Coal gas purification system adopting rotational flow plate gas-liquid separator

A technology of gas-liquid separator and purification system, which is applied in the direction of combustible gas purification, combustible gas purification/transformation, petroleum industry, etc., which can solve the problems of inconvenient cylinder protection treatment and inconvenient automatic discharge treatment of ammonium sulfate mother liquor, so as to improve the convenience performance, ensure integrity, and reduce leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

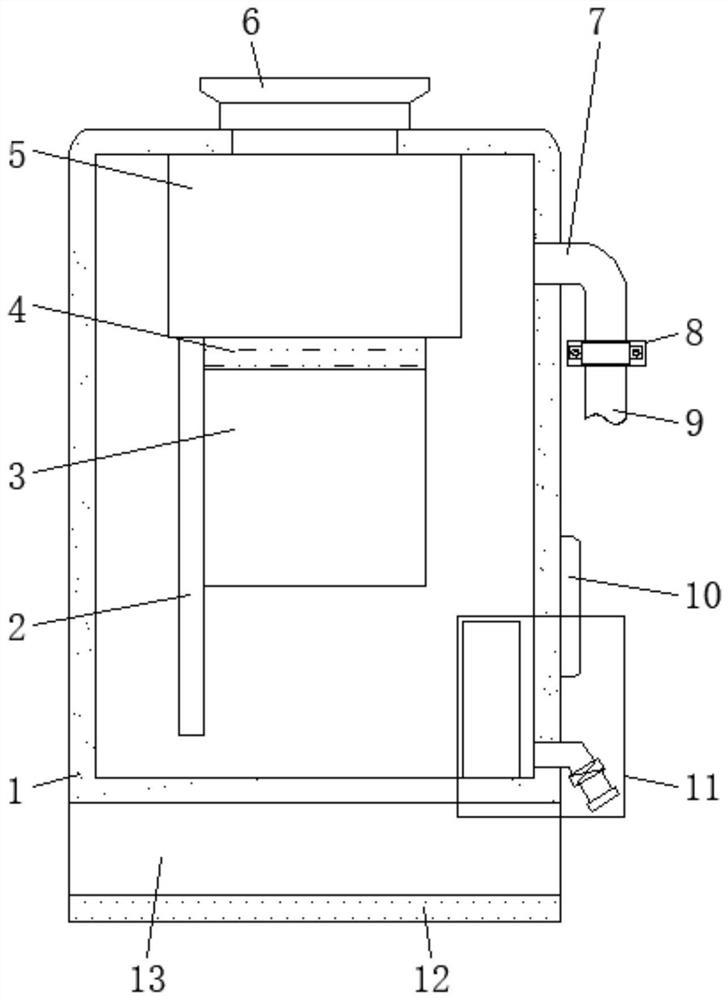

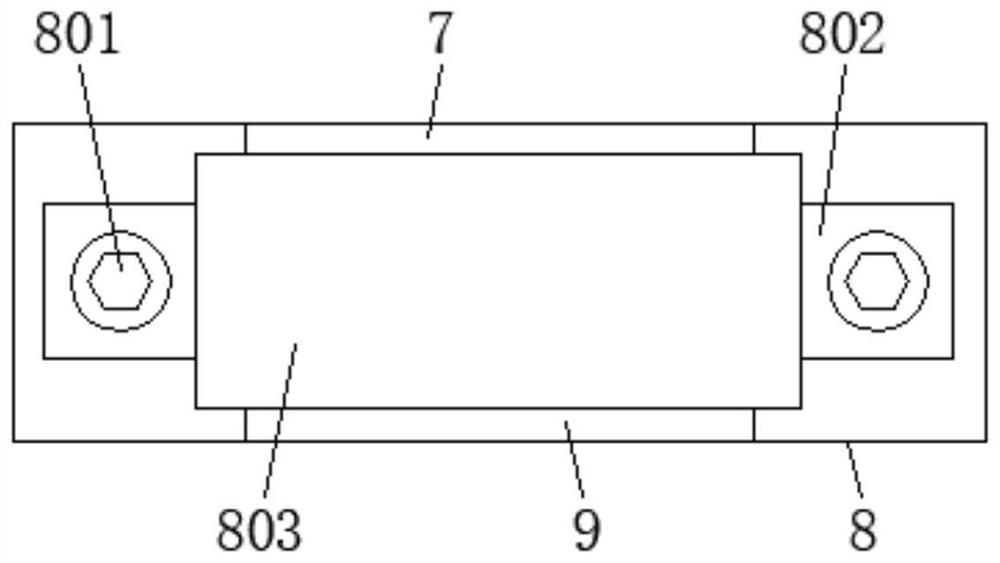

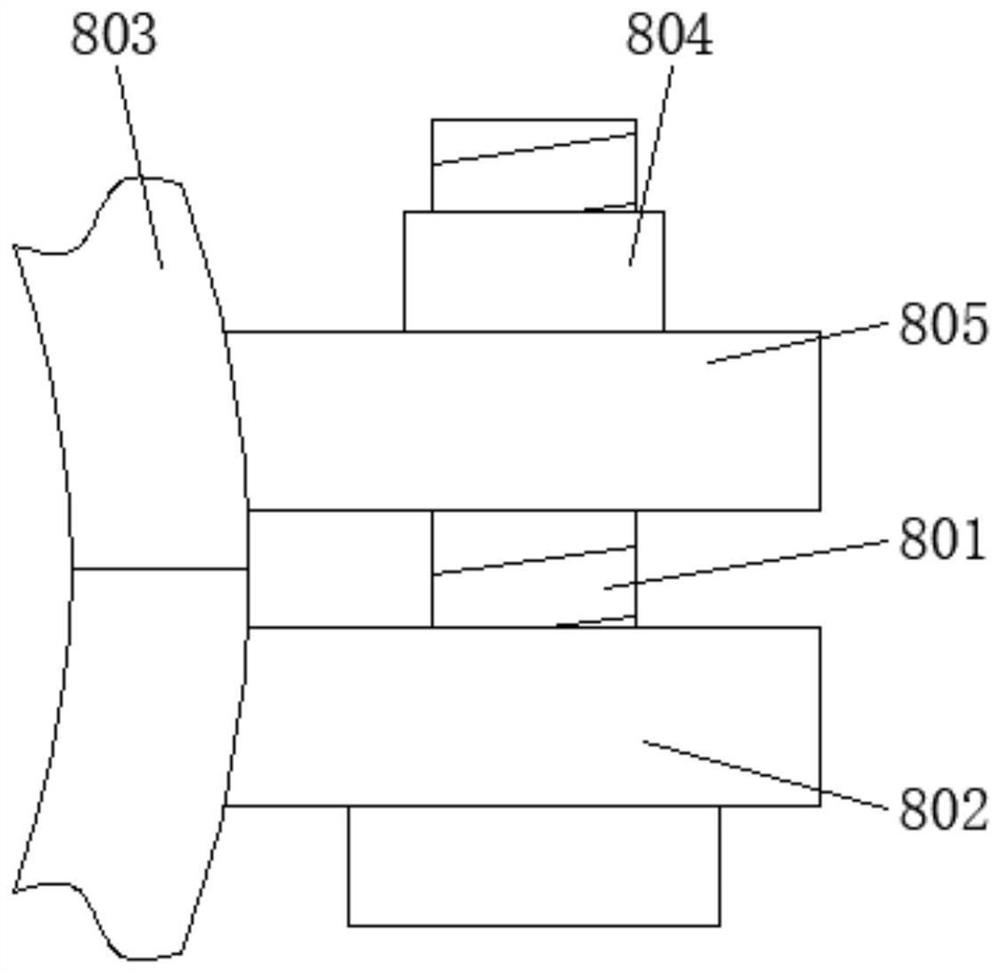

[0026] see Figure 1-5 , an embodiment provided by the present invention: a gas purification system using a cyclone plate gas-liquid separator, comprising a cylinder 1, a lower end conduit 3, a cyclone plate 4, a cyclone separation chamber 5 and an exhaust port 6, A swirl separation chamber 5 is installed at the central position of the top of the cylinder body 1, and a swirl plate 4 is arranged at the central position of the bottom end o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap