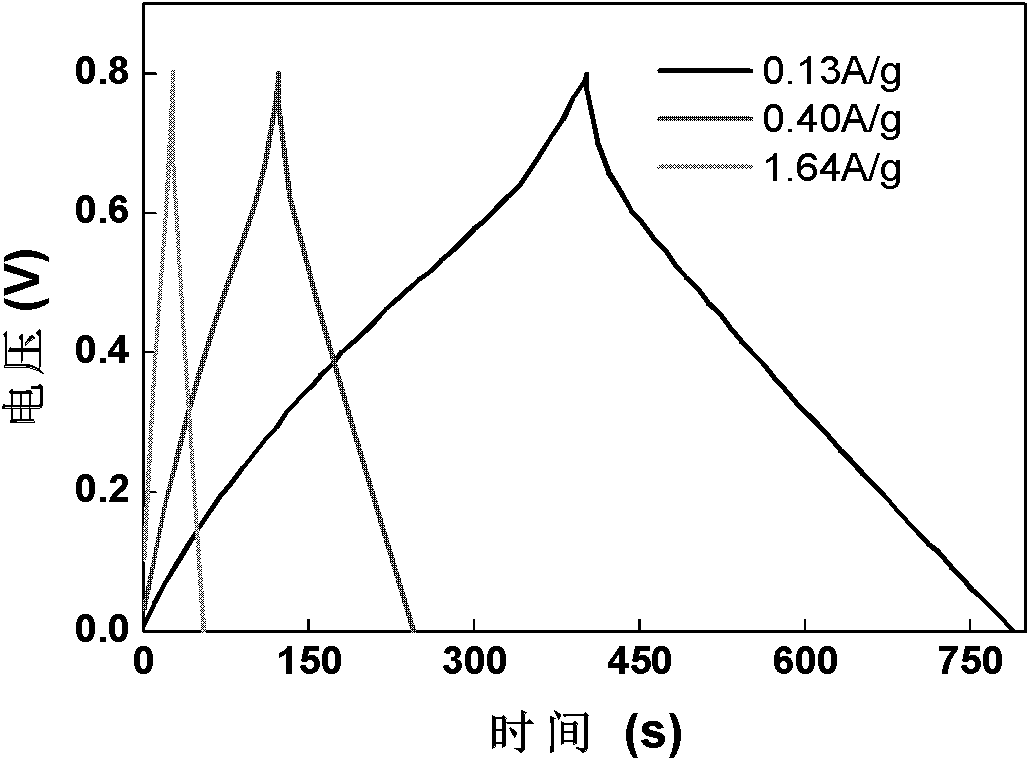

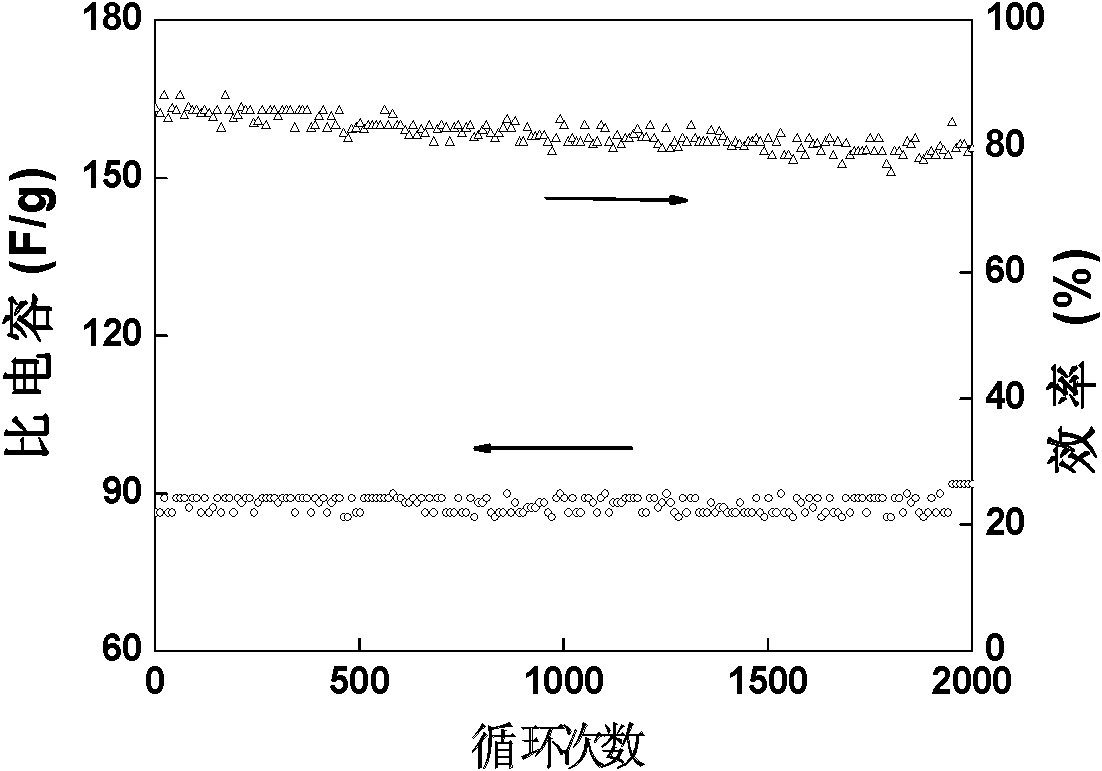

A supercapacitor and composite electrode technology, applied in capacitors, electrolytic capacitors, circuits, etc., can solve the problems of poor cycle stability and achieve high specific capacitance, high energy density, and good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Add 2ml of aniline (Ani) and 8.3ml of sulfuric acid to 100ml of deionized water to form Ani's sulfuric acid solution, and transfer it to a three-necked flask in an ice-water bath, add 0.225g of nanometer metatitanic acid particles to form aniline - Solid-liquid mixture of sulfuric acid-nano metatitanic acid particles. The solid-liquid mixture at 0.2W / cm 2Ultrasonic at high power for 0.5h, and at the same time mechanically stir it, so that the nanoparticles of metatitanic acid are uniformly dispersed in the solution. After the dispersion, nitrogen was passed through the solid-liquid mixture to remove the air in the three-necked flask, so as to avoid the influence of air on the polymerization reaction, and at the same time, the solid-liquid mixture was stirred at a high speed. Add 2.567g of ammonium persulfate (APS) and 8.3ml of sulfuric acid into 100ml of deionized water to make the sulfuric acid solution of APS, move it into the dropping funnel, slowly add it dropwise t

Embodiment 2

[0042] The aniline (Ani) of 4.5ml and the concentrated hydrochloric acid that 16.5ml mass fraction are 38% are added together in the deionized water of 100ml and are made into the hydrochloric acid solution of Ani, and move into the there-necked flask of ice-water bath, add 0.9g of Nano metatitanic acid particles form a solid-liquid mixture of aniline-dilute hydrochloric acid-nano metatitanic acid particles. The solid-liquid mixture at 0.5W / cm 2 Ultrasonic at high power for 1h, and at the same time mechanically stir it, so that the nanoparticles of metatitanic acid are uniformly dispersed in the solution. After the dispersion, nitrogen was passed through the solid-liquid mixture to remove the air in the three-necked flask, so as to avoid the influence of air on the polymerization reaction, and at the same time, the solid-liquid mixture was stirred at a high speed. Add 4.56g of ammonium persulfate (APS) and 16.5ml of concentrated hydrochloric acid with a mass fraction of 38% to

Embodiment 3

[0045] Add 3.5ml of aniline (Ani) and 8.3g of dodecylsulfonic acid to 200ml of deionized water to form Ani's dodecylsulfonic acid solution, and move it into a three-necked flask in an ice-water bath, add 0.6g of nanometer metatitanic acid particles form a solid-liquid mixture of aniline-dodecylsulfonic acid-nano metatitanic acid particles. The solid-liquid mixture at 0.5W / cm 2 Ultrasonic at high power for 0.5h, and at the same time mechanically stir it, so that the nanoparticles of metatitanic acid are uniformly dispersed in the solution. After the dispersion, nitrogen was passed through the solid-liquid mixture to remove the air in the three-necked flask, so as to avoid the influence of air on the polymerization reaction, and at the same time, the solid-liquid mixture was stirred at a high speed. Add 3.8g of cerium sulfate and 8.3g of dodecylsulfonic acid to 100ml of deionized water to form a dodecylsulfonic acid solution of cerium sulfate, transfer it into the dropping funne

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap